Patents

Literature

68 results about "Dye penetrant inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dye penetrant inspection (DP), also called liquid penetrate inspection (LPI) or penetrant testing (PT), is a widely applied and low-cost inspection method used to check surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials, although for ferrous components magnetic-particle inspection is often used instead for its subsurface detection capability. LPI is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components.

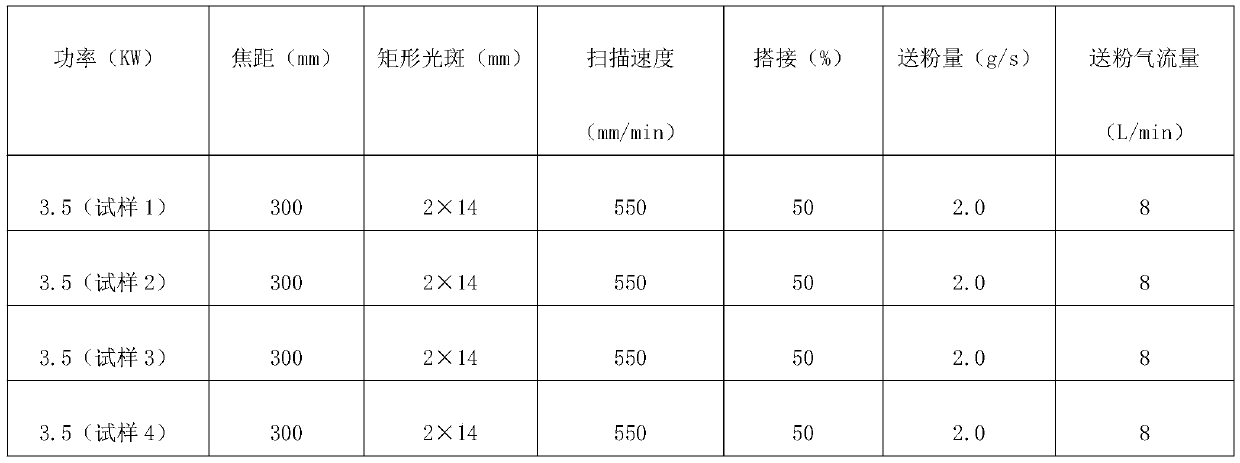

Laser cladding process for abrasion-resistant anticorrosion coating of water turbine unit runner

InactiveCN101994112AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesMelting tankCoronal plane

The invention discloses a laser cladding method for an abrasion-resistant anticorrosion coating of a water turbine unit runner. The method is characterized by comprising the following steps of: performing surface cleaning on greasy dirt and rust layers on the surface of the water turbine unit runner; then selecting iron-based alloy powder, making the alloy powder discharged from an automatic powder feeding head fall into a laser molten pool by adopting laser equipment and an adjustable automatic powder feeding device, adjusting the powder feeding amount, and forming uniform and dense laser claddings on the processing surfaces of the upper and lower coronal planes, wherein the thicknesses of the laser claddings reach 0.2 to 1.8 millimeters; and finally, checking the processing parts of the upper and lower coronal planes of the runner by using a dye penetrant inspection method, wherein the processing parts are required without defects of cracks, air holes and the like. The laser cladding coating is uniform and dense, forms firm metallurgical bonding together with a matrix, has good abrasion resistance and anticorrosion performance, and can remarkably improve the abrasion-resistant and anticorrosion performance of the water turbine unit runner and prolong the service life of the water turbine unit runner.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Detection method for flexible package lithium ion battery aluminum plastic film corrosion

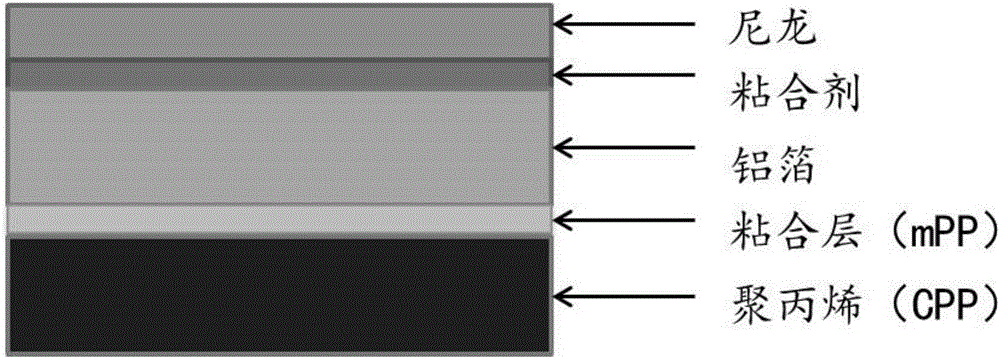

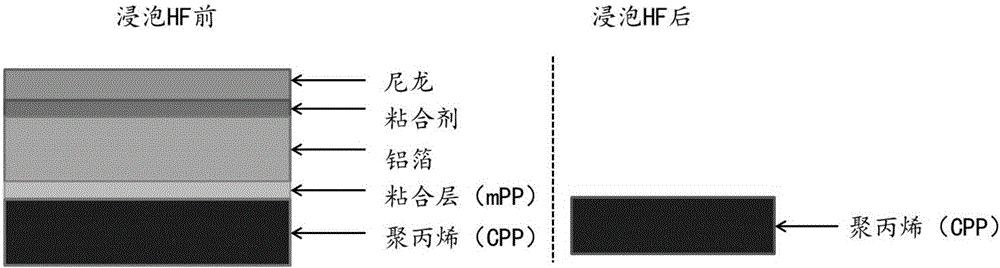

InactiveCN106199199AAvoid mixingAccelerated corrosion reactionResistance/reactance/impedenceOptically investigating flaws/contaminationHigh temperature storageEngineering

The invention relates to a detection method for flexible package lithium ion battery aluminum plastic film corrosion. Firstly, the shell resistance value of a specific type battery is worked out according to the specific resistance between a negative electrode piece and an aluminum plastic film and the size of the negative electrode piece; then, the surface of the aluminum plastic film is covered with electrolyte acceleratedly in a vacuumizing and high-temperature storage mode, the electrolyte is promoted to make contact with a naked aluminum layer at a damaged position of an aluminum plastic CPP layer, the weak positions, caused by the external force, of the CPP layer are exposed more easily, the insulating performance of the aluminum plastic film is reduced, and the recall factor of corrosion hazard behaviors of the aluminum plastic film is increased; then, the shell resistance between the negative electrode piece and the aluminum plastic film aluminum layer is measured through a multimeter, and defective products with the low shell resistance are screened; finally, the damage position of the aluminum plastic film CPP layer of the battery with high shell resistance is detected in a chemical corrosion and dye penetrant inspection permeation mode. According to the detection method, the production process can be guided to be modified, the situation that same questions continue to occur is avoided, and the yield of a battery production manufacturer is increased.

Owner:SHANDONG QIXING NEW ENERGY SCI & TECH CO LTD

Laser cladding process of wear-resistant and corrosion-resistant coating of top cover of hydraulic turbine set

InactiveCN101994113AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesWear resistantEngineering

The invention provides a laser cladding process of a wear-resistant and corrosion-resistant coating of a top cover of a hydraulic turbine set, which is characterized by comprising the following steps: firstly welding a bevel process ring through nickel-base welding wires at a right angle position on which an inner ring surface and a wear-resistant plane of an anti-leakage ring of the top cover are crossed, deoiling and derusting machining surfaces, labeling machining areas, and inspecting machining positions by a dye penetrant inspection method; selecting Fe-based alloy powder, employing laser equipment and adjusting an automatic power feeder so that the alloy powder from an automatic power feed head falls into a laser molten pool, and adjusting powder feeding quantity so that the thickness of the alloy powder coating reaches 0.2-1.8mm; and inspecting whether the machining positions of a wear-resistant plate on the inner ring surface and a wear-resistant plate on the plane of the anti-leakage ring of the top cover have defects such as cracks, air holes and the like by the dye penetrant inspection method. The alloy coating obtained by laser cladding is uniform and compact, can form firm metallurgical bonding with a matrix, has excellent wear resistance and corrosion resistance, and can obviously improve the wear resistance, the corrosion resistance and the service life of the top cover of the hydraulic turbine set.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Method for repairing cold roll

InactiveCN1394703AEasy to useReduce manufacturing costRolling equipment maintainenceMetal rolling arrangementsEngineeringDye penetrant inspection

The method for repairing working roll for cold-rolling includes the following steps: using the combination of dye penetrant inspection and crack depth detector to define crack position and crack depth; turning working roll for cold-rolling, after it is turned, using dye penetrant inspection method to make inspection, checking and confirming that said working roll has no crack and transferring it into next procedure, if said working roll also has the crack, making secondary turning, low-temp. tempering treatment of crackless roll, further grinding so as to make it reach to requirements for use.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for preparing flat headgear self-lubricating wear resisting layer with laser cladding technology

The invention relates to a method for preparing a flat headgear self-lubricating wear resisting layer with a laser cladding technology. The method is characterized in that: a flat headgear surface part requiring laser cladding is cleaned and polished, such that an oxide layer and a fatigue layer are completely removed; laser cladding is carried out, wherein a gradient functional material is adopted in the cladding layer, a cobalt-based powdery material with a self-lubricating performance is adopted in a surface wear resisting layer, and and iron-based alloy powder with good impact resistance and good metallurgy compatibility with a substrate is adopted between the wear resisting layer and the substrate; detections are carried out upon dimensions before and after cladding, such that cladding thickness is determined; through dye penetrant inspection, it is ensured that the cladding layer has no crack, pore, or inclusion. The wear resisting layer is advantaged in that: the bonding strength of the wear resisting layer and the substrate is high, the self-lubricating performance is good, the adaptability is good, the operation is simple, the processing error is small, the thickness of the wear resisting layer is uniform, and the like.

