Machining and detecting system of three-division type large-dip-angle inclined box body and machining and detecting method thereof

A processing method and detection system technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of inability to guarantee size and assembly accuracy, complex processing technology procedures, large hole system offset error, etc. Improve box size and assembly accuracy, save time and manpower, and reduce stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

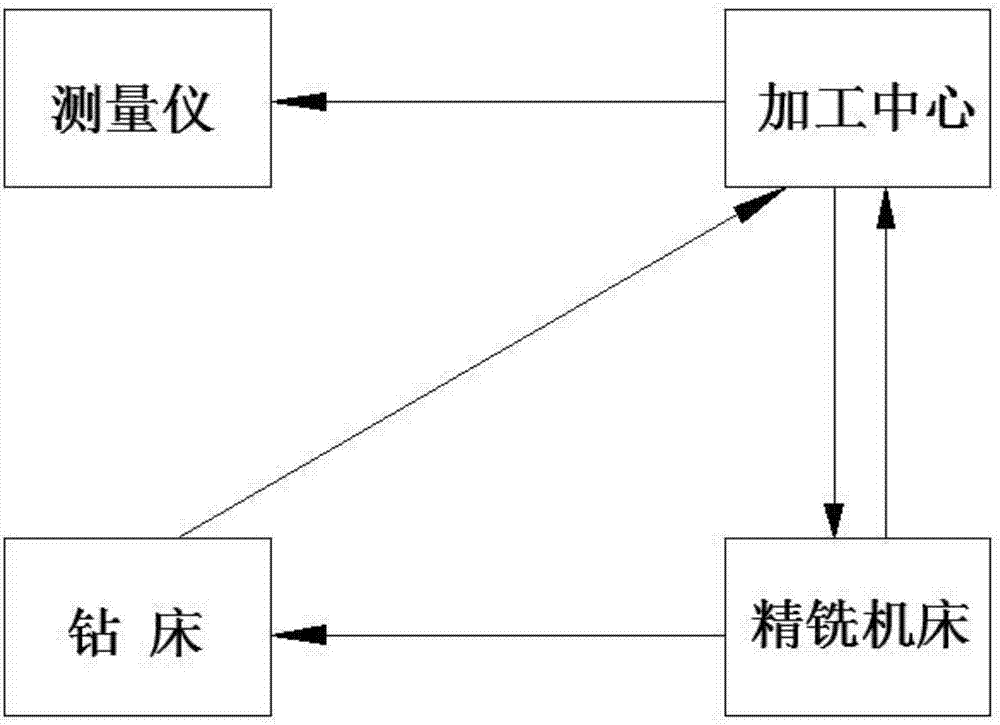

[0058] according to figure 1 The processing and detection system of a three-split type large-inclination tilted box shown includes a horizontal machining center, a gantry milling machine, a radial drilling machine, and a three-coordinate measuring instrument, and the position forms a square. The horizontal machining center There is a conveyor belt between the gantry milling machine and the radial drilling machine, and a conveyor belt between the horizontal machining center and the three-coordinate measuring instrument.

[0059] The conveyor belt between the horizontal machining center and the gantry milling machine described in this embodiment is a two-way conveyor belt. The transmission direction of the conveyor belt between the gantry milling machine and the radial drilling machine is set from the gantry milling machine to the radial drilling machine. The transmission direction of the conveyor belt between the drilling machines is set to be transmitted from the radial drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com