Patents

Literature

38 results about "Specific gravity measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Specific gravity. Specific Gravity (SG) is a measure of the relative density of one material compared to another. For brewing, the reference material is water, so the specific gravity of wort or beer is simply the density of the liquid divided by the density of water.

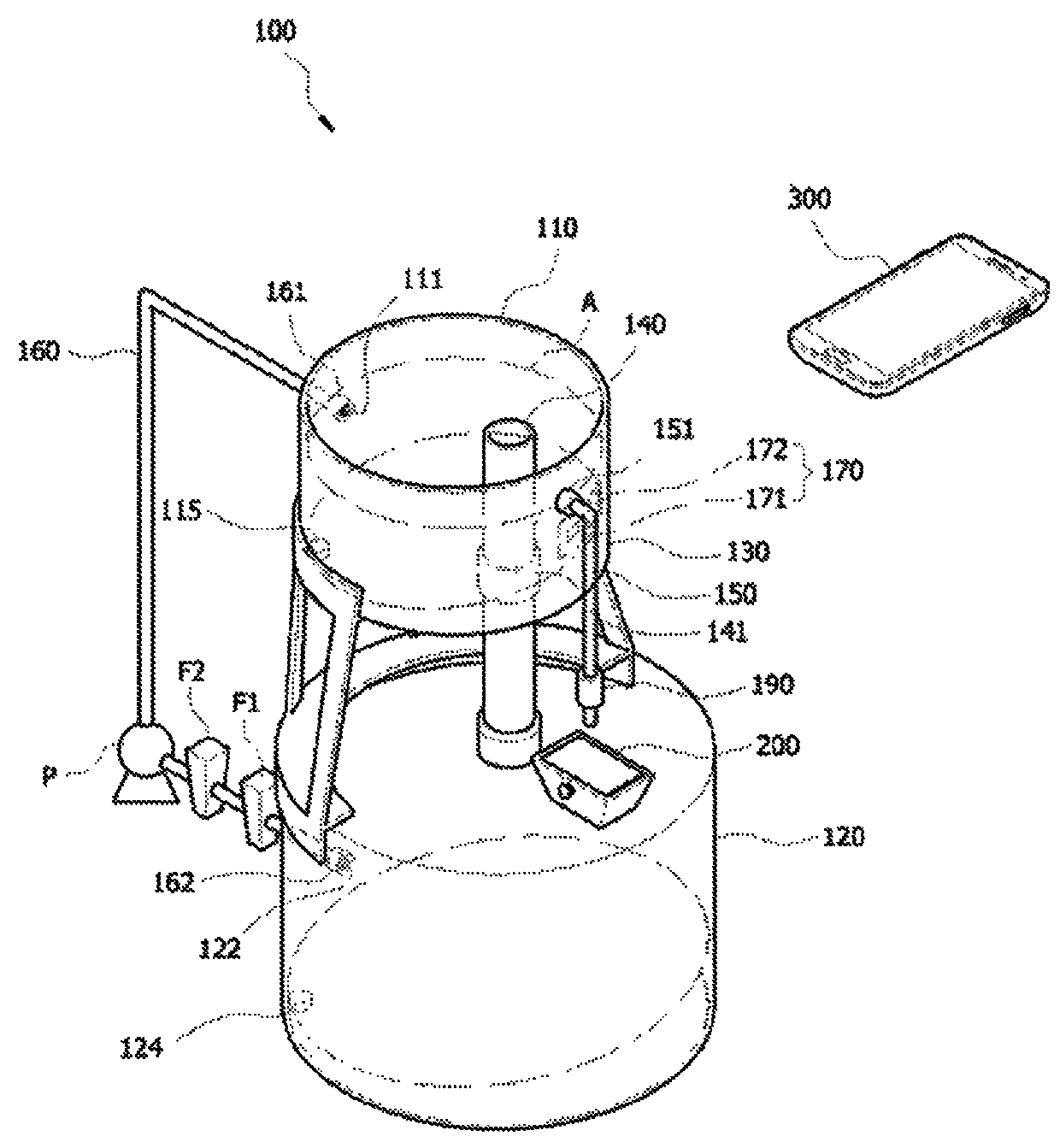

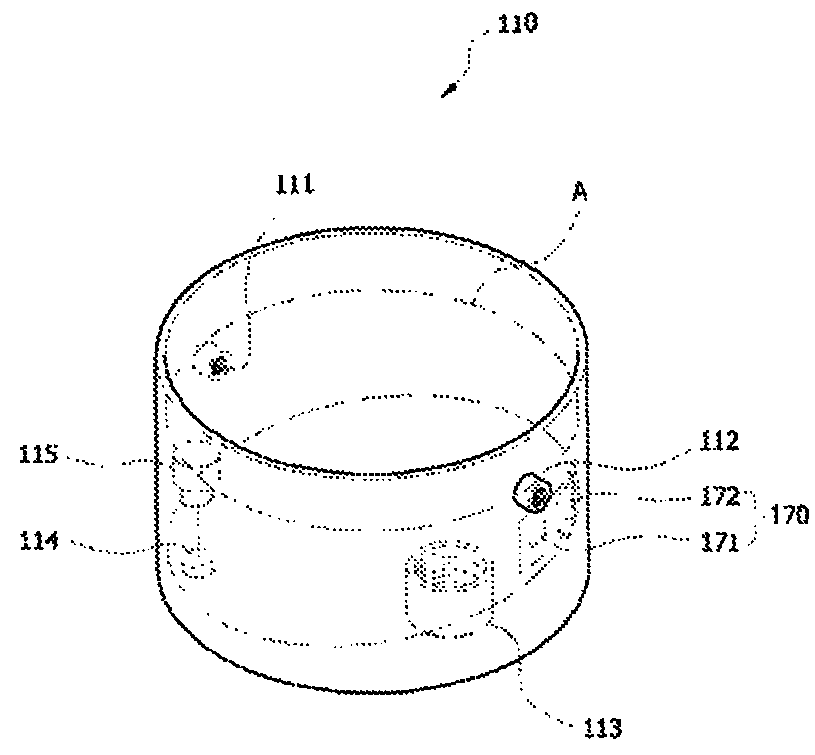

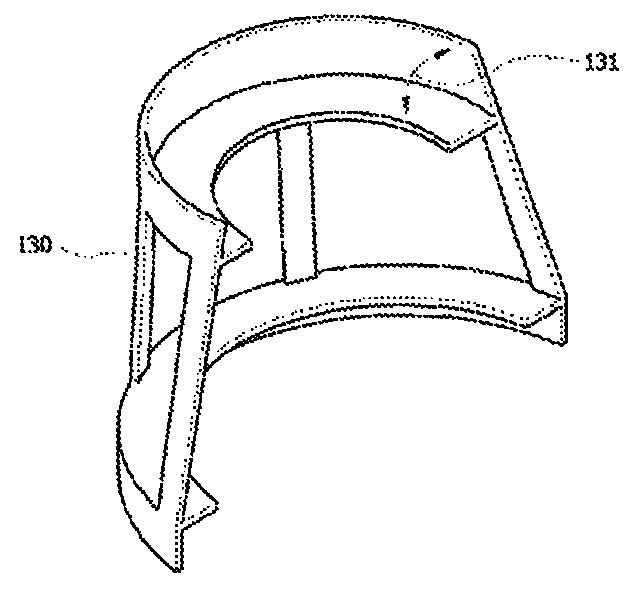

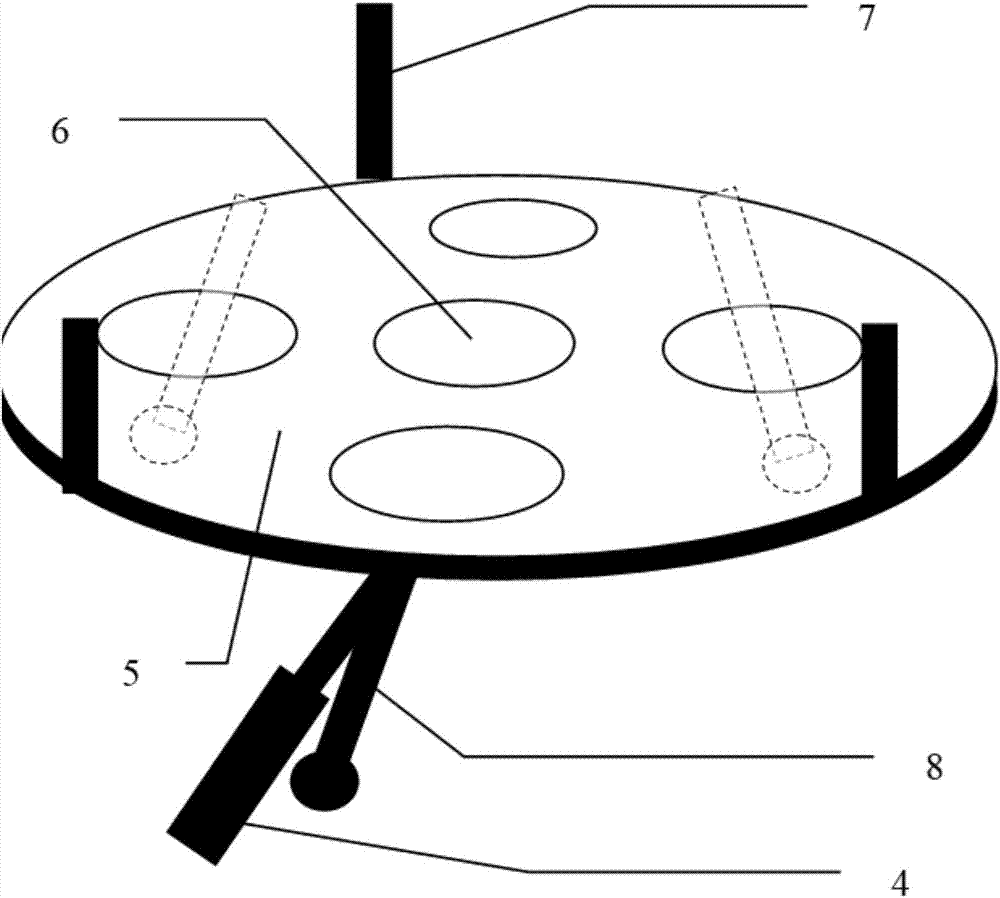

Simplified valuable mineral sorting apparatus and method of sorting valuable minerals using the same

ActiveUS9227197B2Effectively and economically sortingEasy to installGas current separationFlotationEngineeringLevel line

Disclosed herein is a simplified valuable mineral sorting apparatus including, a first storage tank which accommodates a mixture of water and heavy powder and includes a specific gravity measurement module; a second storage tank accommodating a portion of the mixture exceeding a capacity level line of the first storage tank; a first discharge tube which is connected to the first storage tank and the second storage tank to introduce the excess portion of the mixture into the second storage tank, and which is positioned at the capacity level line of the first storage tank; a second discharge tube which is connected to the first storage tank to discharge the mixture in the first storage tank and which includes a flow rate control module; a specific gravity sorting device which includes a sorting container for receiving the mixture discharged from the second discharge tube and which changes a slope of the sorting container to sort minerals from the mixture in the sorting container; and a control unit for controlling the flow rate control module and the specific gravity sorting device.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

Specific weight measurer

A specific gravity measuring device, which can reliably and quickly obtain the specific gravity of various solid substances through one measurement operation very simply. The specific gravity measuring device includes: a liquid tank; a first measuring part supporting the liquid tank; a measured object receiver, which is set in the liquid tank and immersed in the liquid; a second measuring part , the second part of the measuring part supports the measured object receiver in a non-contact manner relative to the liquid tank; an arithmetic operation unit is used to calculate the specific gravity value according to the measured values of the first and second measuring parts; and A display device is used to display the specific gravity value obtained by the arithmetic operation unit. The first measuring part measures the increase in weight as the measured object is immersed in the liquid as a buoyant force, and the second measuring part measures the weight of the measured object in water. The arithmetic operation unit finds specific gravity from the measured buoyancy and weight in water to display them on the display device.

Owner:MIRAGE TRADING

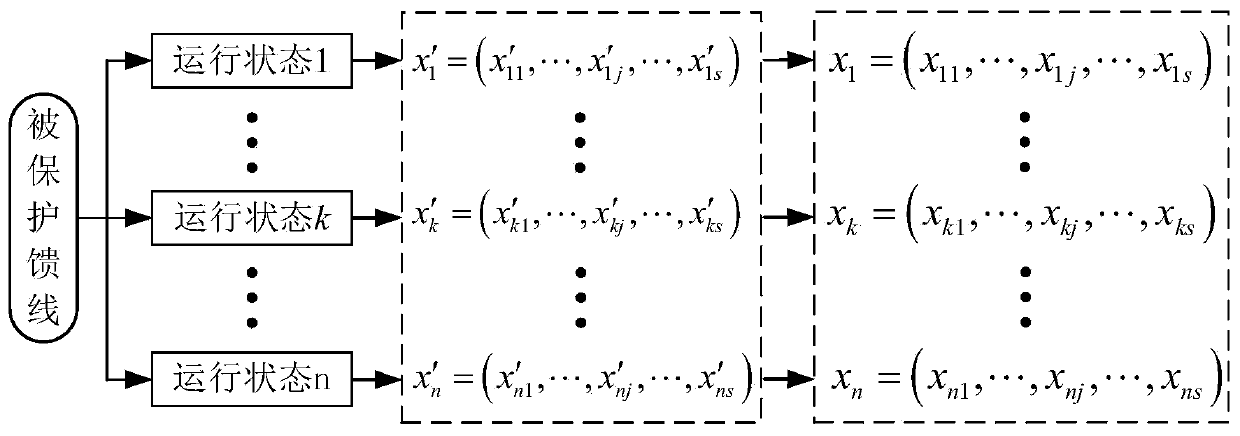

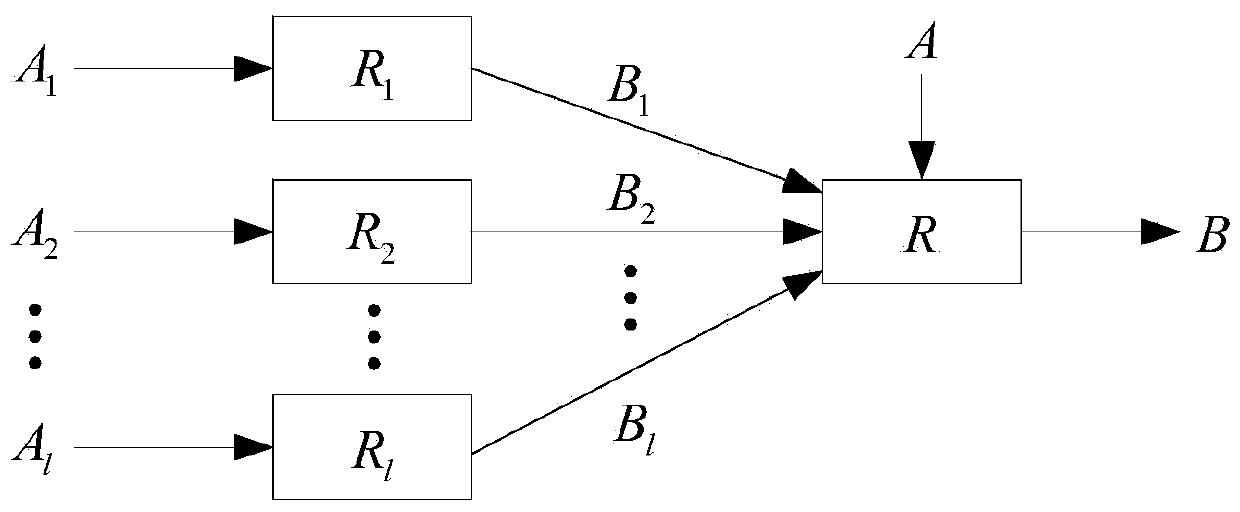

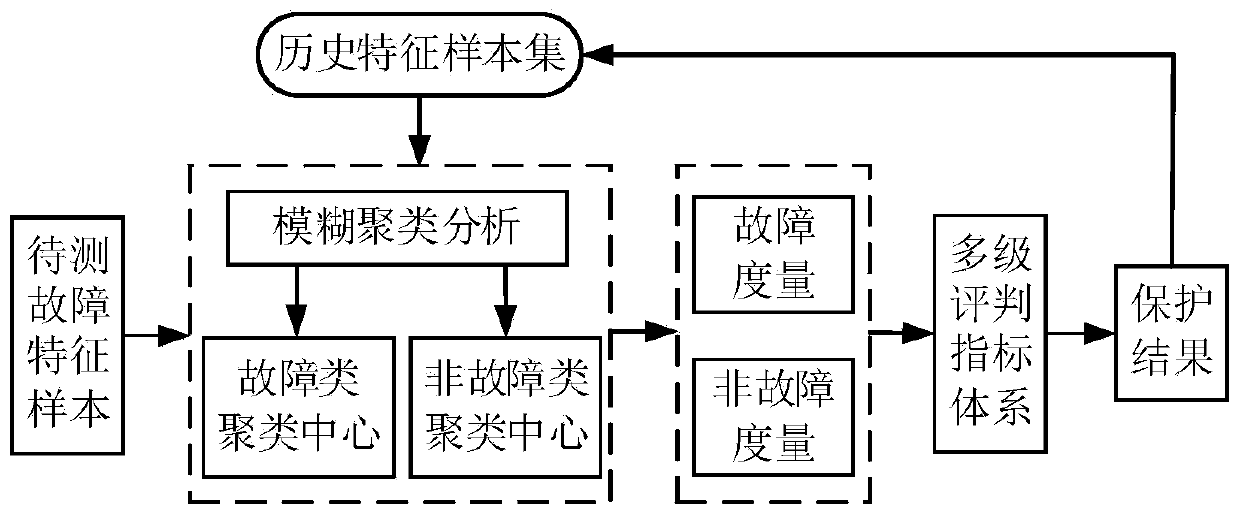

Power distribution network grounding fault protection method based on fuzzy measurement fusion criteria

ActiveCN110609200ABroaden the fault judgment rangeAvoid misjudgmentElectrical testingCharacter and pattern recognitionCluster algorithmWeight coefficient

The invention discloses a power distribution network grounding fault protection method based on fuzzy measurement fusion criteria. The method comprises the following steps: acquiring a plurality of fault characteristic quantities of a protected feeder line to form a historical sample, and acquiring a sample to be tested according to the same method; clustering and dividing n historical samples into a fault class and a non-fault class by adopting a clustering algorithm; respectively taking membership degree, distance specific gravity measurement and angle specific gravity measurement as similarity measurement criteria, calculating a fault measurement value and a non-fault measurement value of the sample to be tested, and constructing a fuzzy measurement fusion criterion matrix of the sampleto be tested; and taking the fuzzy measurement fusion criterion matrix as a judgment set of a judgment index system, constructing a factor set of the judgment index system by using all similarity metric criteria, presetting the weight coefficient of each element in the factor set, and judging the fuzzy measurement fusion criterion matrix to obtain whether the distribution network to be tested isin fault or not. According to the method, the fault judgment interval is broadened, erroneous judgment caused by factors such as power system oscillation is effectively avoided, and the robustness isimproved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

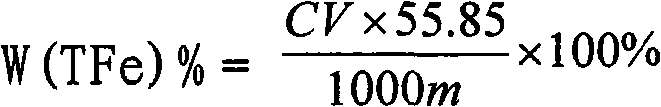

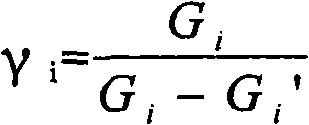

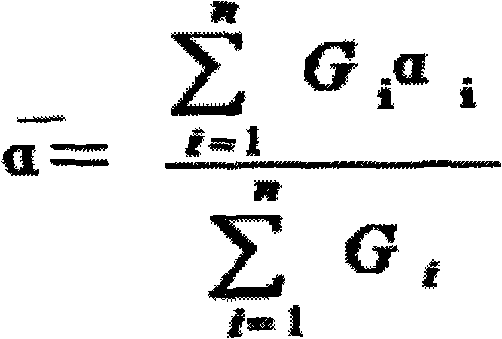

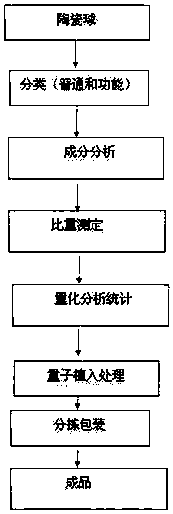

Method for measuring ore grade by hydrometer method

InactiveCN101929925AReduce consumptionEasy to operateMaterial analysis by measuring buoyant forcesWithdrawing sample devicesHydrometerEnergy conservation

The invention relates to a method for measuring ore grade, in particular to a method for measuring ore grade by a hydrometer method. The method comprises the following steps: sampling and specific gravity measurement: putting each sample ore into a cage, weighing weight G of each sample ore in the air and weight G' of each sample ore in the water with a weighing machine one by one, inputting the weight data into a spreadsheet document set by a computer, working out specific gravity gamma of each sample ore, checking a specific gravity-ore grade curve by utilizing the worked out ore specific gravity so as to obtain the grade of the sample ore, working out grade mean value of the ore sample by the weighting method, comparing the average ore grade with the planned ore grade, finally making judgments on ore grade to indicate whether the sample ore is qualified product or not. The method of the invention has simple operation, environment friendliness, energy conservation, less consumption of materials and devices, safe, fast and accurate measurement of ore grade.

