Non-penetrating welding method of feed components through electron beams

A welding method and a technology of feeder components, which are applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of welding deformation in the heat-affected zone with large output heat, uneven surface weld formation, and high electron beam power density, etc. problems, to achieve the effect of eliminating "nail-shaped" defects and pores, improving welding strength and reliability, and avoiding welds that are too narrow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further illustrated in the following examples, which are only used to illustrate the present invention and not to limit the present invention.

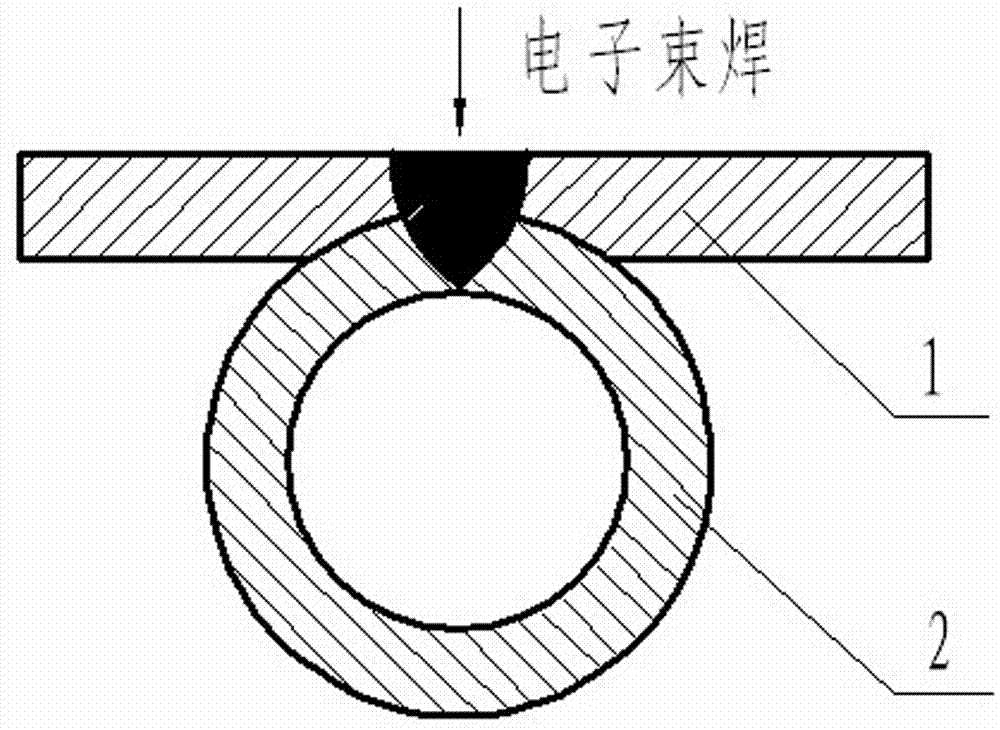

[0017] see figure 1 . The feed assembly consists of a feed sheet 1 and a bushing 2 below it. Electron beams can be used to penetrate and weld the upper feeder sheet and the lower casing into one body. The welding material is hard aluminum alloy, and the welding thickness is 1+1 mm.

[0018] First, insert the acid-washed bushing into the equal-diameter groove of the fixture, install the feeder piece on the bushing, and use the rigid fixing method to use the pressure plate on the fixture to be "symmetrical at eight points on the left and right, and pressed up and down to fix it", so that the bushing Fit and press the feed piece, the pre-tightening force in the up and down direction is adjusted by the spring washer on the screw, a copper rod of equal diameter is inserted into the casing, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com