Thermal protection flocculus and manufacturing method thereof

A manufacturing method and technology of wadding, which is applied in the direction of non-woven fabrics, textiles, papermaking, fabric surface trimming, etc., can solve the problems of uneven carding of thermal wadding, hard hand feeling of thermal wadding, and low heat retention of thermal wadding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] At first, by weight, be equipped with following fiber raw material: fine denier fiber 56% (wherein 30% is the fine denier polyester fiber that fiber fineness is 0.78dtex, length is 51mm; Other 26% is that fiber fineness is 1.32dtex, Fine denier polyester fiber with a length of 51mm), hollow fiber 30% (all are hollow three-dimensional crimped polyester fiber, its fiber fineness is 3.3dtex, length is 64mm), bonding fiber 14% (all are bonding fiber 4080 , That is, low-melting polyester fiber with skin-core structure, the fiber fineness is 4.4dtex, and the length is 51mm).

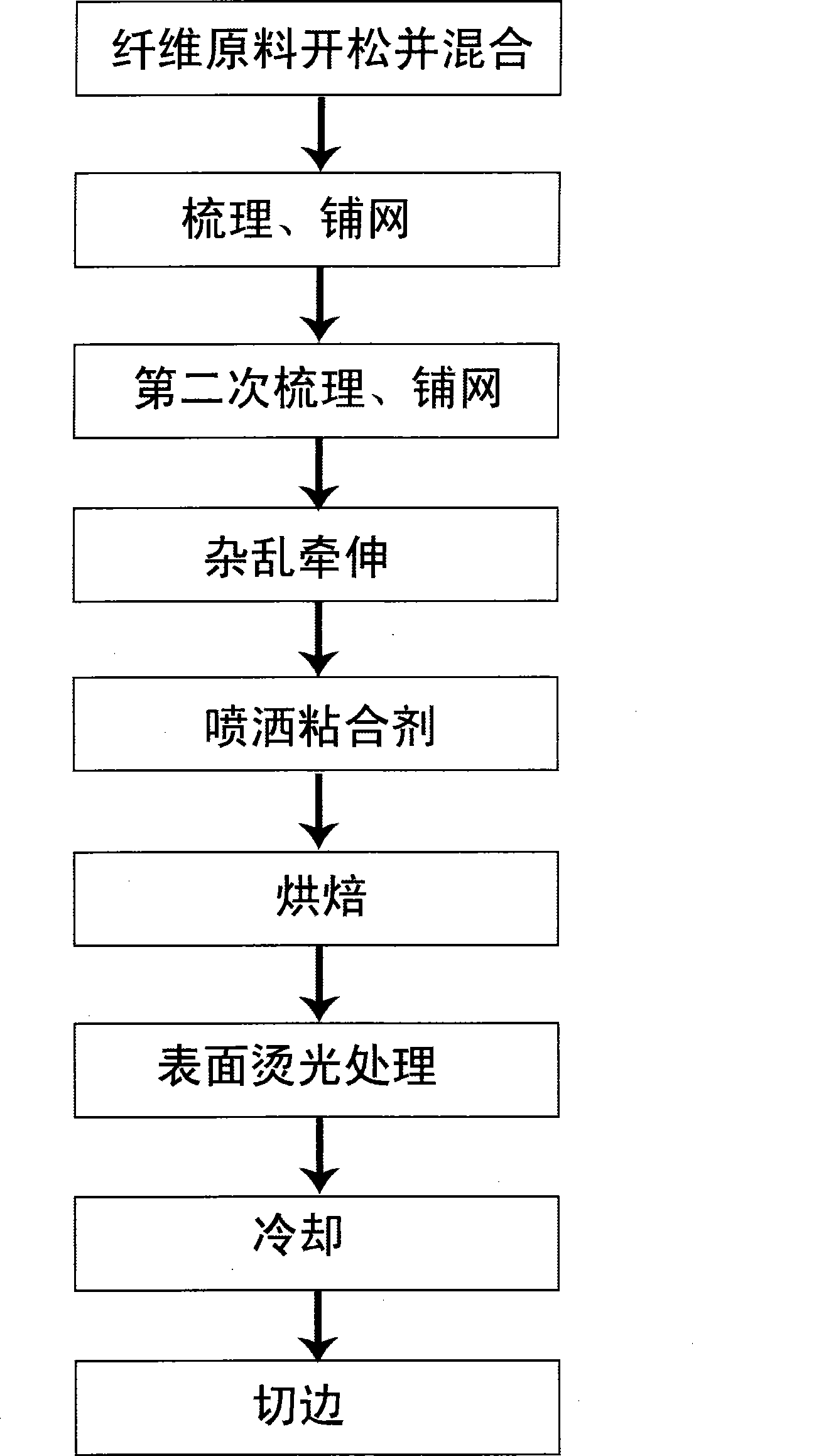

[0035] Then, follow the steps below to make thermal insulation batting successively (refer to figure 1 ):