Owner:ANSTEEL GRP MINING CO LTD

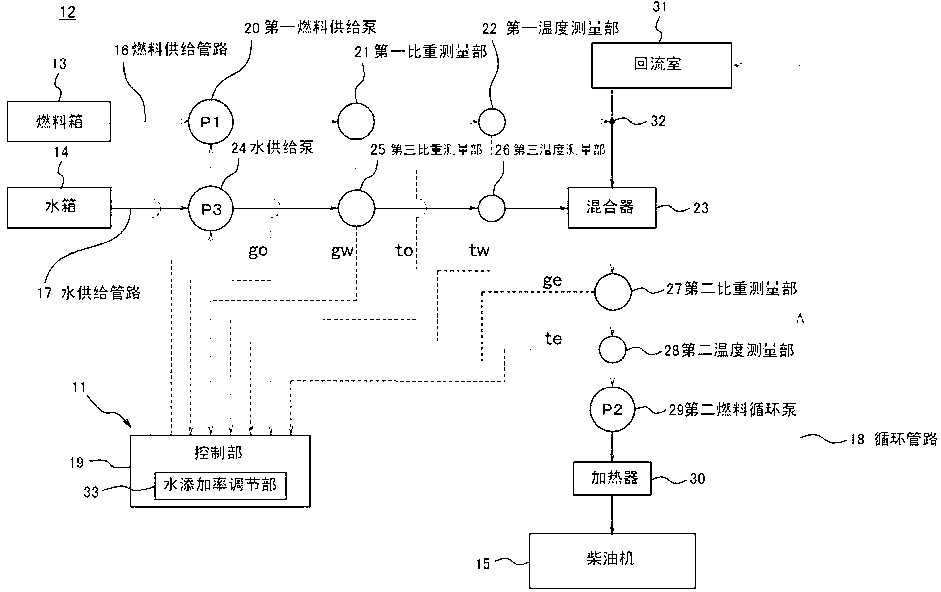

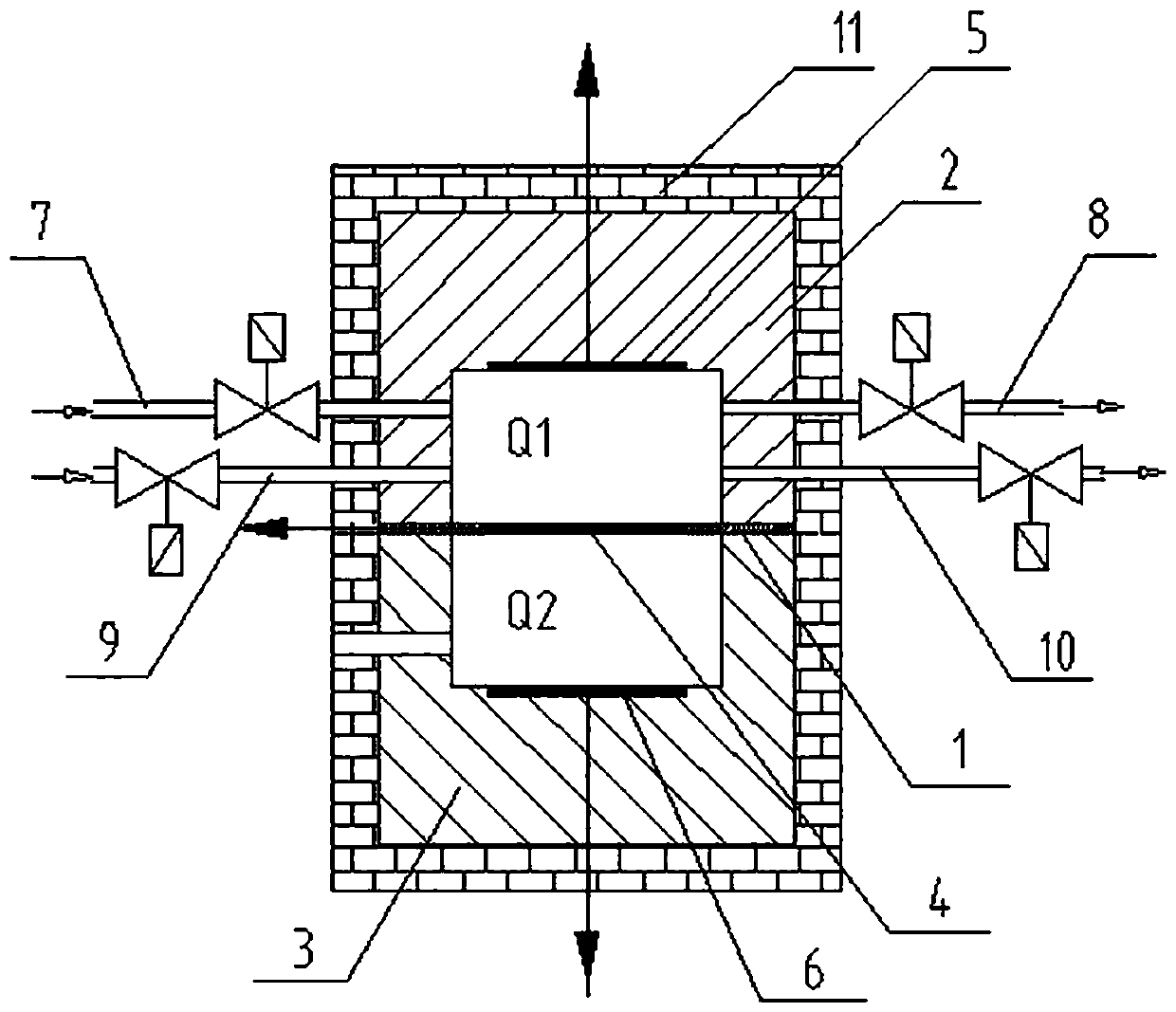

Specific gravity monitoring control device and fuel supply apparatus provided with same

InactiveCN103003634AProper and stable combustion efficiency operationProper and stable operationLiquid fuel feeder/distributionElectrical controlEmulsionFuel oil

Provided is a specific gravity monitoring control device capable of measuring and monitoring the specific gravity of fuel oil actually used when water emulsion fuel is produced by adding water to the fuel oil, and capable of producing the water emulsion fuel with an accurate target additional water weight ratio by adjusting the amount of the water to be added to the fuel oil using the specific gravity of the fuel oil obtained by the measurement. The specific gravity monitoring control device has a configuration in which when fuel oil is emulsified by adding water to the fuel oil, water emulsion fuel with a desired accurate target additional water weight ratio (T) can be produced by measuring the specific gravity of the fuel oil by a first specific gravity measuring unit (21), making a calculation using a first measured specific gravity (go) obtained by the measurement by the first specific gravity measuring unit (21), and adjusting the amount of the water to be added to the fuel oil on the basis of the result of the calculation.

Owner:KAWASAKI HEAVY IND LTD

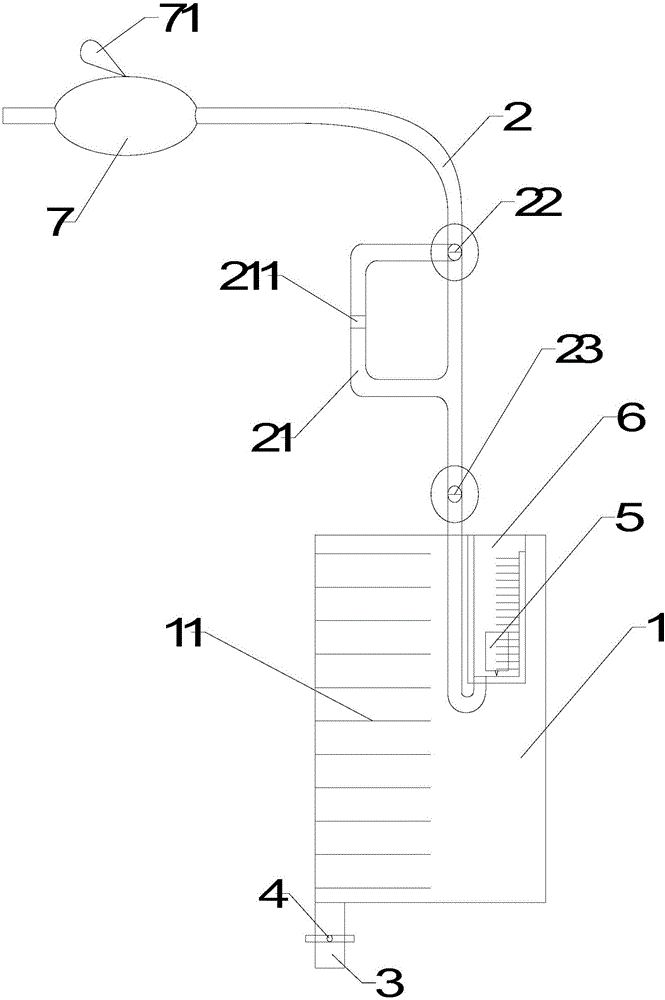

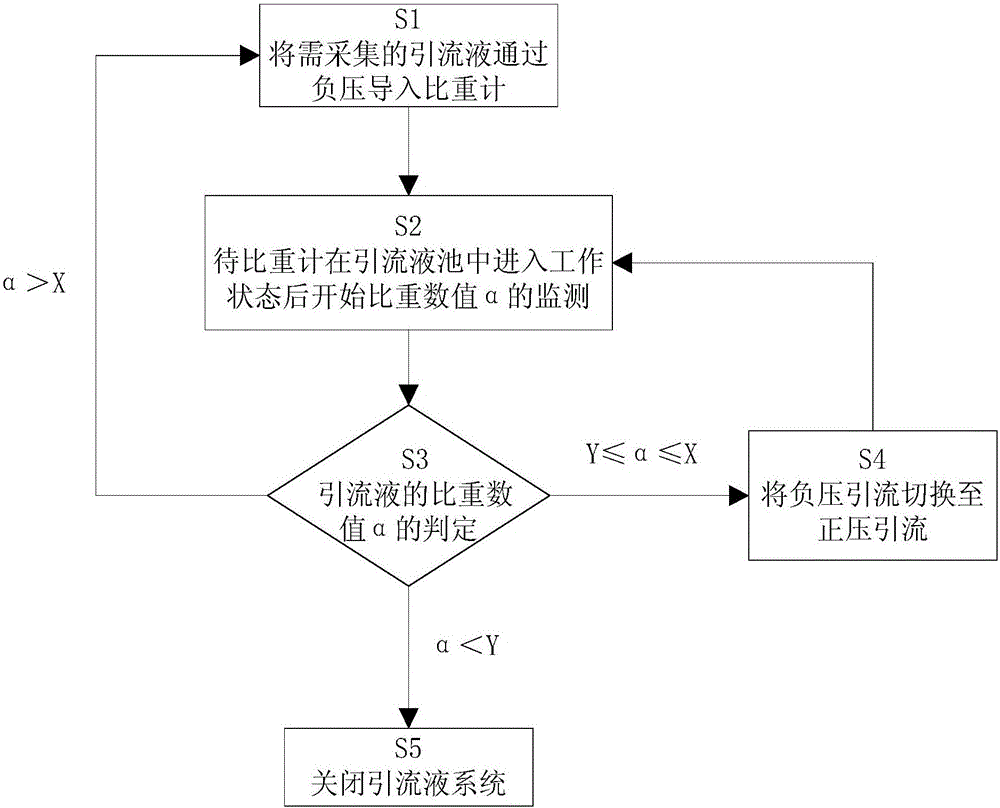

Drainage apparatus for leakage of cerebrospinal fluid after spinal operation and positive-negative-pressure drainage switching determining method

PendingCN106730055AAvoid the problem of inaccurate sedimentation measurementFacilitate surgeryMedical devicesIntravenous devicesEngineeringControl valves

The invention relates to a drainage apparatus for leakage of cerebrospinal fluid after spinal operation and a positive-negative-pressure drainage switching determining method. The drainage apparatus comprises a liquid storage bag and a drainage pipe, wherein one end of the drainage pipe is inserted into an inlet of the liquid storage bag, the other end is inserted into a cerebrospinal fluid accumulated position, the bottom of the liquid storage bag is connected with a liquid discharging pipe, the liquid discharging pipe is provided with a discharging control valve, and the drainage apparatus is characterized by also comprising a gravimeter and a specific gravity box for accommodating the accumulated fluid for measuring the specific gravity, the gravimeter is arranged inside the specific gravity box, the drainage pipe enters the liquid storage bag and is communicated with the inlet of the specific gravity box, and the top of the specific gravity box is provided with an opening and is communicated with an inner cavity of the liquid storage bag; and the drainage pipe is serially connected with a negative-pressure drainage ball. The drainage apparatus has the beneficial effects that while the drainage is realized, the cerebrospinal fluid can be primarily tested. By matching the switching determining method, the situation of the cerebrospinal fluid can be dynamically observed, the operation of nursing personnel is facilitated, and collection and detection procedures are simplified.

Owner:SECOND AFFILIATED HOSPITAL SECOND MILITARY MEDICAL UNIV

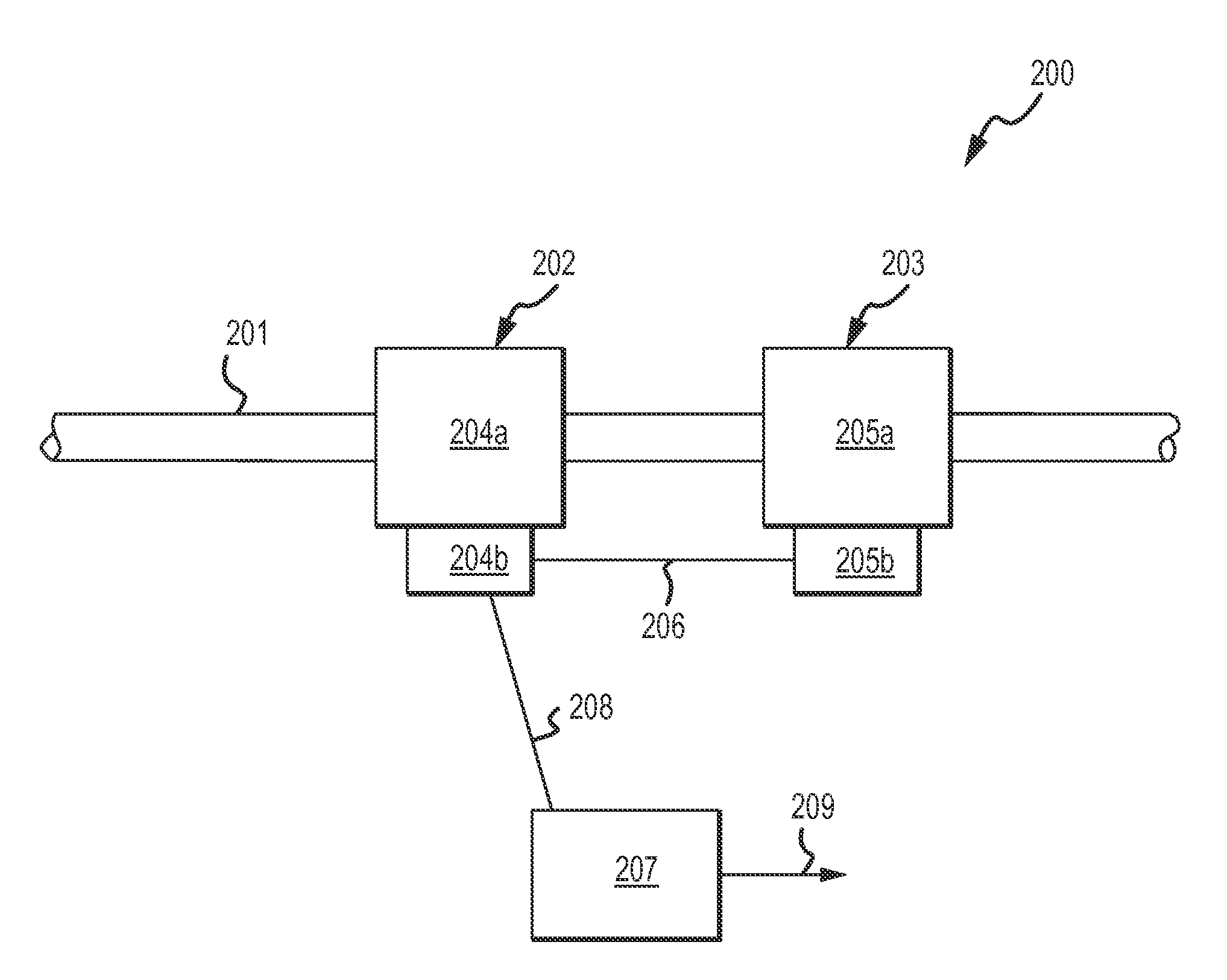

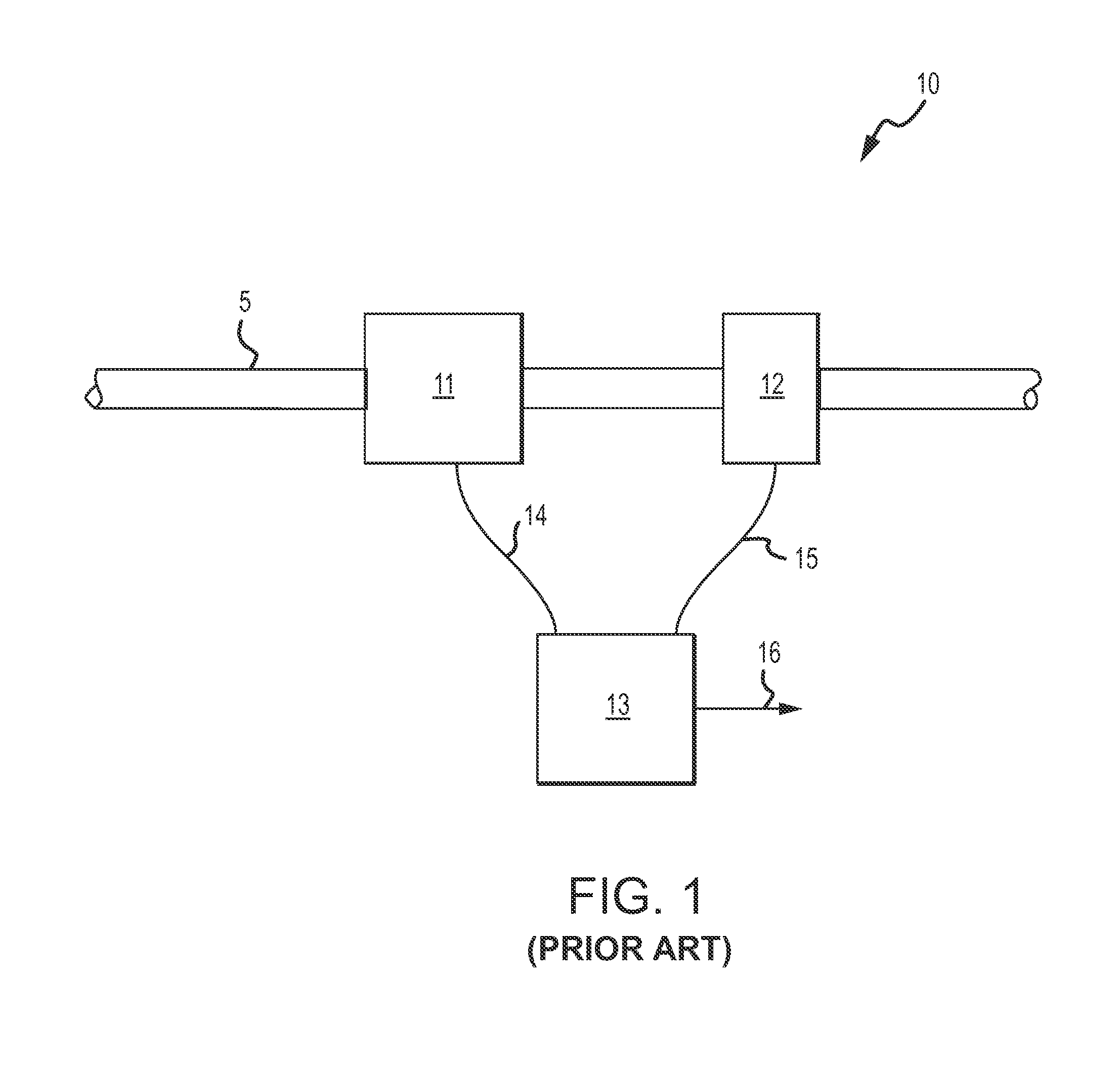

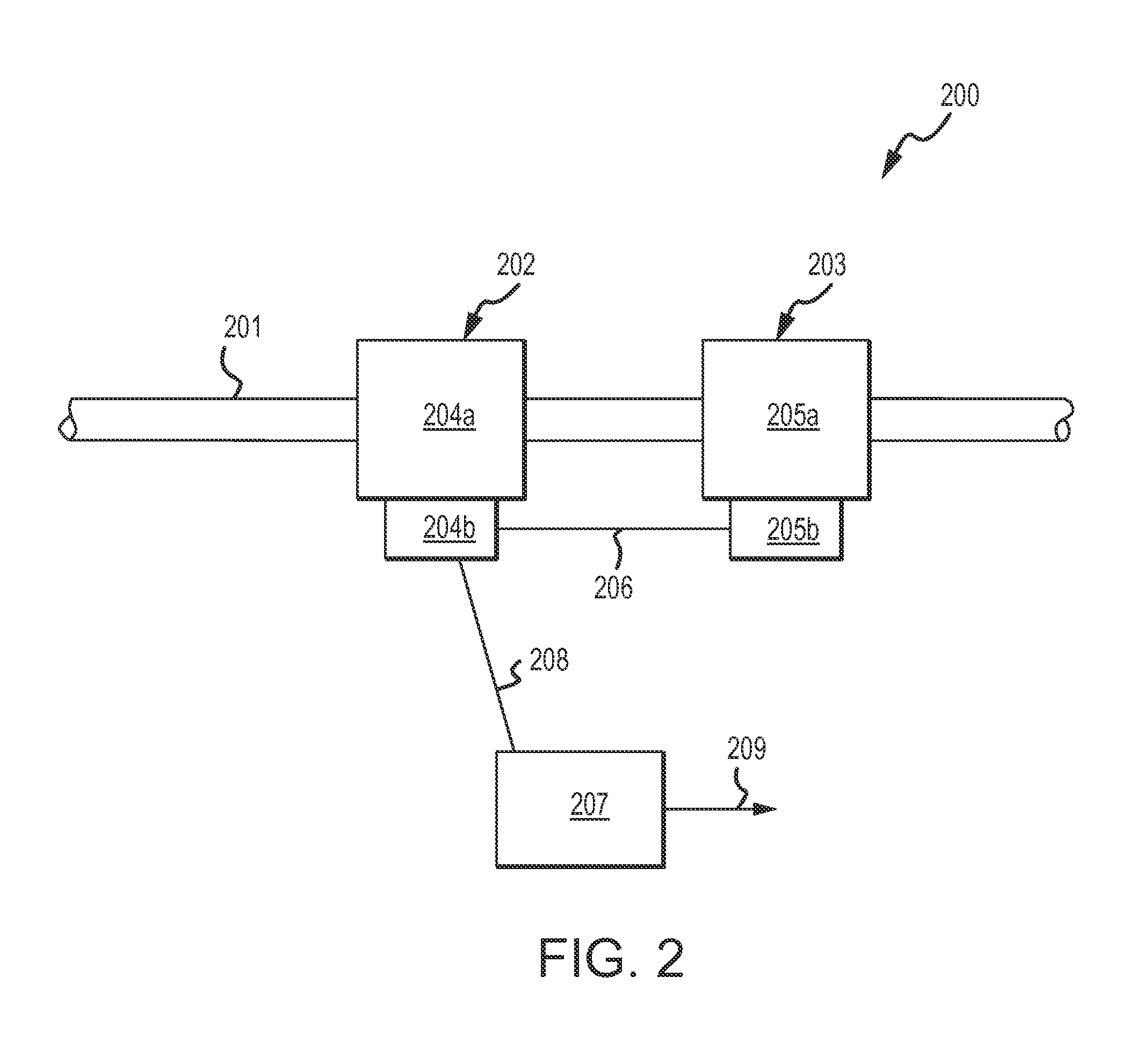

Volume flow sensor system comprising a mass flowmeter and a density meter

ActiveUS20160084691A1Volume variation compensation/correction apparatusDirect mass flowmetersElectricityGeneration process

A flow rate sensor system (200) is provided. The flow rate sensor system (200) includes a density or specific gravity meter (202) including a sensor assembly (204a) and a density or specific gravity meter electronics (204b) configured to generate a density or specific gravity measurement of a process fluid. The flow rate sensor system (200) further includes a mass flow meter (203) including a sensor assembly (205a) and a mass flow meter electronics (205b) configured to generate a mass flow rate of the process fluid and in electrical communication with the density or specific gravity meter electronics (204b). A remote processing system (207) is provided that is in electrical communication with only one of the density or specific gravity meter electronics (204b) or the mass flow meter electronics (205b). The remote processing system (207) is configured to receive a volume or energy flow measurement of the process fluid generated by the density or specific gravity meter electronics (204b) or the volumetric meter electronics (205b) based on the generated density or specific gravity measurement and the generated mass flow rate.

Owner:MICRO MOTION INC

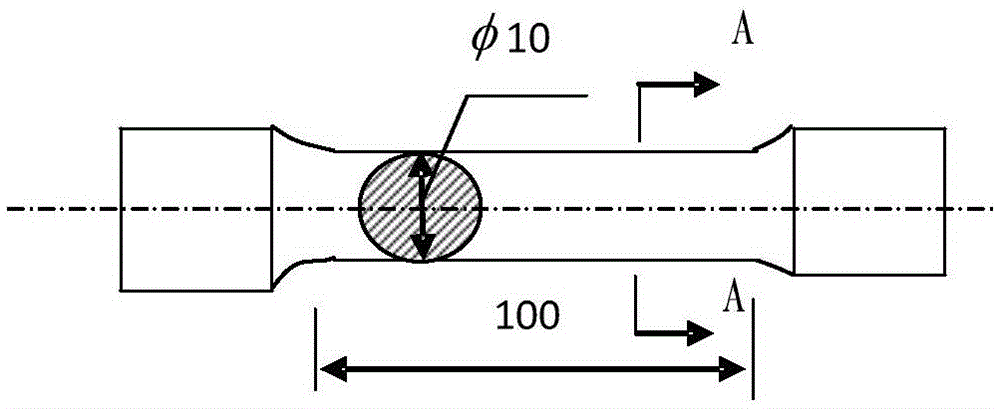

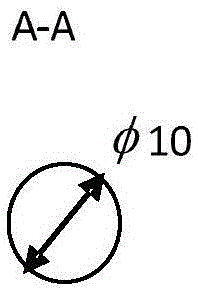

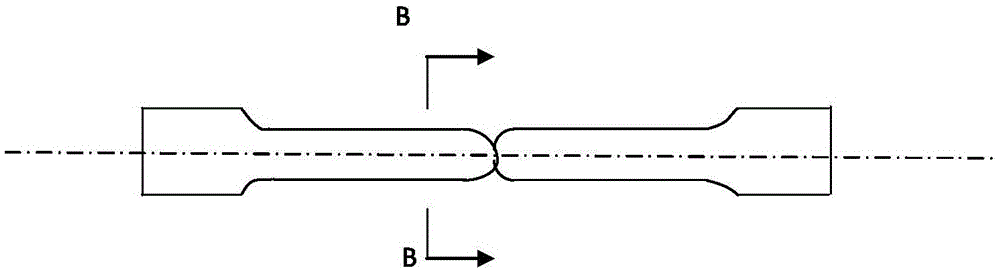

Method for determining fatigue damage degree of metal material based on specific gravity measurement

InactiveCN105424554AImprove reliabilitySimple stepsSpecific gravity measurementFatigue damageMetallic materials

The invention discloses a method for determining the fatigue damage degree of a metal material based on specific gravity measurement. The method includes the following steps that 1, the density rho of the metal material without damage and the density (with the symbol shown in the specification) of the metal material with damage are measured; 2, the fatigue damage value of the metal material is calculated according to the formula (shown in the specification), wherein D indicates the fatigue damage value of the metal material. The method for determining the fatigue damage degree of the metal material based on specific gravity measurement is high in reliability and easy to implement.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for detecting influence degree of hydrogen content of molten aluminum

InactiveCN104792657AAchieve confirmationImprove detection reliabilityMaterial analysis by optical meansSpecific gravity measurementDirect observationPhysical chemistry

The invention discloses a method for detecting the influence degree of the hydrogen content of molten aluminum. The method comprises the following steps: a, the value of specific gravity of a sample is detected; b, a section is machined on the sample, whether a pinhole point exists on the section is observed, if the pinhole point does not exist, the hydrogen content of the sample is qualified, and the hydrogen content is unqualified if the pinhole point exists. According to the method, the section is machined on the sample after detection of the specific gravity, hydrogen is uniformly distributed through negative pressure pumping before the detection of the specific gravity, so that the distribution condition of pores formed by hydrogen after solidification of the sample can be observed directly through the section, a specific gravity parameter obtained with a specific gravity measurement method is further confirmed, the detection reliability of the hydrogen content is improved, and the potential safety hazards for hub quality control are reduced; dye penetrant inspection and / or polishing are performed on the section, the section observing reliability is further improved, and the reliability of the detection of the influence degree of the hydrogen content is guaranteed.

