A kind of vacuum freeze-drying processing method of white onion quilt

A technology of vacuum freeze-drying and processing method, which is applied in the fields of food preservation, fruit and vegetable preservation, food science, etc., can solve the problems of physical health threat, spoilage, deterioration of the color of onions, etc., and achieves easy preservation, little damage, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

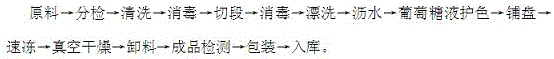

Method used

Image

Examples

Embodiment 1

[0028] Take 200kg of white onion quilts that are fresh, disease-free, without withered yellow, without damage, without pesticide residues, without pollution, and white in color, and select qualified raw materials according to the raw material acceptance method (pay attention to removing inclusions), rinse with running water, wash Remove surface sediment. After soaking in 200PPM sodium hypochlorite for 12 minutes for disinfection, use a slicer to cut shallots into 4mm slices, soak in 200PPM sodium hypochlorite for 5 minutes for primary disinfection, then soak in 150PPM sodium hypochlorite for 5 minutes for secondary disinfection, and finally soak in 50PPM sodium hypochlorite Disinfect three times in 5 minutes. After the sterilized product is washed 3 times with running water, it is installed in a drain net to drain. Use 16% glucose solution boiled to 80°C to cool to 10-15°C, then add 0.9 kg of 16% glucose solution to 4 kg green onions per plate to stir and protect the color, s...

Embodiment 2

[0030] Take 300kg of white onion quilts that are fresh, disease-free, without withered yellow, without damage, without pesticide residues, without pollution, and white in color, and select qualified raw materials according to the raw material acceptance method (pay attention to removing inclusions), rinse with running water, wash Remove surface sediment. After soaking in 300PPM sodium hypochlorite for 10 minutes for disinfection, cut into 4.5mm shallots with a slicer, soak in 200PPM sodium hypochlorite for 5 minutes for primary disinfection, then soak in 150PPM sodium hypochlorite for 5 minutes for secondary disinfection, and finally use 50PPM sodium hypochlorite Soak for 5 minutes for three disinfections. After the sterilized product is washed 3 times with running water, it is installed in a drain net to drain. Use 20% glucose solution boiled to 80°C to cool to 10-15°C, then add 1 kg of 20% glucose solution to 4.5 kg green onions per plate to stir and protect the color, spre...

Embodiment 3

[0032] Take 400kg of white onion quilts that are fresh, disease-free, yellow-free, damage-free, pesticide-free, pollution-free, and white in color, and select qualified raw materials according to the raw material acceptance method (pay attention to removing inclusions), rinse with running water, wash Remove surface sediment. After soaking in 400PPM sodium hypochlorite for 8 minutes for disinfection, use a slicer to cut into 5mm shallots, soak in 200PPM sodium hypochlorite for 5 minutes for primary disinfection, then soak in 150PPM sodium hypochlorite for 5 minutes for secondary disinfection, and finally soak in 50PPM sodium hypochlorite Disinfect three times in 5 minutes. After the sterilized product is washed 3 times with running water, it is installed in a drain net to drain. Use 24% glucose solution boiled to 80°C to cool to 10-15°C, then add 1.1 kg of 24% glucose solution to 5 kg green onions per plate to stir and protect the color, spread the color-protected evenly into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com