Owner:BEIJING DALU TIANRUI LASER ENG TECHCO

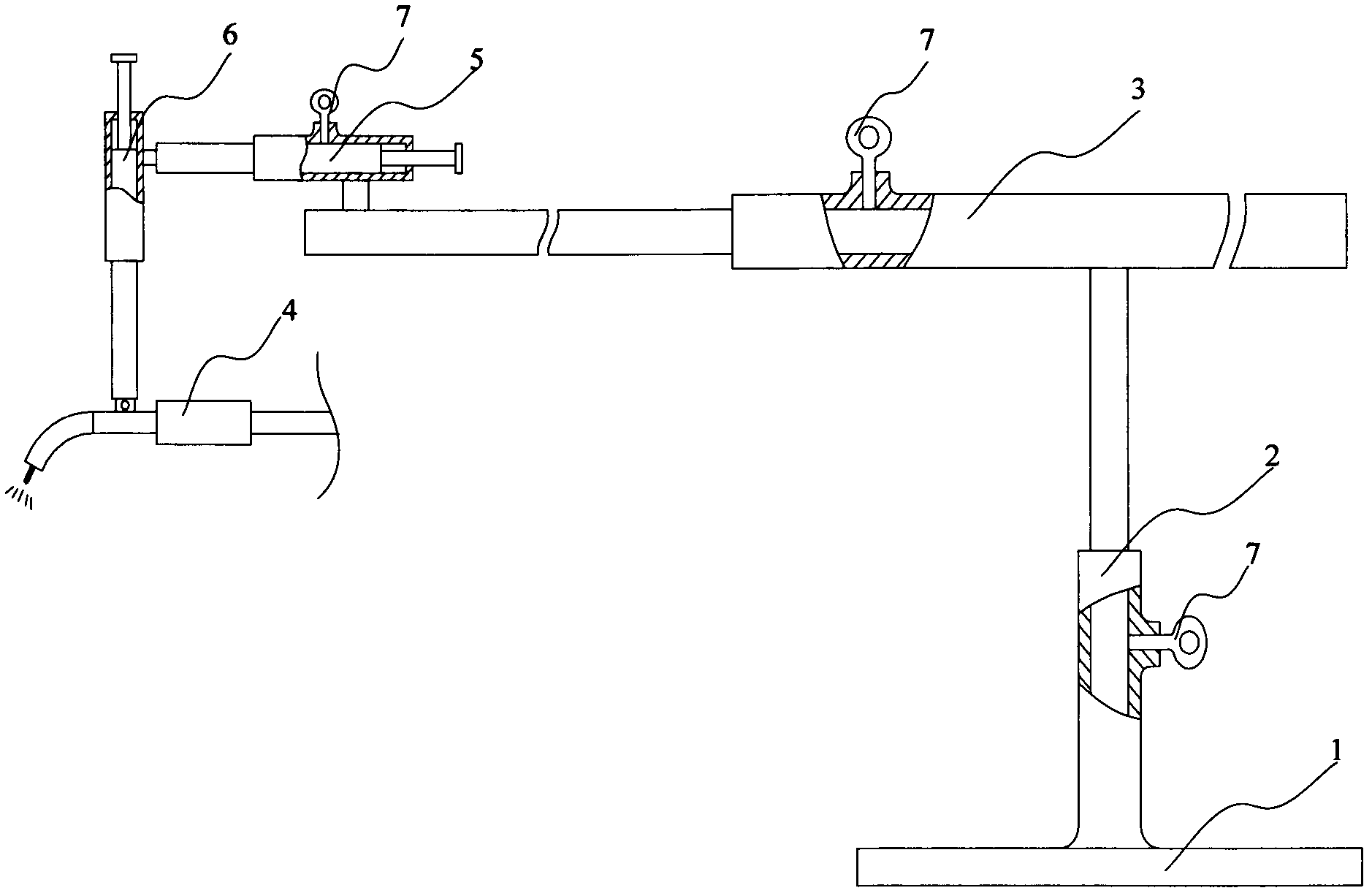

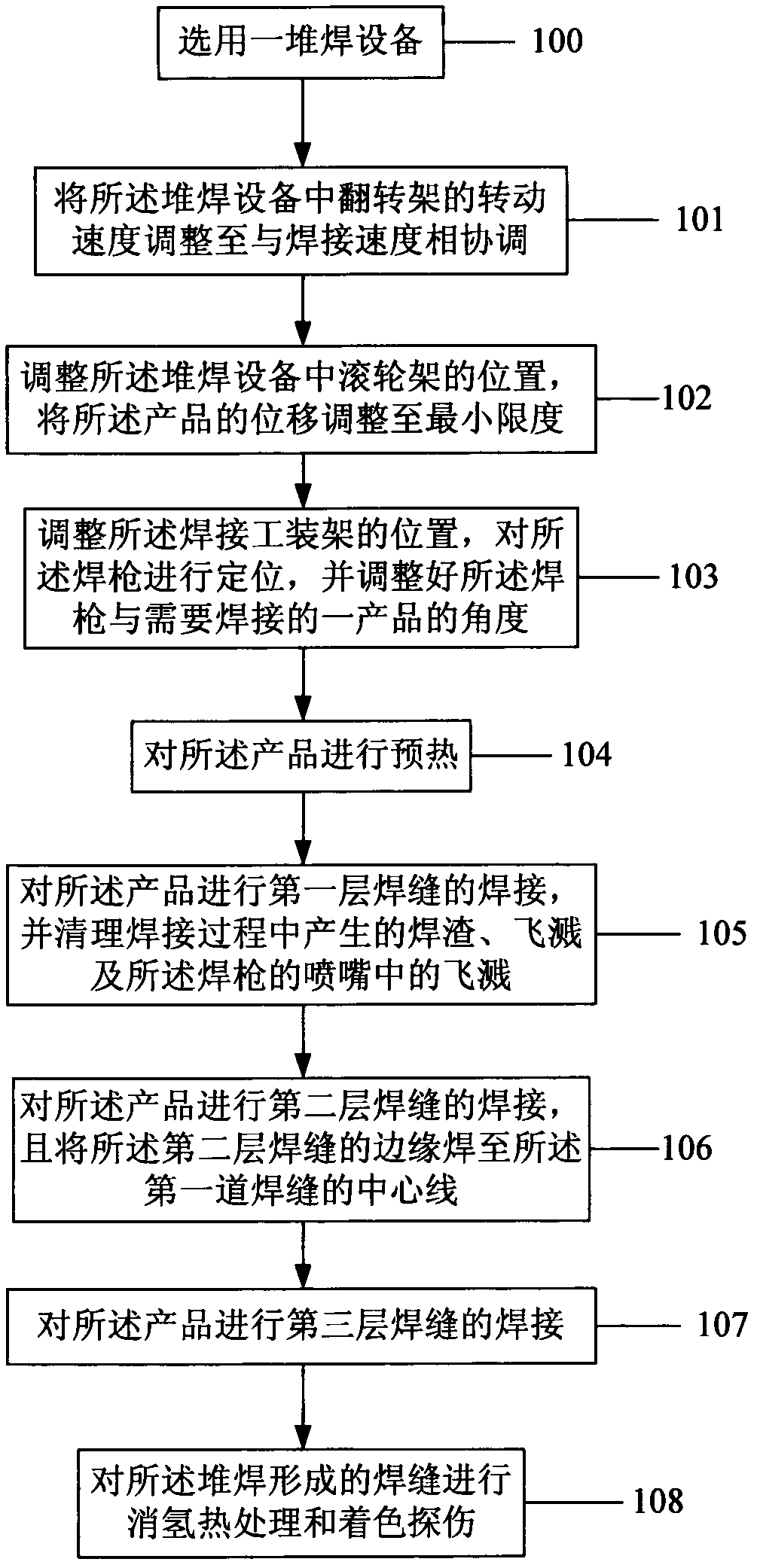

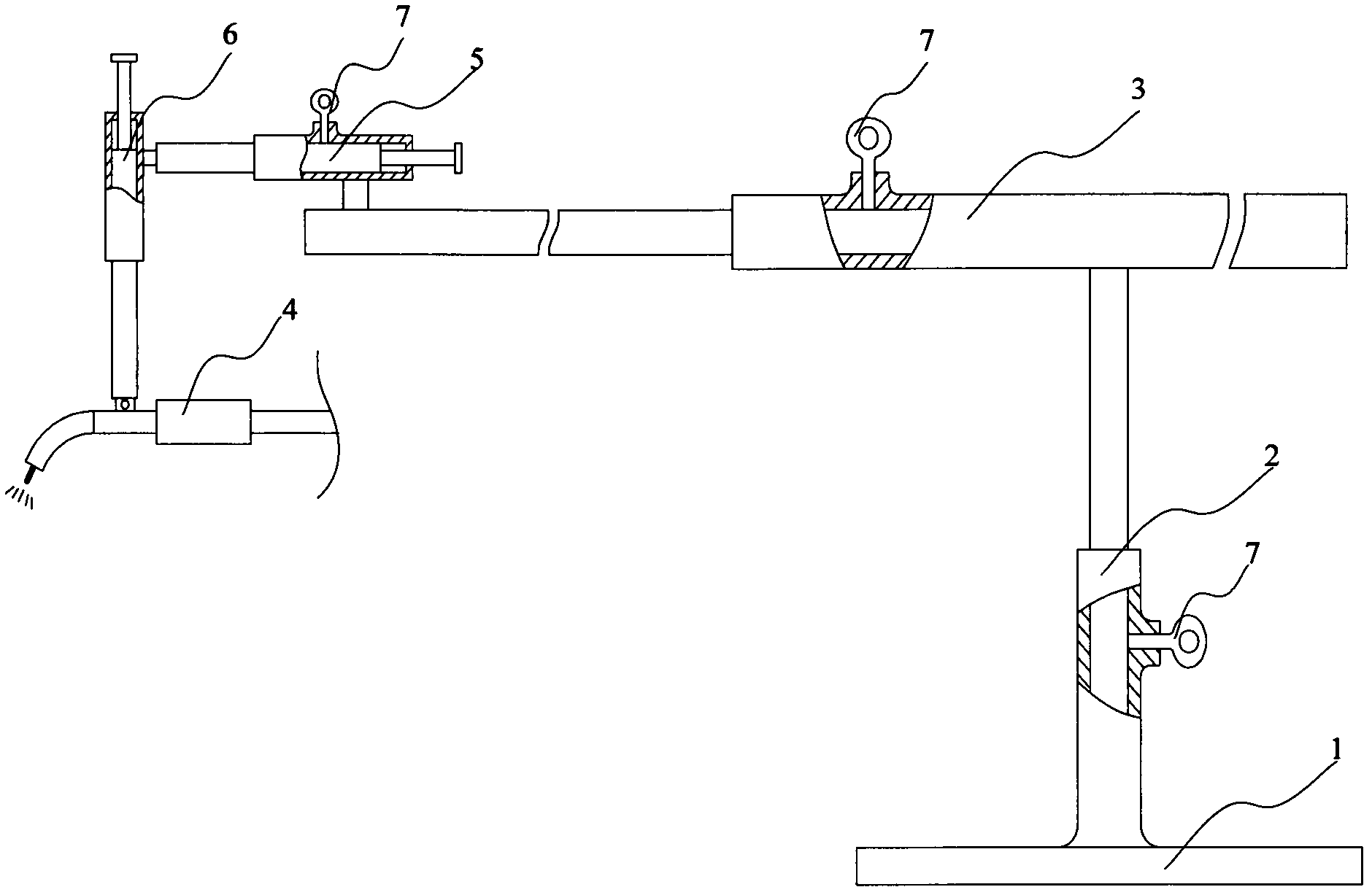

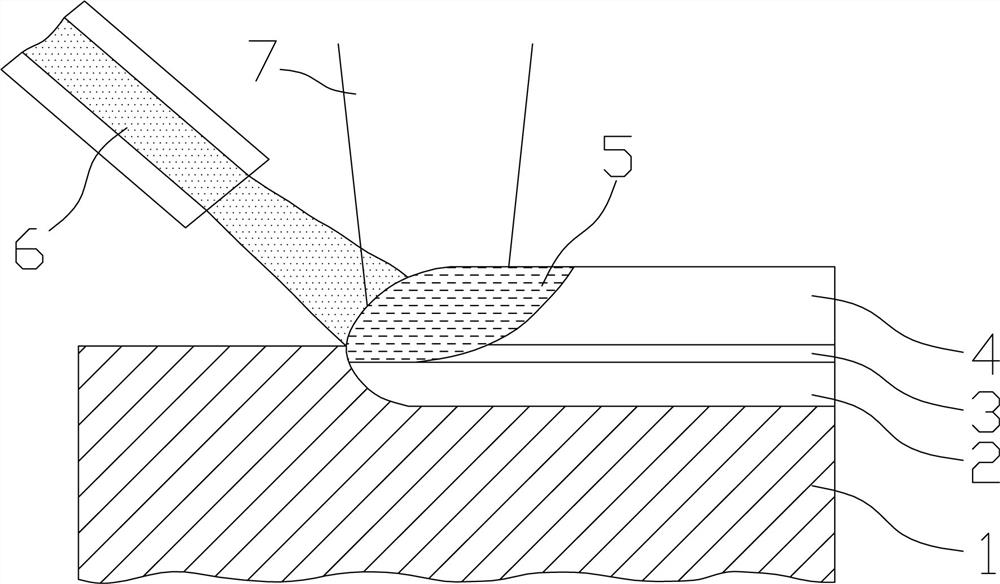

Welding tooling support for carbon dioxide arc welding and welding method thereof

ActiveCN102581452AReduce labor intensityReduce radiationElectrode supporting devicesDye penetrant inspectionHeat treated

The invention discloses a welding tooling support for carbon dioxide arc welding. The welding tooling support comprises a base and an adjusting device for adjusting a welding torch, wherein one end of the adjusting device is fixed on the base, and the other end of the adjusting device is connected with the welding torch. The invention further discloses a welding method in which the welding tooling support is utilized. The welding method comprises step 1 adjusting the position of the welding tooling support, positioning the welding torch, and adjusting an angle formed by the welding torch and a product to be welded; step 2 preheating the product; step 3 subjecting the product to surfacing; and step 4 subjecting welding seams formed by surfacing to hydrogen relief heat treatment and dye penetrant inspection. The welding tooling support for carbon dioxide arc welding reduces labor intensity of welders and improves welding quality and production efficiency. According to the welding method, short time is required, continuous welding is achieved, time of replacing welding electrodes is decreased, and welding cycle is shortened.