Owner:江苏新安驰铝业有限公司

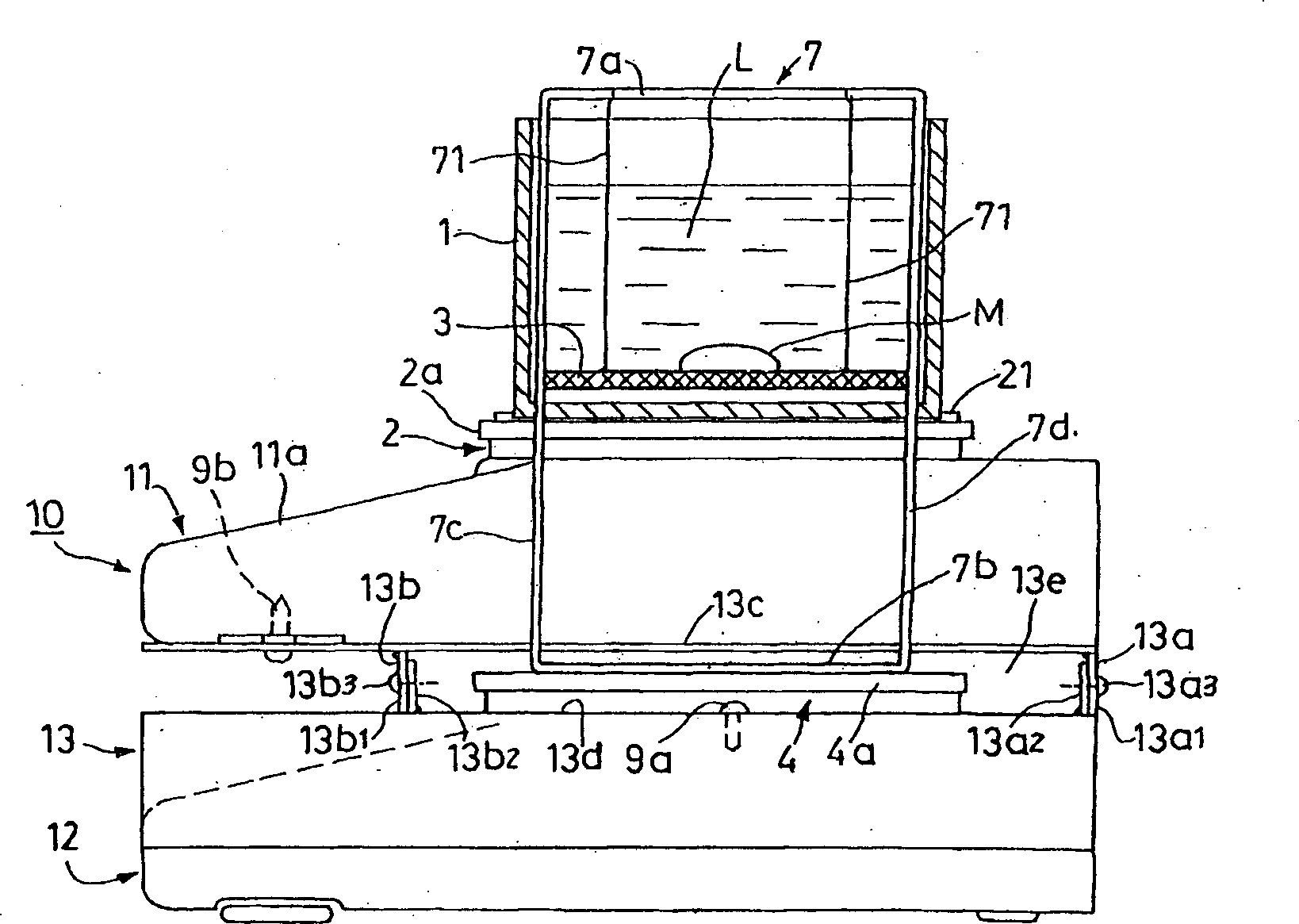

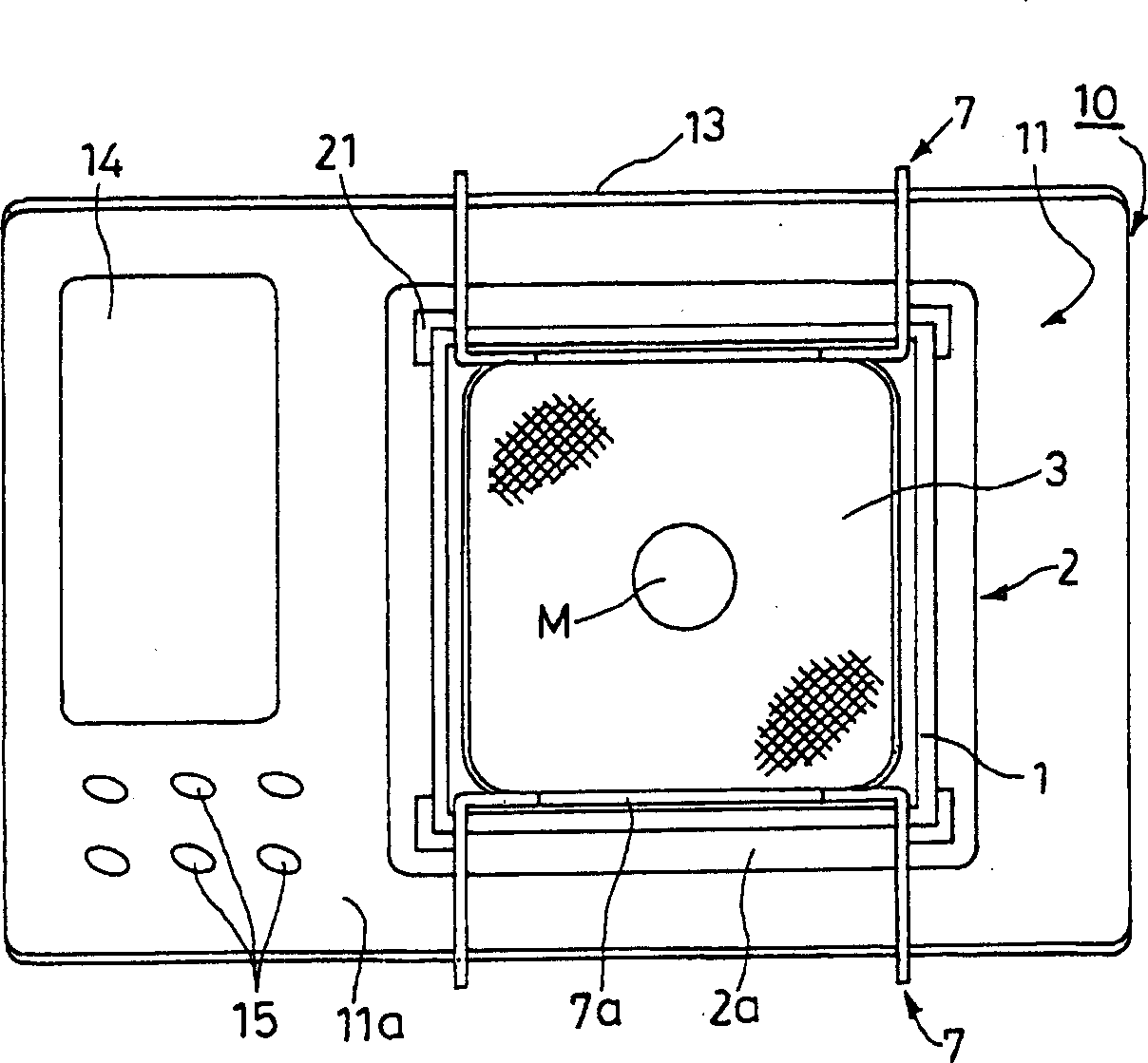

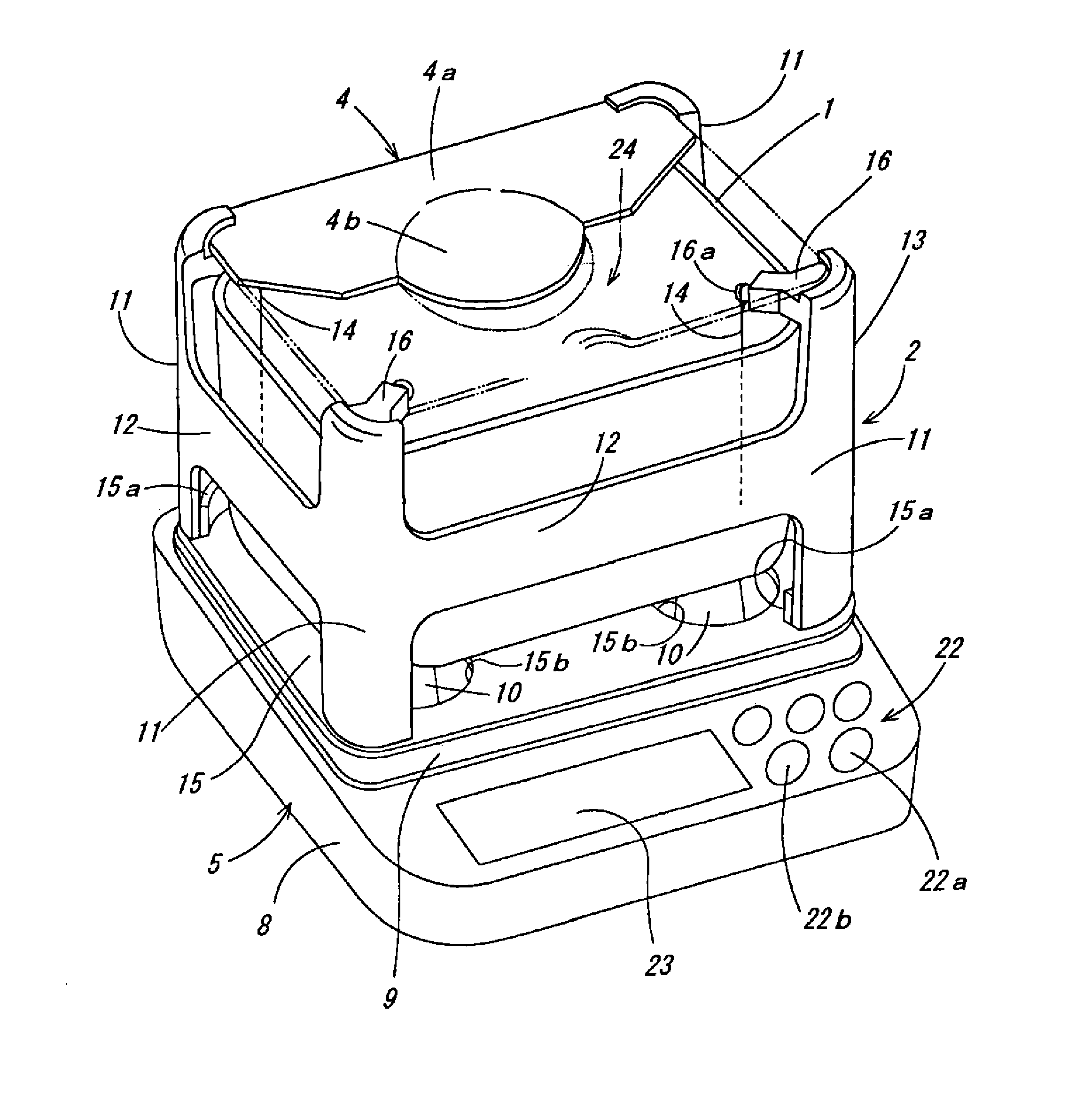

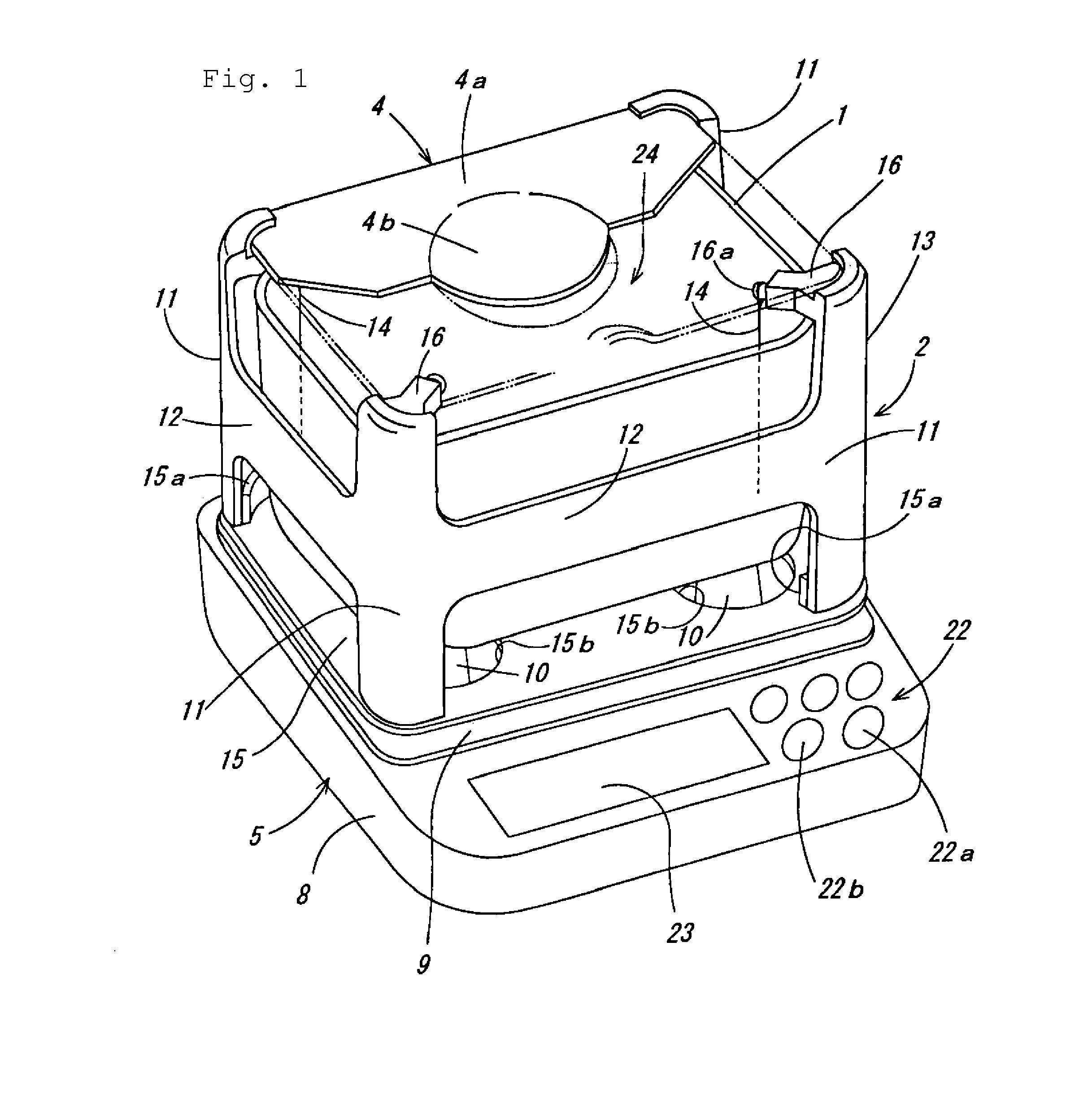

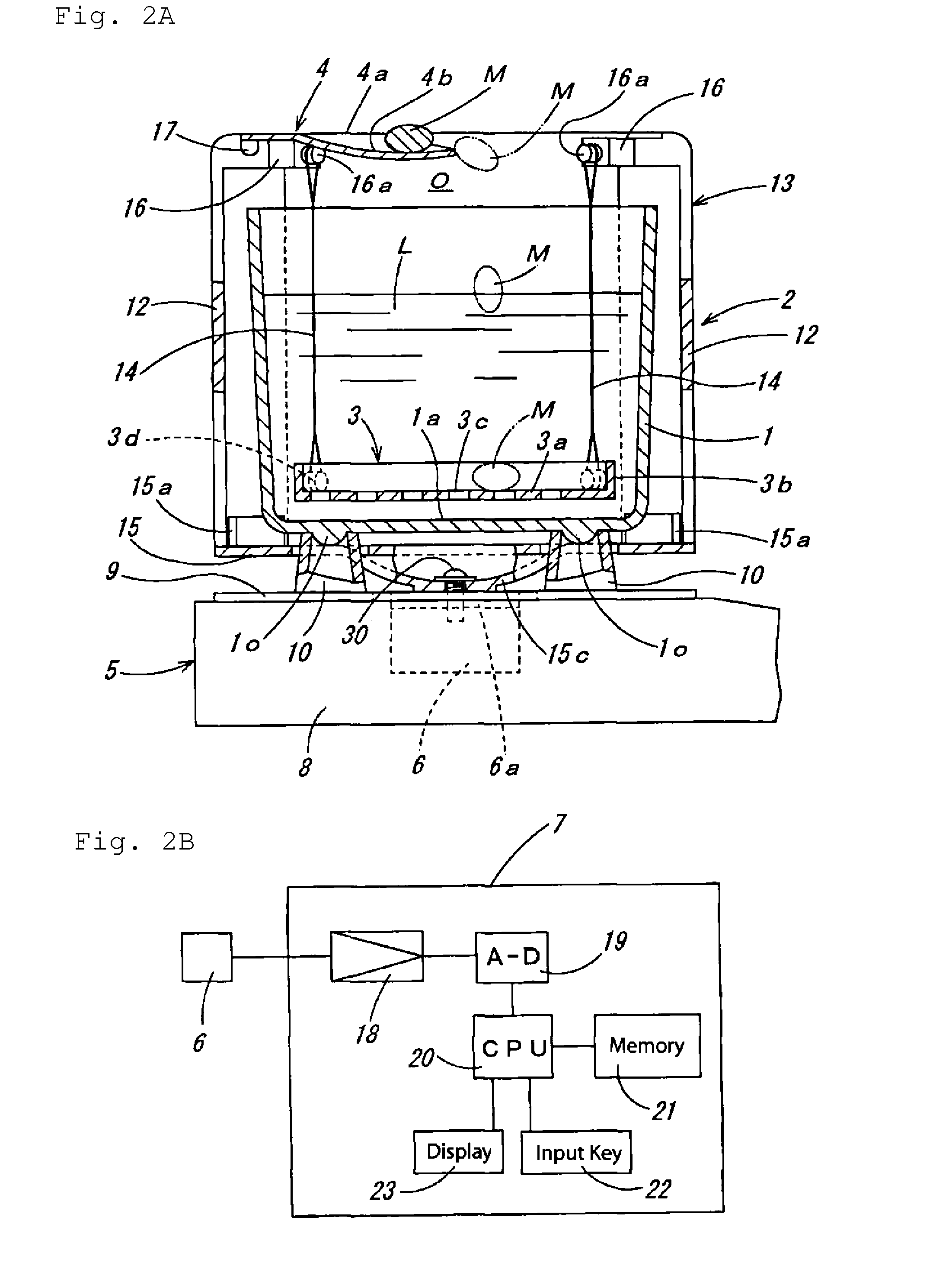

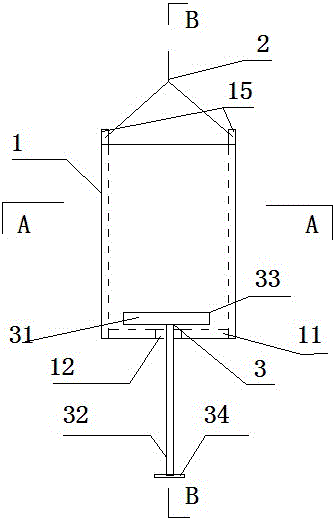

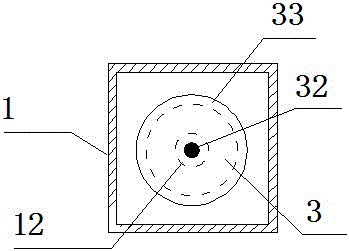

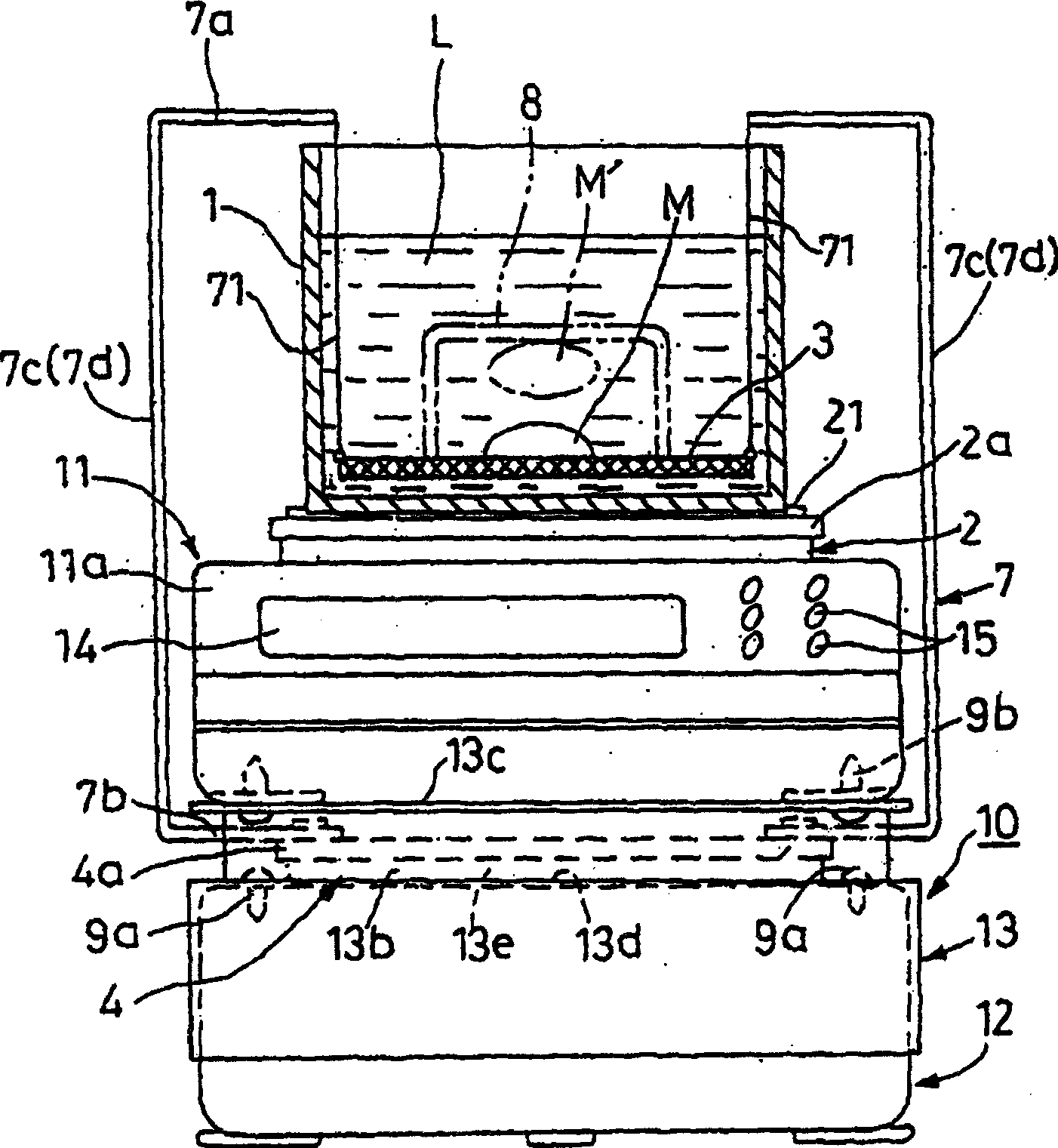

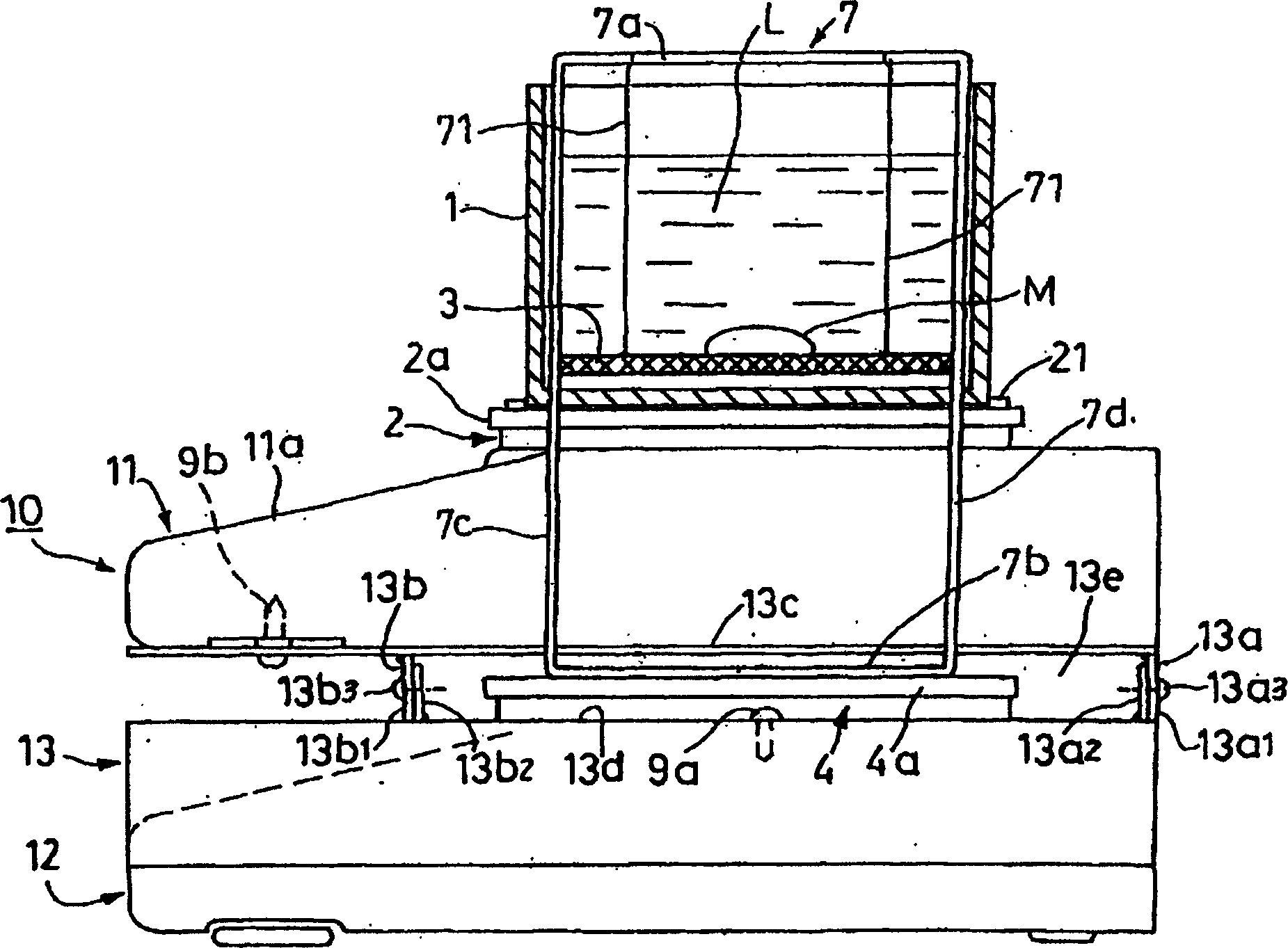

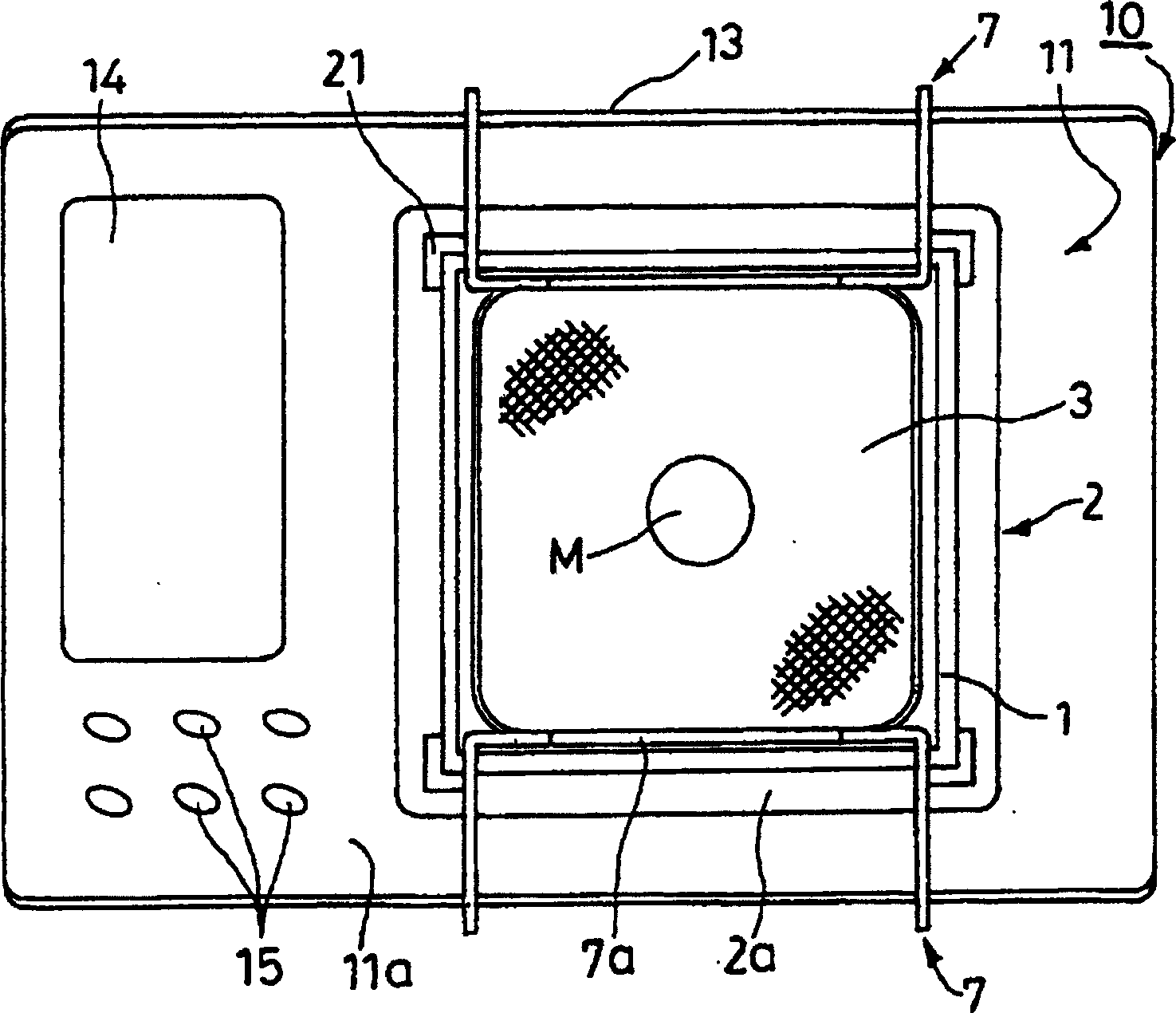

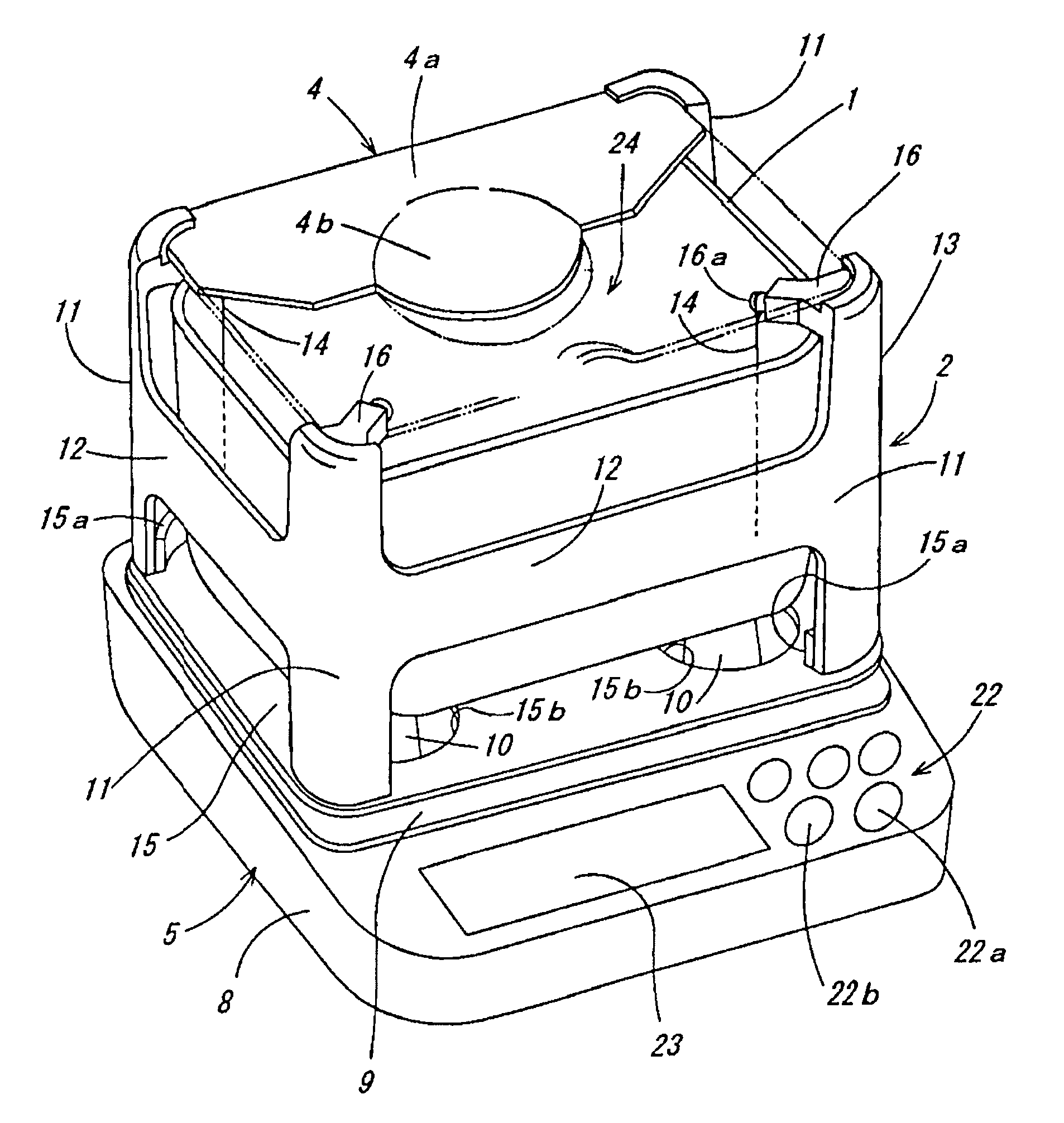

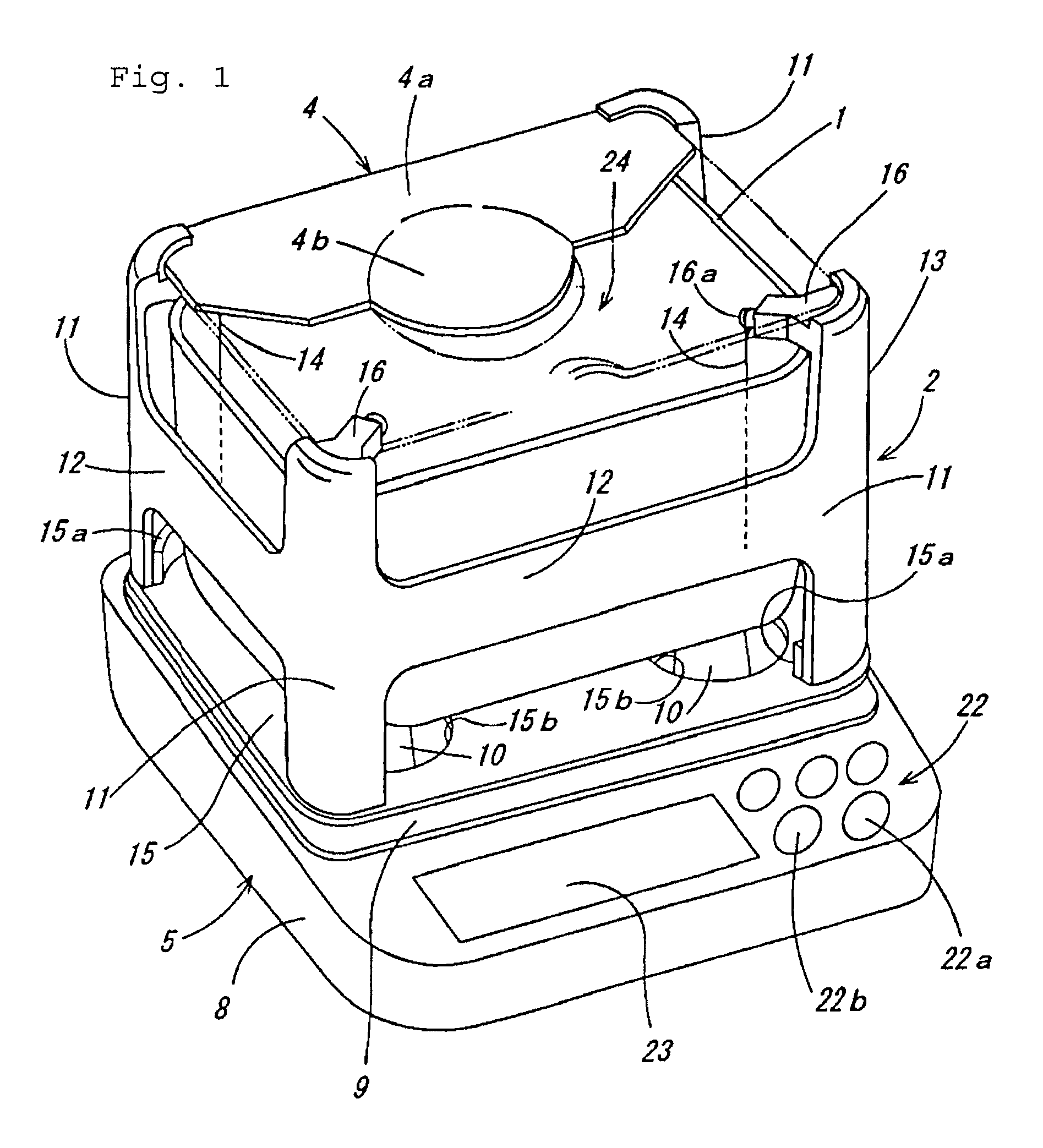

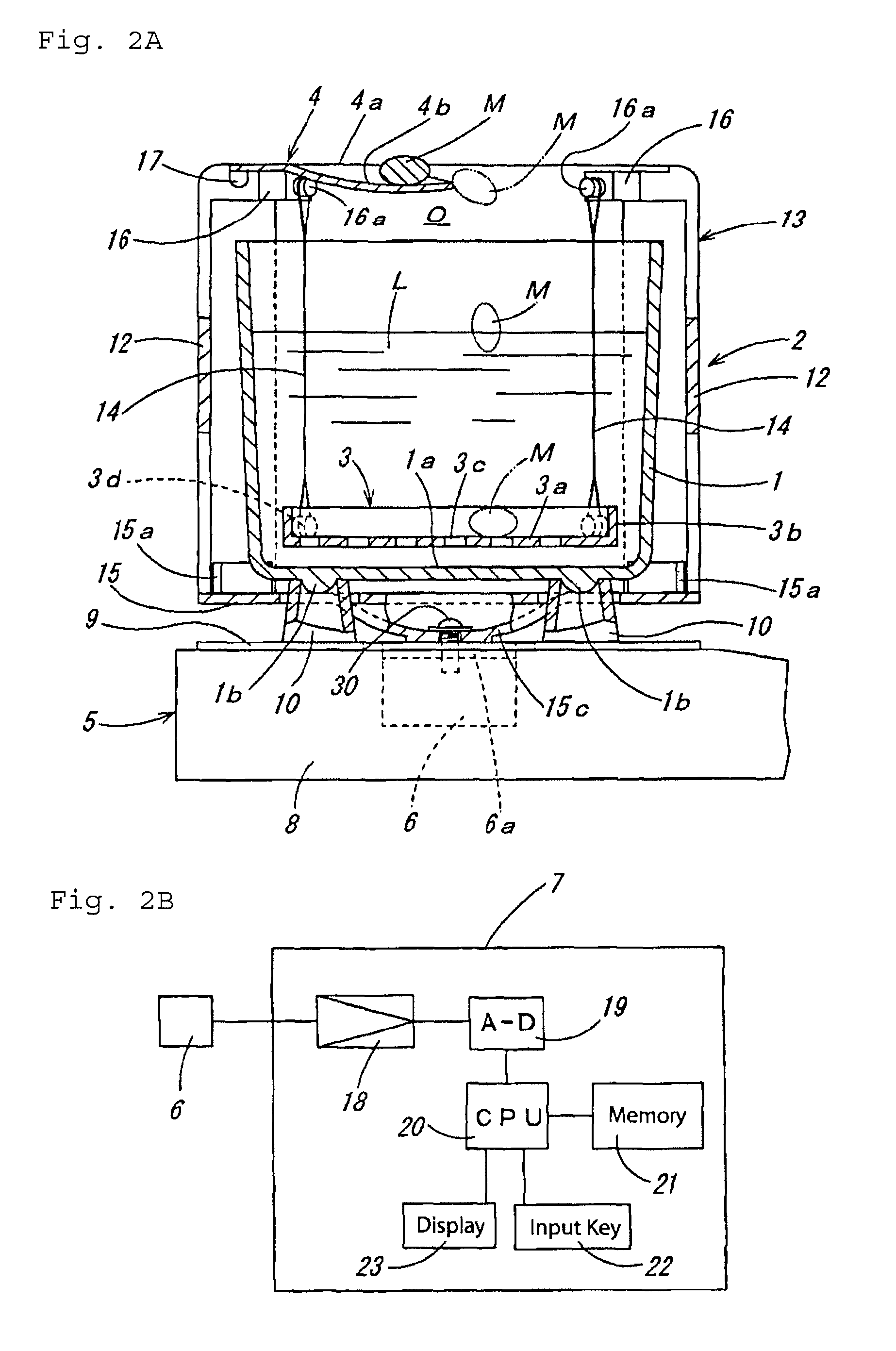

Specific gravity measuring apparatus

ActiveUS20130086984A1Improve specific gravity measurement accuracyLabor of closingMaterial analysis by measuring buoyant forcesEngineeringMechanical engineering

A specific gravity measuring apparatus includes a liquid bath, a measured object receiving member which is housed in the liquid bath via a support means in a non-contact manner and into and out of which a liquid within the liquid bath can freely flow, an aerial mounting member which is supported by the support means and on which a measured object is placed in order to measure gravity thereof in the air, and a weighing apparatus receiving and supporting the measured object receiving member via the support means. The weighing apparatus 5 is provided with a sensor and a measuring section. The aerial mounting member is provided in such a manner as to cover a part of an opening O at an upper part of the liquid bath.

