Manufacturing technology of walking machinery bracket casting

A manufacturing process and casting technology, which is applied in the field of bracket castings for automatic control of hydraulic systems, can solve the problems of wasting molten iron, high production costs, and low yield of casting processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

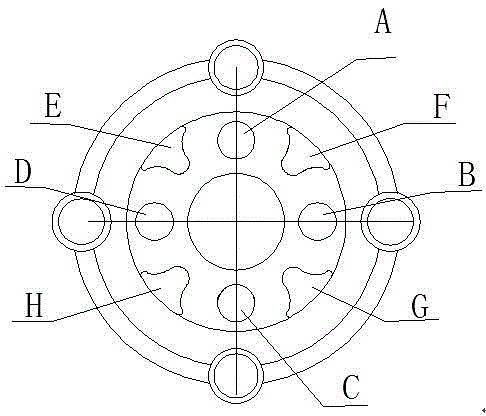

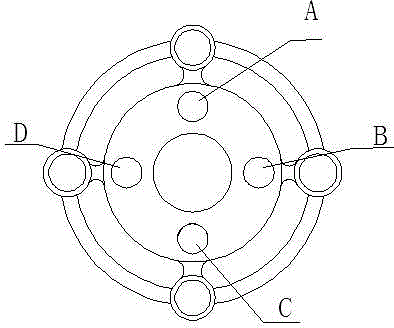

[0041] This embodiment discloses the 6324120-0203 bracket casting.

[0042] Such as figure 1 , Figure 3 to Figure 10 Shown: the specific process is as follows:

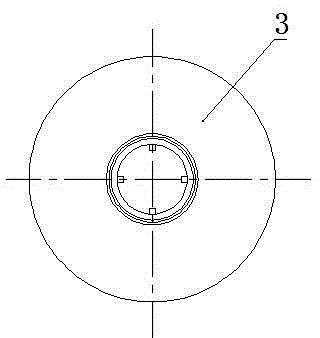

[0043] a. Make the shell mold of the film-coated sand box, including a bottom mold 1, a cover mold 3 and a middle mold 2, and the bottom mold 1, middle mold 2 and cover mold 3 are stacked sequentially from bottom to top, and the bottom mold 1 and the cover mold 3 and the middle mold 2 are positioned by cylindrical positioning protrusions,

[0044] b. Set a 90mm heating riser 5 at the center of the upper die 1; the riser 5 is a traditional riser that is sawed at 1 / 3 from the middle and upper part in the radial direction to form two upper and lower sections (5a, 5b), and A filter screen 4 is placed on the parting surface between the sections, and the upper and lower sections (5a, 5b) are bonded together with an adhesive to form a riser with a filtering function. It is worth noting that in this embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com