Method for testing crack resistance of welding wire

An experimental method and anti-cracking technology, applied in welding equipment, arc welding equipment, welding/welding/cutting items, etc., can solve problems such as unqualified welds, poor weldability, hot cracks in welds, etc., to avoid welding seams Unqualified, the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

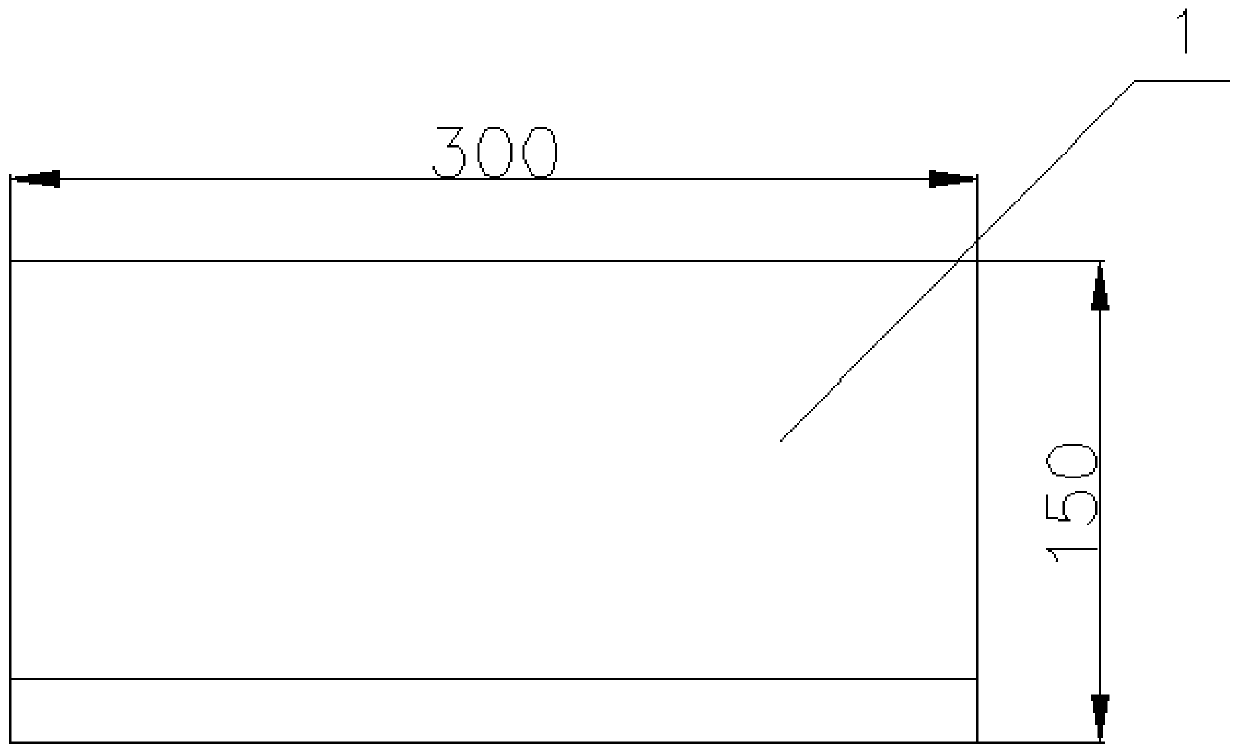

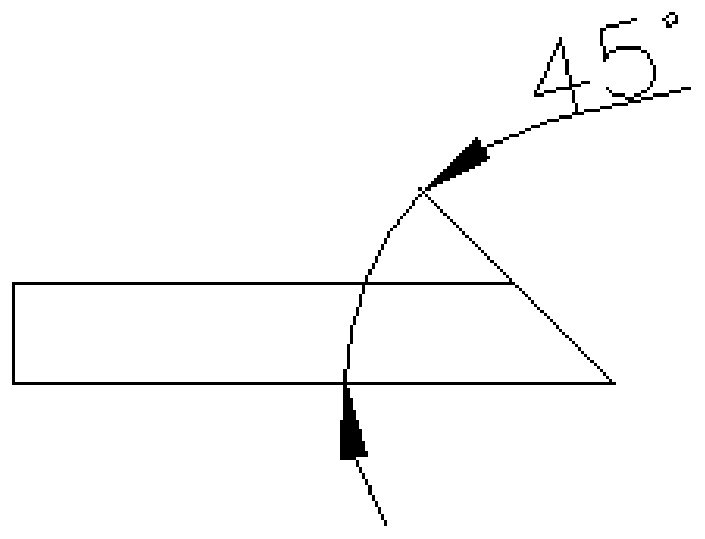

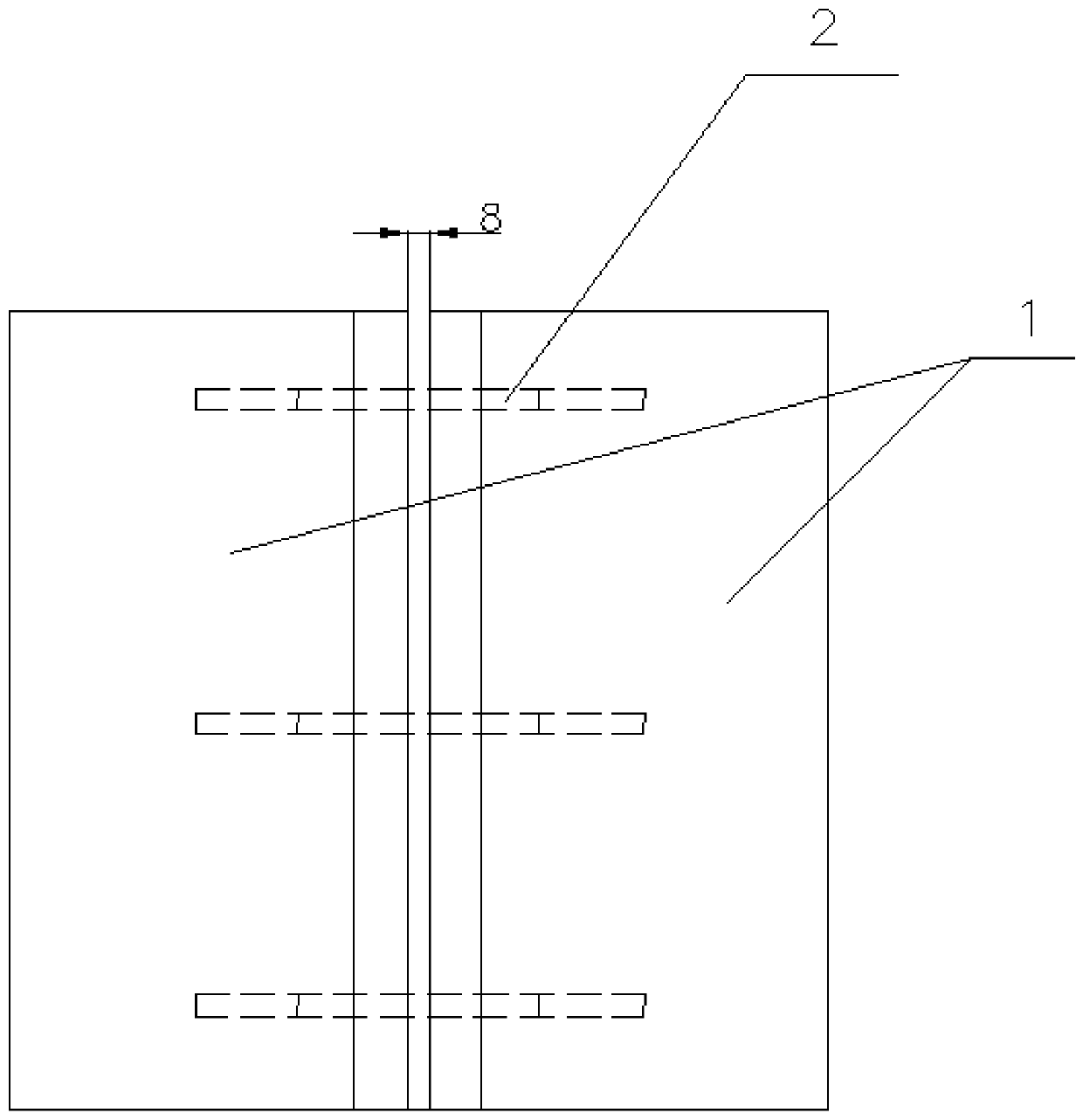

[0039] To study the crack resistance of a certain type of welding material, prepare two E36 steel plates with a size of 300mm*150mm, and open a 45-degree bevel on the long side of the plate. The two boards are fixed together by 3 horse boards, the gap between the boards is 8mm, the horse board and the steel plate are welded together, and the welding angle is 8mm. The reverse side of the board is pasted with a ceramic liner. CO2 gas shielded welding is used for bottom welding of the ceramic liner butt weld in the horizontal position, and the thickness of the weld is 3mm. Place it for more than 24 hours, carry out coloring flaw detection, and check whether the weld seam is cracked.

[0040] By adopting the welding wire crack resistance test method provided by the invention, the present invention provides a simple and quick method for the welding wire type selection and welding wire crack resistance test of the marine low-alloy high-strength steel plate before welding, avoiding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com