Welding method for manufacturing jet pump by using ultra-low carbon austenitic stainless steel

A technology of carbon austenite and welding method, which is applied in the field of welding of ultra-low carbon austenitic stainless steel to make jet pumps, to achieve the effects of avoiding intergranular corrosion, controlling overall deformation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

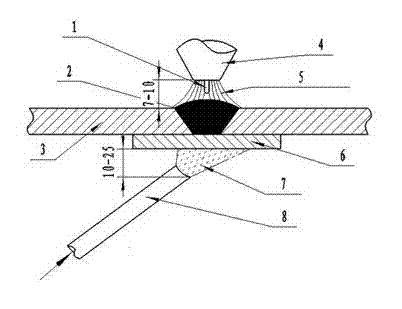

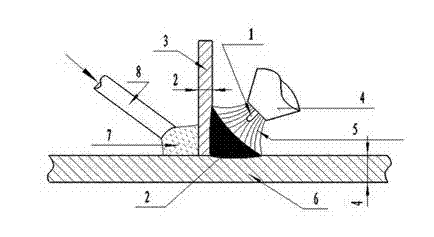

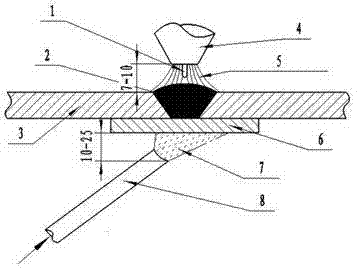

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] This embodiment is a welding method for making a jet pump with ultra-low carbon austenitic stainless steel. Because the jet pump is a pipe body rolled by plates, and then welded by pipe body and pipe body fillet welds and flat welds, the welding method of the present invention is:

[0011] 1. Use manual tungsten argon arc welding, hand-held welding torch, welding and cooling water cooling at the same time, welding on one side, and cooling the weld with cold water on the other side, the water cannot directly contact the molten pool, the amount of cold water should be large, and the welding temperature should be low At 80°C, the welding speed is above 45-50cm / min, and the weld seam in contact with the corrosive medium is welded last. The temperature of the weldment drops to room temperature within 2 seconds after the arc is closed, and the thickness of the weldme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com