Drum brake

A technology of drum brakes and brake drums, which is applied to the types of brakes, brake components, brake parts, etc., can solve the problems of short service life of friction plates, increased maintenance costs, and damage to brake drums, etc., to achieve increased frictional braking The effect of power, prolonging service life and reducing maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

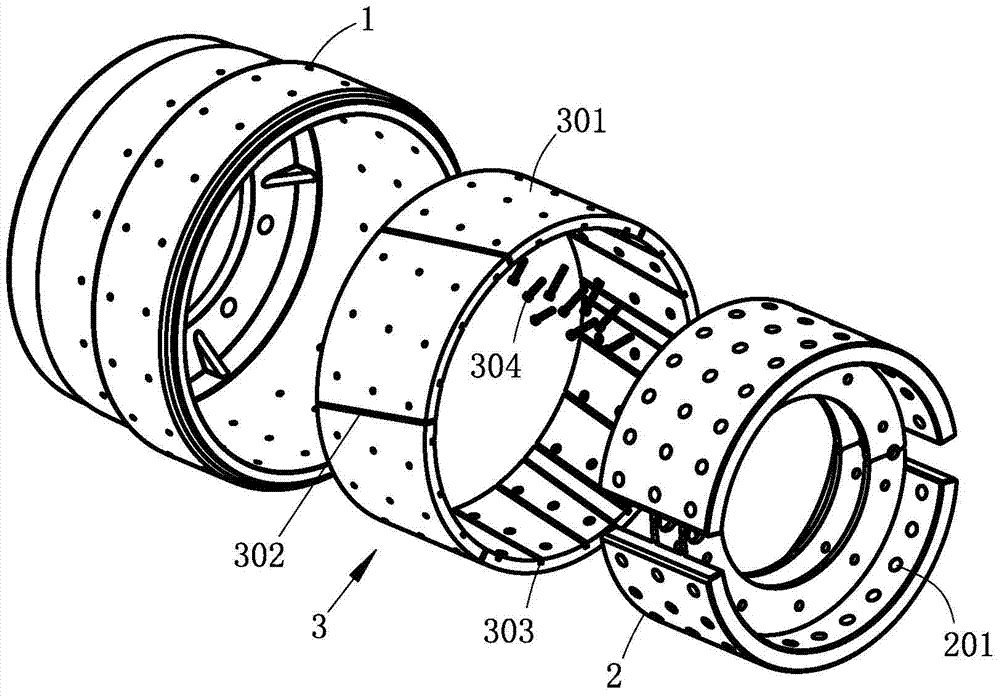

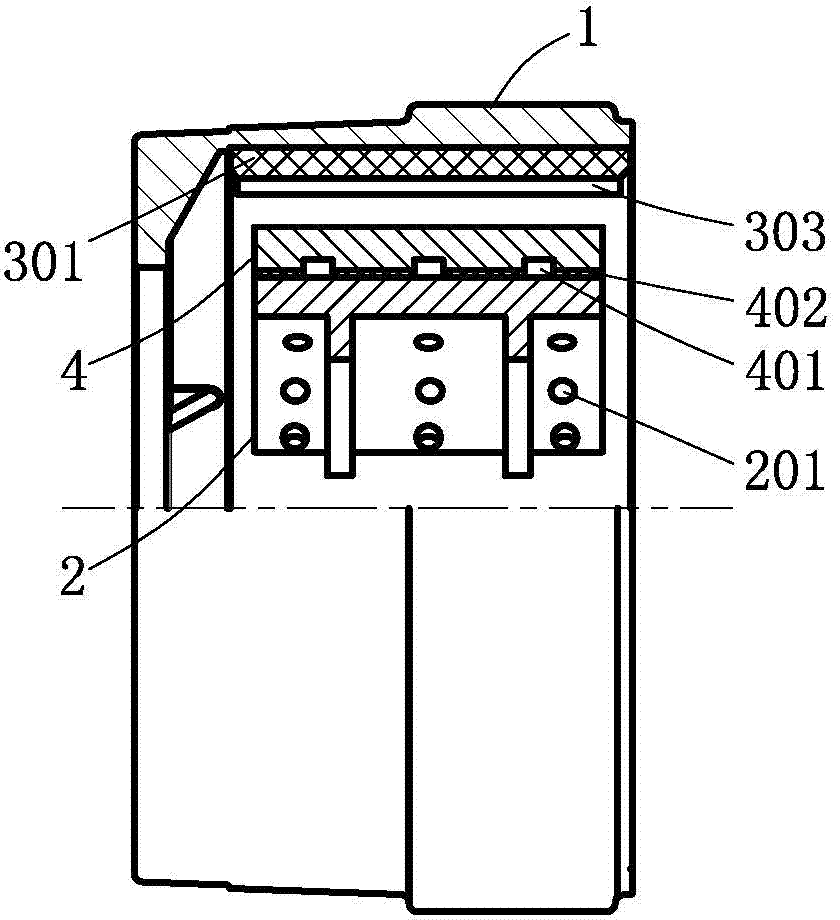

[0035] Such as figure 1 As shown, the present invention provides a drum brake, including a brake drum 1, a friction plate 3 and a brake shoe 2, the friction plate 3 is fixedly installed on the inner side of the brake drum 1, and the inner surface of the friction plate 3 forms a friction On the other hand, there are many ways to fix the friction plate 3 and the brake drum 1 , which can be connected by screws 304 , rivets, or other forms of fixing, which are not limited here.

[0036] The main concept of the present invention is to fix the friction plate 3 on the inner side of the brake drum 1, changing the traditional structure of fixing the friction plate 3 on the brake shoe 2, and blocking the heat from the friction plate 3 during friction braking. Transfer to the brake drum 1, avoiding various hazards caused by the thermal deformation of the brake drum 1. Moreover, the use area of the friction plate 3 is increased, the wear of the friction plate 3 is reduced, and the serv...

Embodiment 2

[0039] Such as figure 1 As shown, the present invention provides a drum brake, the structure of which is basically the same as that of Embodiment 1, including a brake drum 1, a friction plate 3 and a brake shoe 2, and the friction plate 3 is fixedly installed on the inner side of the brake drum 1 , The inner surface of the friction plate 3 forms a friction surface. The inventor has done further research. The friction plate 3 is divided into several friction plate monomers 301. A gap 302 is provided between two adjacent friction plate monomers 301. The gap 302 is set obliquely. The inclined setting refers to the gap 302 The extension direction forms an included angle with the extension direction of the bus bar of the friction disc 3, and the size of the included angle is not limited here. Since the material of the friction disc 3 itself is relatively soft, it does not affect the brake shoes 2 and other braking components during braking. Cutting force will be generated and brak...

Embodiment 3

[0041] Such as figure 1As shown, the present invention provides a drum brake, the structure of which is basically the same as that of Embodiment 1, including a brake drum 1, a friction plate 3 and a brake shoe 2, and the friction plate 3 is fixedly installed on the inner side of the brake drum 1 , The inner surface of the friction plate 3 forms a friction surface. The inventor has done further research. The inner surface of the friction plate 3 is provided with a number of grooves 303. One end of the groove 303 can be opened and the other end can be blocked. Each groove 303 can also be connected to the two end surfaces of the friction plate 3. The groove 303 is arranged obliquely. The oblique setting means that the extending direction of the groove 303 forms an included angle with the extending direction of the busbar of the friction plate 3. The angle is not limited here. For the same reason, the friction plate 3 has The groove 303, because the material of the friction plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com