Owner:ALFA MIRAGE

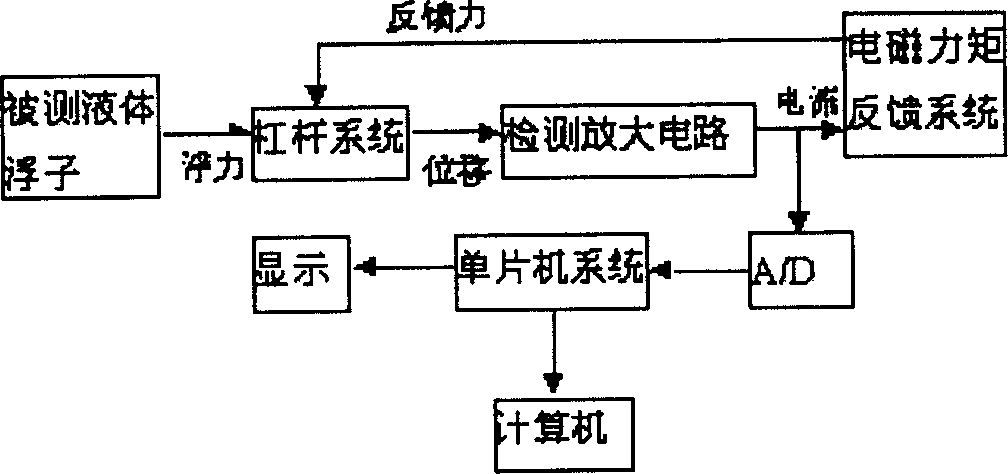

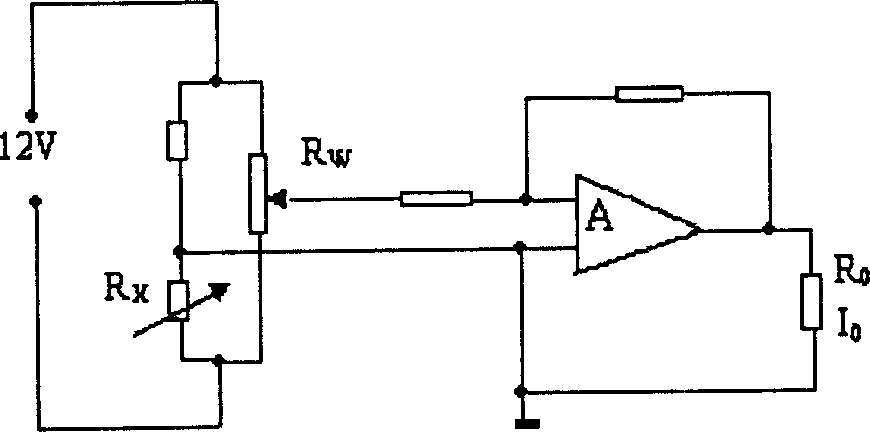

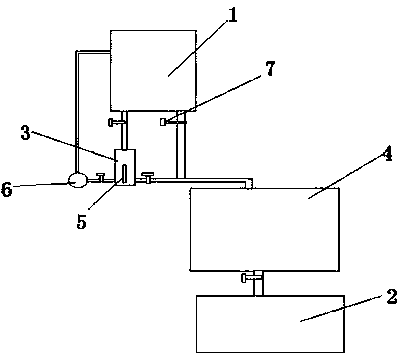

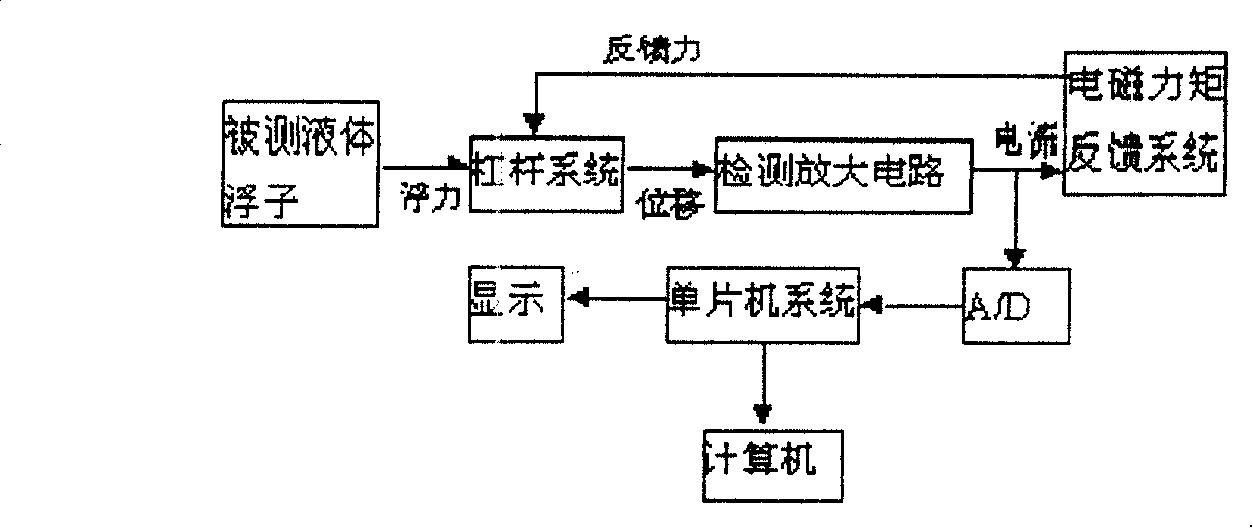

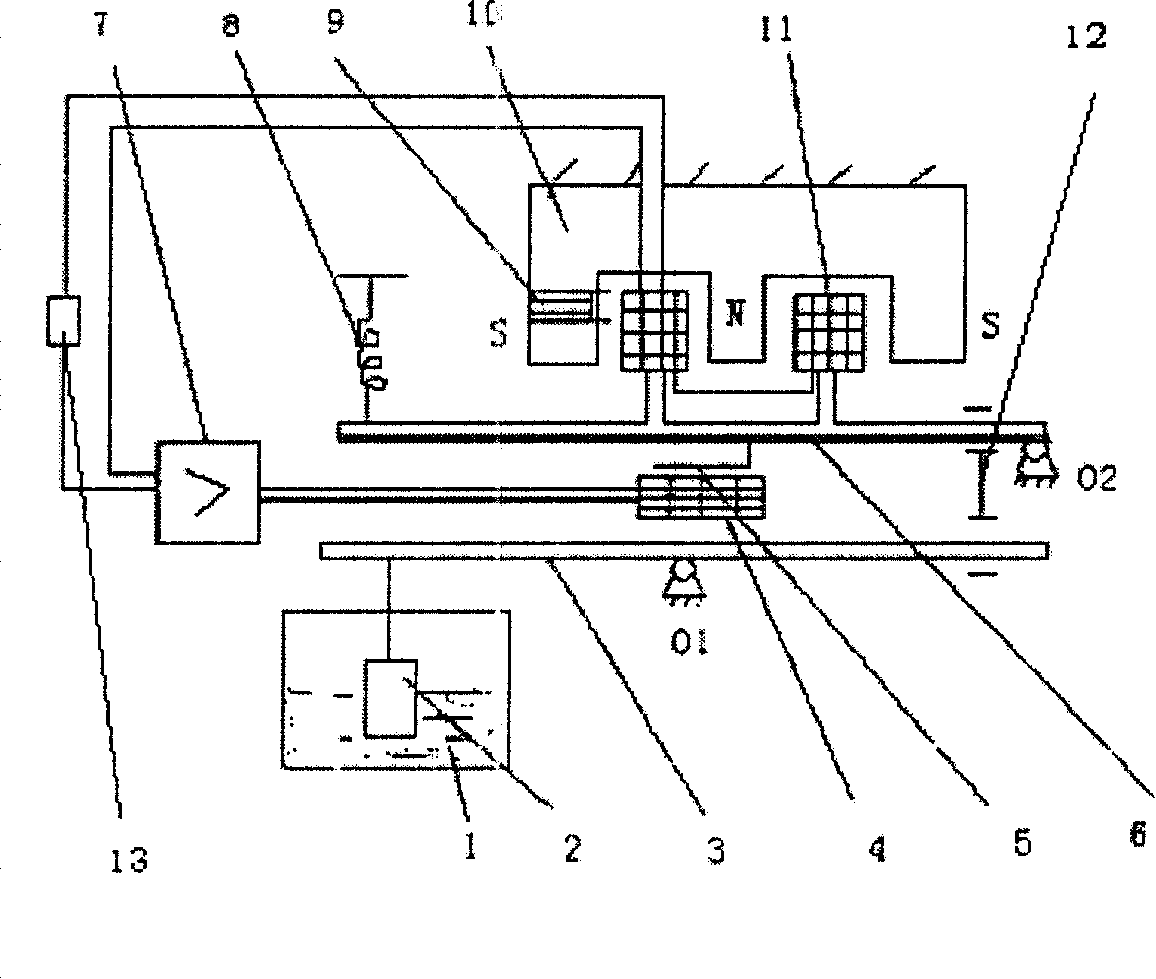

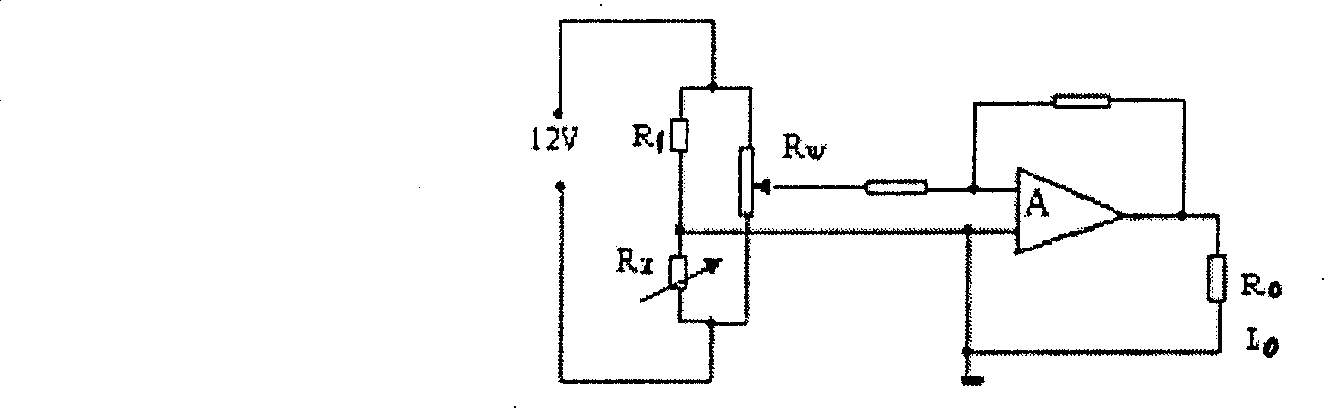

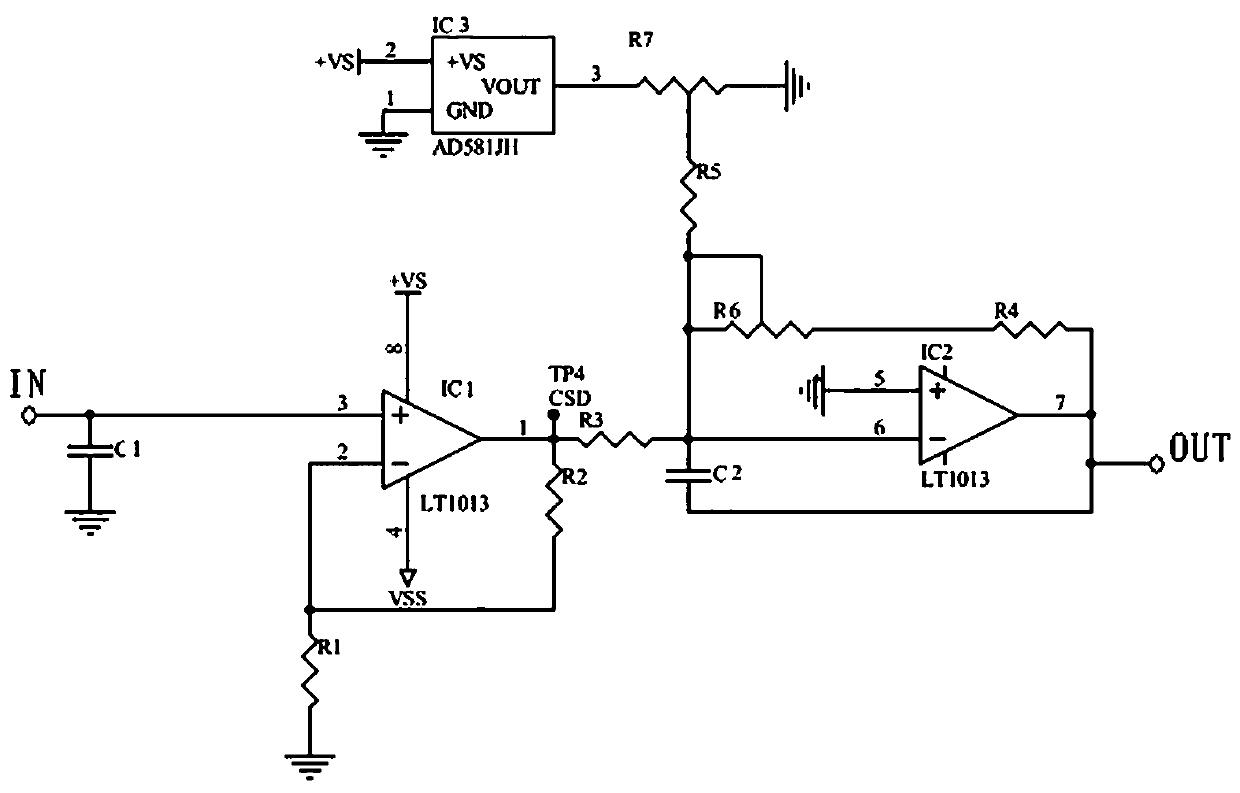

Digital system for liquid specific density measurement

InactiveCN1699959ARealize automatic measurement of specific gravityRealize automatic measurementMaterial analysis by observing immersed bodiesAudio power amplifierTransformer

The invention discloses a measuring method for digital liquid specific weight, which comprises the following parts: specific weight measuring device, A / D transformer, digital display circuit or computer; and specific weight measuring device including float posited on one side of main gauge peg, main gauge peg with fulcra in the middle, auxiliary gauge peg, amplifier, permanent magnet, feedback coil; wherein main gauge peg connects with auxiliary gauge peg by link block; transform measuring slice posits on auxiliary gauge peg; transform measuring slice posited below transform measuring device; one side of auxiliary gauge peg has fulcra and the other side has zeroing device; feedback coil which posited in permanent magnet is on auxiliary gauge peg; transform measuring device connects with feedback coil by measuring amplifying circuit.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

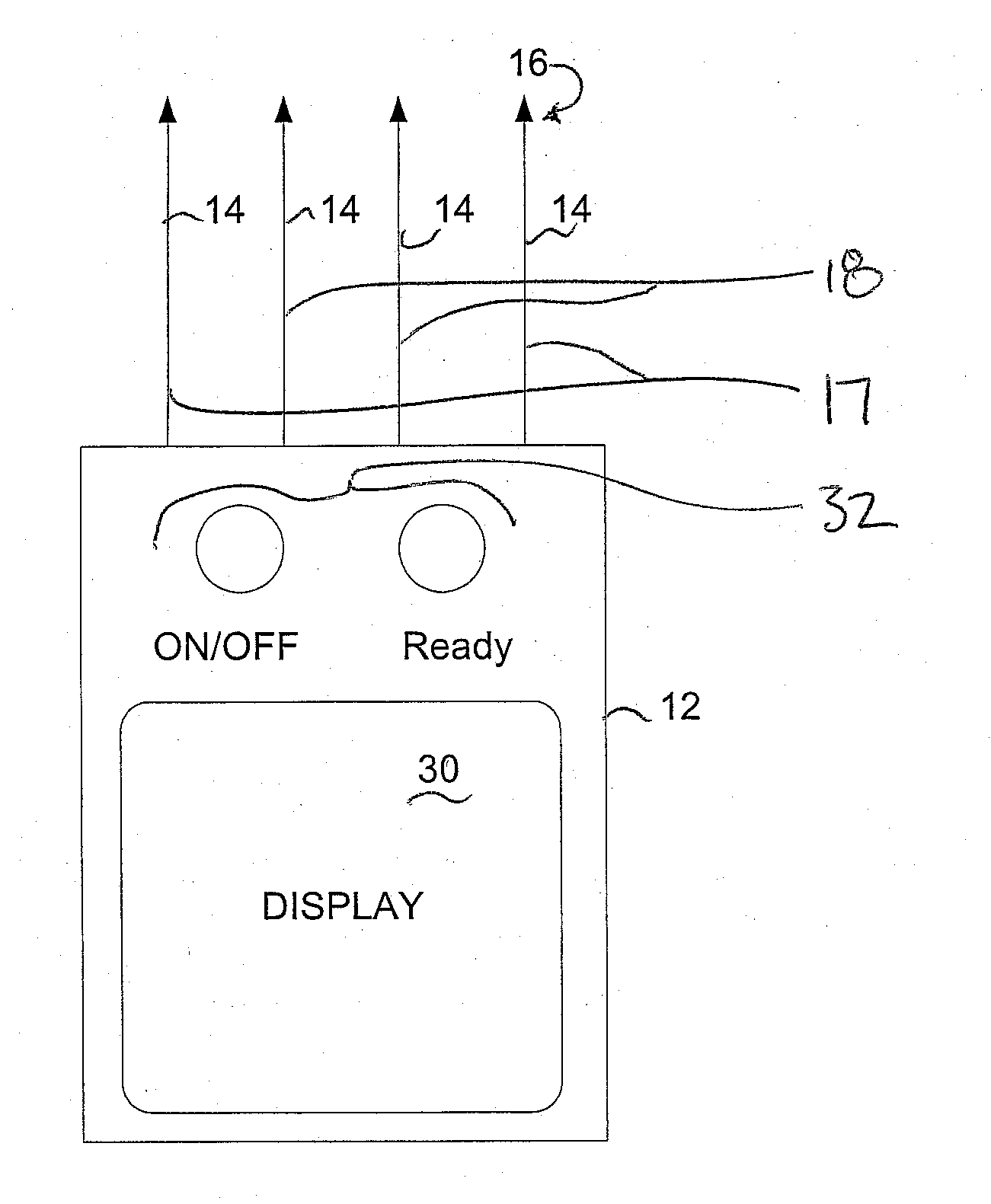

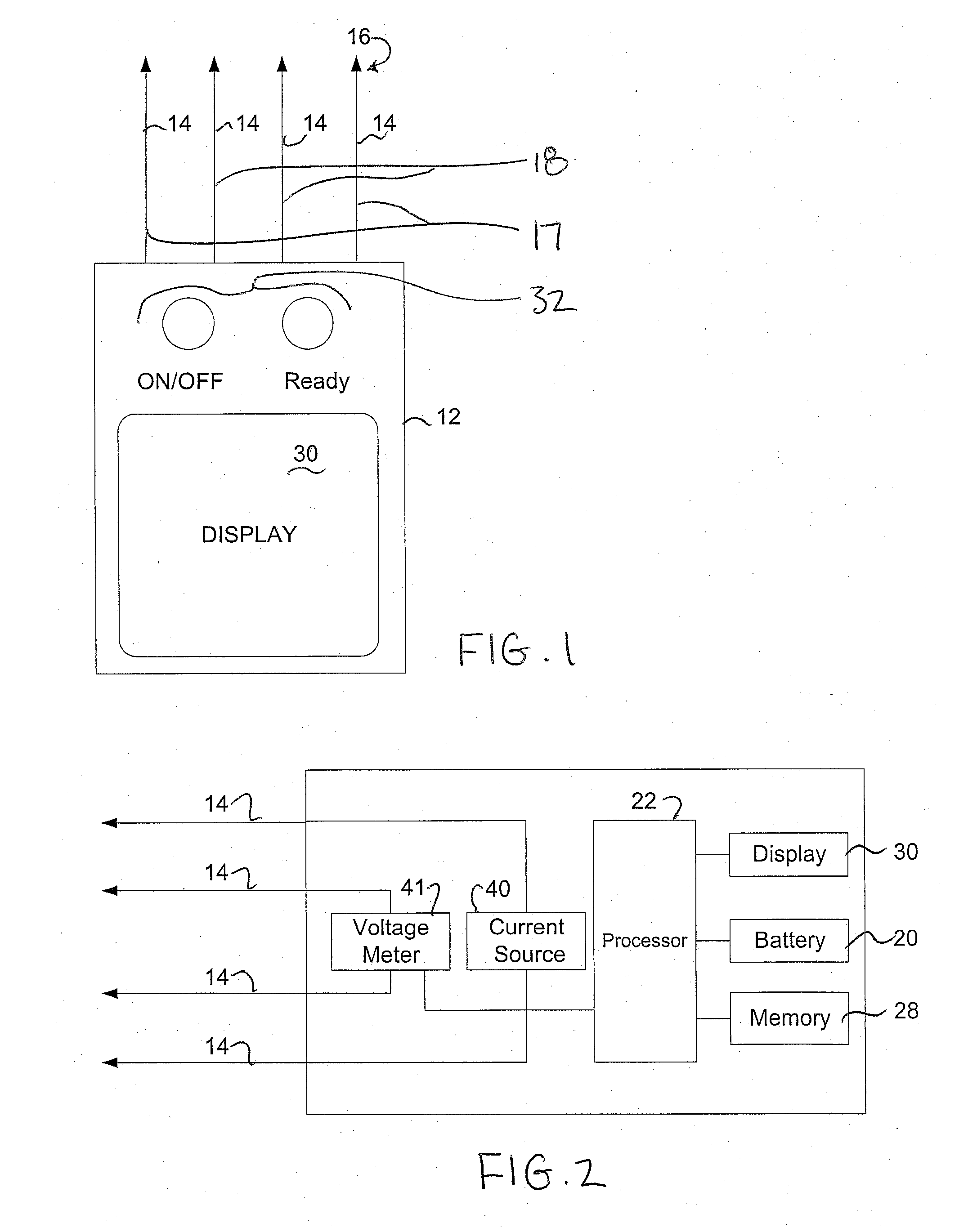

Specific gravity measuring tool

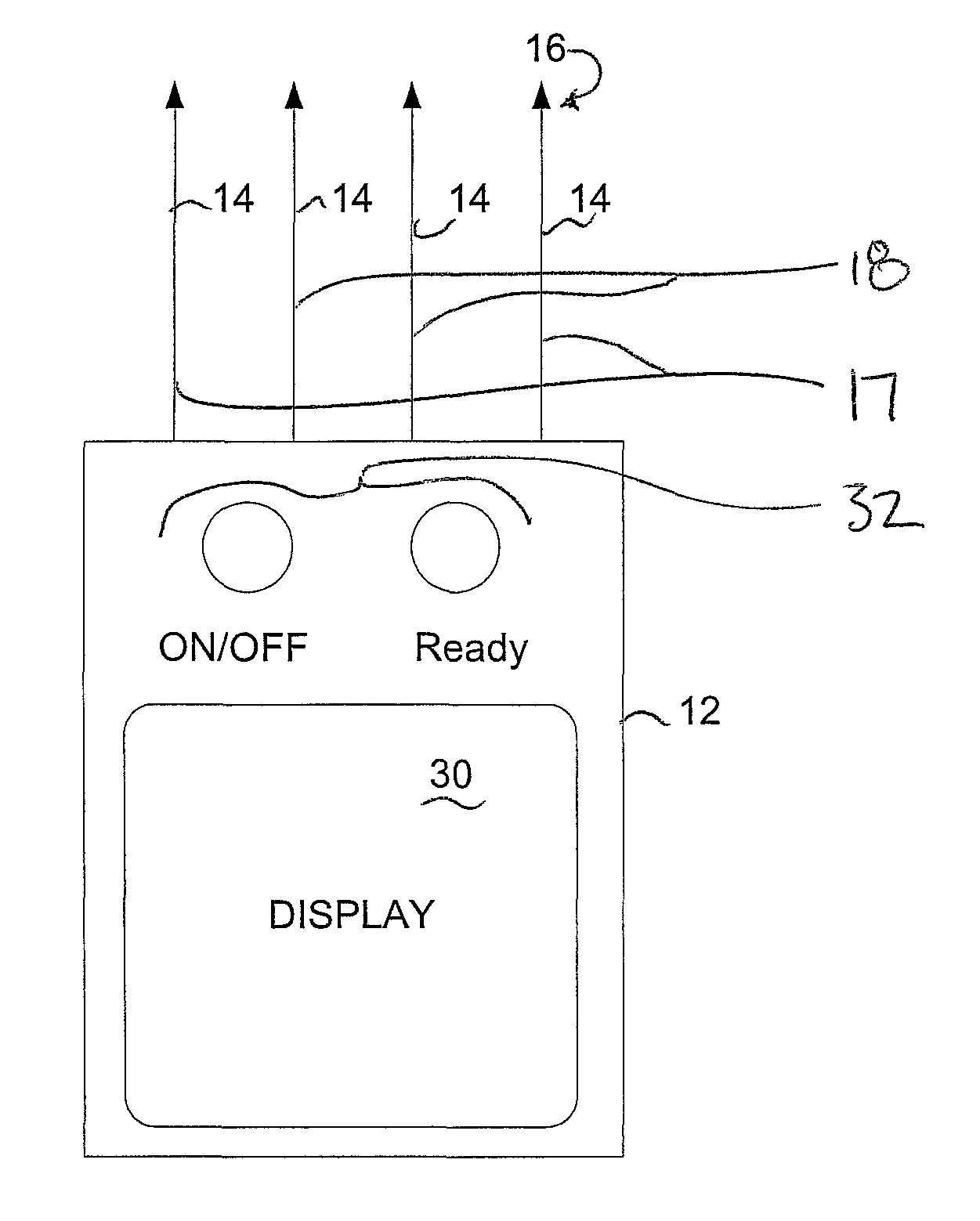

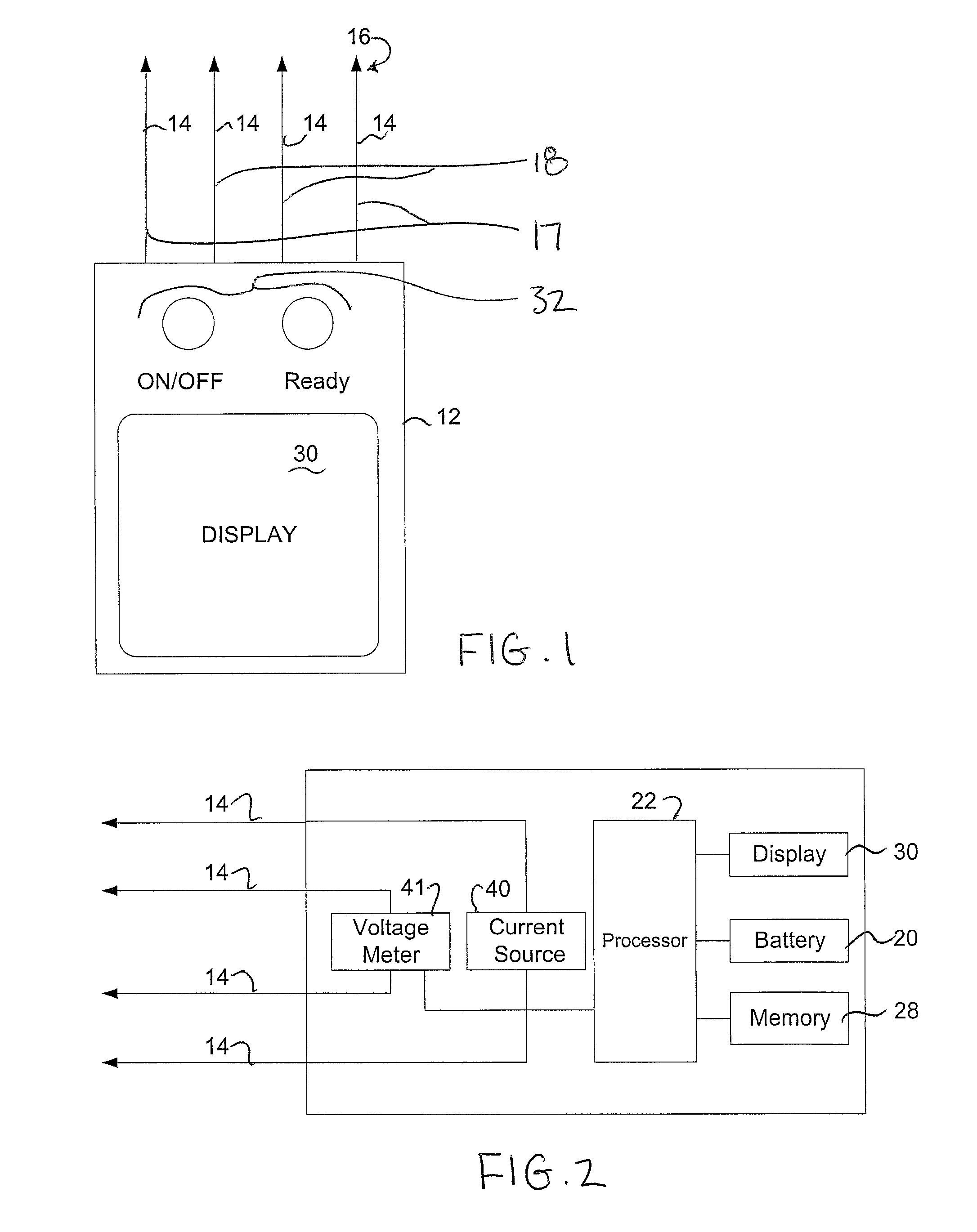

InactiveUS9026395B2Amplifier modifications to reduce noise influenceSpecific gravity using flow propertiesElectrical resistance and conductanceDisplay device

A specific gravity measuring tool comprises a portable handheld housing supporting a plurality of electrodes at a fixed known spacing thereon and a display for displaying a determined specific gravity thereon. The electrodes are arranged to be penetrated into the object to be measured, for example a potato. The electrodes include a first pair across which an electrical potential is arranged to be generated, and a second pair across which an electrical potential is arranged to be sensed. A processor of the tool is arranged to calculate electrical impedance using the electrical potential generated across said first pair of the electrodes, the electrical potential sensed at said second pair of electrodes, and the known spacing between the electrodes so that the specific gravity can be determined using a predetermined relationship between electrical impedance and specific gravity.

