An automatic batching method and a ternary precursor production method for its application

A technology of automatic batching and raw materials, applied in the direction of electrode manufacturing, etc., to achieve the effects of stable system control, precise control, and improved product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An automatic batching method, comprising the steps of:

[0035] S1. The raw materials are dissolved respectively: the nickel sulfate raw material is passed through the vibrating screen at a constant speed by the unpacking station and enters the nickel sulfate raw material dissolving tank, the automatic batching program is opened on the DCS interface, and the mass percentage of the solution of the concentrated nickel sulfate is set to 9% (multiple times The corresponding specific gravity at 45°C is 1.2192) in the small test test. The nickel content of nickel sulfate input is 22.15%, and the weight of nickel sulfate input is 6000kg. The automatic batching program of the DCS configuration program calculates according to the corresponding calculation formula and needs to add water 8767kg, actually add 99.7% of water first to get 8740kg, the temperature of the whole process is controlled at 45°C, the stirring speed is 60-80rpm, and stirred for 2.5h. After the time is up, the ...

Embodiment 2

[0039] An automatic batching method, comprising the steps of:

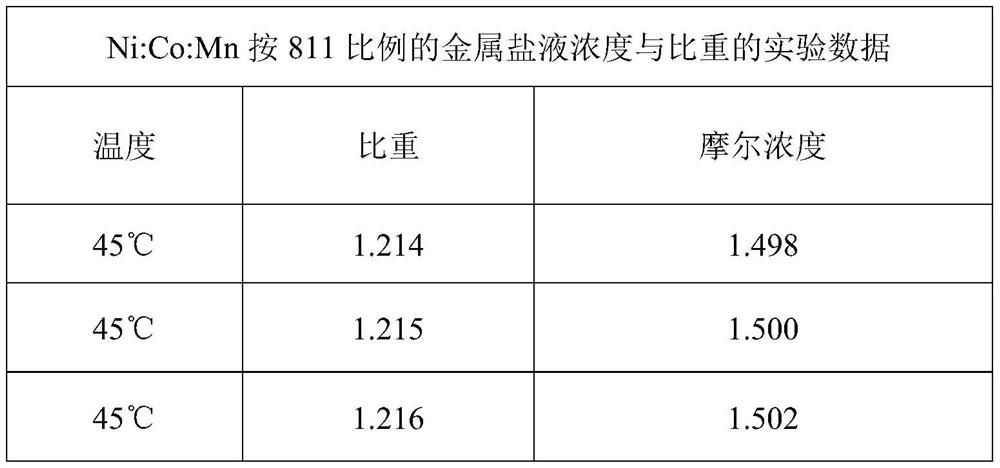

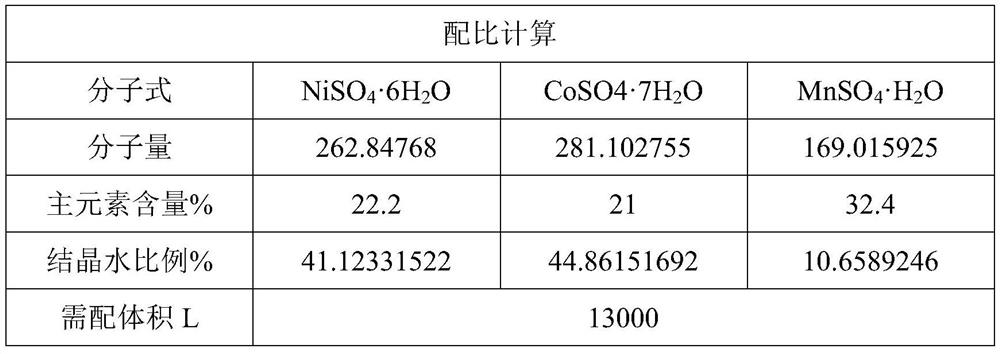

[0040] S1. Raw materials are dissolved separately: the incoming cobalt sulfate, manganese sulfate, and nickel sulfate are sampled and tested to obtain the main element content and impurity content. The impurity content is generally controlled at a low level, as shown in Table 1:

[0041] Table 1

[0042]

[0043] First add a certain amount of pure water or hot water to each raw material dissolution tank, start low-speed stirring, and then pass the qualified cobalt sulfate, manganese sulfate, and nickel sulfate raw materials through the unpacking station, pass through the vibrating screen, and then add them to their respective dissolution tanks , open the automatic batching program on the DCS interface, set the mass percentage of the concentrated nickel sulfate solution to 9% (the corresponding specific gravity is 1.2192 at 45°C measured by multiple small tests and tests), and input the nickel content value of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com