Preparation method of laser cladding reinforcement centrifugation roller

A technology of laser cladding and centrifugal roller, which is applied in coating, metal material coating process, etc., can solve the problems affecting the continuous production of rock wool production line, short service life of centrifugal roller, complicated working conditions, etc., and achieve excellent high temperature resistance Burning loss, not easy to crack, automatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

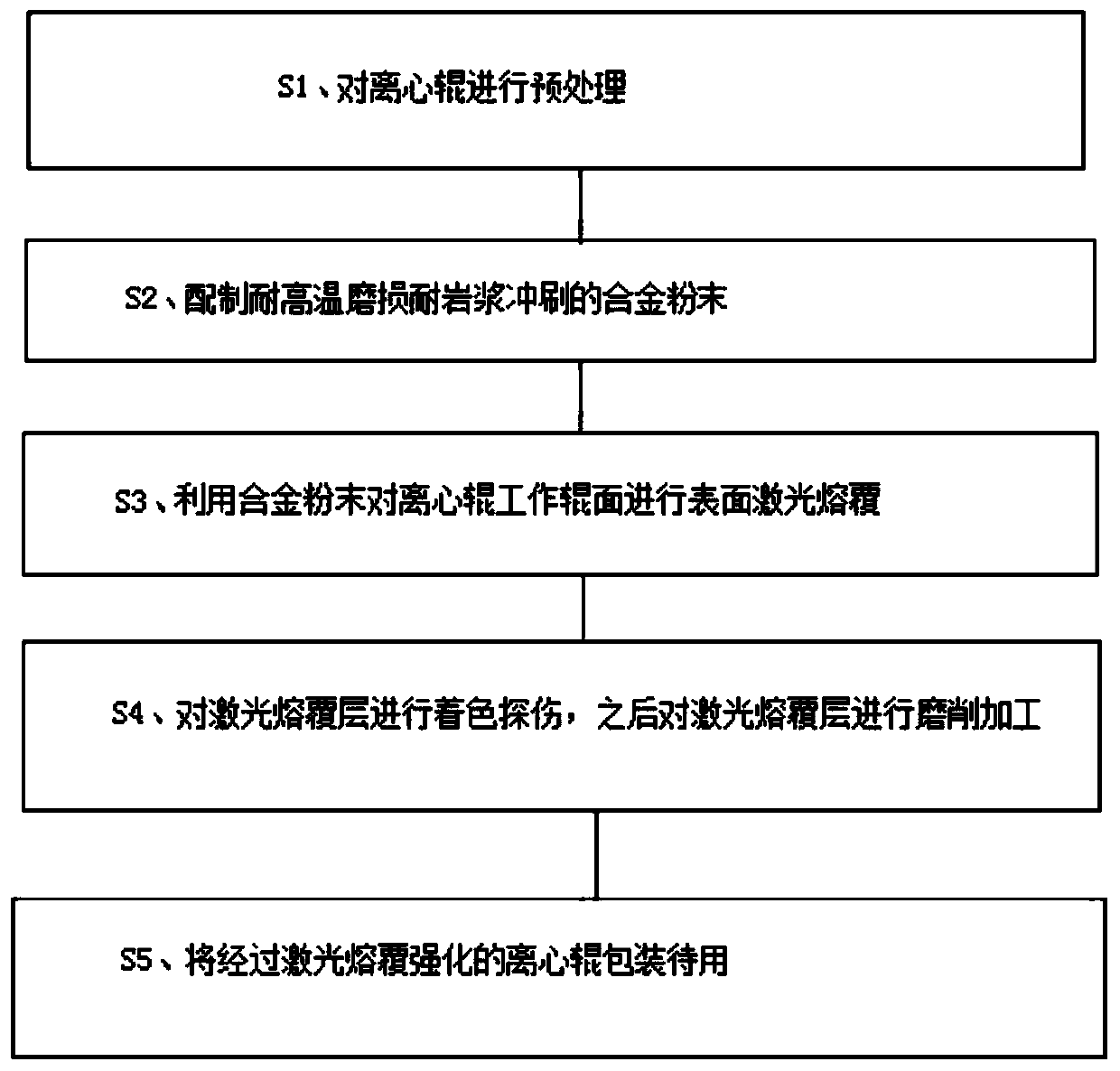

[0033] This embodiment provides a method for preparing a laser cladding reinforced centrifugal roll, which includes the following steps:

[0034] 1) The processed centrifugal roll is turned along the surface of the work roll, and the amount of turning on one side is 1.0 mm.

[0035] 2) Use industrial alcohol to clean the turned surface to remove scale, impurities and oil stains.

[0036] 3) Prepare alloy powders resistant to high temperature wear and liquid magma erosion. The components are: C: 0.25%, Ni: 18%, Cr: 6%, Co: 3.2%, Al: 0.4%, WC: 5.5%, the balance is Fe, and the particle size of the powder is 135-325 mesh.

