Manufacturing technique of pure nickel tube

A production process, pure nickel technology, applied in the field of pipe manufacturing, can solve the problems of affecting the service life of production equipment, poor pipe forming quality, difficult processing, etc., and achieve the effect of easy processing, improved strength and elongation performance, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

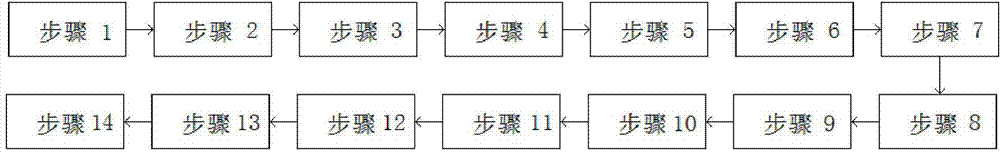

[0030] refer to figure 1 , a production process of pure nickel tubes, including the following production steps: 1) nickel plate baking; 2) vacuum refining; 3) electroslag remelting; 4) forging processing; 5) ultrasonic flaw detection; 6) processing round rods; 7) Coloring flaw detection; 8) Piercing to tube billet; 9) Cutting and grinding of tube billet; 10) Cold rolling and annealing; 11) Surface treatment; 12) Finish rolling to finished product; 13) Annealing; 14) Forming.

[0031] in,

[0032] The baking temperature in step 1) is 800°C-820°C, and the baking duration is 6 hours.

[0033] The vacuum degree in step 2) is 0Pa-0.5Pa, the smelting time lasts 2.5 hours-3 hours, and the smelting temperature is controlled at 1510°C-1540°C.

[0034] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com