Owner:SHANGHAI BOILER WORKS

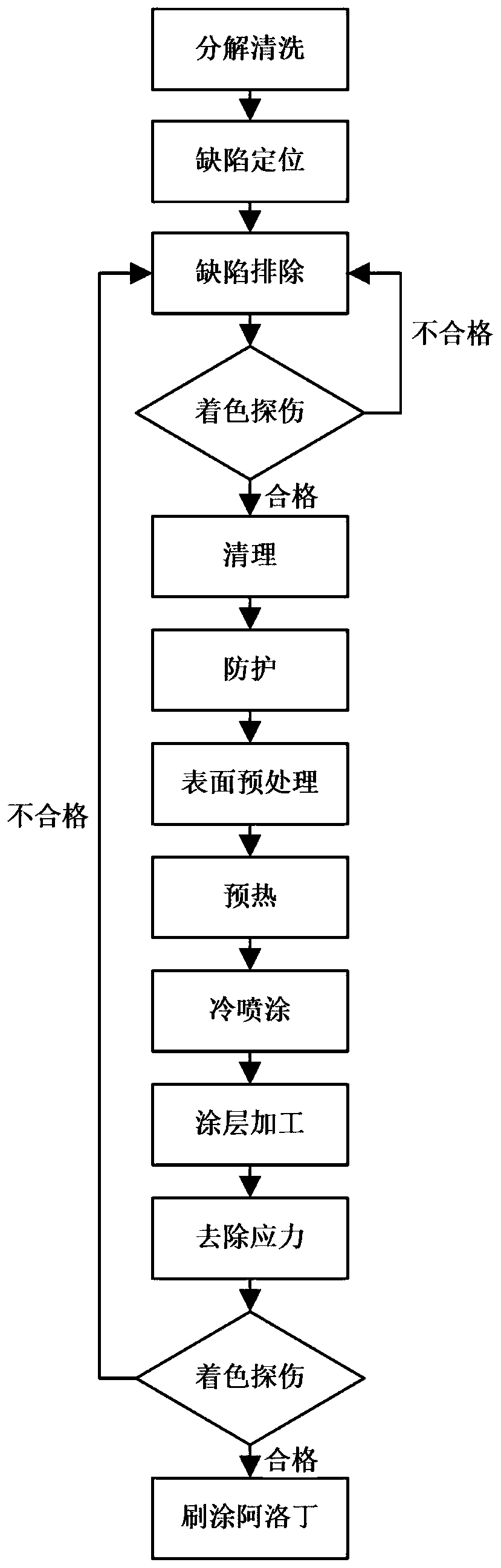

Method for repairing aircraft fuel system aluminum silicon alloy shell casting defects

ActiveCN110480254AAvoid heat cracksAvoids the problem of substrate annealing softeningAircraft componentsAircraft fuel systemDecomposition

The invention relates to the technical field of aircraft fuel system mechanical part accessory repairing, in particular to a method for repairing aircraft fuel system aluminum silicon alloy shell casting defects. The method includes the following steps of S1, decomposition cleaning; S2, defect positioning and removal; S3, dye penetration; S4, cleaning; S5, protection; S6, surface pretreatment; S7,preheating before spraying; S8, cold spraying; S9, coating processing; S10, stress relief treatment; S11, dye penetrant inspection; and S12, anti-corrosion treatment. According to the method for repairing the aircraft fuel system aluminum silicon alloy shell casting defects, the problems of a heat crack of a shell and base material annealing softening caused by large heat input of a traditional surfacing process are effectively avoided, the repairing problem of the aircraft fuel system aluminum silicon alloy shell casting defects is solved, at the same time, casting defect repairing of the shell can be realized under the operation temperature of less than 120 DEG C, the problem of scrapping of a whole part of accessories due to shell damage or secondary damage caused by repairing is avoided, and economic benefits are significant.