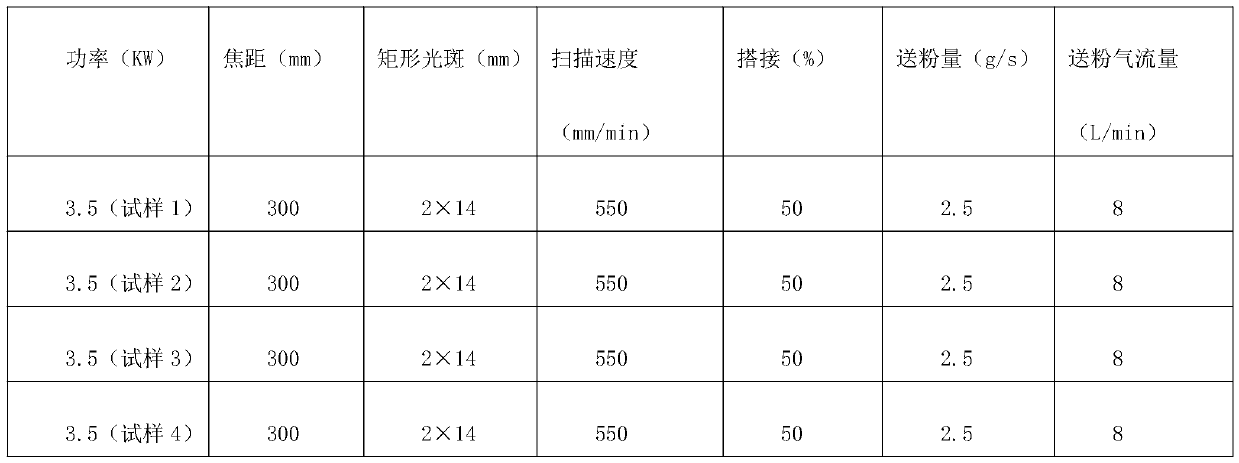

[0037] 4) Install the centrifugal roller on a high-power semiconductor laser processing machine tool, and carry out laser cladding on the surface of the working roller surface of the centrifugal roller by synchronously feeding and transporting the alloy powder in place through laser scanning. The specific process parameters are as follows: semiconductor laser ...

Embodiment 2

[0043] This embodiment provides a method for preparing a laser cladding reinforced centrifugal roll, which includes the following steps:

[0044] 1) The processed centrifugal roll is turned along the surface of the work roll, and the amount of turning on one side is 1.0 mm.

[0045] 2) Use industrial alcohol to clean the turned surface to remove scale, impurities and oil.

[0046] 3) Prepare alloy powders resistant to high temperature wear and magma erosion. The components are as follows in terms of mass percentage: C: 0.20%, Ni: 16%, Cr: 4%, Co: 3.0%, Al: 0.2%, WC: 5.2 %, the balance is Fe, and the particle size of the powder is 135-325 mesh.

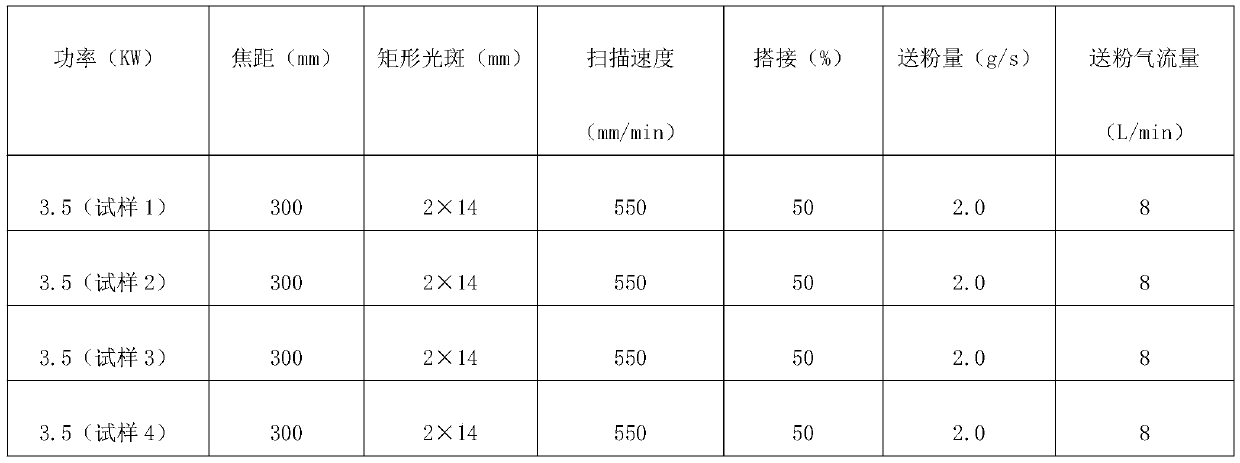

[0047] 4) Install the centrifugal roller on a high-power semiconductor laser processing machine tool, and carry out surface laser cladding on the surface of the working roller of the centrifugal roller by synchronously feeding and transporting the alloy powder in place through laser scanning. The specific process parameters are as fol...

Embodiment 3

[0052] This embodiment provides a method for preparing a laser cladding reinforced centrifugal roll, which includes the following steps:

[0053] 1) The processed centrifugal roll is turned along the surface of the work roll, and the amount of turning on one side is 1.0 mm.

[0054] 2) Use industrial alcohol to clean the turned surface to remove scale, impurities and oil.

[0055] 3) Prepare alloy powders resistant to high temperature wear and magma erosion. The components are as follows in terms of mass percentage: C: 0.35%, Ni: 122%, Cr: 8%, Co: 7.2%, Al: 0.6%, WC: 5.5 %, the balance is Fe, and the particle size of the powder is 135-325 mesh.

[0056] 4) Install the centrifugal roller on a high-power semiconductor laser processing machine tool, and carry out surface laser cladding on the surface of the working roller of the centrifugal roller by synchronously feeding and transporting the alloy powder in place through laser scanning. The specific process parameters are as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com