Method for repairing aircraft fuel system aluminum silicon alloy shell casting defects

A fuel system, aluminum-silicon alloy technology, applied in aircraft parts, transportation and packaging, etc., can solve the problems of high processing difficulty, holes, shell cracks, etc., and achieve the effect of avoiding large heat input and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

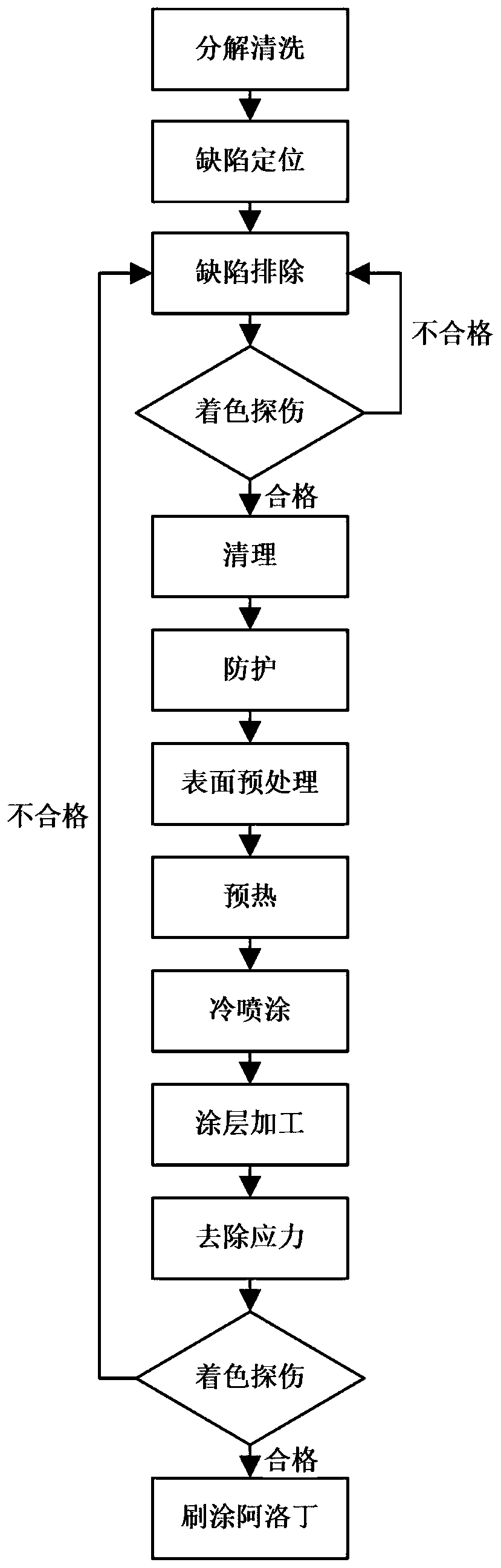

[0036] like figure 1 As shown, a method for repairing casting defects of an aluminum-silicon alloy shell of an aircraft fuel system is characterized in that: its specific steps are as follows:

[0037] S1: Decomposition and cleaning: decompose the auxiliary structure on the shell into the smallest repair unit that cannot be decomposed, and clean the shell with an organic solvent after decomposition, so as to avoid the residual fuel in the internal pipeline and inner hole of the shell from affecting subsequent repairs ;

[0038] S2: Defect location and elimination: use coloring penetration to locate the defect, mark the defect position with a marker pen after positioning, and remove the paint / plating layer around the area to be repaired by blowing plastic particles or quartz sand larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com