Method for identifying cracks in laser cladding process

A technology of laser cladding and cracks, which is applied in the field of infrared images and image recognition, can solve problems such as cracks are difficult to identify, difficult to control, and cannot be monitored in real time, and achieve the effect of overcoming the lack of eigenvalues and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

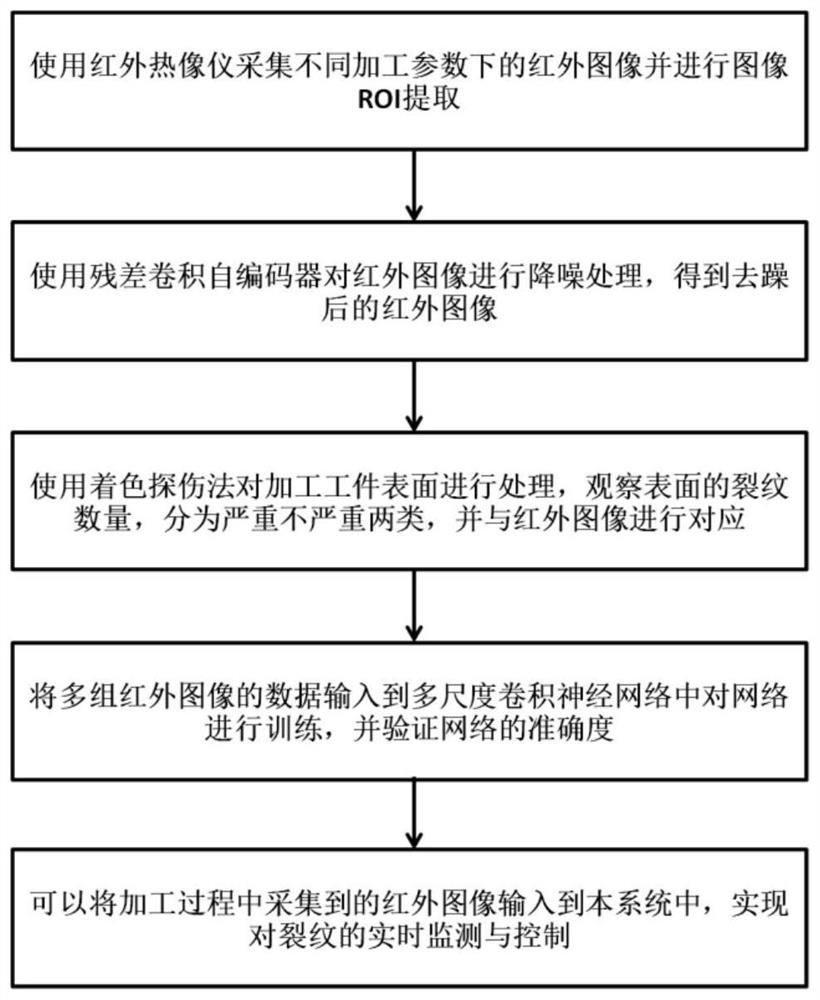

[0041] A method for identifying cracks in the laser cladding process, the implementation steps are as follows figure 1 ,Proceed as follows:

[0042] Step 1: Use an infrared thermal imager to collect infrared images of the nickel-based alloy laser cladding process processed with different processing parameters, and extract the image ROI from the infrared images;

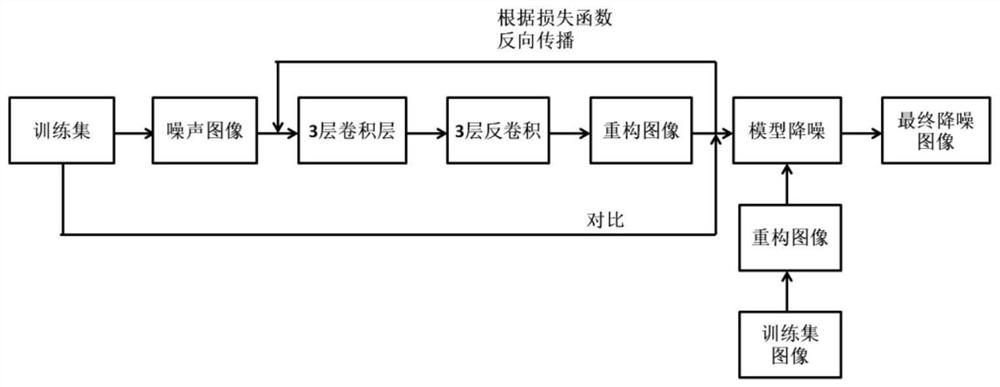

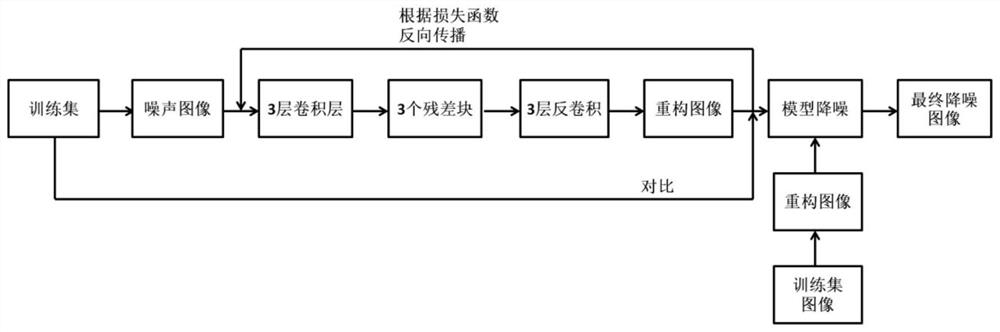

[0043] Step 2: Further process the extracted infrared image ROI, and use the residual convolutional autoencoder structure to denoise the infrared image; the residual convolutional autoencoder is an improvement on the basis of the convolutional autoencoder, The structure of convolutional autoencoder is divided into input layer, convolution layer, pooling layer, deconvolution layer and output layer, such as figure 2 shown. The residual convolutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com