Composite molded body with a layer of a copolymer of tetrafluoroethylene and perfluoro(ethyl vinyl ether)

A technology of ethyl vinyl ether and tetrafluoroethylene, which is applied in coatings, layered products, chemical instruments and methods, etc., can solve problems not seen in etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

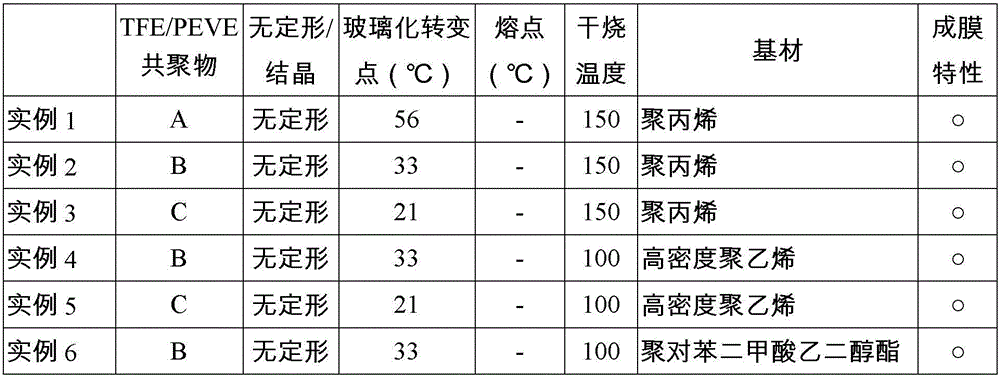

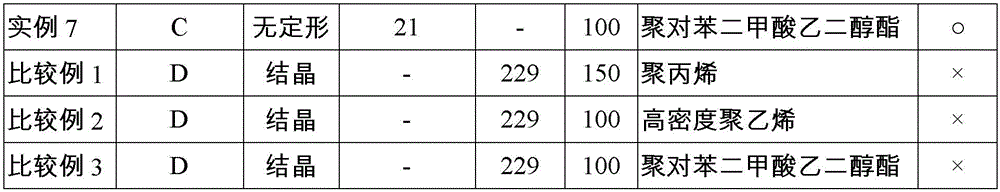

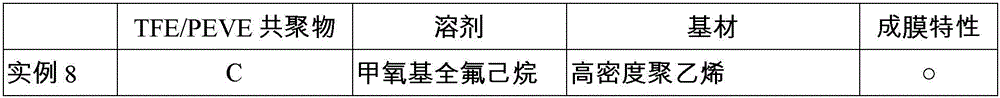

Examples

example

[0057] The present invention will be described in further detail below through examples and comparative examples, but the present invention is not meant to be limited to these examples. Measuring methods of physical properties and raw materials used in the present invention are as follows.

[0058] A. Physical Property Measurement

[0059] Melting point (melting peak temperature)

[0060] A differential scanning calorimeter (Pyris 1 type DSC, Perkin Elmer) was used. Weigh 10mg of the sample and place it in the aluminum pan prepared for the current device, after crimping it with the crimper prepared for the current device, put it in the main body of the DSC, and set its temperature at a rate of 10°C / min The rate was increased from 100°C to 300°C. The melting peak temperature (Tm) was calculated from the melting curve obtained at that point.

[0061] (2) Glass transition point

[0062] As a measuring instrument, a dynamic viscoelasticity tester manufactured by Rheomet...

preparation example 1

[0072] Preparation example 1-preparation of TFE / PEVE copolymer A

[0073] 2400 mL of deionized water was degassed in a 1 gallon (3.8 L) reaction vessel with a horizontal stirring paddle by purging with exhaust gas and nitrogen. At atmospheric pressure, 5.3 g ammonium perfluorooctanoate (APFO, CF 3 (CF 2 ) 6 COONH 4 ) was added to the reaction vessel. The stirrer was run at 150 rpm and the temperature was raised to 85 °C, then the valve corresponding to the ethane tank was opened and ethane was supplied to the reaction vessel until the reaction vessel pressure rose to 0.03 MPa. Then, 140 g of PEVE was supplied to the reaction vessel. Then, the reaction vessel was pressurized to 2.06 MPa by TFE. Next, add 40 mL of 1.3 g / L ammonium peroxodisulfate (APS, (NH 4 ) 2 S 2 o 8 )) aqueous solution. After the reaction started (0.03 MPa pressure drop could be observed), the same initiator solution was supplied at a rate of 0.5 mL / min, PEVE was supplied at 1.8 g / min, and TFE w...

preparation example 2-

[0075] Preparation example 2-preparation of TFE / PEVE copolymer B

[0076] A TFE / PEVE copolymer was prepared in the same manner as in Preparation Example 1 above, except that the supply amount of PEVE before starting the polymerization was made 210 g, and the supply rate of PEVE after starting the reaction was made 1.4 g / min. The solid content ratio of the dispersion liquid was 20% by weight. pass 19 The composition of the product resin measured by F-NMR was TFE / PEVE=63 / 37 by weight. The melting point of the crystals was not checked by DSC. The glass transition temperature is 33°C. The melt flow rate (MFR) measured under a weight of 5 kg and at a temperature of 250° C.±0.1 was 29 g / 10 min according to ASTM D1238.

[0077] The obtained TFE / PEVE copolymer is considered to be TFE / PEVE copolymer B, and the dispersion is considered to be a dispersion of TFE / PEVE copolymer B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com