Thermal deformation coordinated missile dome attachment ring

A connecting ring and thermal deformation technology, applied in the field of connecting rings, can solve problems such as damage to the missile hood, and achieve the effects of reducing thermal deformation, saving space, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

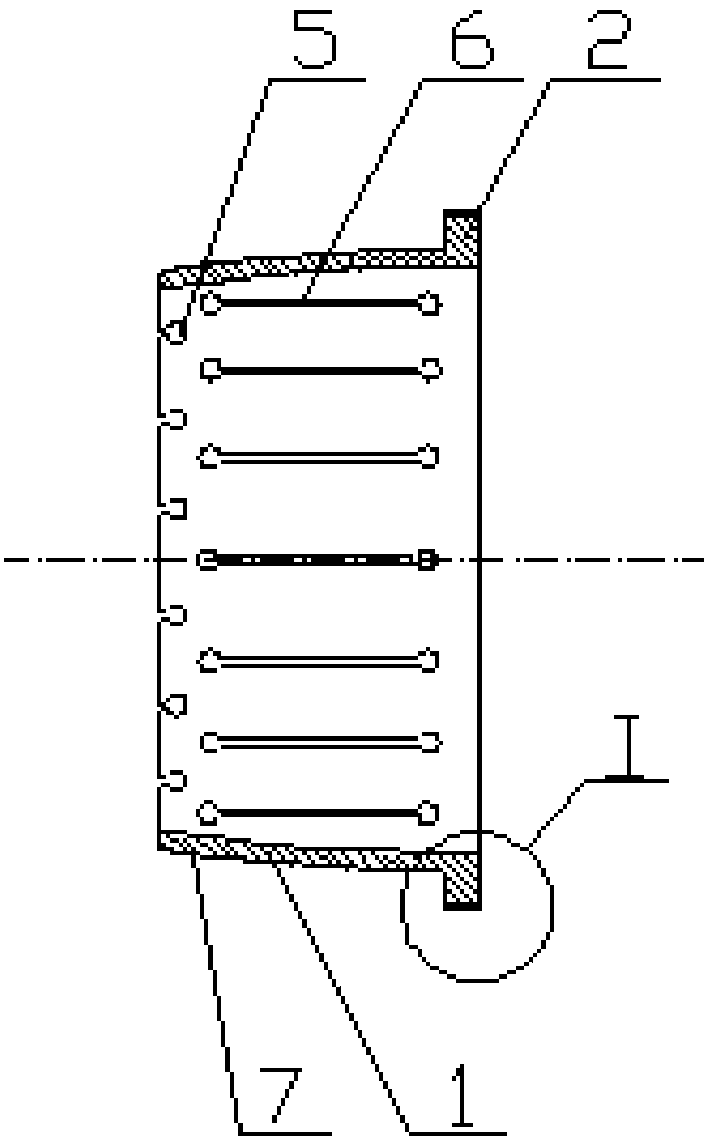

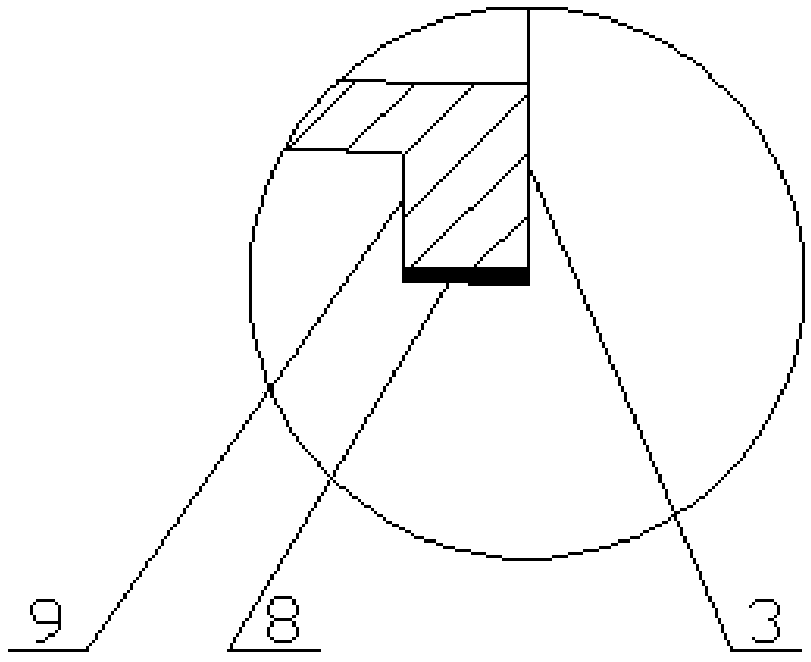

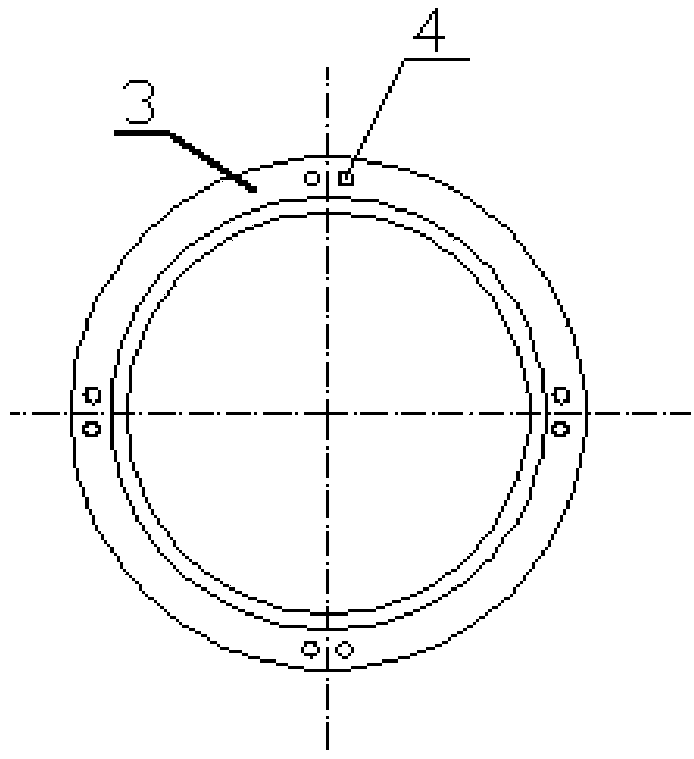

[0019] Such as Figure 1 to Figure 3 As shown, the missile head cover connecting ring with coordinated thermal deformation of the present invention includes a connecting ring lining 1, a connecting ring flange 2, a rear end face 3 of the connecting ring flange, a connecting ring threaded hole 4, a hole type stress groove 5, a linear stress Groove 6, connecting ring lining front face 7, heat-resistant coating 8, connecting ring flange front face 9, connecting ring lining 1 and connecting ring flange 2 are fixedly connected, and connecting ring lining front face 7 is located in the connecting ring On the lining 1, the hole-type stress groove 5 is located on one end of the front end face 7 of the connecting ring lining, the linear stress groove 6 is located on the front face 7 of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com