Thrust pad repairing method based on laser cladding process

A laser cladding and repair method technology, applied in the field of bearings, can solve the problems of poor flatness of steel billet and babbitt alloy layer, difficulty in control, large heat input, etc., and achieve good forming accuracy, good performance and low heat input small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

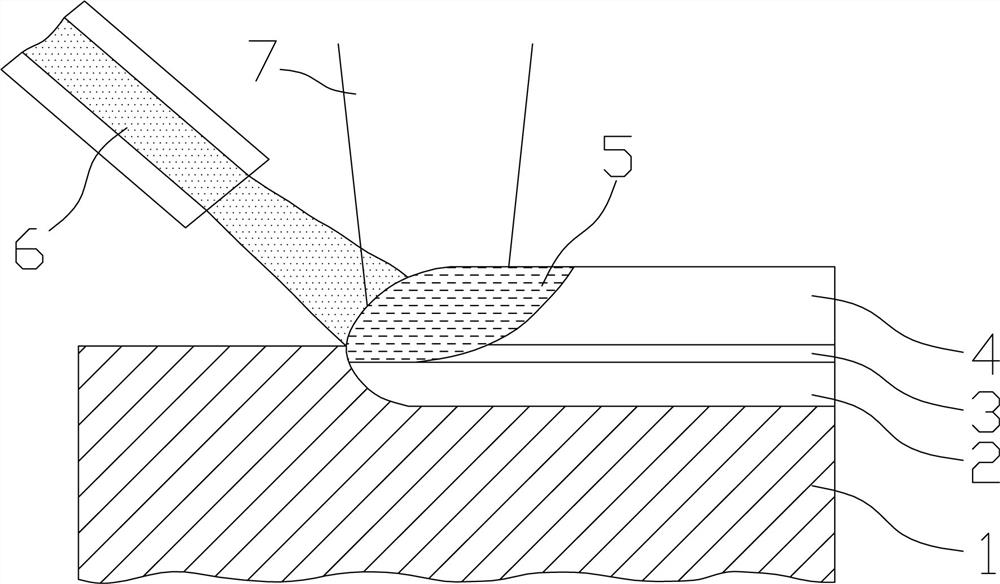

[0045] like figure 1 , the repair method of the thrust tile specifically includes the following steps:

[0046] 1) Preprocess the thrust tile to be repaired to remove the original babbitt alloy layer on the thrust tile;

[0047] 2) Clean the pretreated steel billet 1 with an organic solvent to remove oil contamination on the surface of the steel billet 1;

[0048] 3) Place the SnSb8-8 babbitt powder in an oven at 60°C for 2.5h for drying;

[0049] 4) Using the dried babbitt powder as the raw material, the new babbitt layer is additively manufactured on the billet 1 by means of laser cladding;

[0050] 5) Semi-finishing milling of the surface of the new babbitt alloy layer, the milling amount of semi-finishing milling is controlled to be leveled on the surface of the babbitt alloy layer to ensure that there is still enough machining allowance for the babbitt alloy layer of the thrust pad

[0051] 6) Use ultrasonic flaw detection technology to perform ultrasonic flaw detectio...

Embodiment 2

[0062] On the basis of Example 1, the following steps are used to carry out the laser cladding operation described in step 4):

[0063] 1) A laser 7 is generated by a laser transmitter as a heat source, and the surface of the billet 1 is irradiated to form a molten pool 5;

[0064] 2) The powder-containing gas stream 6 is sent into the molten pool 5 through the gas powder feeding equipment for rapid melting;

[0065] 3) Remove the laser emitter and partially solidify the molten powder to form a solidified layer 4.

[0066] In a preferred solution, a bonding layer 3 is formed between the solidified layer 4 and the steel billet 1 .

[0067] In a preferred solution, the surface of the steel billet 1 is irradiated by the laser 7 to form a heat-affected zone 2 , and the output direction of the powder-containing airflow 6 faces the heat-affected zone 2 .

[0068] In this example, the parameters of the laser cladding operation are as follows:

[0069] The rectangular laser spot is...

Embodiment 3

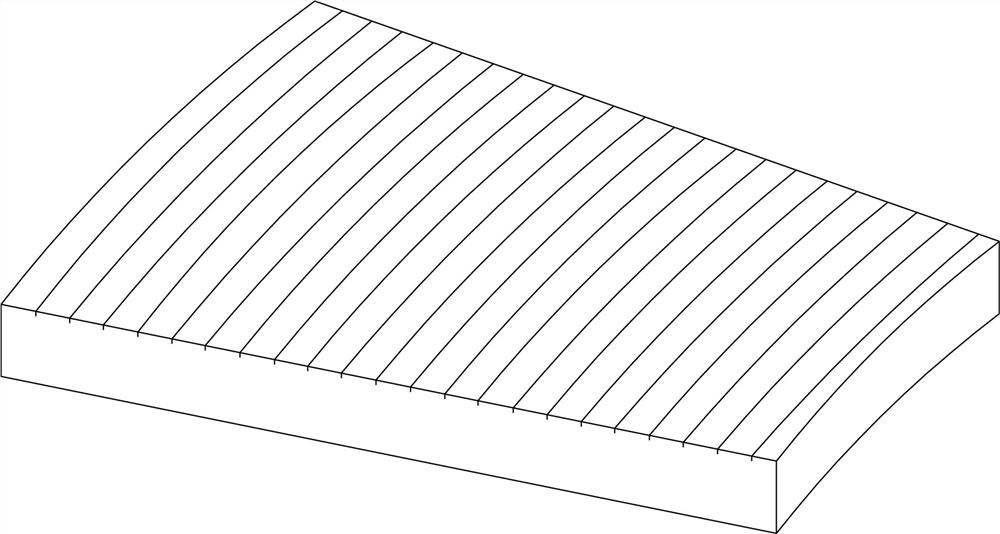

[0071] On the basis of Example 2, by controlling the movement of the robotic arm, the laser generator and the powder feeding mechanism are driven to translate on the surface of the billet 1, and the laser cladding additive manufacturing of the babbitt alloy is completed.

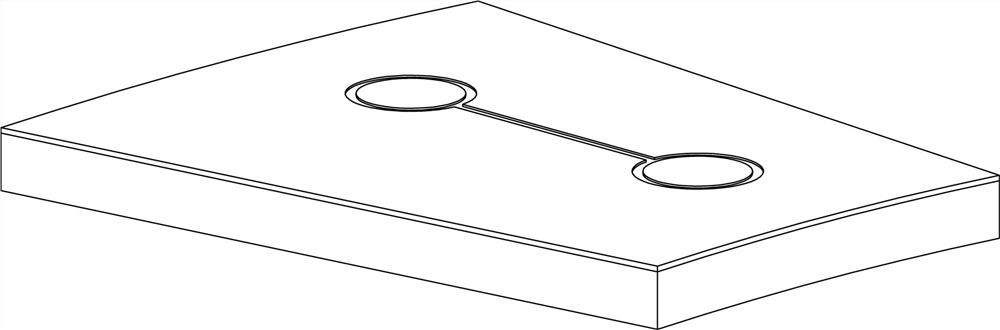

[0072] In this example, the laser cladding is completed along the arc edge, back and forth in both directions, a total of 3 layers are clad, to ensure that the thickness of the babbitt layer produced by the laser cladding additive manufacturing is about 3.3mm, and the overall thickness of the thrust pad is about 55.8mm (such as image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com