Detection method for flexible package lithium ion battery aluminum plastic film corrosion

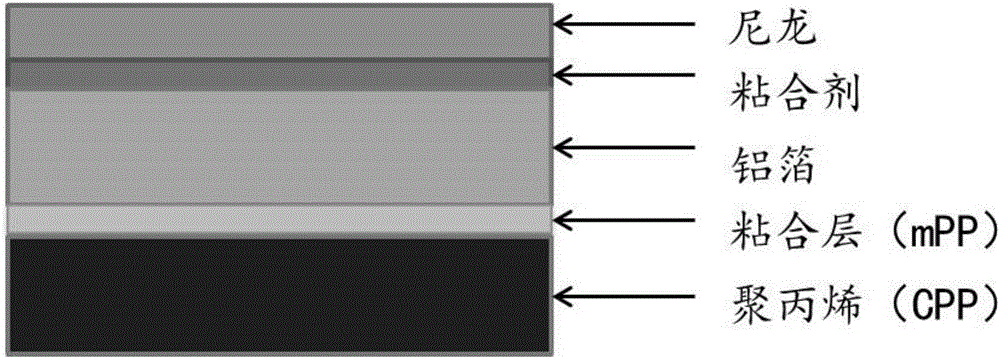

A technology for lithium-ion batteries and detection methods, which is applied to the detection of corrosion of aluminum-plastic films of flexible-packaged lithium-ion batteries and the detection of corrosion positions of aluminum-plastic films for flexible packaging materials of lithium-ion batteries. , to achieve the effect of improving the measurement detection rate, improving the yield rate, and accelerating the corrosion reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

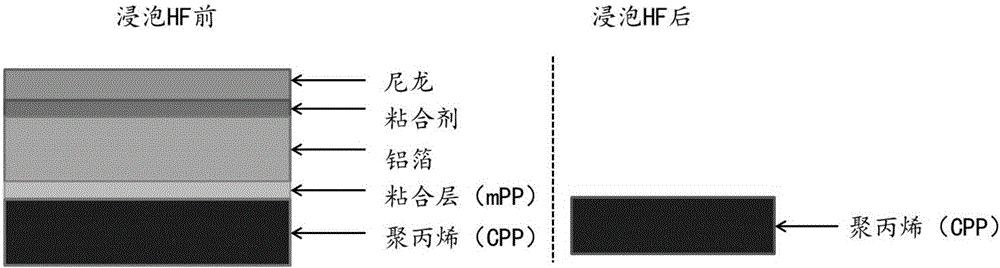

[0029] A method for detecting corrosion of aluminum-plastic film of a flexible package lithium-ion battery, comprising steps as follows:

[0030] (1) Calculate the shell resistance value of the negative pole piece and the aluminum layer of the aluminum-plastic film, and use the scale of the finished battery as shown in Table 1

[0031] Substituting inches into the formula for calculation: the resistivity between the negative pole piece and the aluminum layer of the aluminum-plastic film = 1*10 7 Ω cm;

[0032] Table 1 Dimensions of Negative Electrode Sheets for Experimental Batteries

[0033]

[0034] Shell resistance value=(shell resistance value=(resistivity between negative pole piece and aluminum-plastic film aluminum layer*negative pole piece width) / (negative pole piece thickness*negative pole piece length)={10 7 *8.35 / (0.0127*104.2)}*10- 6 =63MΩ

[0035] (2) Put the finished battery in the oven, vacuumize it for 20 minutes, the vacuum degree is -80KPa, and then pa...

experiment example

[0044] For lithium-ion batteries produced after the improved shelling process as described in Example 1, follow the steps (1) and (2) described in Example 1, and count the detection rate of defective products with low shell resistance values.

[0045] Table 2 Example 1, Comparative Examples 1-2 and Experimental Example Measure the shell resistance value defective product detection rate of the same number of batteries

[0046]

[0047] By comparing the data in Table 2, it can be seen that the method of vacuuming and nitrogen replacement and then high-temperature storage has an important impact on the detection rate of the present invention, and the method mentioned in the present invention has a higher detection rate of defective products. After the improvement of the production process is guided by analyzing the damaged position of the CPP layer, the ratio of defective products is greatly reduced, which shows that the method is highly effective and is conducive to the improv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com