Owner:BEAULIEU KELLY +1

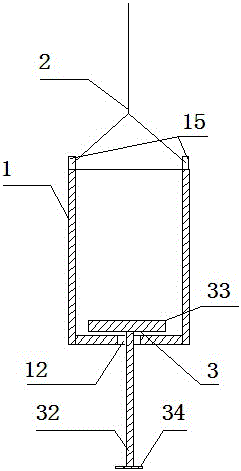

Automatic sampling barrel for pile bottom slurry

The invention discloses an automatic sampling bucket for pile bottom mud, in particular to an automatic sampling bucket for pile bottom mud with simple operation, convenient sampling and high speed. The technical problem to be solved is that the mud at the top of the hole is used for the measurement of the specific gravity of the cast-in-place pile mud, which cannot fully represent the mud at the bottom of the hole. The invention includes a barrel, a lead wire and a bottom sealer. The lead wire is arranged above the barrel body, and the bottom plate of the barrel body Bottom holes are provided, and the bottom sealer includes a bottom cover plate and a stop bar arranged at the bottom of the back cover plate, the back cover plate is arranged in the barrel body, and the stop bar passes through the bottom hole of the barrel and is movably connected with the bottom plate. The present invention after adopting such a technical solution has a simple structure, does not need to measure the height, is convenient to use, and uses corner scraps for processing, thereby saving costs.

Owner:THE FOURTH OF CHINA CONSTR SEVENTH ENG

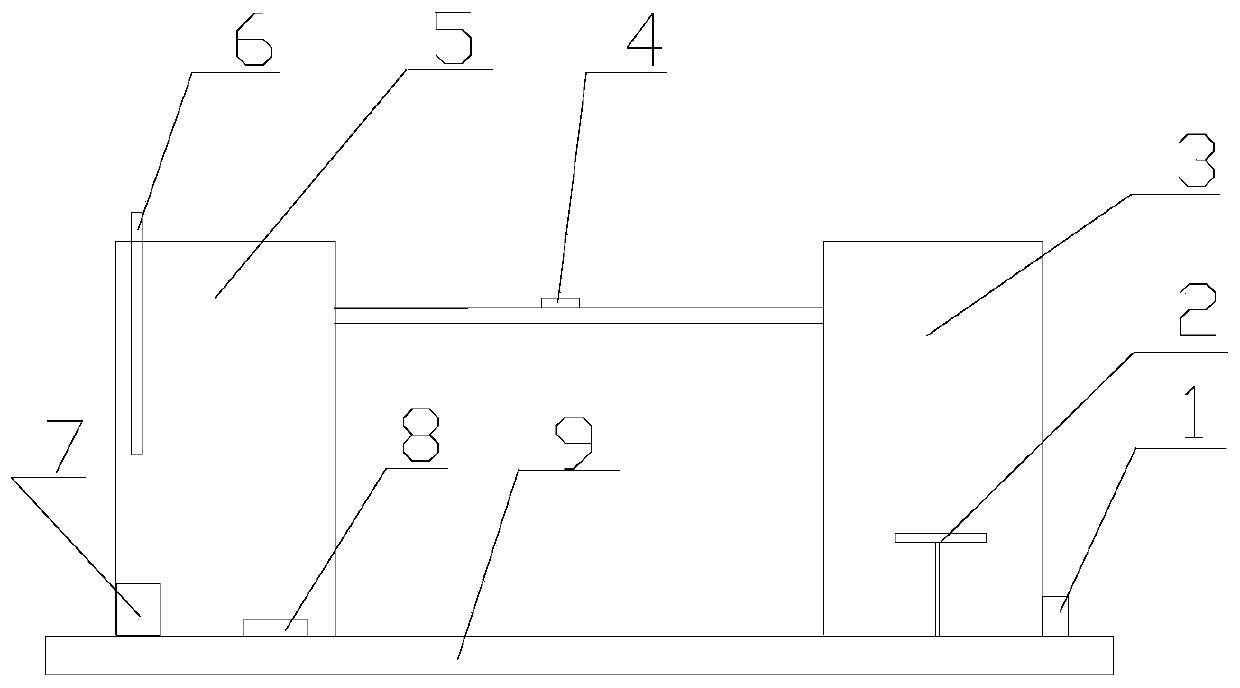

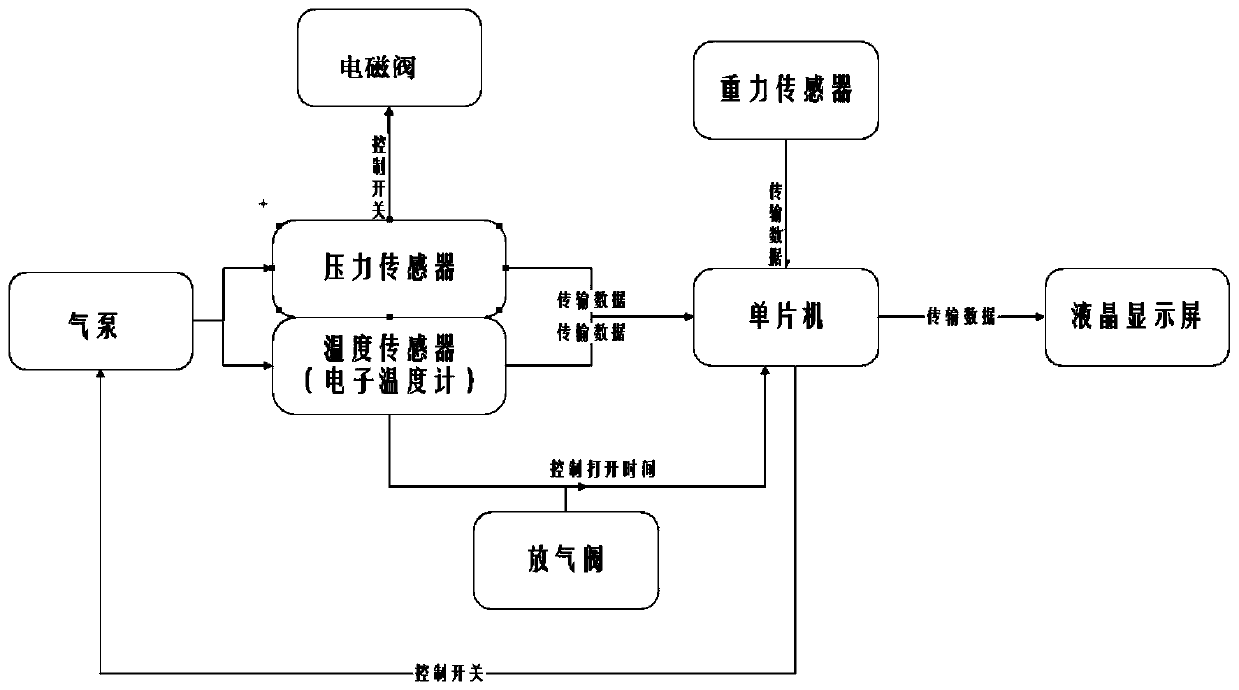

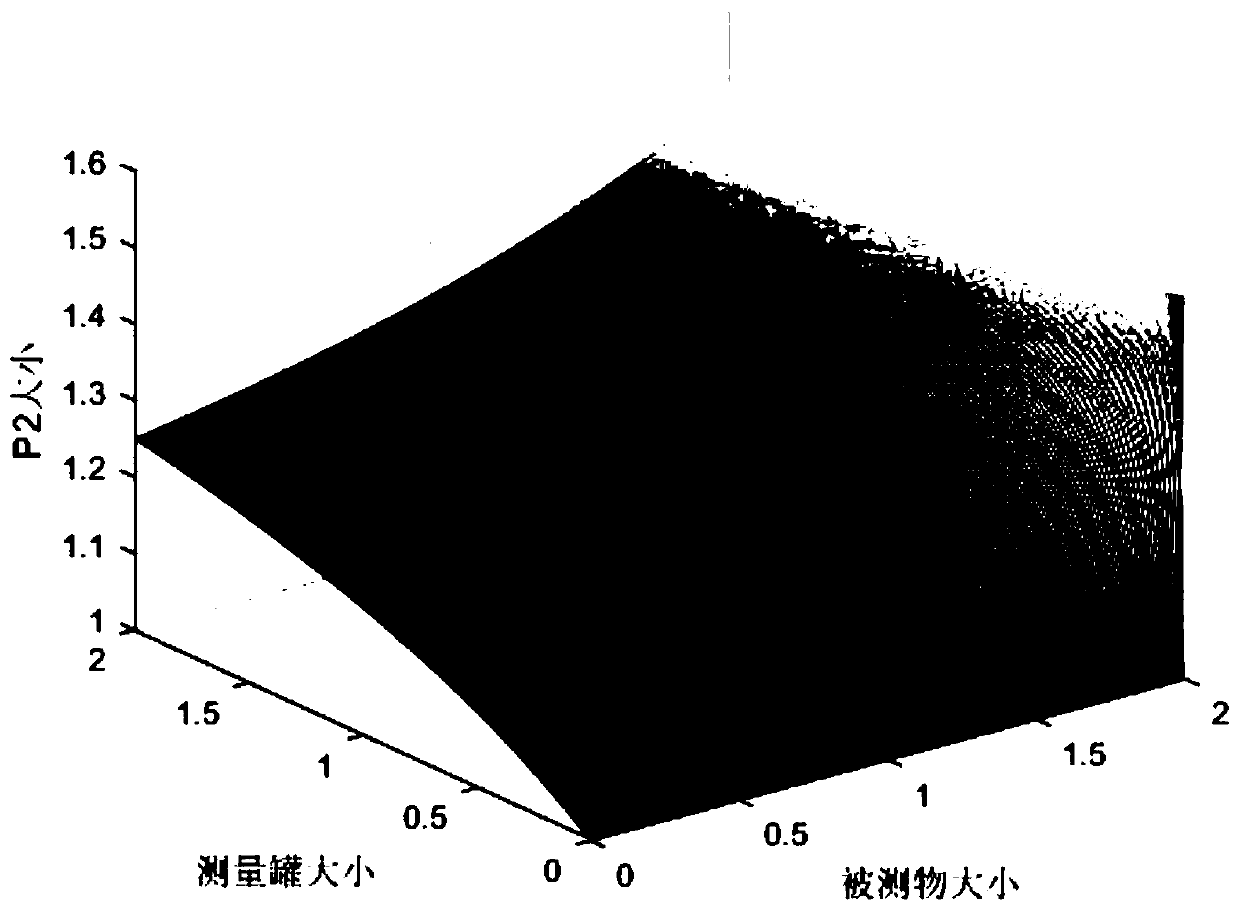

Portable specific gravity instrument based on air pressure measurement and specific gravity measurement method

InactiveCN109856007AMeasuring Energy SavingsMeasuring Environmental ProtectionSpecific gravity measurementAir pumpEngineering

The invention relates to a portable specific gravity instrument based on air pressure measurement and a specific gravity measurement method. The portable specific gravity instrument comprises a firstsealed space, a second sealed space, a temperature sensor, a pressure sensor and a controller, wherein the first sealed space is used for placing a measured object, and the first sealed space is internally provided with a gravity sensor and an air release valve; the connection between the second sealed space and the first sealed space is controlled by an electromagnetic valve, and the second sealed space is internally provided with an air pump so as to inflate the second sealed space; the temperature sensor is arranged in the second sealed space and used for measuring the temperature before and after the pressure intensity changes; the pressure sensor is arranged in the second sealed space and used for measuring the pressure intensity; and the controller is used for controlling the measurement time sequence, receiving the temperature, pressure intensity and gravity data and processing the data. The portable specific gravity instrument completes the accurate measurement of the density of solid and liquid substances to the greatest extent through measuring the pressure intensity change in the same sealed container and calculating the relevant formula, and completes the energy-saving,environment-friendly and non-loss efficient measurement.

Owner:JILIN UNIV

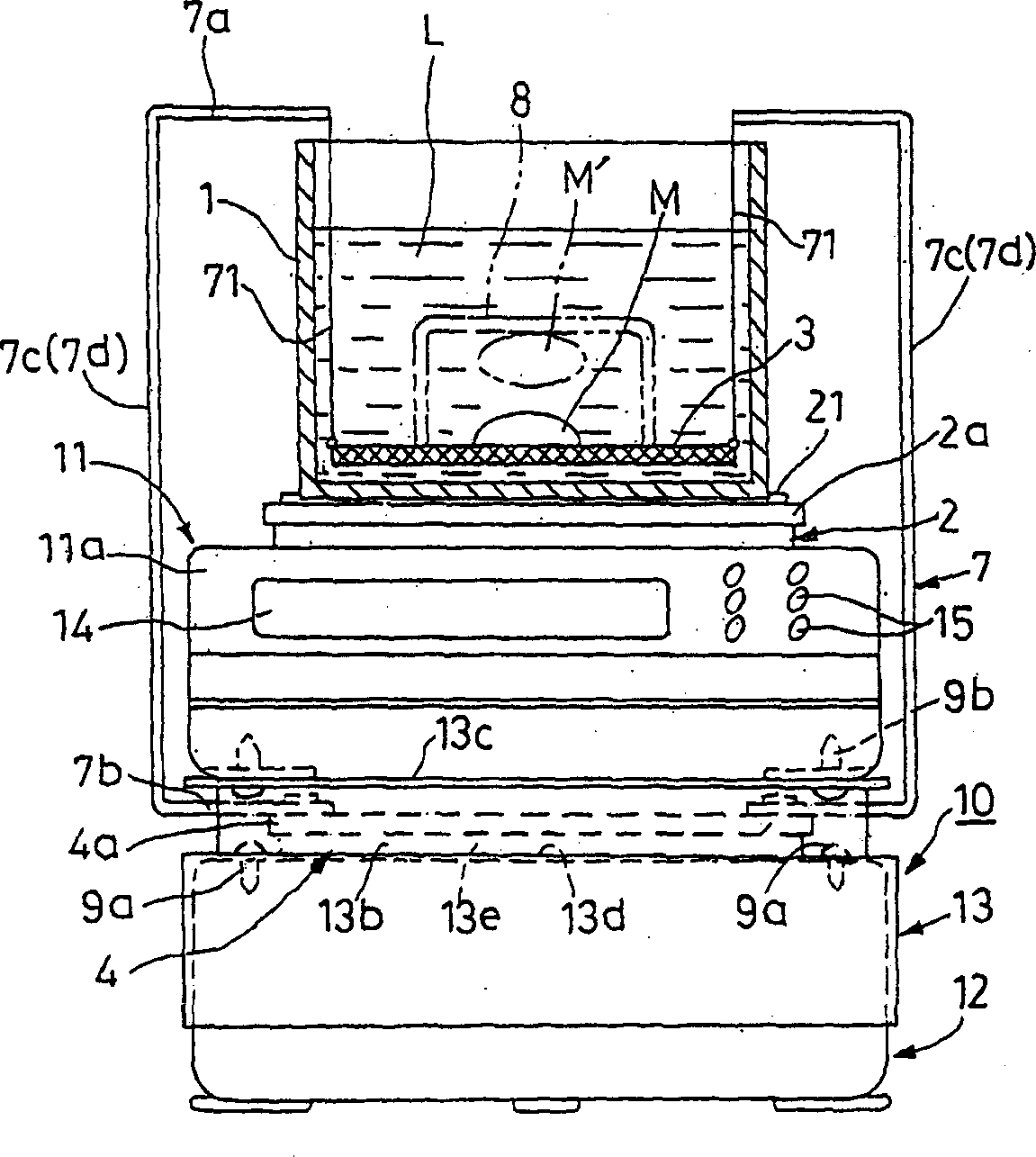

Specific weight measurer

A specific gravity measuring device can certainly and instantly measure specific gravity of various solid state substances through one measurement operation quite simply. The specific gravity measuring device includes a liquid bath, a first measuring portion supporting the liquid bath, a measuring object receptacle member arranged in the liquid bath in a condition dipped in the liquid, a second measuring portion supporting the measuring object receptacle member in non-contact condition relative to the liquid bath, an arithmetic unit deriving a specific gravity value on the basis of measured values of the first and second measuring portions and a display unit for displaying the specific gravity value derived by the arithmetic unit. The first measuring portion measuring increase of weight associating with dipping of the measuring object in the liquid by the first measuring portion, as buoyancy, and the second measuring portion measures a weight of the measuring object in the liquid by the second measuring portion. The arithmetic unit derives the specific gravity value from a measured value of the buoyancy and the weight in liquid for displaying on the display unit.

Owner:MIRAGE TRADING

Electronic mud specific gravity measuring device and measuring probe

PendingCN114486626ARapid Construction ParametersEasy to operateSpecific gravity by measuring pressure differencesSlurry wallElectrical resistance and conductance

The invention discloses an electronic mud specific gravity measuring device and a measuring probe. The invention provides the device for measuring the specific gravity of the slurry by using the resistance strain gauges and related parts, when the device is immersed in the slurry to be measured, the device can output different electric signals, so that the specific gravity of the slurry can be measured through the change of the electric signals, and the device is not influenced by the depth of the device immersed in the slurry or the change of the specific gravity of the slurry. Therefore, during drilling cast-in-place pile hole forming and underground diaphragm wall grooving operation, the device is hung in a pile hole or an underground diaphragm wall groove section, the specific gravity of wall protection slurry at any depth and any position in the pile hole or the underground diaphragm wall groove section can be directly measured, operation is easy, convenient and rapid, sampling is not needed, and the device is convenient to operate and high in practicability. Therefore, rapid and accurate construction parameters can be provided for related construction processes.