Owner:国营芜湖机械厂

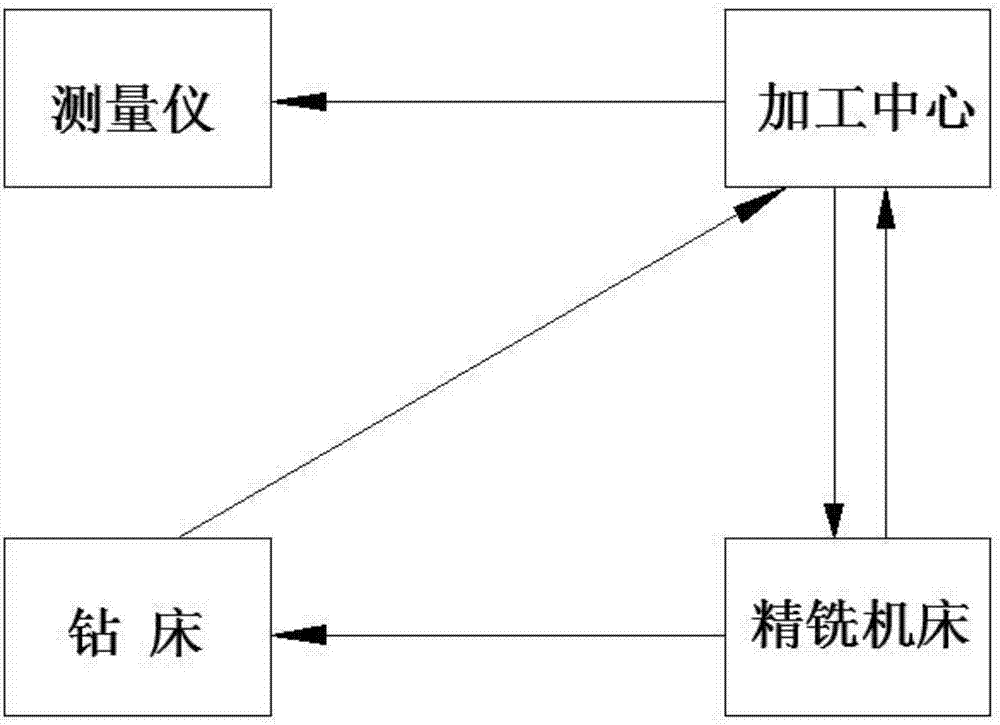

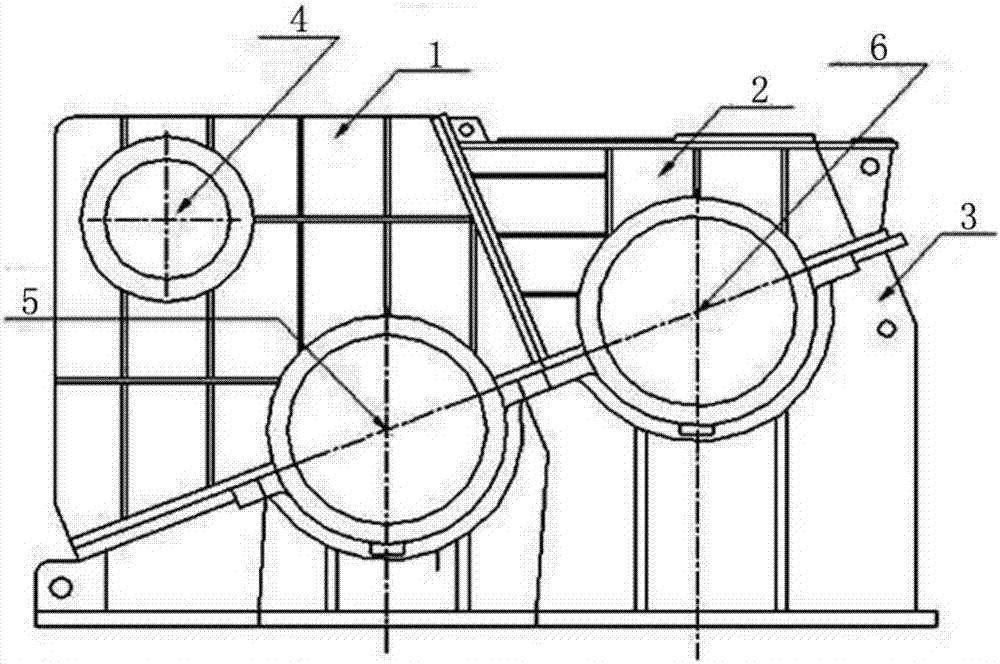

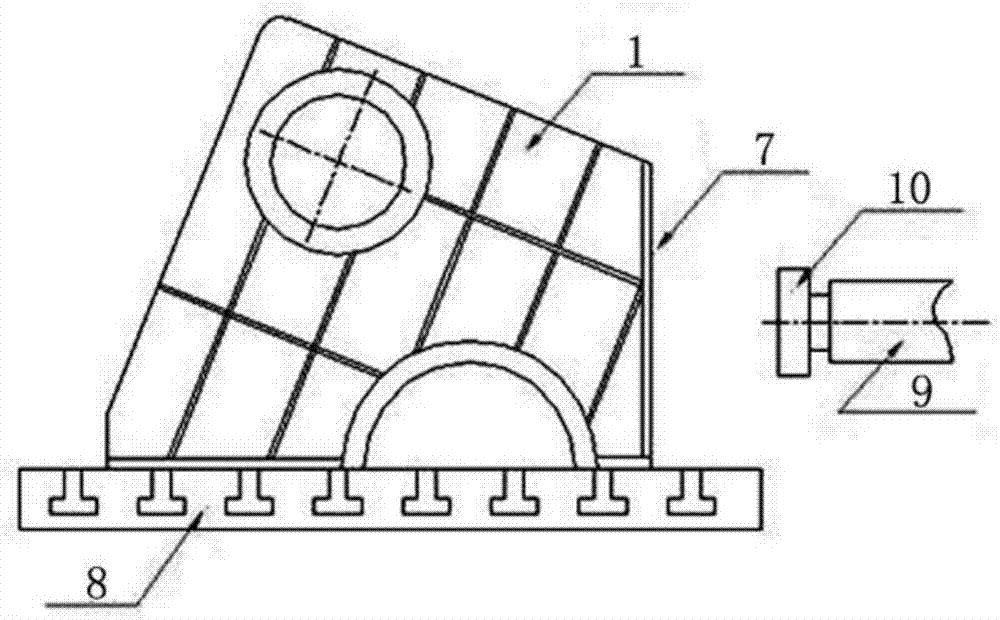

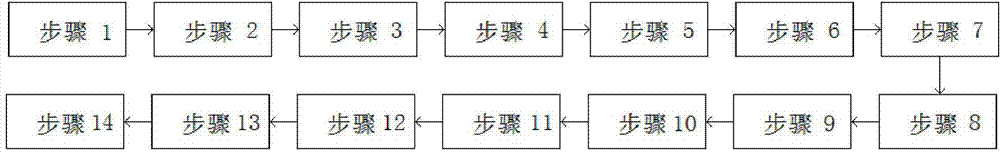

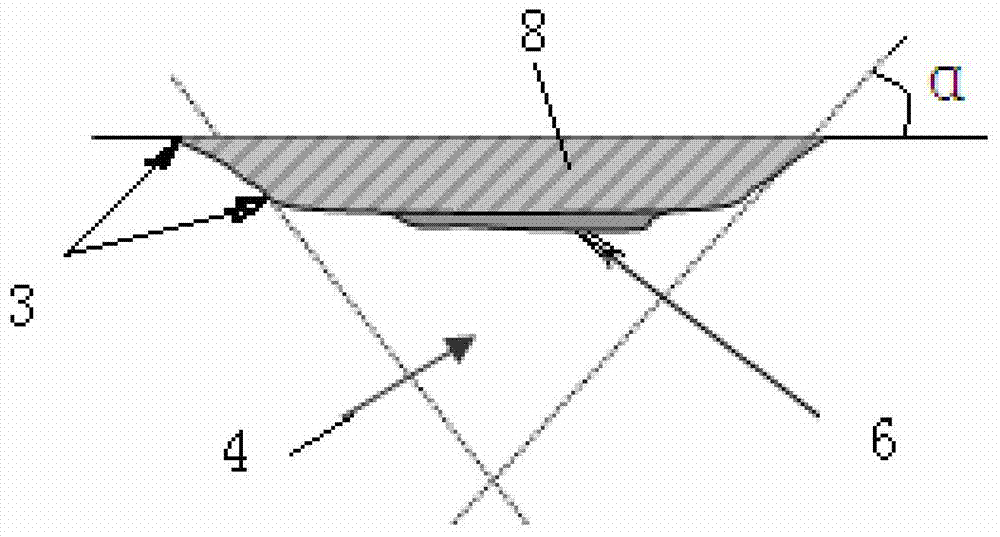

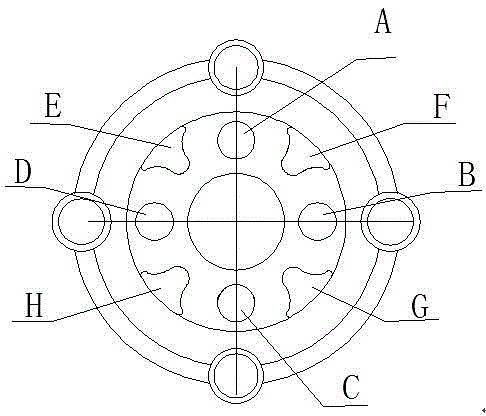

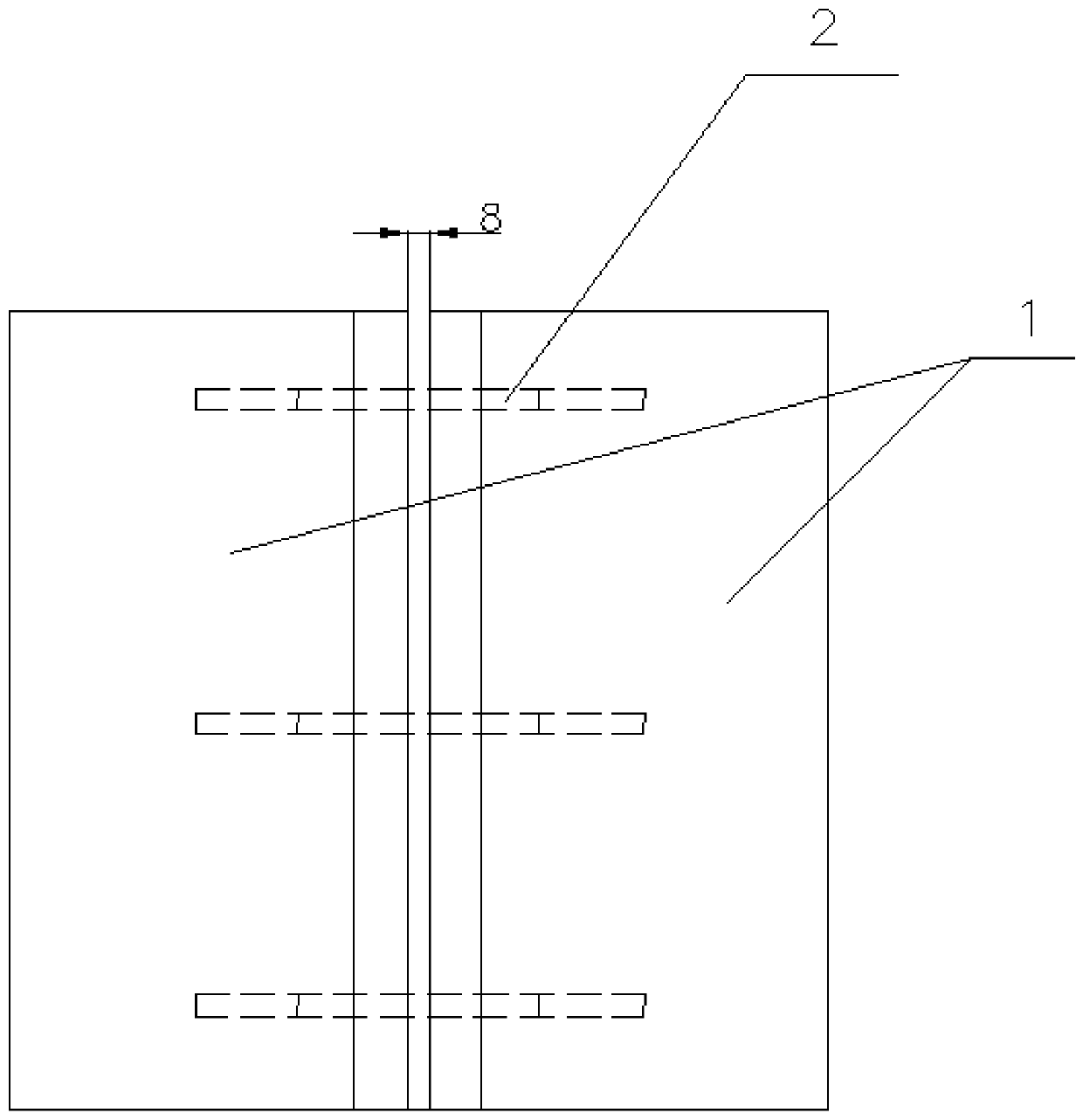

Machining and detecting system of three-division type large-dip-angle inclined box body and machining and detecting method thereof

PendingCN107378497AReduce the burden onHigh dimensional accuracyMeasurement/indication equipmentsOther manufacturing equipments/toolsMeasuring instrumentEngineering

The invention discloses a machining and detecting system of a three-division type large-dip-angle inclined box body and a machining and detecting method thereof. The system comprises a machining center, a finish-milling machine tool, a drilling machine and a measuring instrument, wherein the position is square, a conveying belt is arranged every two of the horizontal machining center, the finish-milling machine tool and the drilling machine, and a conveying belt is arranged between the machining center and the measuring instrument. The method comprises the steps of finish-milling and semi finish-milling, wherein margin is reserved for the semi finish-milling according to the requirement for dye penetrant inspection, milling and combination are alternatively conducted on a housing according to the machining sequence, and the housing is gradually assembled. When the reference axis is too short during coaxiality measurement, and the centers of two holes having the farther distance are used as references to evaluate offsets of the centers of other holes. Devices can be utilized at highest efficiency, floor area can be decreased, the burden of workers can be reduced, time and labor are saved, box body size can be increased, and the assembling precision can be improved, so that the machining process is simple and easy to operate, the box body size precision is improved, the box body is not likely to deform, the measuring errors are decreased, and the accuracy of hole system positioning is ensured.

Owner:NANJING HIGH ACCURATE MARINE EQUIP CO LTD

Manufacturing technique of pure nickel tube

The invention relates to the technical field of tubular material manufacture and particularly relates to a manufacturing technique of a pure nickel tube. The manufacturing technique of the pure nickel tube comprises the following production steps: (1) baking a nickel plate; (2) performing vacuum refining; (3) performing electroslag remelting; (4) forging; (5) performing ultrasonic flaw detection; (6) processing a round bar; (7) performing dye penetrant inspection; (8) perforating to tube blank; (9) cropping tube blank and coping; (10) performing cold rolling, deoiling and annealing; (11) performing surface treatment; (12) performing finish rolling to obtain the product; (13) annealing; (14) shaping. By adopting the technical solution, the low finished product rate of the traditional manufacture process is solved, the finished product rate is increased, the production cost is reduced, the shaped product is easy to process, the intensity and the elongation property are greatly increased, the impurities are reduced, the degree of purity is increased and the service life of the processing device is prolonged.

Owner:上海宏慧镍合金材料科技股份有限公司

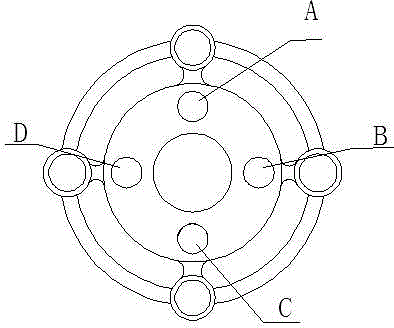

Process for laser cladding for abrasion-resistant and etch-resistant coating of water turbine set bottom ring

InactiveCN101994115AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesMachined surfaceWater turbine

The invention relates to a method for laser cladding for an abrasion-resistant and etch-resistant coating of a water turbine set bottom ring. The method is characterized by comprising the following steps of: welding an oblique angled process ring at a right angle where the inner ring surface of a leak-preventing ring of the bottom ring is jointed with an abrasion-resistant plane by using a nickel-based welding wire; removing oil and rust from a machined surface; marking subareas of a machined area; inspecting the machined places of an abrasion-resistant plate of the inner ring surface of the leak-preventing ring of the bottom ring and a plane abrasion-resistant plate by a dye penetrant inspection method; selecting iron-based alloy powder; making the alloy powder out from an automatic powder feeding head drop into a laser weld pool by using laser equipment and adjusting an automatic powder feeding device; regulating the powder feeding amount to make the thickness of an alloy powder coating between 0.2 and 1.8mm; and inspecting the machined places of the abrasion-resistant plate of the inner ring surface of the leak-preventing ring of the bottom ring and the plane abrasion-resistant plate by the dye penetrant inspection method. The laser cladding alloy coating is uniform and compact, has firm metallurgical bonding with a substrate and has high abrasion resistance and etch resistance.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

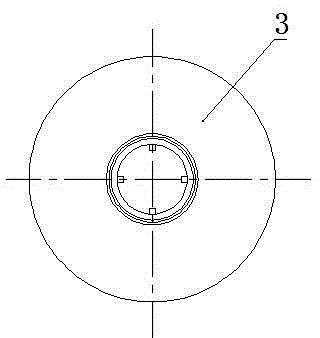

Laser surface cladding process of boiler pipe anticorrosive layer

ActiveCN104099611AAccelerated corrosionImprove oxidation capacityMetallic material coating processesMelting tankRoom temperature

The invention relates to a laser surface cladding process, in particular to a laser surface cladding process of a boiler pipe anticorrosive layer. Detergent is used for removing oil and rust of a boiler pipe at the room temperature; a part to be treated is checked by using a dye penetrant inspection method; nickel-based alloy powder is fed in a laser molten pool by adopting a coaxial or paraxonic powder feeding device, and comprises the following chemical components in percentage by weight: 0.01-0.05% of C, 21-22% of Cr, 1.0-2.0% of Fe, 8-10% of Mo, 0.1-0.7% of Si, 3.5-4.2% of Nb, and 63-64.5% of Ni; a corrosion and abrasion resistant layer is formed on the surface of the part to be treated; and the process parameters are as follows: a focusing mirror F is 300-400 mm; the cladding power P is 2000-5000 W; the spot size D is 3-10 mm; the scanning speed V is 200-1000 mm / min; the overlap rate is 40-60%; and the crack flaw detection is performed for the prepared cladding coating layer. The laser surface cladding process enhances the high-temperature corrosion and oxidization resistance of the boiler pipe, prolongs the service life of the boiler pipe, reduces the production cost, largely improves the production efficiency of power plant boilers, and promotes the development of coal, coal power and coal chemical industry in the east junggar basin region.

