Method for measuring ore grade by hydrometer method

A specific gravity method and ore technology, which is applied in the field of measuring ore grade by the specific gravity method, can solve the problems of long time consumption, consumption of medicines, large wear of laboratory crushers, etc., and achieves the effect of simple operation and time saving.

Inactive Publication Date: 2010-12-29

ANSTEEL GRP MINING CO LTD

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of visual judgment is poor accuracy, and the disadvantage of sampling and testing is that it takes a long time, and when sampling and testing, the ore is made into a testable sample, which requires multiple crushing processes, which wears out the laboratory crusher, and the test consumes medicines and discharges chemicals. Pollution of the environment, two types of work for sample preparation and testing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

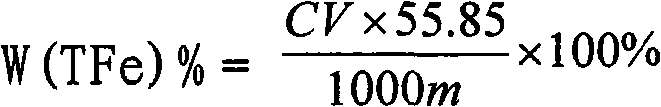

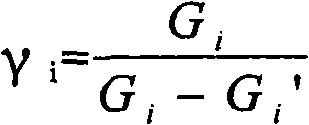

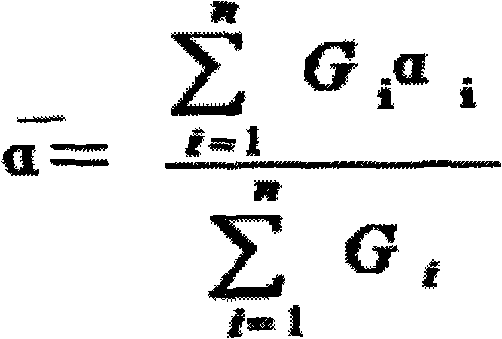

The invention relates to a method for measuring ore grade, in particular to a method for measuring ore grade by a hydrometer method. The method comprises the following steps: sampling and specific gravity measurement: putting each sample ore into a cage, weighing weight G of each sample ore in the air and weight G' of each sample ore in the water with a weighing machine one by one, inputting the weight data into a spreadsheet document set by a computer, working out specific gravity gamma of each sample ore, checking a specific gravity-ore grade curve by utilizing the worked out ore specific gravity so as to obtain the grade of the sample ore, working out grade mean value of the ore sample by the weighting method, comparing the average ore grade with the planned ore grade, finally making judgments on ore grade to indicate whether the sample ore is qualified product or not. The method of the invention has simple operation, environment friendliness, energy conservation, less consumption of materials and devices, safe, fast and accurate measurement of ore grade.

Description

technical field The invention belongs to a method for measuring ore grade, in particular to a method for measuring ore grade by specific gravity method. Background technique In the mine production process, before the ore enters the concentrator for processing, quality inspection is carried out. The usual judgment methods for inspection are: one is visual judgment, and the other is sampling and testing. The naked eye judgment is mainly based on the work experience of the inspector to judge whether the grade of the incoming ore in the stope meets the standard according to the situation of the miscellaneous stones. Sampling and testing is to send the sample to the sample preparation room for sample preparation and then to the laboratory for testing after sampling, and judge according to the test results. The steps are as follows: 1) Sampling: 1.1) Depending on the size of the ore in the car body, the amount and distribution of miscellaneous rocks, select a representative ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N1/04G01N9/08

Inventor 陈志华李荣波孙德明刘兴惠孙胜义吴焕庭王志春

Owner ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com