Manufacturing method of assembly part and foot stool manufactured by adopting the manufacturing method

A manufacturing method and assembly technology, which is applied in the direction of machines/brackets, casings/cabinets/drawer parts, supporting machines, etc., and can solve problems such as surface sand holes, complex structures, shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

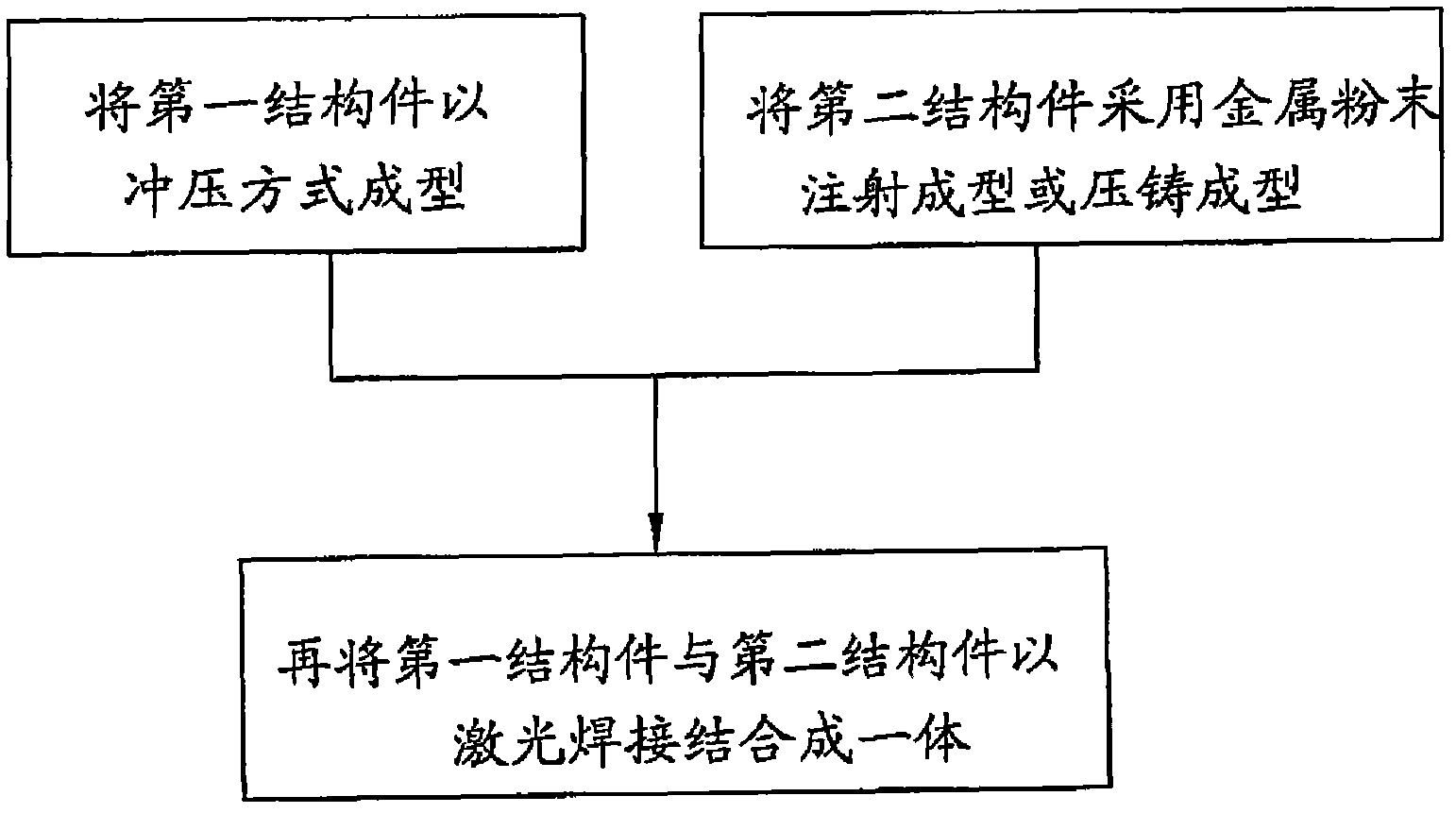

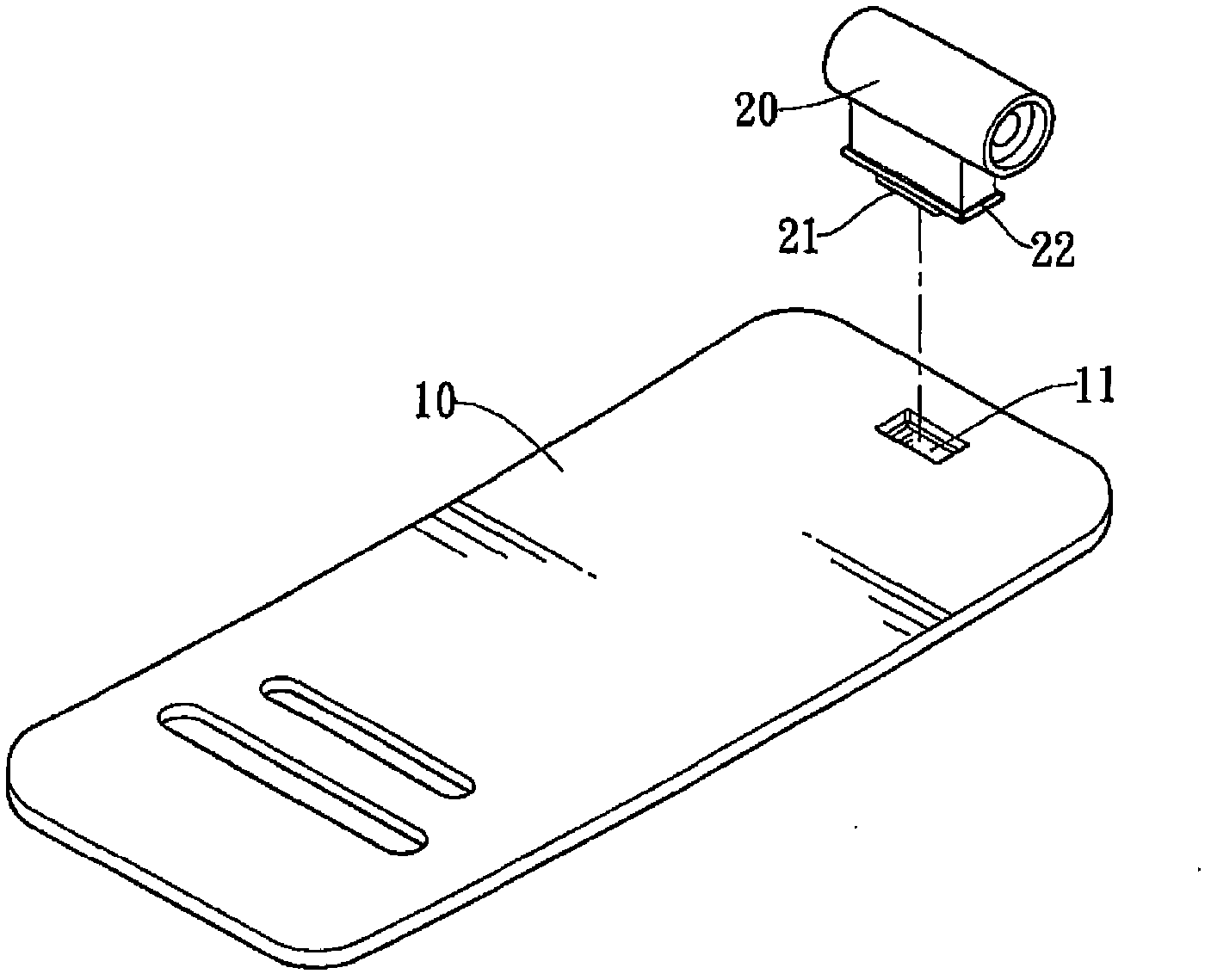

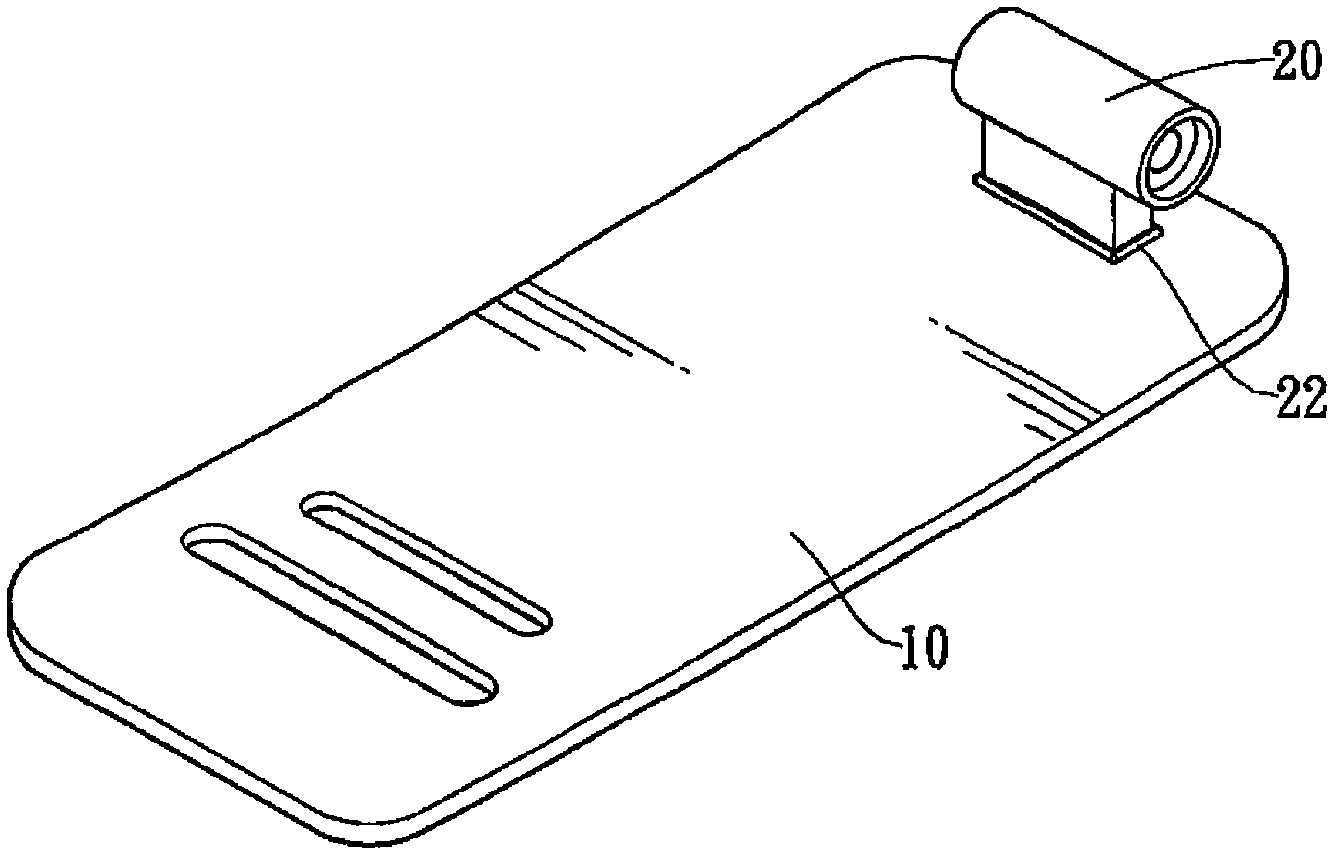

[0022] See Figure 1 to Figure 3 , which are respectively a schematic flow chart of the manufacturing method of the present invention, an exploded view of parts of the assembly and a three-dimensional view of the assembly. The manufacturing method of the assembly of the present invention is to form the first structural member 10 by stamping, and the second structural member 20 is formed by metal powder injection molding or die casting, and then the first structural member 10 and the second structural member 20 are combined Laser welding combined into one piece.

[0023] The first structural part 10 is an appearance part, which can be stamped and formed from a metal plate without problems of shrinkage and surface sand holes, and can provide a good and delicate appearance quality. The second structural member 20 can be molded into a more complex shape and structure through metal powder injection molding or die casting, and can have functions such as connection and combination. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com