Owner:江苏点金激光科技有限公司

Repair method for crankshaft of constant-width hot press

PendingCN110747458AExtended service lifeHigh bonding strengthMetallic material coating processesMachine partsMachined surface

The invention discloses a repair method for a crankshaft of a constant-width hot press. According to the repair method for the crankshaft of the constant-width hot pressure, the surface of the crankshaft is pre-treated to remove an oxide layer and a fatigue layer, the surface of the crankshaft is cleaned and polished, and the machined part of the crankshaft is inspected through a dye penetrant inspection method; the surface of the crankshaft is clad with lasers to prepare a priming layer and a face layer, wherein the priming layer is made of nickel-base alloy powder, and the face layer is madeof cobalt-base alloy powder; a laser cladding machine is adopted, the crankshaft is placed on a workbench, the crankshaft rotates to enable alloy powder to be fed to a laser bath through a powder feeding device, the quantity of the fed powder is adjusted to meet the thickness requirement of a coating, a laser beam and a powder feeding head advance in the axial direction of the crankshaft, and therotating speed is set, so that a uniform and compact laser cladding layer is formed on the machined surface of the crankshaft; and the dye penetrant inspection method is adopted for inspection to avoid the defects of cracks and pores. According to the repair method, a self-lubricating wear-resistant layer is prepared through laser cladding to restore the size of the crankshaft, and the bonding strength of the wear-resistant layer and a matrix is high; and the self-lubricating performance is achieved, so that the service life of the crankshaft is prolonged, and the production quality and the production efficiency of steel billets are guaranteed.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

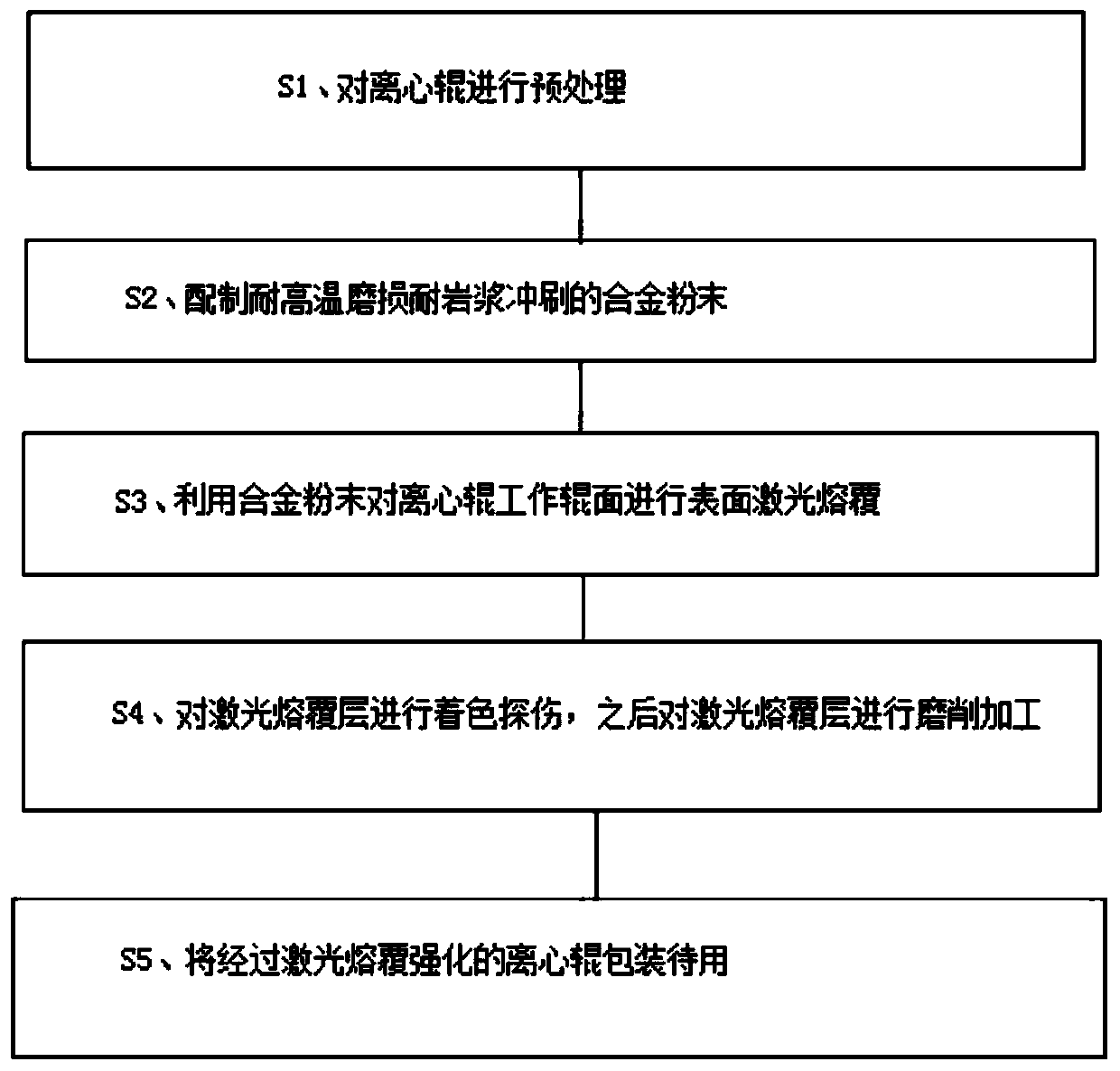

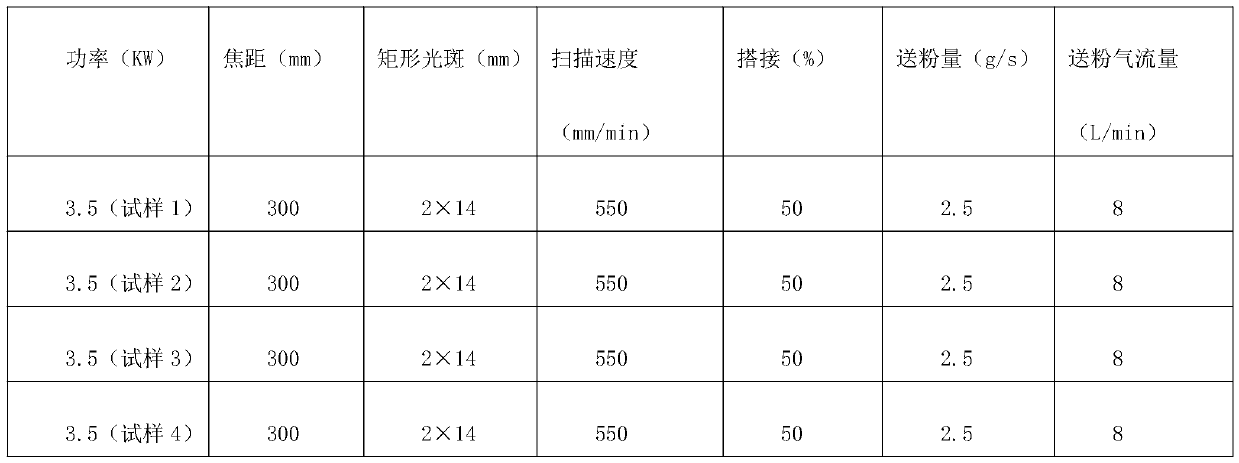

Preparation method of laser cladding reinforcement centrifugation roller

ActiveCN110396689AWith high temperature resistance to burning lossWith flow scourMetallic material coating processesNumerical controlLaser scanning

The invention provides a preparation method of a laser cladding reinforcement centrifugation roller. The preparation method of the laser cladding reinforcement centrifugation roller includes followingsteps: S1, performing pretreatment on a centrifugation roller: lathing the centrifugation roller after being processed along a work roller surface, cleaning the surface, after being lathed, of the centrifugation roller, and removing oxide skin, impurities and oil contamination; S2, compounding alloy powder resistant to high temperature abrasion and magma erosion; S3, installing the centrifugationroller on a machining tool of a high power semiconductor laser, using laser for scanning the alloy powder synchronously conveyed in place, and using the alloy powder for performing surface laser cladding on the work roller surface of the centrifugation roller; S4, performing dye penetrant inspection on a laser cladding layer, and then performing abrasive machining on the laser cladding layer; andS5, packing the centrifugation roller after being reinforced through the laser cladding for future use. The preparation method of the laser cladding reinforcement centrifugation roller uses a laser numerical control machining system, achieves automation of the reinforcement preparation process, guarantees uniformity of product quality, and prepares the reinforcement centrifugation roller which has use life reaching above 3 times of use life of a traditional bead welding stainless steel centrifugation roller.

Owner:YANSHAN UNIV

Rapid remanufacturing method of continuous casting machine roller

The invention provides a rapid remanufacturing method of a continuous casting machine roller. The method comprises steps as follows: the continuous casting machine roller is subjected to unilateral turning; submerged arc surfacing is performed; machining replication is performed; roller surface polishing and cleaning are performed; magnetic particle flaw detection and ultrasonic flaw detection areperformed; the continuous casting machine roller is coated with an oil film; the oil film is coated with alloy powder; an alloy powder coating is subjected to laser scanning, and a clad alloy layer is formed; surface dye penetrant inspection is executed; the qualified continuous casting machine roller after inspection is the remanufactured continuous casting machine roller. According to the method, the alloy powder is sprayed to the continuous casting machine roller, the alloy clad layer is formed on the surface of the roller with the laser cladding technology, so that remanufacturing of thecontinuous casting machine roller is realized, the service life of the roller can be prolonged, service efficiency can be improved, and cost of an iron and steel enterprise can be reduced; the methodhas the advantages of simple technology, high controllability, energy-saving and environment-friendly performance, low cost and the like.

Owner:天津北基新激光科技有限公司

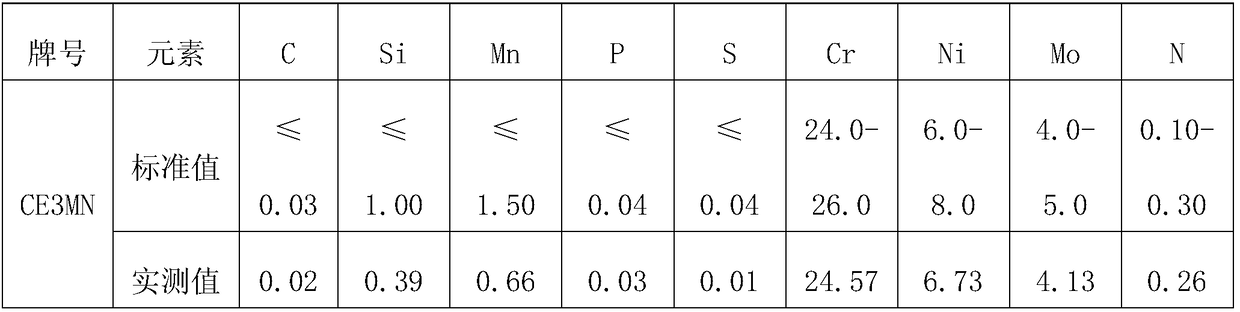

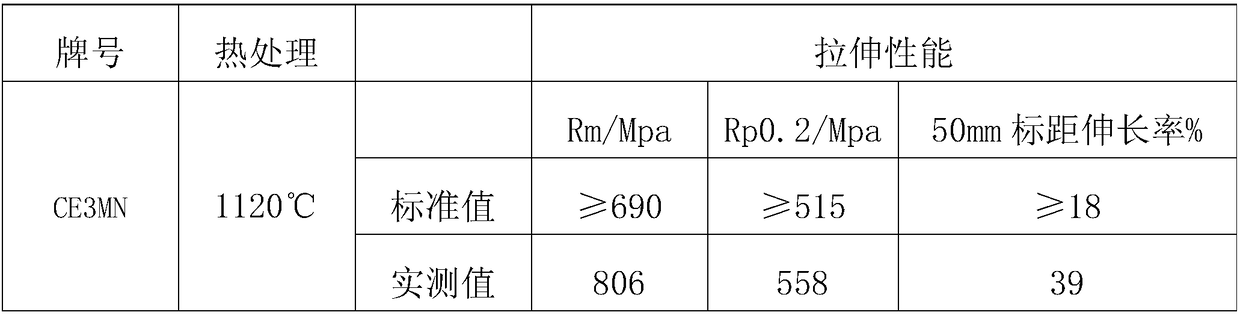

Machining process of large super duplex stainless steel guide vane body

InactiveCN108608176APrevent thermal deformation during hoistingUniform relative positionSurface finishEngineering

The invention relates to a machining process of a large super duplex stainless steel guide vane body. The machining process comprises the steps of casting, deformation protection before heat treatment, solid solution treatment, casting cleaning rough grinding, component rechecking, mechanical performance checking, PT dye penetrant inspection, defect cleaning-away repair welding rough grinding, rough machining, finishing, stress relief heat treatment, semi-finish machining, finish grinding finish machining and the like. According to the machining process, the machining hardening effect is small, size deformation is small, the machining size precision of the guide vane body is good, and surface smoothness is high. Finishing size checking is controlled to be below 40 DEG C; and the machiningefficiency is high, quality is good, the size precision and small form and position and dimensional tolerance deformation of the guide vane body can be guaranteed, and the drawing size requirement andthe technical requirement are met.

