Method for determining fatigue damage degree of metal material based on specific gravity measurement

A metal material, fatigue damage technology, applied in specific gravity measurement, measurement device, analysis material, etc., can solve the problems of inability to apply metal material stretching, difficulty, and difficulty in area measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

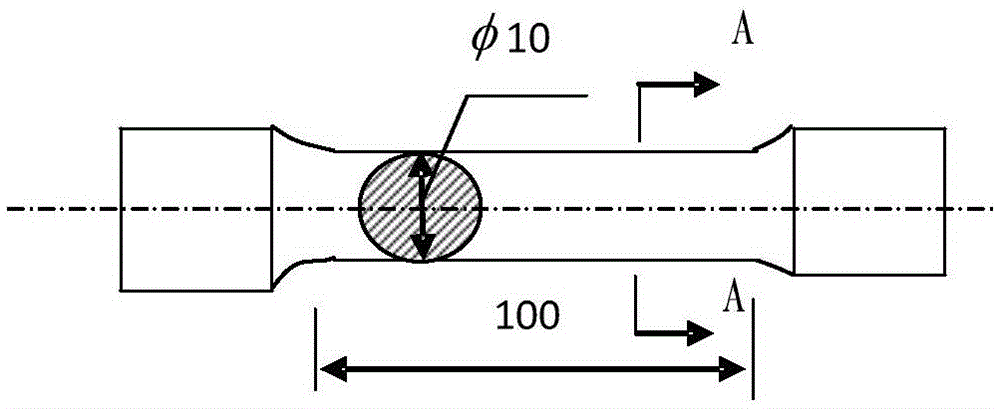

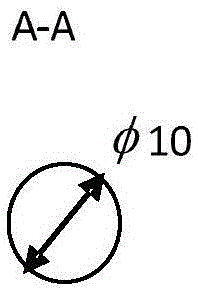

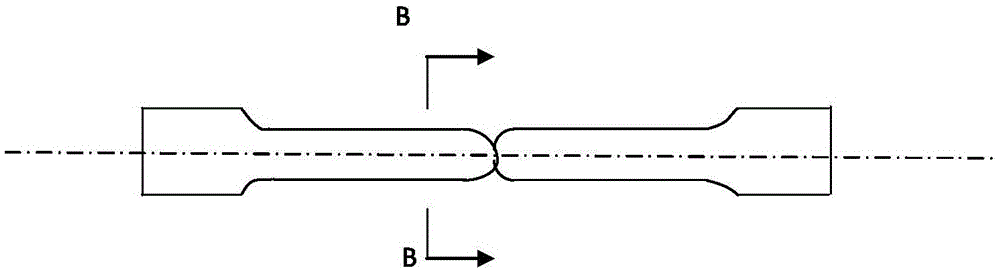

[0120] Such as Figure 1-6 As shown, a method for determining the degree of fatigue damage of metal materials based on specific gravity measurement, this method is a method for testing (testing) material performance:

[0121] step 1:

[0122] Step 1.1: Process the metal material to be tested (specifically, 45# low-carbon steel, namely GB / T699-199945 steel) into 12 standard samples, and the standard samples are diameter φ 1 and a cylindrical sample of length L; N=12; φ 1 is 10mm, L is 100mm; here the diameter φ 1 A cylindrical specimen with a length of L means that the diameter of the middle section of the specimen is φ 1 , the length of the middle section is L;

[0123] Step 1.2: carrying out different degrees of load tests on N standard samples on a tensile testing machine; making the N samples produce tensile deformation;

[0124] Step 1.3:

[0125] The original sample that has not undergone loading and unloading experiments is processed into φ 2 × L 2 Standard cylin...

Embodiment 2

[0153] A method for determining the fatigue damage degree of metal materials based on specific gravity measurement, which is used to test the damage degree of a certain key component in practice (such as a spindle with a large force, etc.),

[0154] For metal materials that have experienced actual deformation after actual use [such as a certain part of a certain machine equipment, which has been used for many years, it is now disassembled, and its fatigue damage is measured and studied, so as to determine the fatigue damage of the rest of the same batch of machines To make an assessment and reference (reference) of the situation, or to test the fatigue resistance of the material of a certain key component by the manufacturer] The method for determining the degree of fatigue damage includes the following steps:

[0155] Step 1.1:

[0156] Raw metal material that has not been used and has not undergone tensile deformation is processed into φ 2 × L 2 Standard cylindrical sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com