Owner:陆占磊

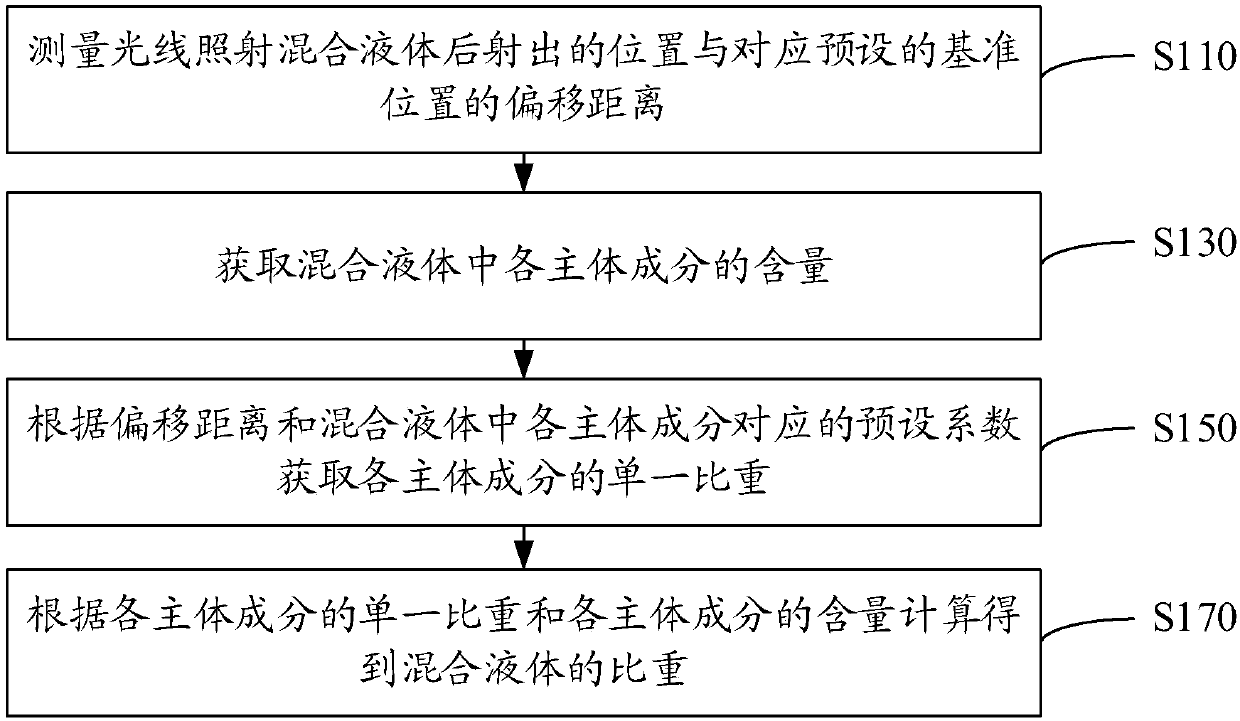

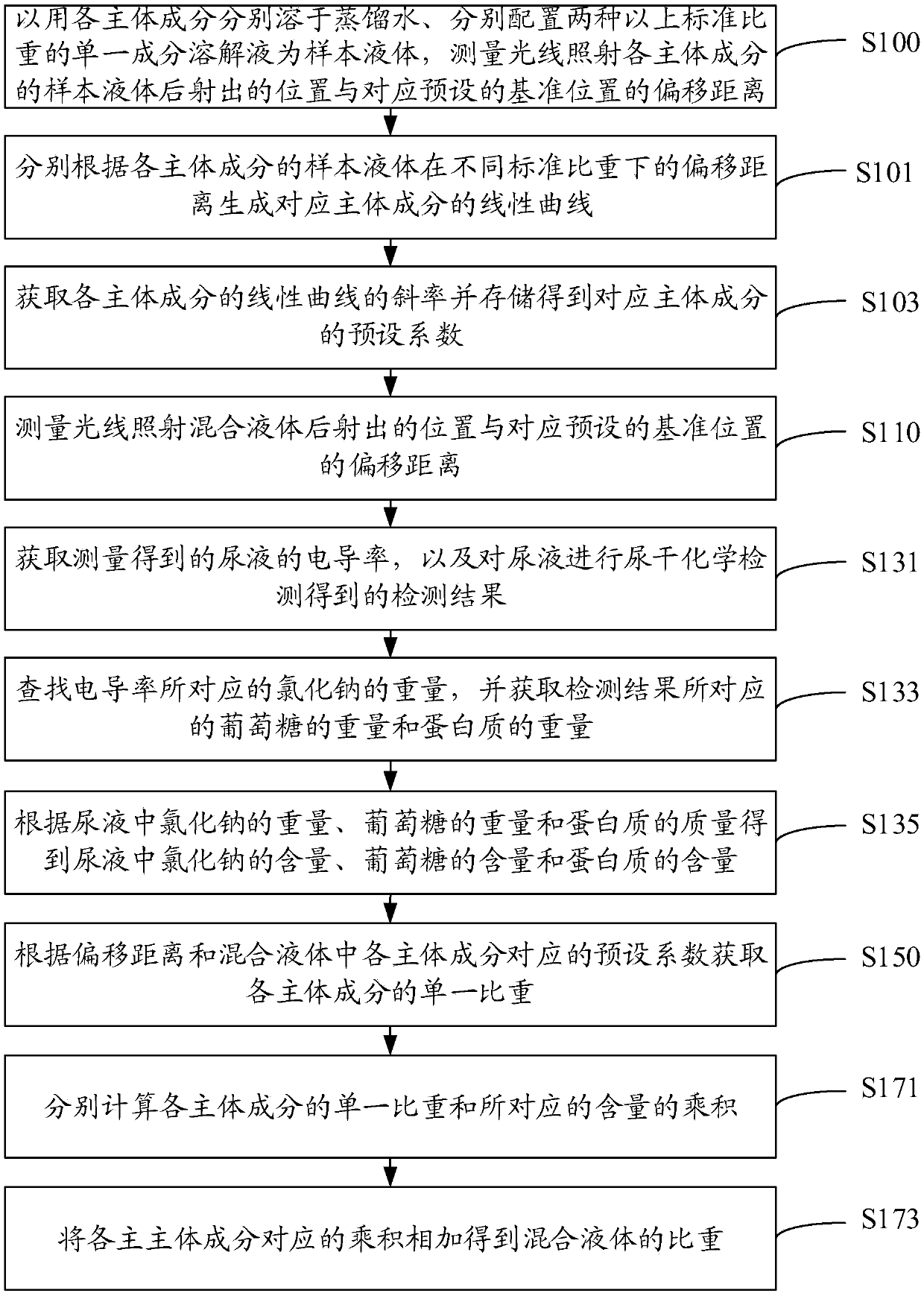

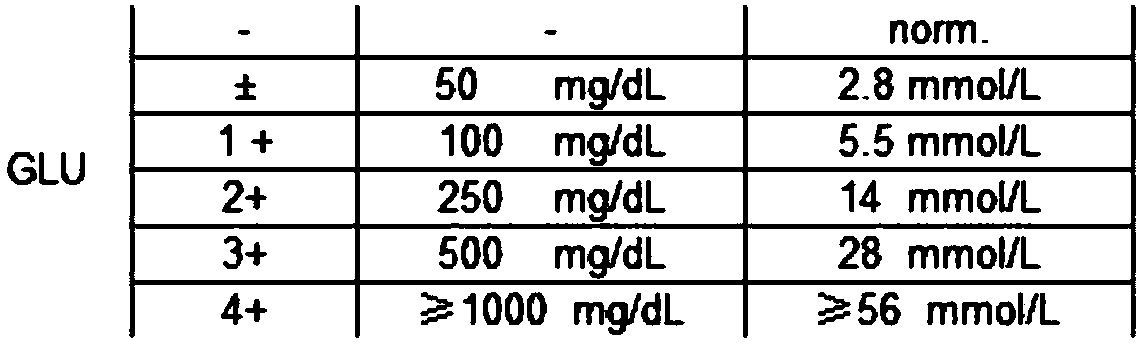

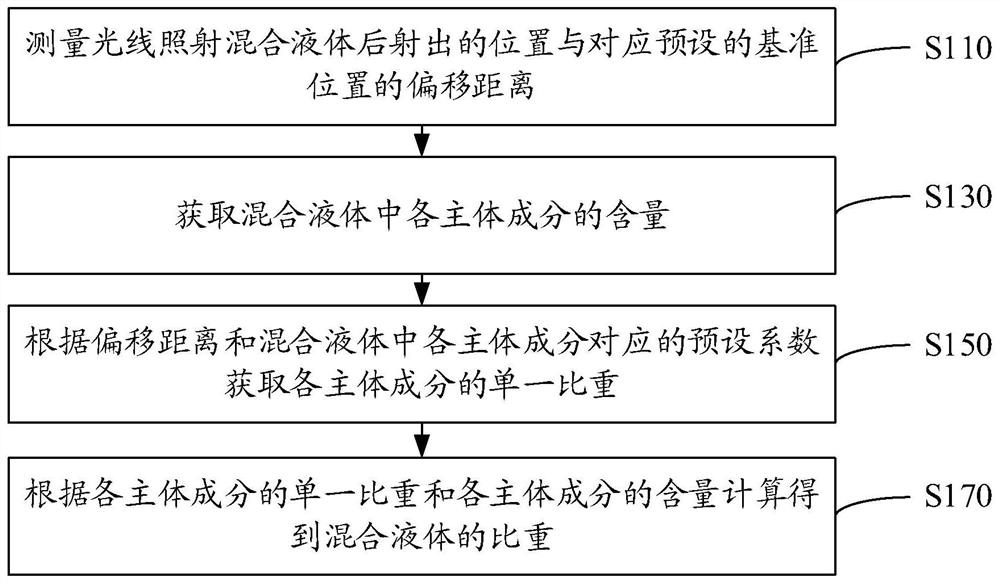

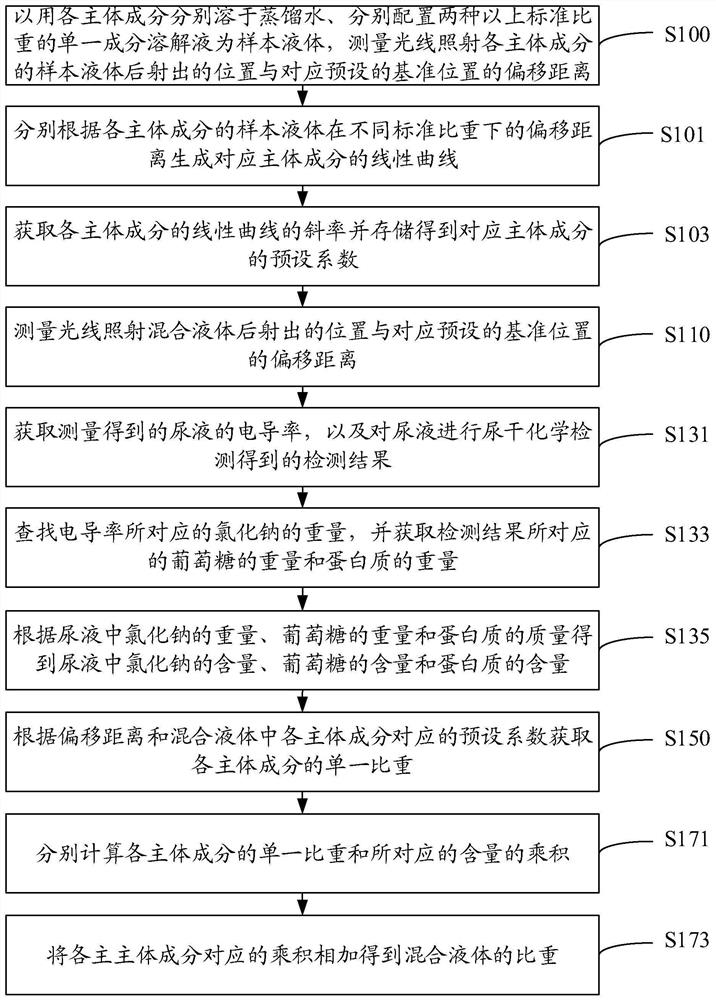

Specific gravity detection method for mixed liquid, medium and equipment and specific gravity detection equipment of urine

The invention relates to a specific gravity detection method for mixed liquid, a medium and equipment and specific gravity detection equipment for urine. The method comprises the following steps: measuring a deviation distance between an emergent position after light irradiates mixed liquid and a corresponding preset reference position; obtaining the content of each main component in the mixed liquid; obtaining the single specific gravity of each main component according to the offset distance and a preset coefficient corresponding to each main component in the mixed liquid; and calculating the specific gravity of the mixed liquid according to the single specific gravity of each main component and the content of each main component. Therefore, the specific gravity of the mixed liquid can be measured, the deviation caused by specific gravity detection by adopting a correlation coefficient of a single substance is avoided, and the detection accuracy is high.

Owner:AVE SCI & TECH CO LTD

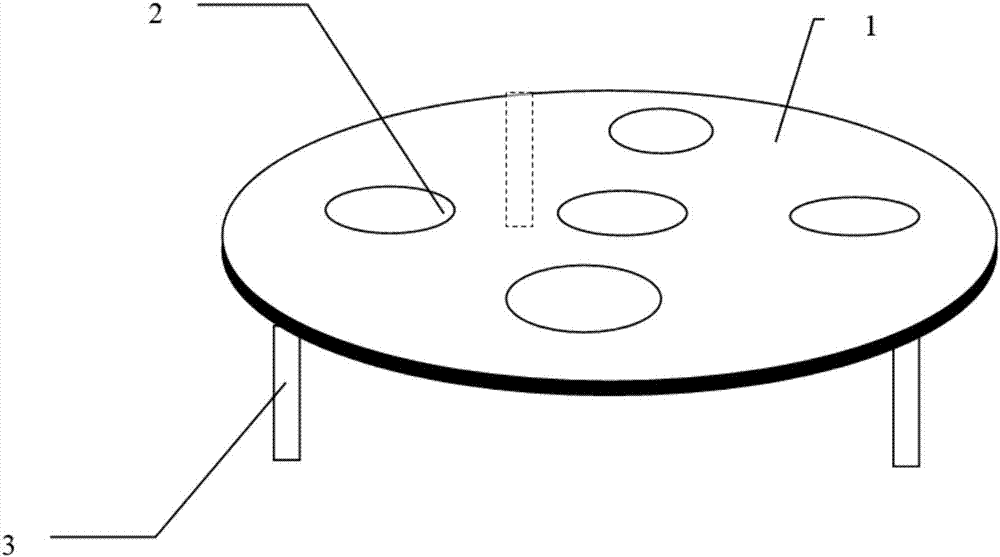

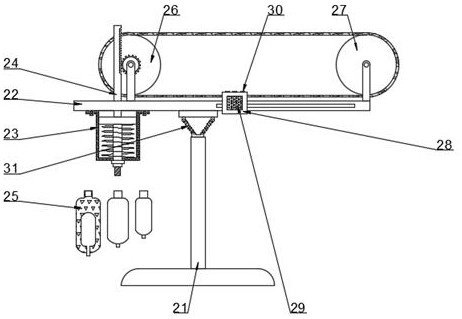

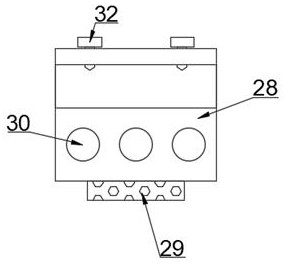

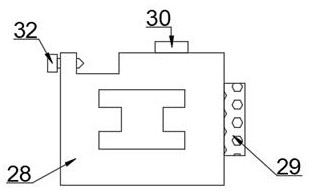

Specific gravity measuring bench and operation method thereof

InactiveCN107084910ASimple structureEasy to operateSpecific gravity measurementTest efficiencyEngineering

The invention discloses a specific gravity measuring bench and an operation method thereof. The specific gravity measuring bench comprises an upper bench body and a lower bench body. The upper bench body is provided with a circle of small fixed bottleneck port and three fixing sleeves. A shaking rod is arranged at the opposite side of one of the three fixing sleeves on the upper bench body. The lower bench body is provided with a circle of big fixed bottom port. The lower bench body is also equipped with three fixing solid pipes, the positions of which are corresponding to positions of the three fixing sleeves on the upper bench body. Three supporting legs are arranged below the lower bench body. The specific gravity measuring bench has a simple structure, is easy to operate, is low-cost, and is fast, easy and safe. One-time measurement quantity can be adjusted according to actual situation, and the measurement efficiency is high. Testing speed of the specific gravity measuring bench is 5-10 times faster than testing speed of traditional testing. The specific gravity measuring bench is fast, large in quantity, easy and safe.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Liquid specific gravity measuring equipment

InactiveCN112858092AReduce mistakesImprove efficiencySpecific gravity measurementPower beltEngineering

The invention discloses liquid specific gravity measuring equipment which comprises a base capable of being provided with various mechanisms, as shown in figure 1. A transmission mechanism used for transmitting power is arranged on the upper side of a machine body, the transmission mechanism is provided with a main wheel and an auxiliary wheel, and a conversion mechanism for changing weight into displacement is arranged on the lower side of the machine body. A transfer rod, a hollow column and a liquid suction pipe are arranged in the conversion mechanism, errors existing in measurement are reduced, manual calculation is not needed, the specific gravity of liquid is directly displayed on a display screen, efficiency is improved, the position of a balancing weight on a power belt is adjusted to control the level of equipment to be normally used, the measurement error is further reduced, and the accuracy is greatly improved.

Owner:深圳市北纬零度贸易有限公司

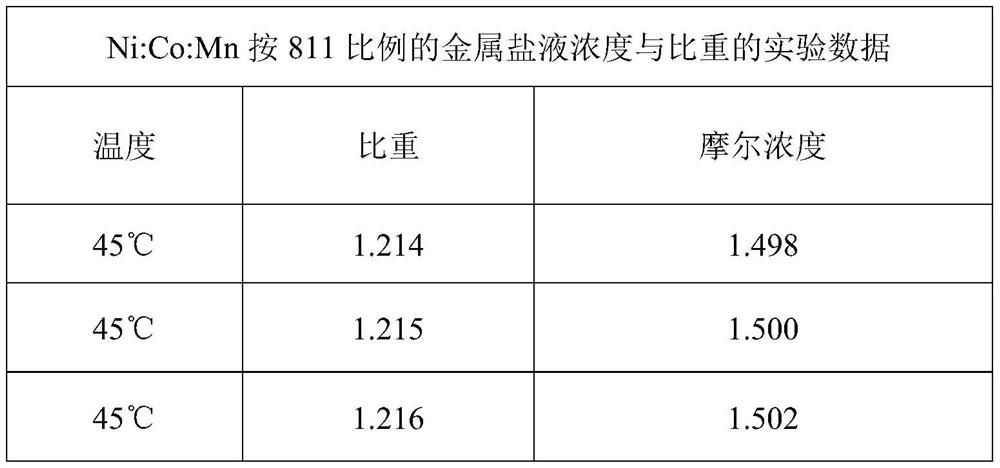

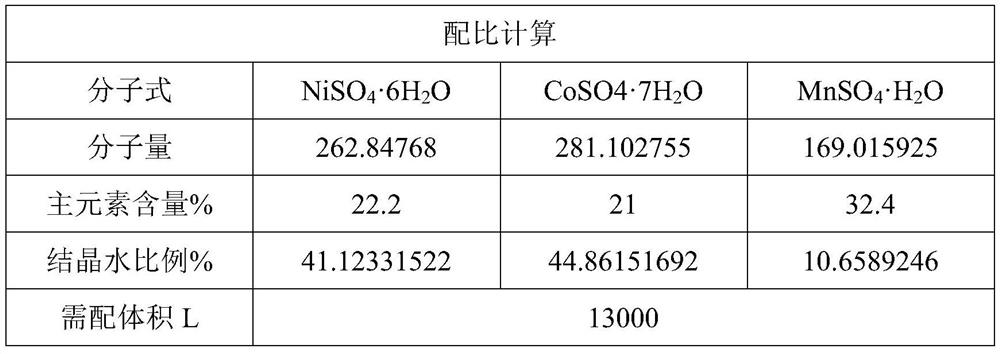

An automatic batching method and a ternary precursor production method for its application

ActiveCN110534694BSmall fluctuationRelatively small errorElectrode manufacturing processesProcess engineeringSalt solution

The invention provides an automatic batching method and a ternary precursor production method applied thereto. The automatic batching method includes the following steps: the raw materials are dissolved separately, and the specific gravity is measured, and the DCS calculates the corresponding weight according to the measured value and the set specific gravity to obtain the water to be replenished, and then automatically replenishes the water, and prepares the raw material liquid with the set specific gravity; Add the three kinds of raw material liquids into the batching device, according to the ratio and concentration of the metal salt liquid to be prepared, control the quality of the three raw material liquids and water added through DCS, stir evenly, and control the temperature to obtain the metal salt solution with the set ratio . The automatic batching method of the present invention dissolves each raw material separately, the fluctuation and relative error of the main content of the raw material and the impurity content are small, and the mass percentage is controlled according to the specific gravity of the raw material liquid, the control is more accurate and stable, and there is no need for negative pressure pipeline transportation, reducing Energy consumption, to maximize the accuracy and stability of ingredients.

Owner:乳源东阳光新能源材料有限公司

Mixed liquid specific gravity detection method, medium, equipment and urine specific gravity detection equipment

The invention relates to a method for detecting the specific gravity of a mixed liquid, a medium, a device and a device for detecting the specific gravity of urine. The method for detecting the specific gravity of the mixed liquid includes: measuring the offset distance between the position where the light irradiates the mixed liquid and the corresponding preset reference position; obtaining the content of each main component in the mixed liquid; The single specific gravity of each main component is obtained by the preset coefficient of each main component; the specific gravity of the mixed liquid is calculated according to the single specific gravity of each main component and the content of each main component. In this way, the specific gravity measurement of the mixed liquid can be realized, the deviation caused by the specific gravity detection using the correlation coefficient of a single substance is avoided, and the detection accuracy is high.

Owner:AVE SCI & TECH CO LTD

Specific gravity measuring apparatus

ActiveUS8806938B2High measurement accuracyLabor of closingMaterial analysis by measuring buoyant forcesMaterial analysis by observing immersed bodiesEngineeringMechanical engineering

A specific gravity measuring apparatus includes a liquid bath, a measured object receiving member which is housed in the liquid bath via a support means in a non-contact manner and into and out of which a liquid within the liquid bath can freely flow, an aerial mounting member which is supported by the support means and on which a measured object is placed in order to measure gravity thereof in the air, and a weighing apparatus receiving and supporting the measured object receiving member via the support means. The weighing apparatus 5 is provided with a sensor and a measuring section. The aerial mounting member is provided in such a manner as to cover a part of an opening O at an upper part of the liquid bath.

Owner:ALFA MIRAGE

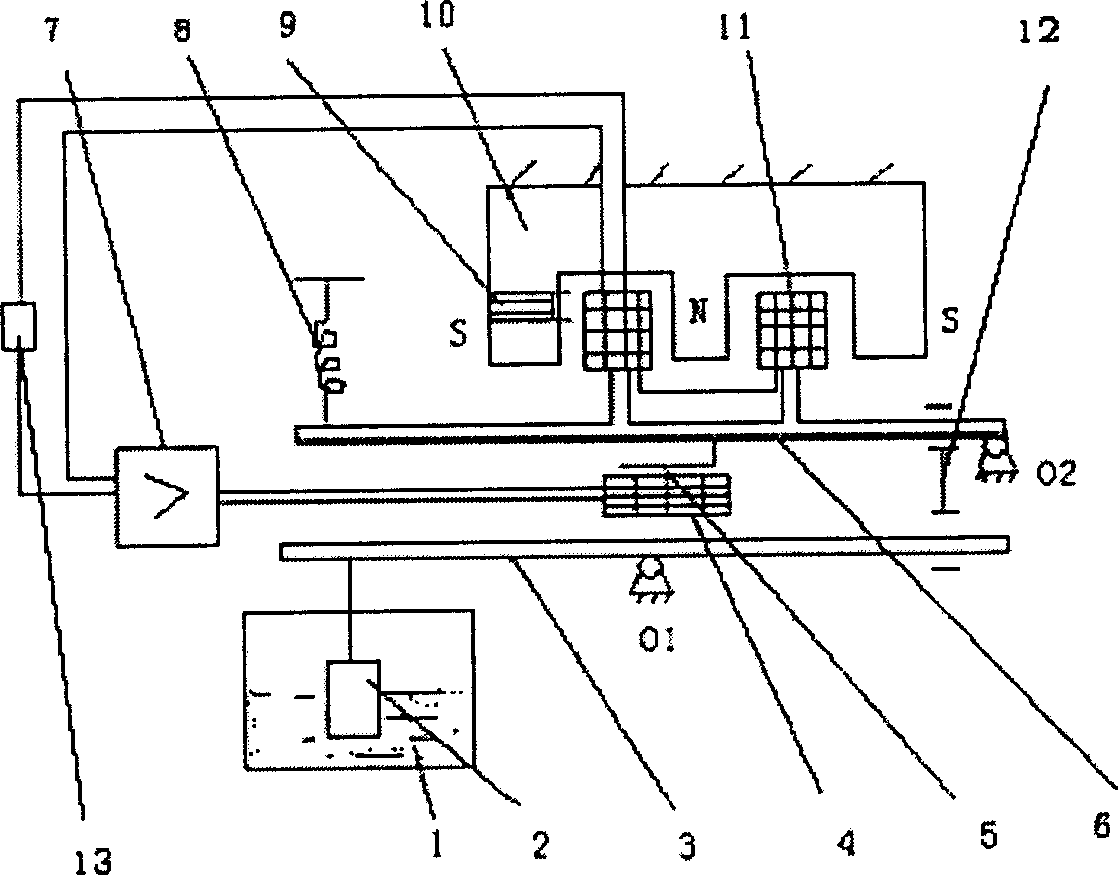

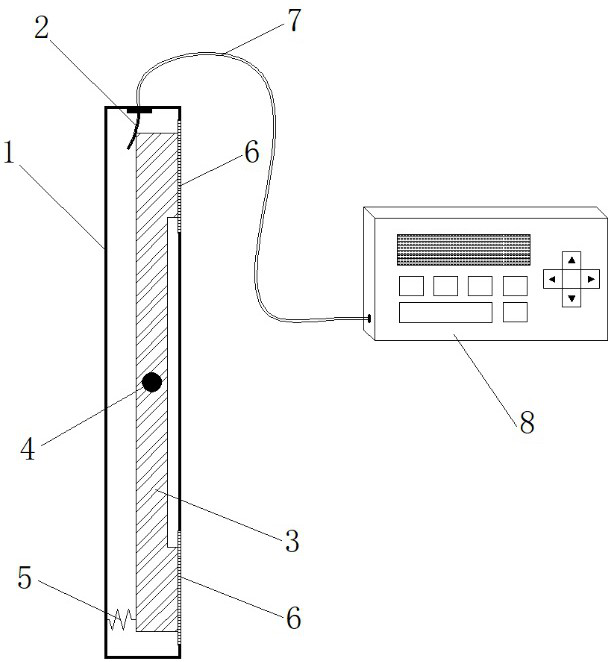

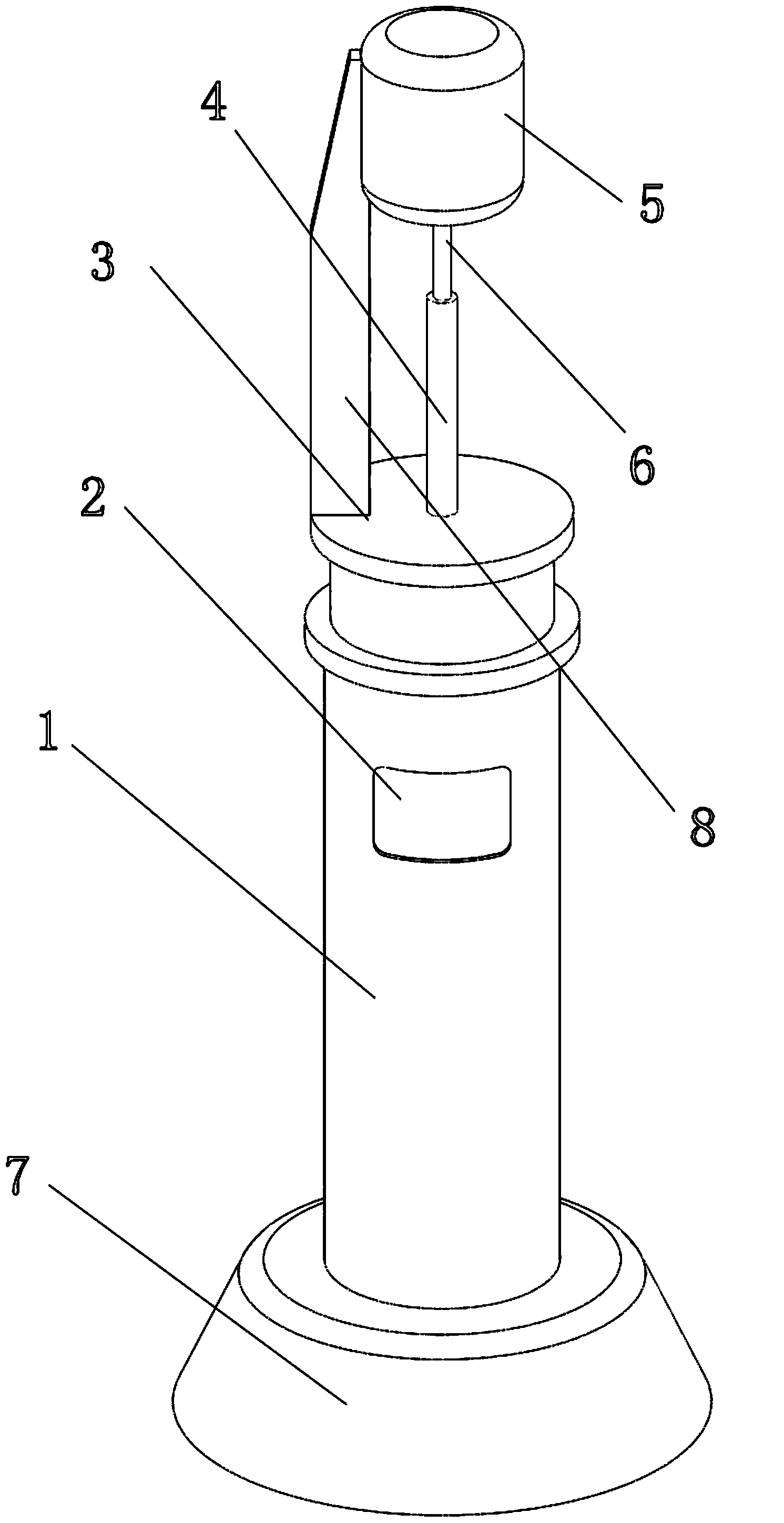

Numerical-control automatic specific gravity measurement device

The invention relates to the technical field of automatic specific gravity measurement, and provides a numerical-control automatic specific gravity measurement device capable of accurately measuring volume and specific gravity of irregular polyhedrons. The numerical-control automatic specific gravity measurement device is characterized in that a weight sensor 7 is mounted on a container 1 and connected with a computer, the container 1 is filled with a right amount of liquid, and a piston 3 is inserted into the container 1; a step used for limiting maximum stroke of the piston is processed on the inner side of the top of the piston 3 or the bottom of the container 1; an axial through hole is formed in the piston 3, a measuring rod 4 is mounted in the through hole, and an electrode is mounted at one end of the measuring rod and connected with the computer; the other end of the measuring rod is processed with an internal thread and is in threaded connection with a screw 6 on a shaft of a stepping motor 5, the stepping motor 5 is mounted on the piston 3 through a support 8, and the stepping motor is connected with a motor controller which is connected with the computer. The numerical-control automatic specific gravity measurement device has the advantages that the device can compute specific gravity of a measured object through measured size and weight; and the specific gravity can be acquired at one step.