Owner:SHENYANG SANKE VALVES IND CO LTD

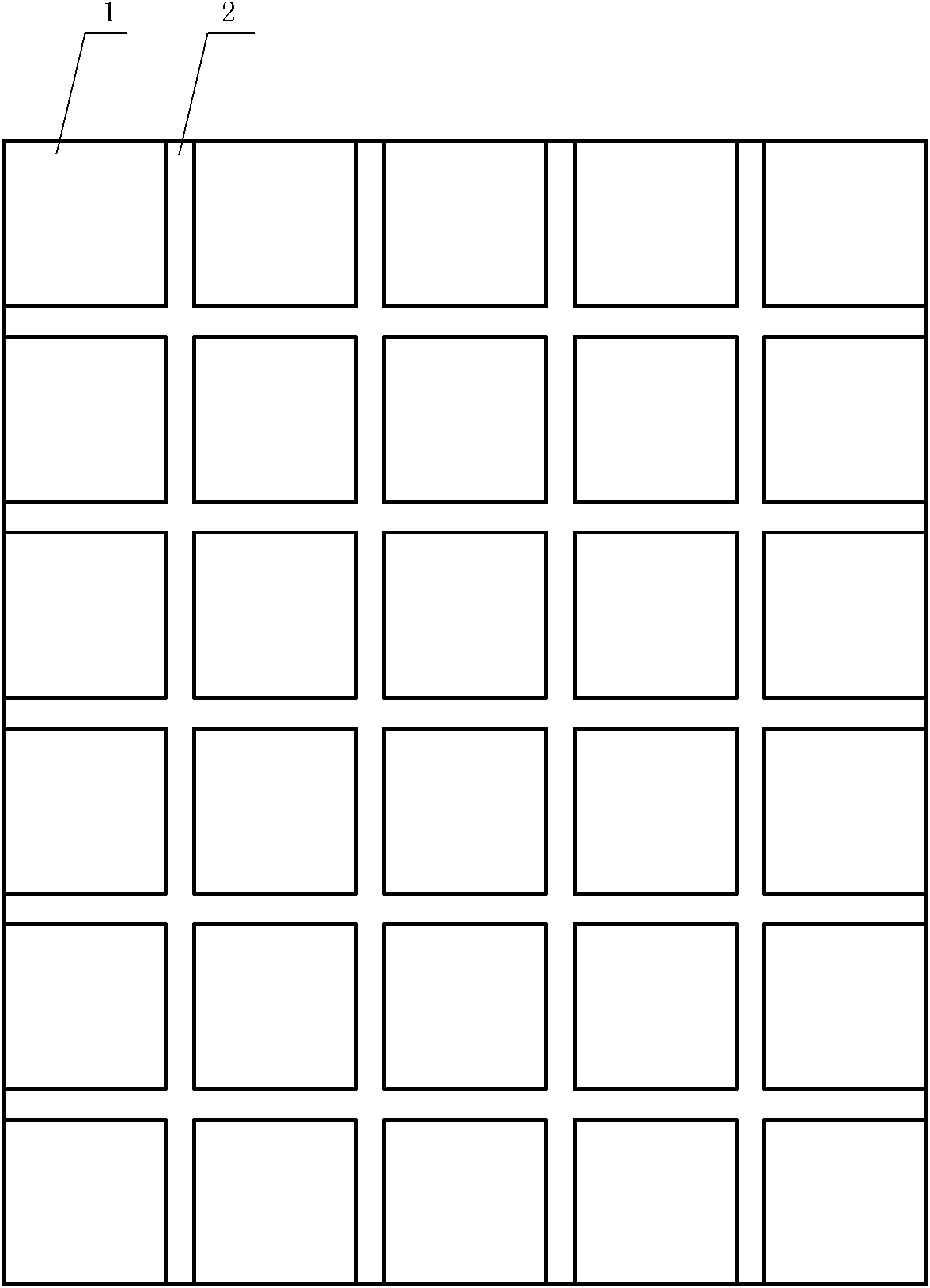

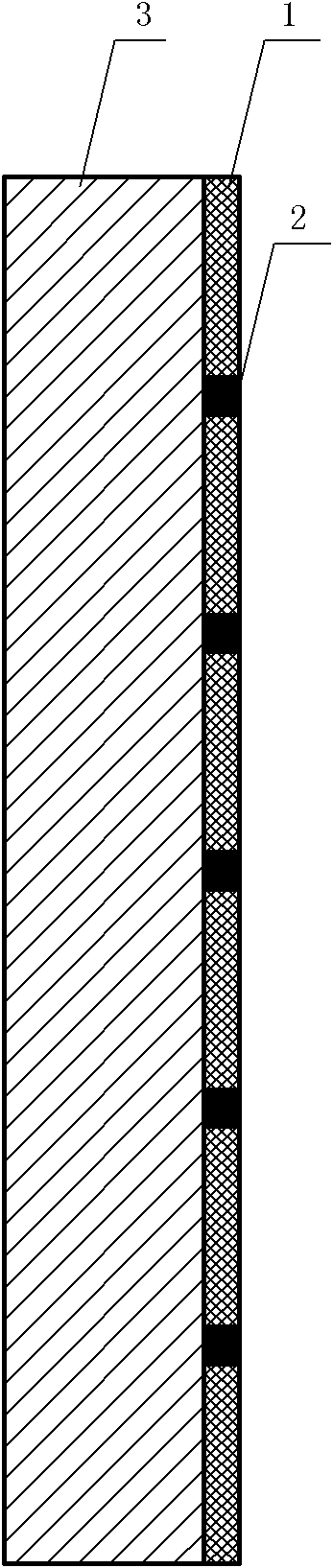

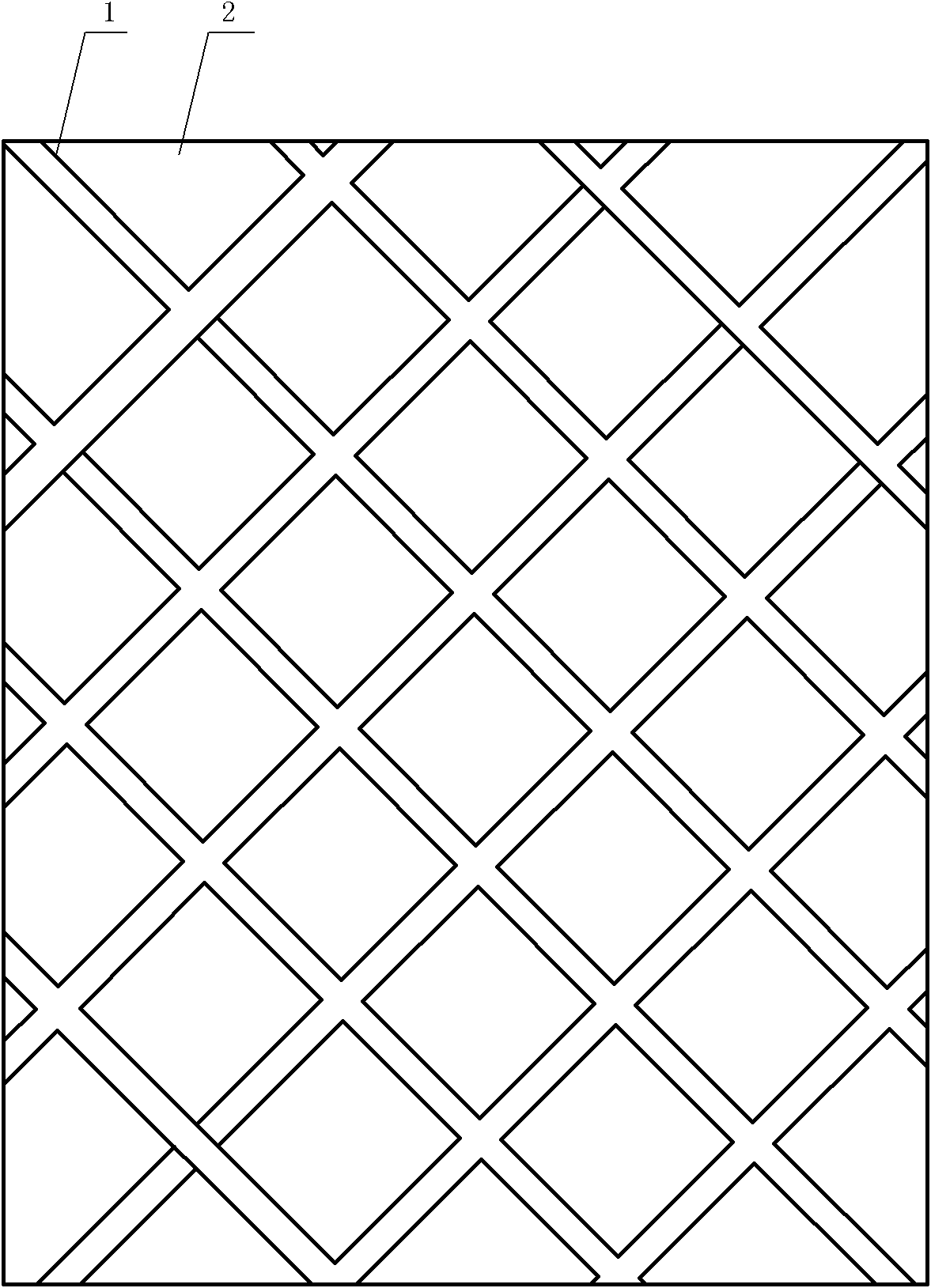

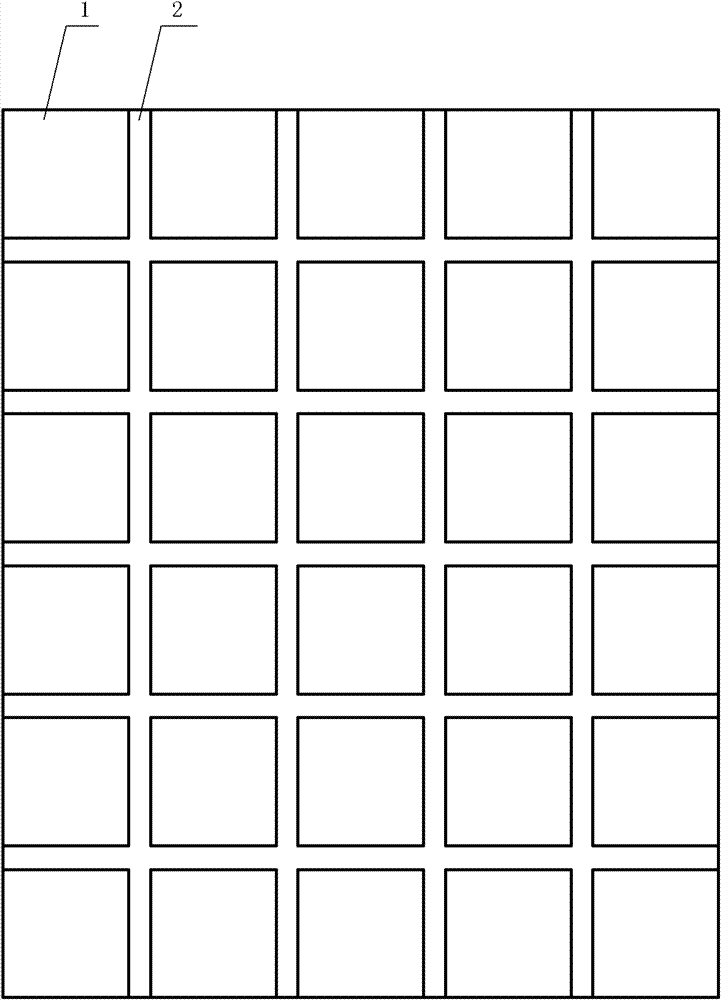

Method for repairing mill housing

The invention relates to a method for repairing a mill housing, which comprises the following steps of: washing and cleaning the surface of the mill housing to be repaired; carrying out dye penetrant inspection on the surface of the whole mill housing to be repaired and measuring the size of the housing; removing a fatigue layer; at least welding latticed block layers through resurfacing welding, which have the same hardness with the material of a substrate of the surface of the mill housing to be repaired, in the width direction and the length direction of the surface of the mill housing to be repaired; carrying out machining on the block layers which are subjected to resurfacing welding on the surface of the mill housing to be repaired; carrying out resurfacing welding on hard layers in gaps among the block layers, wherein the hardness of the hard layers is more than the hardness of 0 to 40HRC of the block layers; and carrying out repairing so that the thickness of the hard layers is the same with the thickness of the block layers and the surface of the repaired mill housing is level and meets the repair requirement. Compared with a method for welding by totally using the hard materials on the whole surface of the housing, the method ensures the machining process easier and is also convenient to machine.