[0036] (1) Opening and mixing fiber raw materials such as fine denier fibers, hollow fibers and bonding fibers;

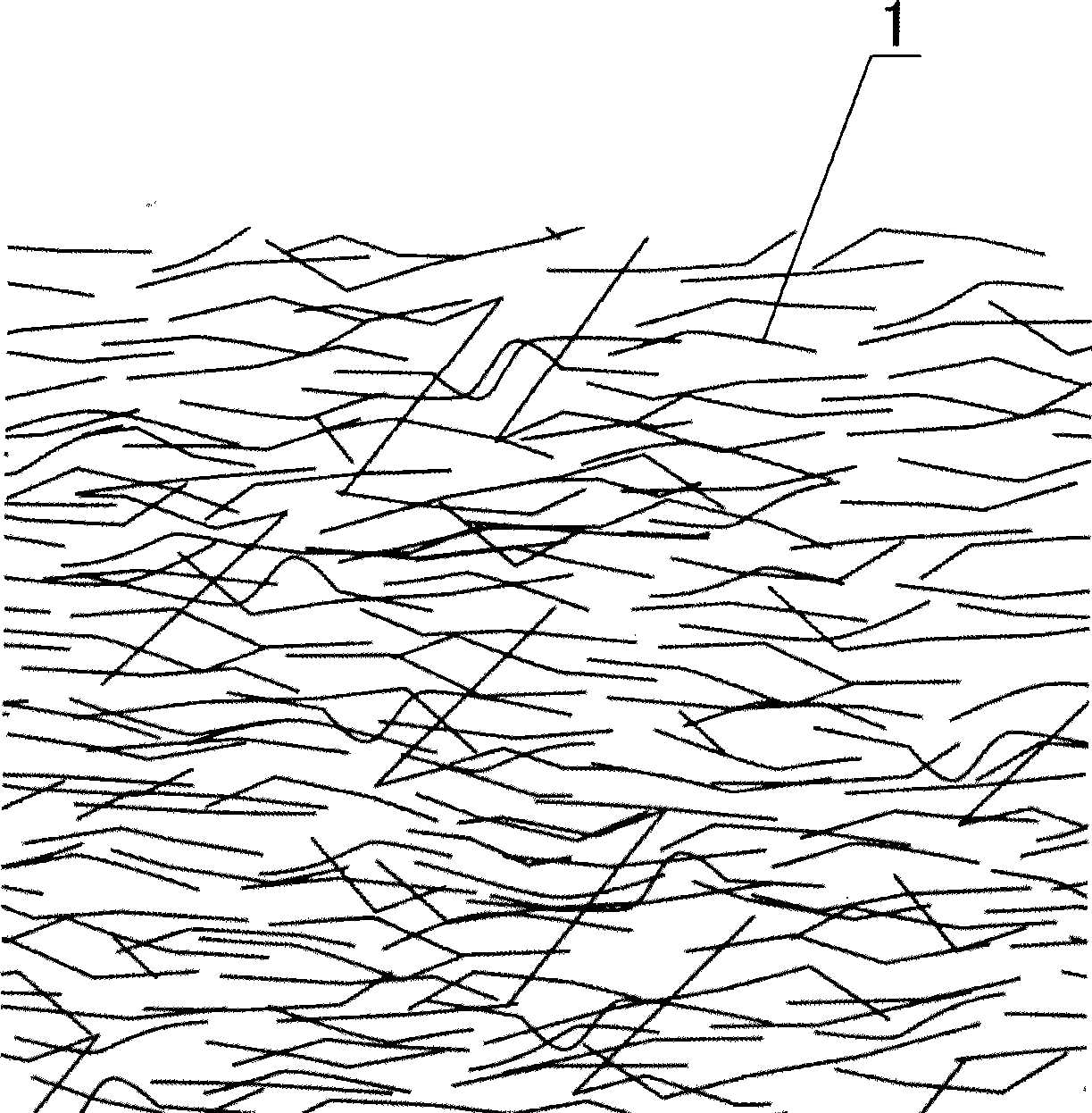

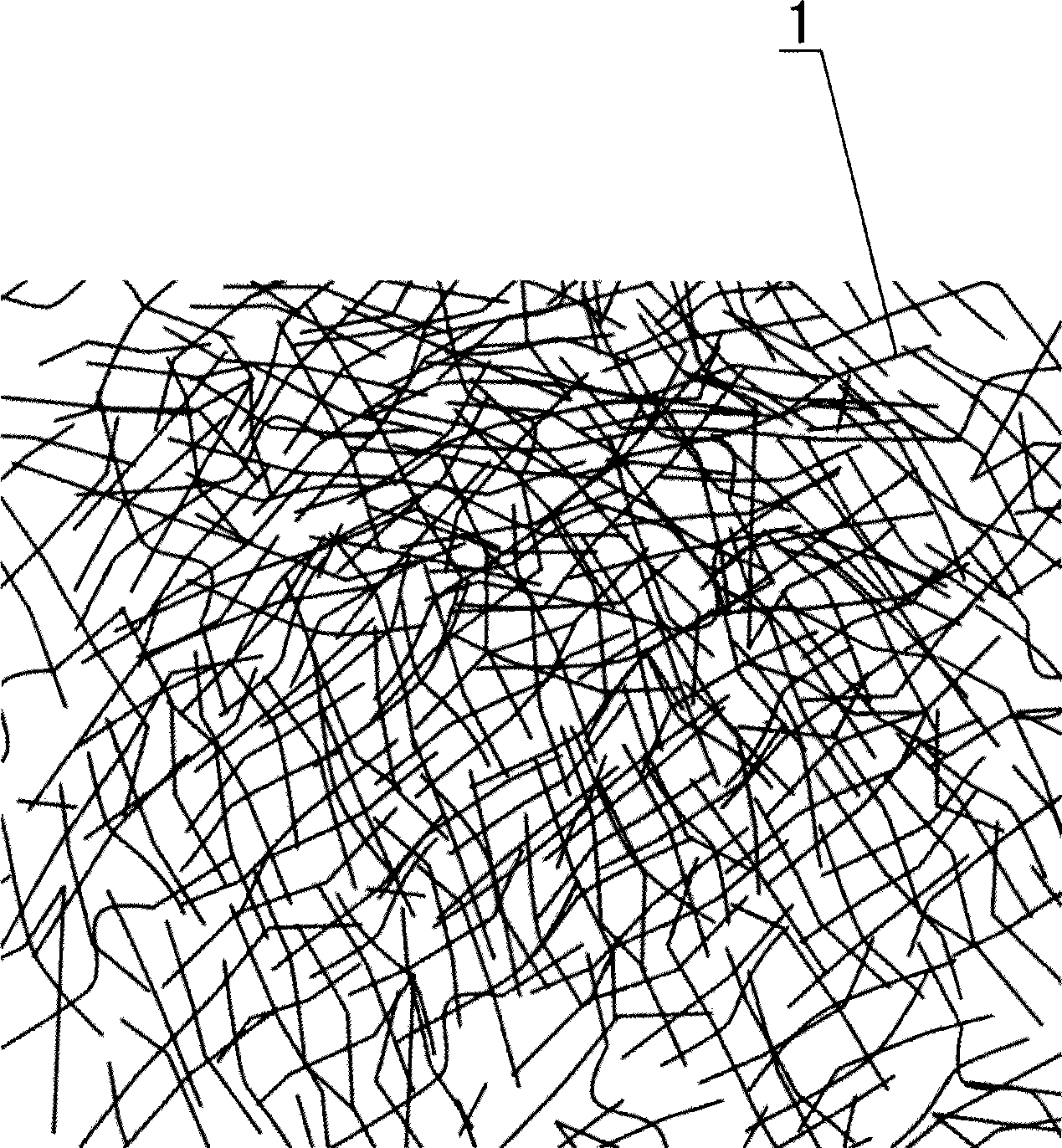

[0037] (2) Combing and laying the mixed fiber raw materials to form a fiber web; the carding equipment used uses single cylinder and double doffers, and the card clothing adopts an u...

Embodiment 2

[0045] First, by weight, the following fiber raw materials are equipped: 80% fine denier fibers (all are fine denier polyester fibers, wherein 40% of the fiber fineness is 1.32dtex, and the length is 51mm, and the other 40% of the fiber fineness is 0.78 dtex, length is 51mm), binder fiber 20% (all are polypropylene fibers, its fiber fineness is 4.4dtex, length is 51mm).

[0046] The manufacture method of this warm-keeping batting is identical with embodiment 1.

Embodiment 3

[0048] At first, by weight, be equipped with following fiber raw material: fine denier fiber 50% (wherein 30% is the fine denier polyester fiber that fiber fineness is 0.5dtex, length is 32mm; Other 20% is that fiber fineness is 1.5dtex, Micro-denier polyester fibers with a length of 64mm), ultra-fine denier fibers 20% (all are ultra-fine denier polyester fibers, the fiber fineness is 0.012dtex, and the length is 32mm), hollow fibers 22% (including two-dimensional hollow poly 10% of ester fiber, its fiber fineness is 7.6dtex, and its length is 32mm; 12% of hollow three-dimensional crimped far-infrared fiber, its fiber fineness is 2.2dtex, its length is 51mm), bonding fiber 8% (all are polypropylene polypropylene Ester composite fiber with a fiber fineness of 2.2dtex and a length of 64mm).

[0049] The manufacture method of this warm-keeping batting is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com