Owner:胡达广

Thiodicarb producing equipment

The invention discloses thiodicarb producing equipment. The thiodicarb producing equipment comprises a sulfur dichloride reactor, a thiodicarb synthesis reactor, a specific gravity measurement container and a metering container, wherein a first outlet of the sulfur dichloride reactor is communicated with an inlet of the metering container; a second outlet of the sulfur dichloride reactor is communicated with an inlet of the specific gravity measurement container; a first outlet of the specific gravity measurement container is communicated with an inlet of the sulfur dichloride reactor througha pump; a second outlet of the specific gravity measurement container is communicated with the inlet of the metering container; an outlet of the metering container is communicated with an inlet of thethiodicarb synthesis reactor. According to the thiodicarb producing equipment disclosed by the invention, pungent smell is effectively reduced.

Owner:ZHEJIANG PIONEER CROPSCI CO LTD

Digital system for liquid specific density measurement

InactiveCN100389316CRealize automatic measurement of specific gravityRealize automatic measurementMaterial analysis by observing immersed bodiesAudio power amplifierTransformer

The invention discloses a measuring method for digital liquid specific weight, which comprises the following parts: specific weight measuring device, A / D transformer, digital display circuit or computer; and specific weight measuring device including float posited on one side of main gauge peg, main gauge peg with fulcra in the middle, auxiliary gauge peg, amplifier, permanent magnet, feedback coil; wherein main gauge peg connects with auxiliary gauge peg by link block; transform measuring slice posits on auxiliary gauge peg; transform measuring slice posited below transform measuring device; one side of auxiliary gauge peg has fulcra and the other side has zeroing device; feedback coil which posited in permanent magnet is on auxiliary gauge peg; transform measuring device connects with feedback coil by measuring amplifying circuit.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

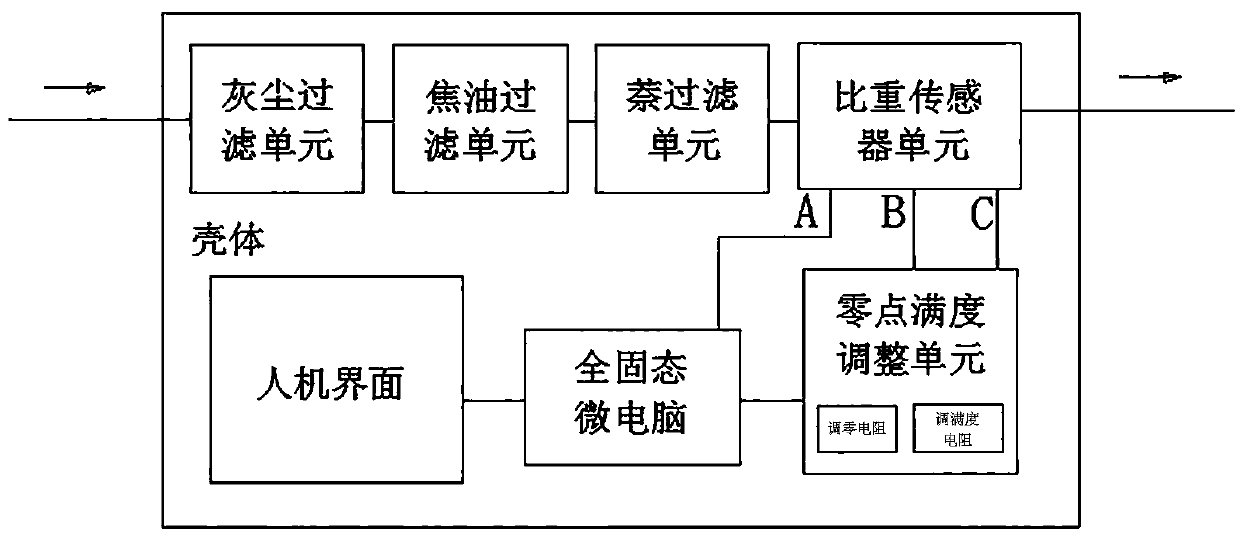

Online specific gravity measuring system of coke oven gas

PendingCN109708994AEfficient removalImprove performanceSpecific gravity measurementGas analysisFull scale

The invention relates to the field of online gas analysis and measurement, in particular to an online specific gravity measuring system of coke oven gas. A dust filtering unit, a tar filtering unit, anaphthalene filtering unit and a specific gravity sensor unit are communicated successively through a pipeline based on a process sequence in a housing. An air inlet end of the dust filtering unit isconnected with a coal gas inlet pipe on the housing; and an air outlet end of the specific gravity sensor is connected with a coal gas outlet pipe arranged at the housing. A zero-regulating resistorand a range-regulating resistor are arranged at a zero-point full scale adjusting unit. During zero point and full scale adjustment, a controller is calibrated intelligently to set an offset value between a specific gravity measuring value and 1 to be a constant and the offset value is compensated into follow-up coke oven gas specific gravity measurement when the specific gravity measuring value of the specific gravity sensor in a no-load state is 0.98 to 1.02. Compared with the prior art, the provided system has the following advantages: impurities like tar, naphthalene, dust, and sulfide areremoved and the reference zero point of the sensor is adjusted automatically and rapidly, so that the need of online and automatic specific gravity measurement of the coke oven gas is met.

Owner:辽宁博镁兴业科技有限公司

Specific Gravity Measuring Tool

InactiveUS20100332178A1Specific gravity using flow propertiesDigital computer detailsElectrical resistance and conductanceDisplay device

A specific gravity measuring tool comprises a portable handheld housing supporting a plurality of electrodes at a fixed known spacing thereon and a display for displaying a determined specific gravity thereon. The electrodes are arranged to be penetrated into the object to be measured, for example a potato. The electrodes include a first pair across which an electrical potential is arranged to be generated, and a second pair across which an electrical potential is arranged to be sensed. A processor of the tool is arranged to calculate electrical impedance using the electrical potential generated across said first pair of the electrodes, the electrical potential sensed at said second pair of electrodes, and the known spacing between the electrodes so that the specific gravity can be determined using a predetermined relationship between electrical impedance and specific gravity.

Owner:BEAULIEU KELLY +1

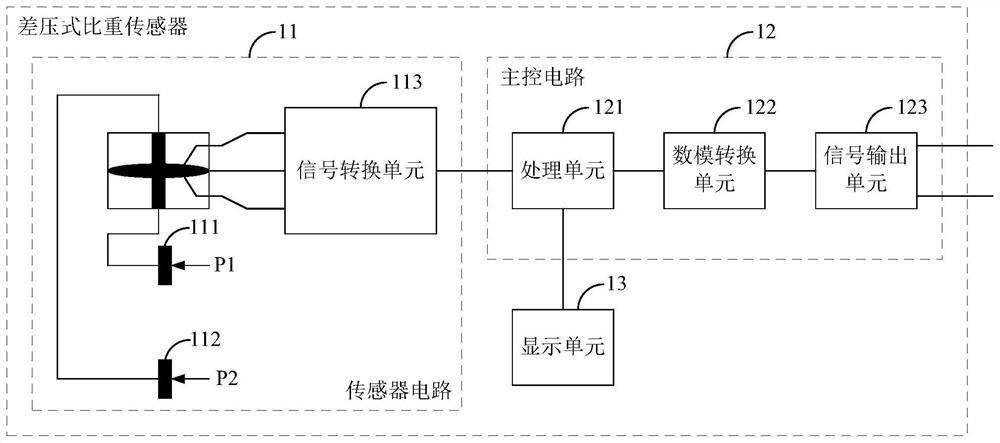

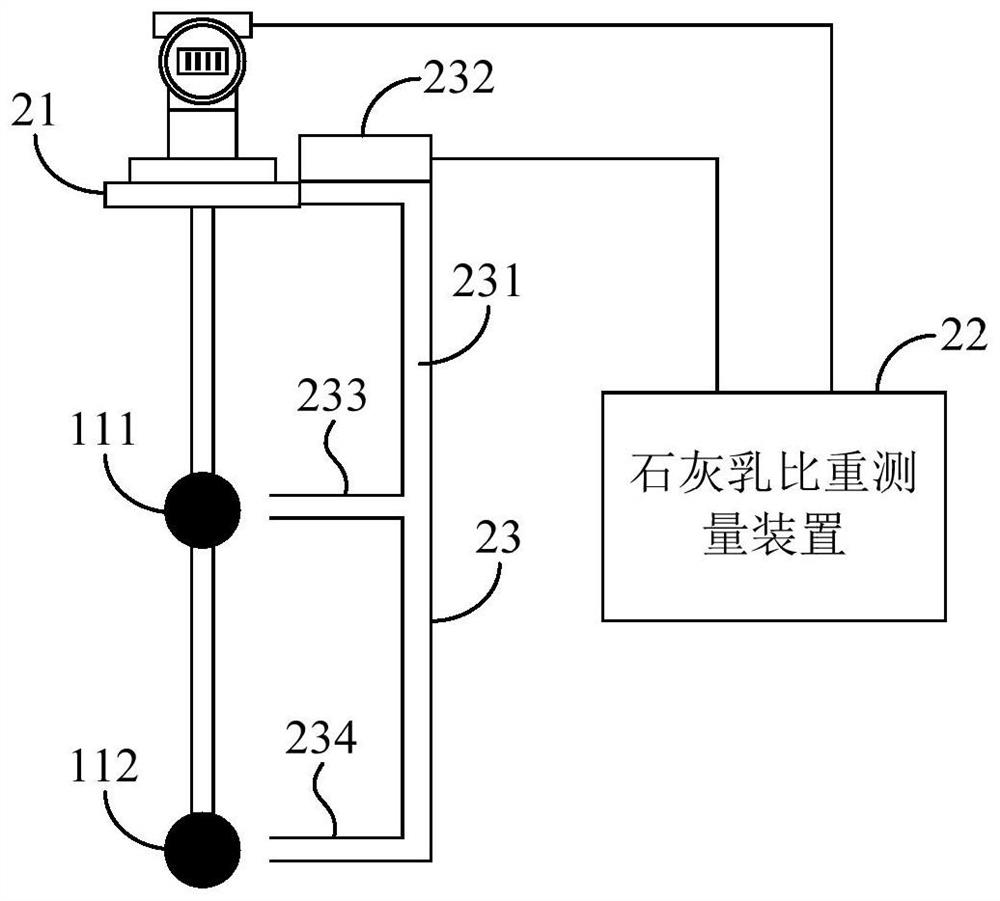

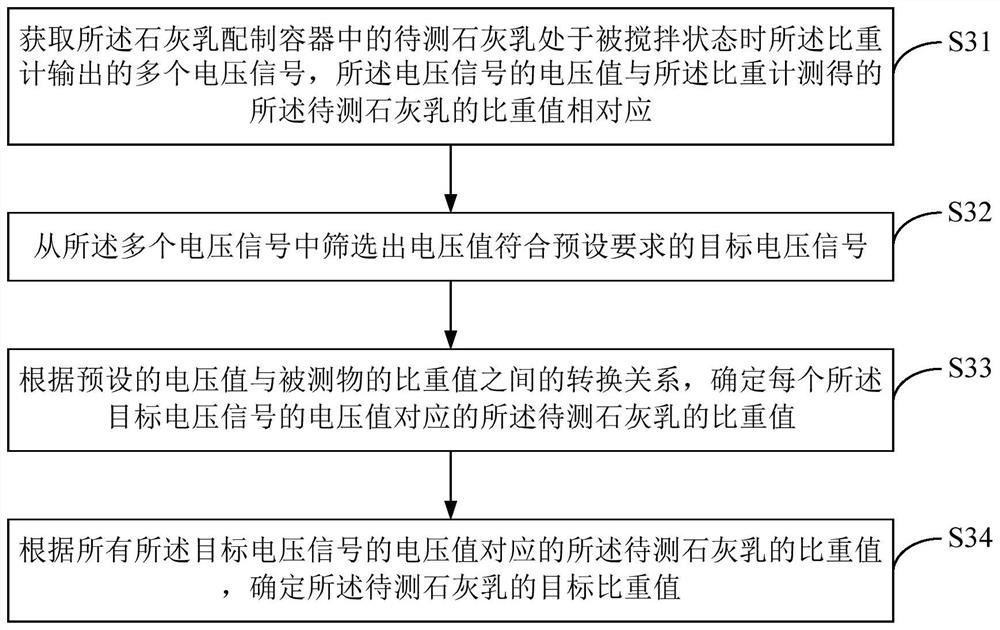

Lime milk specific gravity measuring method, device and system, and computer readable storage medium

PendingCN113640176AAccurate specific gravityAccurate descriptionSpecific gravity measurementHydrometerProcess engineering

The invention is applicable to the technical field of mineral separation key substance detection, and provides a lime milk specific gravity measuring method, device and system and a computer readable storage medium. The method comprises the following steps of: acquiring a plurality of voltage signals output by a hydrometer when to-be-measured lime milk in a lime milk preparation container is in a stirred state, wherein voltage values of the voltage signals correspond to specific gravity values, measured by a hydrometer, of the to-be-measured lime milk; screening out a target voltage signal of which the voltage value meets a preset requirement from the plurality of voltage signals; according to a conversion relation between a preset voltage value and specific gravity values of measured objects, determining the specific gravity value of the to-be-measured lime milk corresponding to the voltage value of each target voltage signal; and determining the target specific gravity value of the to-be-detected lime milk according to the specific gravity values of the to-be-detected lime milk corresponding to the voltage values of all the target voltage signals, thereby improving the accuracy degree of the finally determined target specific gravity value of the to-be-detected lime milk.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿

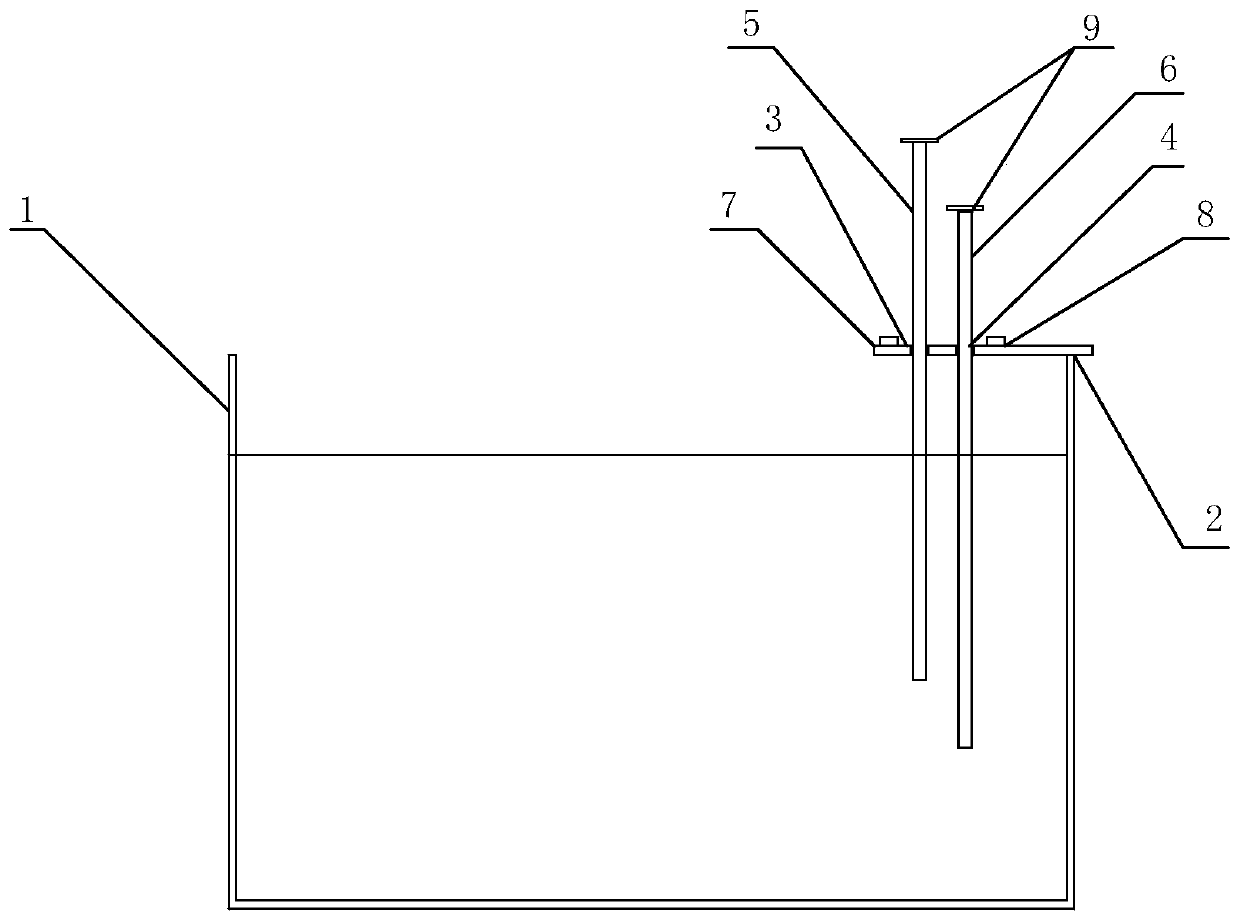

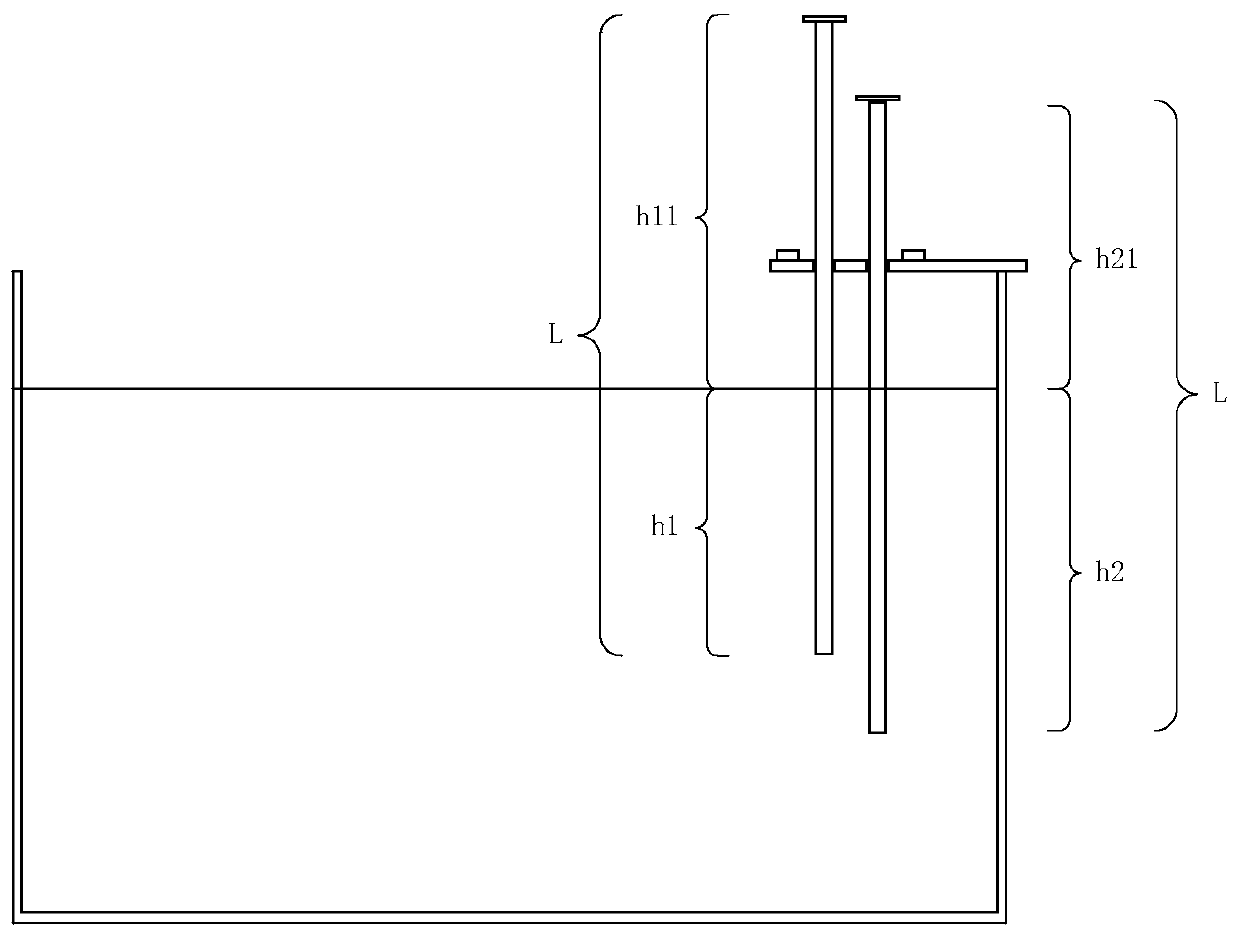

Liquid specific gravity measuring device

PendingCN111443010AImprove work efficiencyMaterial analysis by observing immersed bodiesProgrammable logic controllerEngineering

The invention discloses a liquid specific gravity measuring device. The liquid specific gravity measuring device comprises a measuring platform fixed to a side wall of a container, wherein the measuring platform is provided with a first through hole and a second through hole; a first measuring rod and a second measuring rod which are the same in length and cross section extend into liquid under measurement from top to bottom through the first through hole and the second through hole respectively and freely suspend in the liquid under measurement; a first displacement sensor and a second displacement sensor which are used for detecting vertical movement are arranged beside the first through hole and the second through hole respectively; the weight of the first measuring rod is 1.5-3 times that of the second measuring rod; the first displacement sensor and the second displacement sensor are in signal connection with a PLC (Programmable Logic Controller) control module; and the PLC control module comprises a data acquisition unit, a central processing unit, a storage unit, a power supply unit and a display input unit. Through the adoption of the liquid specific gravity measuring device, the liquid specific gravity can be accurately measured in real time, and the working efficiency is greatly improved.

Owner:杭州开宇环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com