Owner:烟台开发区蓝鲸金属修复有限公司

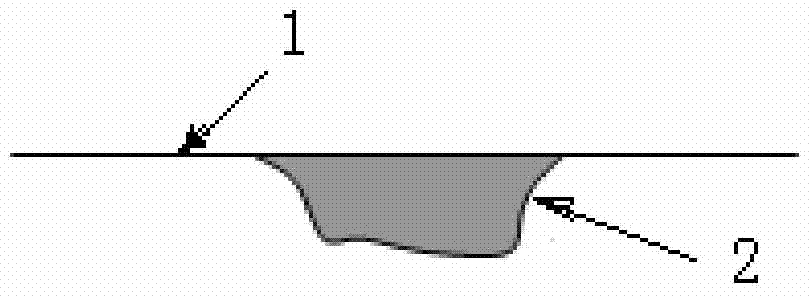

Repairing method for supporting roller of plate and strip rolling mill

The invention discloses a dish-shaped pit repairing method for a supporting roller of a rolling mill. The method includes the following steps that (1) an ultrasonic flaw detection mode is used for confirming the roller body crack range and depth, or the contact fatigue flaking range and depth or the collision flaw range and depth of the supporting roller of the rolling mill; (2) according to the roller body flaw position of the supporting roller of the rolling mill, a grinding machine and a polishing machine are used for conducting manual polishing treatment, a polished pit in a treated face is repaired to be in a bowl shape or in a dish shape, and due to the depth of the bowl-shaped pit or the depth of the dish-shaped pit, the purpose that flaws are eliminated or the flaws are controlled in an unstressed safe area can be achieved; (3) dye penetrant inspection is further matched in the polishing process, and it is guaranteed that the flaws can be completely polished or controlled in the unstressed safe area; (4) the position between the treated face and an adjacent plane or an adjacent curved surface is polished into a smooth transition circular arc; (5) grinding machining is conducted on a grinding machine; (6) the transition circular arc arranged between the treated face and the adjacent plane or the adjacent curved surface is treated again. The grinding amount of the supporting roller is reduced, the repairing efficiency is improved, grinding wheel consumption is reduced, and the use and maintenance cost of the supporting roller is lowered.

Owner:JIGANG GRP

Method for identifying cracks in laser cladding process

ActiveCN111860290AValid reservationImprove recognition accuracyCharacter and pattern recognitionOptically investigating flaws/contaminationRadiologyDye penetrant inspection

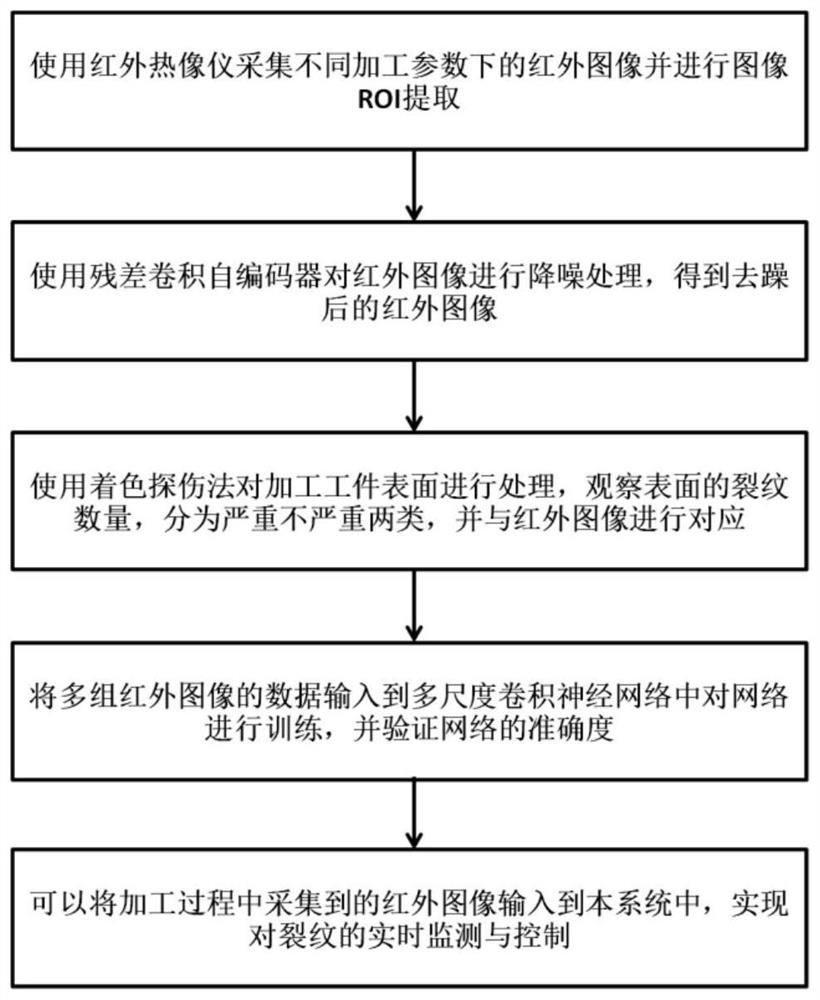

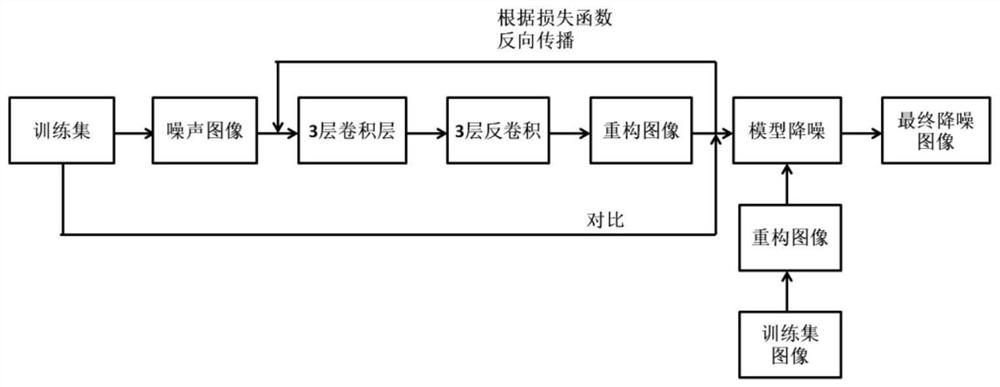

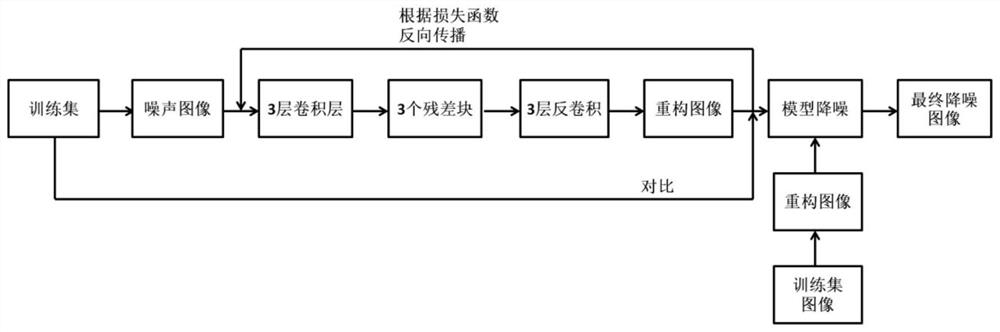

The invention belongs to the technical field of infrared image and image recognition, and provides a method for identifying cracks in a laser cladding process. An infrared thermal imager is used for collecting infrared images of the nickel-based alloy laser cladding process under different machining parameter conditions, and image ROI extraction is conducted on the infrared images; noise reductionprocessing is performed on the extracted infrared image by using a residual convolution auto-encoder; the surfaces of the workpieces processed under different processing parameters are processed by using a dye penetrant inspection method, the crack conditions of the surfaces of the workpieces are observed, the crack conditions are divided into seriousness and non-seriousness, and the reconstructed images are classified according to the crack severity; a multi-scale convolutional neural network is used to process the de-noised reconstructed image; a reconstructed image is divided into multiplegroups of data according to different crack degrees, each group of data is divided into training data and test data in proportion, the training data is input into a multi-scale convolutional neural network for training, and the test data is used for testing the accuracy of the network after training, so that the accuracy of the network is ensured.

Owner:DALIAN UNIV OF TECH

Method for repairing journal of generator rotor

InactiveCN109536945AChange performanceHigh speedMetallic material coating processesOriginal dataAlloy

The invention discloses a method for repairing a journal of a generator rotor. The method comprises the following steps of determining a repair area, detecting original data; carrying out dye penetrant inspection, checking whether cracks exist in the damaged region of the rotor journal; removing the fatigue layer; configuring the laser cladding alloy powder; carrying out repairing by using the laser; restoring the original data size of the rotor journal.

Owner:成都大陆激光技术有限公司

Manufacturing technology of walking machinery bracket casting

InactiveCN103600035AReduce manufacturing costFoundry mouldsFoundry coresManufacturing technologyDye penetrant inspection

The invention discloses a manufacturing technology of a waking machinery bracket casting. The technology comprises the following steps: step a, manufacturing a shell mould of a precoated sand box and an upper mould; step b, arranging an exothermic riser in the center position of the upper mould; step c, pouring molten iron into the precoated sand box within 8 to 10 seconds at a temperature of 1380 DEG C; step d, placing an exothermic agent on the top part of the exothermic riser after the pouring process, allowing the box to stand still, wherein in this process, the exothermic property of the exothermic riser is utilized so as to prolong the solidification time of the molten iron, the feeding is strengthened, the stand-still time is 1 to 1.5 hours, and the molten iron cools and forms a casting blank; step e, subjecting the casting blank to a post-treatment so as to obtain a finished casting. The manufacturing technology has the advantages that: through the experiments of the technology mentioned above, casting dissection and dye penetrant inspection both meet the clients' requirements, the technology yield is raised from 33% to 71%, and thus the casting production cost is largely reduced.

