Method for repairing mill housing

A technology of a rolling mill arch and a repair method, applied in the field of rolling mill arch, can solve the problems of wear failure of the arch face, short service life of the arch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

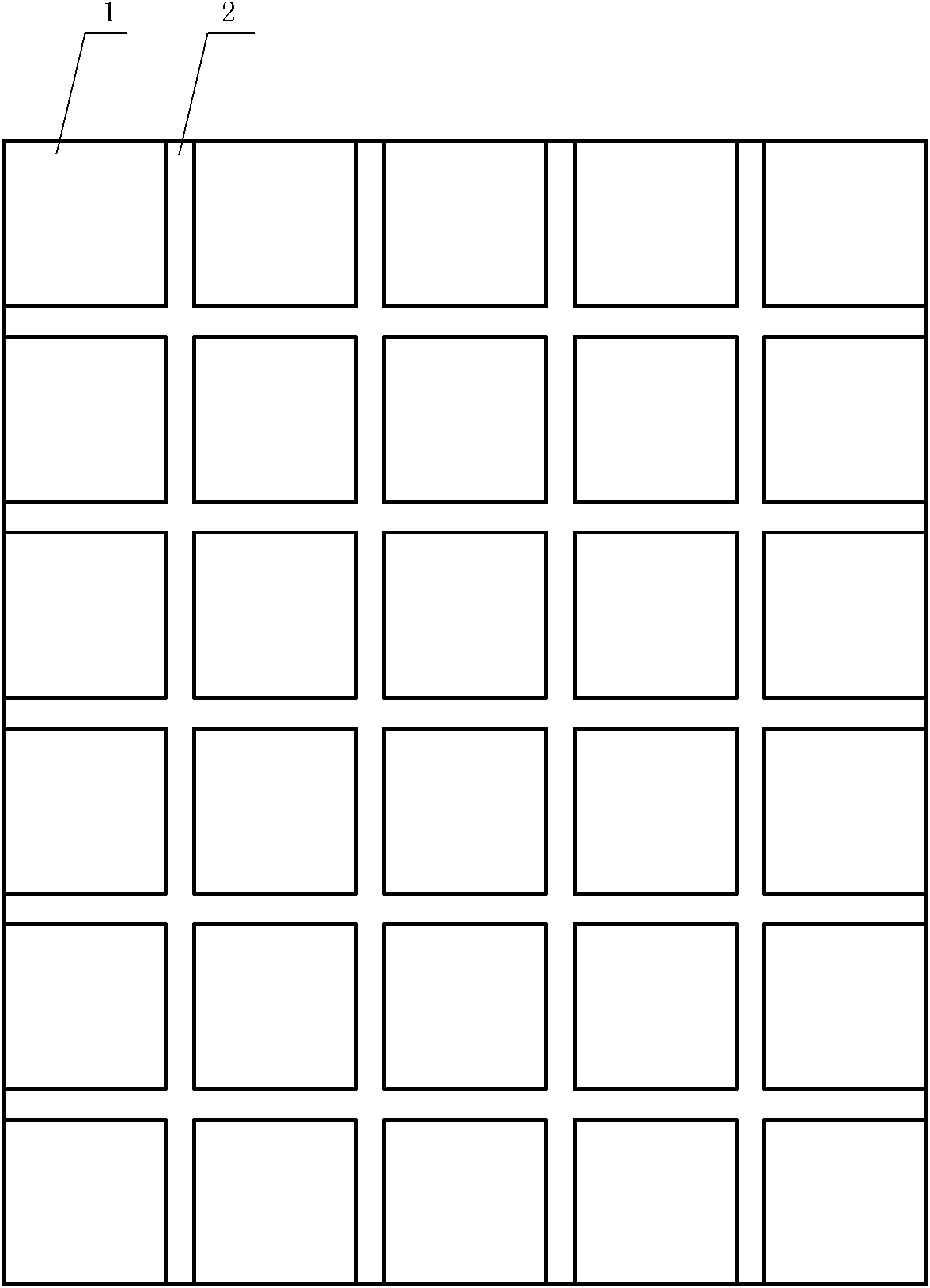

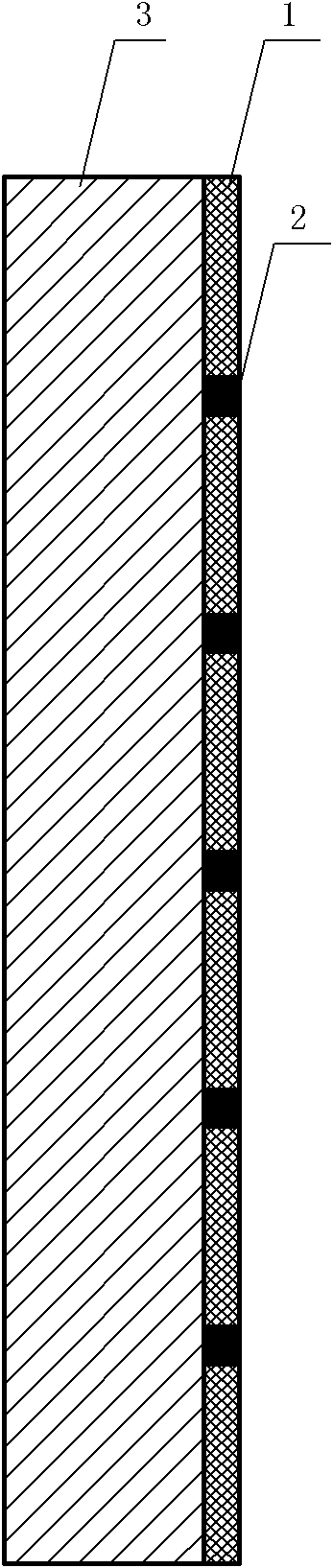

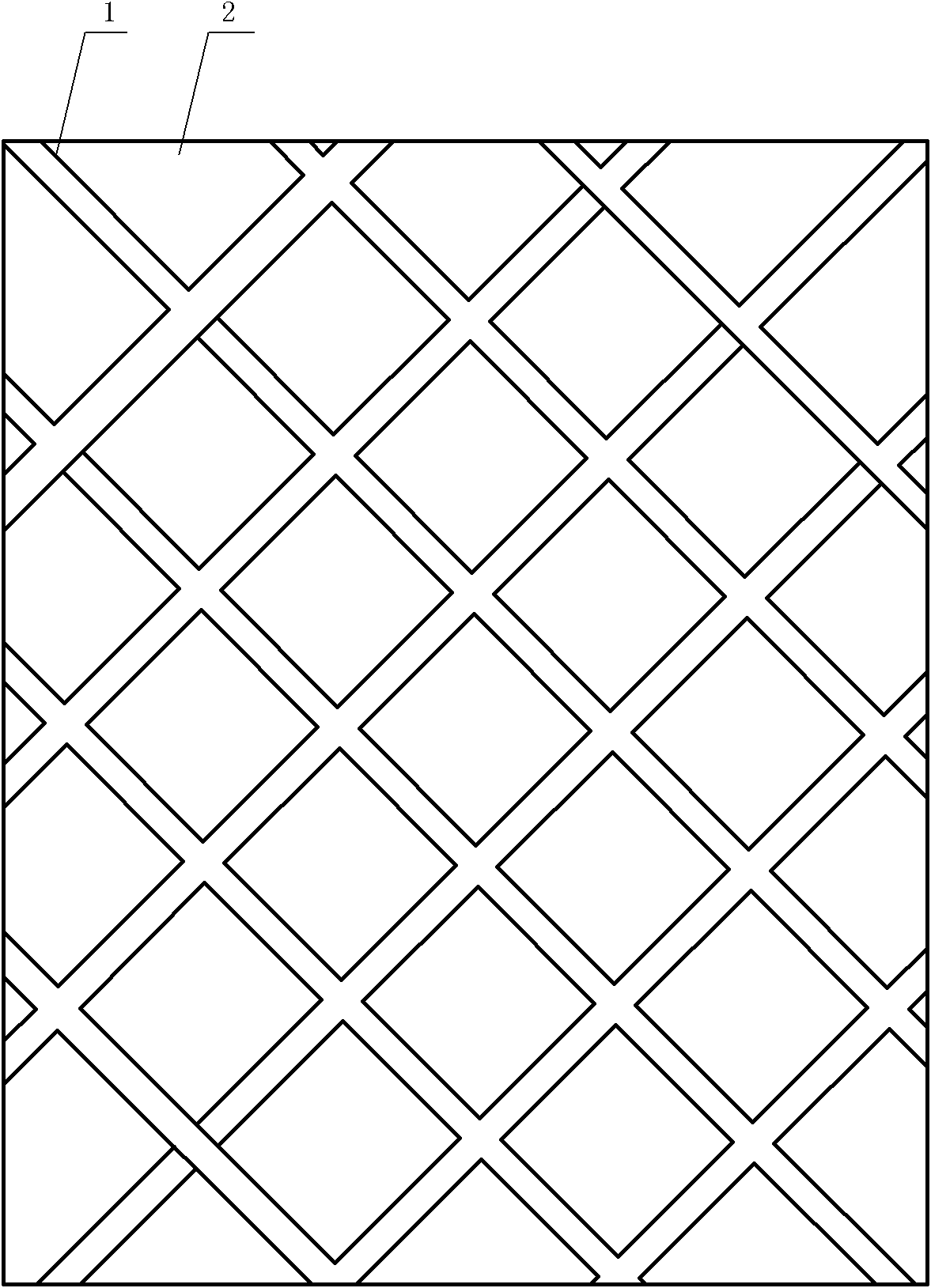

[0031] Such as figure 1 and figure 2 Shown, the repair method of rolling mill archway of the present invention comprises the following steps:

[0032] (a). Clean and clean the surface of the rolling mill archway to be repaired, and remove the oil and impurities on the surface of the rolling mill archway to be repaired;

[0033] (b) Carry out coloring flaw detection on the surface of the entire rolling mill archway to be repaired, the coloring flaw detection is to use ultrasonic, magnetic, X-ray or gamma ray flaw detection, measure the size of the archway, and determine the amount of wear;

[0034] (c) remove the fatigue layer on the surface of the rolling mill archway;

[0035] (d) On the width direction and the length direction of the surface of the rolling mill archway to be repaired, at least a block layer 1 with the same material and hardness as the material and hardness of the surface base material 3 of the rolling mill archway to be repaired, the block layer 1 The sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com