Owner:南通华东油压科技有限公司

Technology method for welding brass H62 and low-alloy cast steel G20Mn5 dissimilar materials

The invention discloses a technology method for welding brass H62 and low-alloy cast steel G20Mn5 dissimilar materials. A manual argon tungsten-arc welding method and an S211 silicon bronze welding wire with the diameter of phi 2.5 are adopted, preheating is performed at 150-200 DEG C before welding, the situation that the interlayer temperature is higher than the preheating temperature in the welding process is guaranteed, heat is preserved for 2 hours after welding, and then dye penetrant inspection is performed. The argon tungsten-arc welding method is adopted, the technological means is simple, welding forming is attractive, the fusion quality of the root of a welding joint is good, the requirement for the skill level of workers is not high, the welding quality is stable, the production efficiency is improved, and the production cost is reduced.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

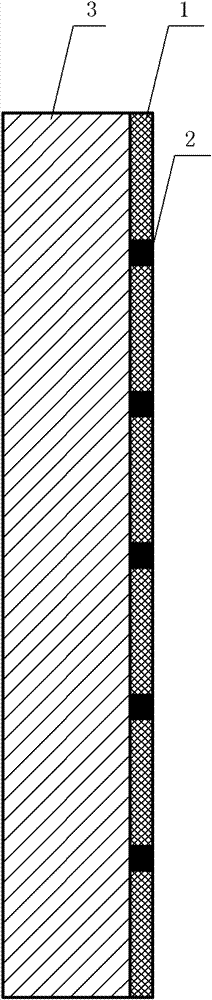

Split face laser seal coating process in gas turbine cylinder

ActiveCN106636754AEasy to operateAdaptableMetallic material coating processesAll solid stateEngineering

The invention relates to a split face laser seal coating process in a gas turbine cylinder. The process is characterized in that detection and preparation are carried out before laser cladding of a gas turbine cylinder body; laser cladding is carried out, wherein a all-solid-state 1KW laser is employed during laser cladding, laser cladding is carried out on split face in the gas turbine cylinder, three mutually-parallel seal lines are co-cladded, width of each seal line is 2+ / -0.2 mm, and the height is 1+ / -0.2 mm, multistage parallel soft metal sealing strips are formed, an air bag-type sealing chamber is formed after a laser cladding layer is subjected to compressional deformation after installation, gradual sealing effect is realized; the sealing strip is sealed after laser cladding and detected and recorded; the sealing strip is treated through pliers, height size and contact area of each point of each strip are ensured; flaw detection is carried out, dye penetrant inspection detection is carried out, no defect is generated on surface and inner part. The process employs laser sealing, and split leakage problem in the cylinder can be effectively solved under matrix performance is not damaged.

Owner:上海闸电燃气轮机发电有限公司

Laser surface cladding treatment technology for tooth surface of roller bit

InactiveCN103741137AExtended service lifeImprove work efficiencyMetallic material coating processesHigh power lasersAlloy

The invention discloses a laser surface cladding treatment technology for the tooth surface of a roller bit, which comprises the following steps: (1) performing pretreatment on the tooth surface of the roller bit; (2) inspecting the tooth surface of the roller bit by a dye penetrant inspection process; (3) adopting the nickel base alloy powder as a base coat of the tooth surface of the roller bit; (4) cladding a base alloy by high-power CO2 laser complete equipment; (5) adopting spherical WC and Ni-Cr-B-Si self-fusion alloy mixed alloy powder as a working layer of the tooth surface of the roller bit; (6) cladding the spherical WC and Ni-Cr-B-Si mixed powder by a high-power laser in two processing modes of narrow-band cladding processing and wide-band cladding processing; and (7) after the cladding, performing flaw detection inspection to ensure that the surface of the processed part is flat. The technology provided by the invention strengthens the tooth surface of the roller bit, prolongs the service life of the roller bit, basically solves the problems of early bald-grinding, peeling and the like of the roller bit, improves the operation efficiency of a drilling machine and reduces the production cost.

Owner:武汉团结点金激光科技有限公司

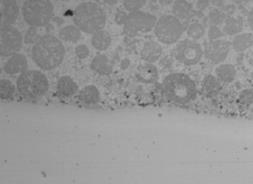

Water-washable dye-penetrant inspection agent and preparation method thereof

InactiveCN109187571AWill not polluteWashing to achieveOptically investigating flaws/contaminationAlkylphenolSolvent

The invention discloses water-washable dye-penetrant inspection agent, which is prepared from the following raw materials in parts by weight: 10-25 parts of fatty alcohol-polyoxyethylene ether, 1-4 parts of dye, 2-8 parts of emulsifier, 2-4 parts of surfactant, 0.2-1.8 parts of polyxyethylated alkylphenol and 50 parts of water. By use of the water-washable dye-penetrant inspection agent disclosedby the invention, adopted solvent is water, so that environment is not polluted, in addition, water washing can be realized, and meanwhile, color development detection sensitivity is high.

Owner:WUJIANG HYPERD NDT MATERIAL

Large-scale tube body welding technology

InactiveCN108188550AAvoid Welding DefectsHigh strengthArc welding apparatusEngineeringUltimate tensile strength

The invention discloses a large-scale tube body welding technology. The large-scale tube body welding technology includes the steps that blanking of tube body steel plates is carried out, the circumference within 120mm is subjected to ultrasonic flaw detection, and qualification is required to reach the level II; and splicing grooves are formed in annular plates, straight slit grooves are formed in tube bodies, dye penetrant inspection is carried out after grinding, and the length of the tube body steel plates is 2-3mm less than the actual size length; the annular plates are spliced, manual welding is adopted for priming, weld preheating is carried out with the preheating temperature being equal to or greater than 100 DEG C, end tabs are added for submerged-arc welding, the submerged-arc welding is carried out after regulation of working faces and back gouging, and heat preservation is carried out after welding; plates are rolled, straight slits are welded after the plates are bent toa round shape, the manual welding is used for priming, the preheating temperature is equal or greater than 100 DEG C, end tabs are added for submerged-arc welding, the submerged-arc welding is carriedout after the regulation of the working faces and the back gouging, and tube segments are rewound after welding. The large-scale tube body welding technology is simple, welding defects can be avoidedduring welding, the stability of the welding can be ensured, and high strength and good stiffness after welding of the tube bodies can be achieved.

Owner:浙江同力重型机械制造有限公司

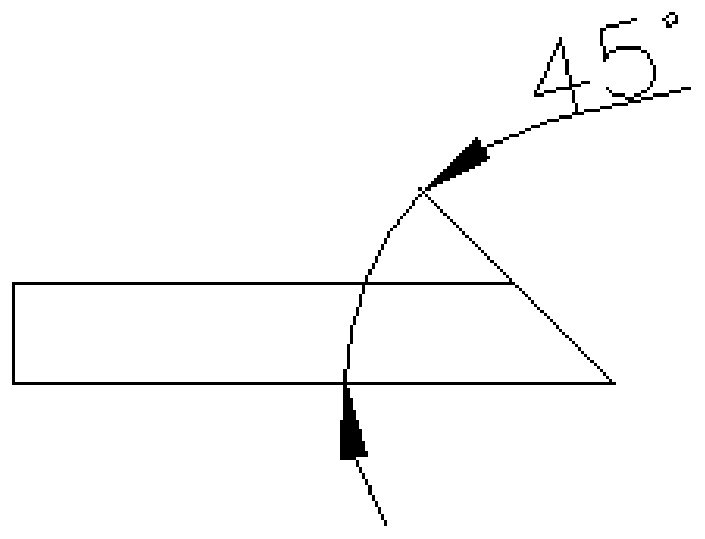

Method for testing crack resistance of welding wire

InactiveCN110726734AAvoid unqualifiedGuarantee welding qualityArc welding apparatusOptically investigating flaws/contaminationButt weldingCrack resistance

The invention discloses a method for testing the crack resistance of a welding wire. The method comprises the steps of: preparing two steel plates, and forming a 45-degree groove on one side of a longedge of each of the two steel plates; splicing the sides with the grooves of the long edges of the two steel plates, and attaching ceramic pads to the opposite sides of the grooves of the two steel plates; performing backing weld on butt welds of the ceramic pads at horizontal positions via CO2 gas shielded welding; and performing dye penetrant inspection on the tested steel plates after the welding is completed to check the crack conditions of the backing weld seams. According to the method disclosed by the invention, the welding and dye penetrant inspection are performed on the tested steelplates to check the crack conditions of the backing weld seams, so as to detect the weld cracks, avoid the disqualification of the seams caused by thermal cracks generated in the seams and to ensurethe welding quality.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Thrust pad repairing method based on laser cladding process

PendingCN112981395ALow heat inputSmall amount of thermal deformationAdditive manufacturing apparatusIncreasing energy efficiencyTinningEngineering

The invention aims at providing a thrust pad repairing method based on a laser cladding process. The deformation amount in the thrust pad repairing process is effectively controlled, the problems of hole shrinkage and shelling of a babbitt metal layer are thoroughly solved, the design size of a thrust pad is recovered, the use performance of the thrust pad is improved, the service life of the thrust pad is prolonged, and extremely high economical efficiency is achieved. The thrust pad repairing method comprises the following steps: removing an original babbitt metal layer of the thrust pad, preparing the babbitt metal layer on the surface of a steel billet through laser cladding, carrying out ultrasonic flaw detection, milling, carrying out dye penetrant inspection and grinding. According to the method, the thrust pad which fails in service is remanufactured, and the use performance of the thrust pad is recovered and improved through a new additive manufacturing method. Compared with pouring and oxyacetylene welding processes, the manufacturing process of the babbitt metal layer is greatly simplified, the steel billet preheating and tinning processes are omitted, and the quality of the babbitt metal layer, the combination condition of the babbitt metal layer and the steel billet, the deformation amount of the steel billet and the labor environment are effectively improved.

Owner:CHINA YANGTZE POWER

Process for laser cladding of nickel-based tungsten carbide on surface of nickel-aluminum bronze

PendingCN113652686AAvoid crackingSolve the problem of stomataMetallic material coating processesSlagWear resistance

The invention relates to a process for laser cladding of nickel-based tungsten carbide on the surface of nickel-aluminum bronze. The process comprises the following steps that (1) the surface of the nickel-aluminum bronze is cleaned, and burrs and oil stains are removed; (2) process parameters are set through laser cladding equipment, and laser cladding is conducted on a nickel-aluminum bronze plate; and (3) after laser cladding is completed, after the nickel-aluminum bronze plate is naturally cooled, dye penetrant inspection is carried out, whether air holes, cracks and other phenomena exist or not is checked, then machining is carried out, the adopted nickel-based tungsten carbide is Ni50 + 60% WC, the hardness of a final cladding layer is HRC45-52, the thickness is 1.8-2.5 mm, and the defects of air holes, slag inclusion, micro cracks, spalling and the like do not exist, and tungsten carbide cladding on the surface of the nickel-aluminum bronze is achieved. The corrosion resistance and wear resistance of the nickel-aluminum bronze are enhanced, the service life of the key parts of ships and the like made of the nickel-aluminum bronze which is in contact with seawater is prolonged, and the nickel-aluminum bronze has wide application benefits.

Owner:江苏智远激光装备科技有限公司

Method for detecting influence degree of hydrogen content of molten aluminum

InactiveCN104792657AAchieve confirmationImprove detection reliabilityMaterial analysis by optical meansSpecific gravity measurementDirect observationPhysical chemistry

The invention discloses a method for detecting the influence degree of the hydrogen content of molten aluminum. The method comprises the following steps: a, the value of specific gravity of a sample is detected; b, a section is machined on the sample, whether a pinhole point exists on the section is observed, if the pinhole point does not exist, the hydrogen content of the sample is qualified, and the hydrogen content is unqualified if the pinhole point exists. According to the method, the section is machined on the sample after detection of the specific gravity, hydrogen is uniformly distributed through negative pressure pumping before the detection of the specific gravity, so that the distribution condition of pores formed by hydrogen after solidification of the sample can be observed directly through the section, a specific gravity parameter obtained with a specific gravity measurement method is further confirmed, the detection reliability of the hydrogen content is improved, and the potential safety hazards for hub quality control are reduced; dye penetrant inspection and / or polishing are performed on the section, the section observing reliability is further improved, and the reliability of the detection of the influence degree of the hydrogen content is guaranteed.

Owner:江苏新安驰铝业有限公司

Method for repairing mill housing

The invention relates to a method for repairing a mill housing, which comprises the following steps of: washing and cleaning the surface of the mill housing to be repaired; carrying out dye penetrant inspection on the surface of the whole mill housing to be repaired and measuring the size of the housing; removing a fatigue layer; at least welding latticed block layers through resurfacing welding,which have the same hardness with the material of a substrate of the surface of the mill housing to be repaired, in the width direction and the length direction of the surface of the mill housing to be repaired; carrying out machining on the block layers which are subjected to resurfacing welding on the surface of the mill housing to be repaired; carrying out resurfacing welding on hard layers ingaps among the block layers, wherein the hardness of the hard layers is more than the hardness of 0 to 40HRC of the block layers; and carrying out repairing so that the thickness of the hard layers is the same with the thickness of the block layers and the surface of the repaired mill housing is level and meets the repair requirement. Compared with a method for welding by totally using the hard materials on the whole surface of the housing, the method ensures the machining process easier and is also convenient to machine.

Owner:烟台开发区蓝鲸金属修复有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com