Patents

Literature

61results about How to "Not prone to short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

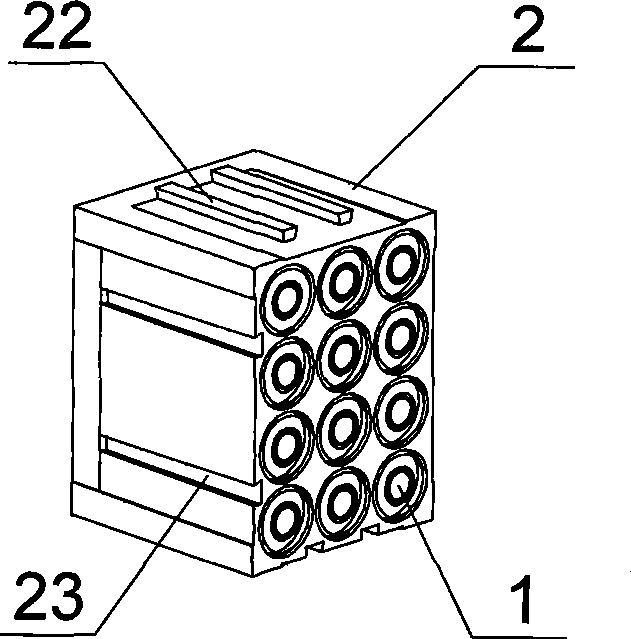

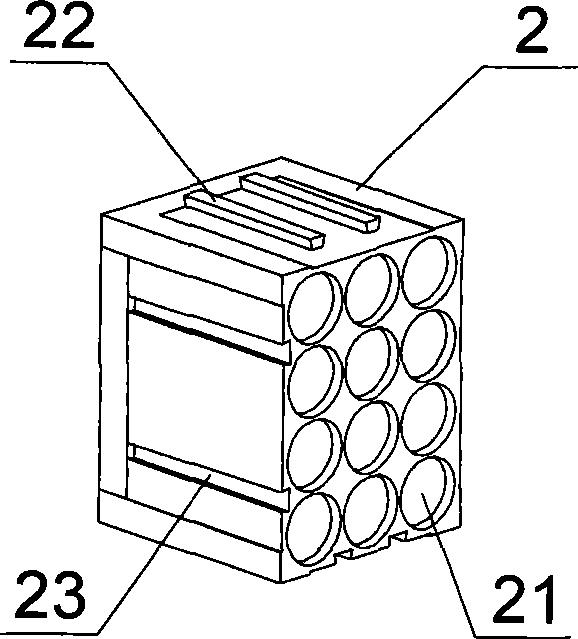

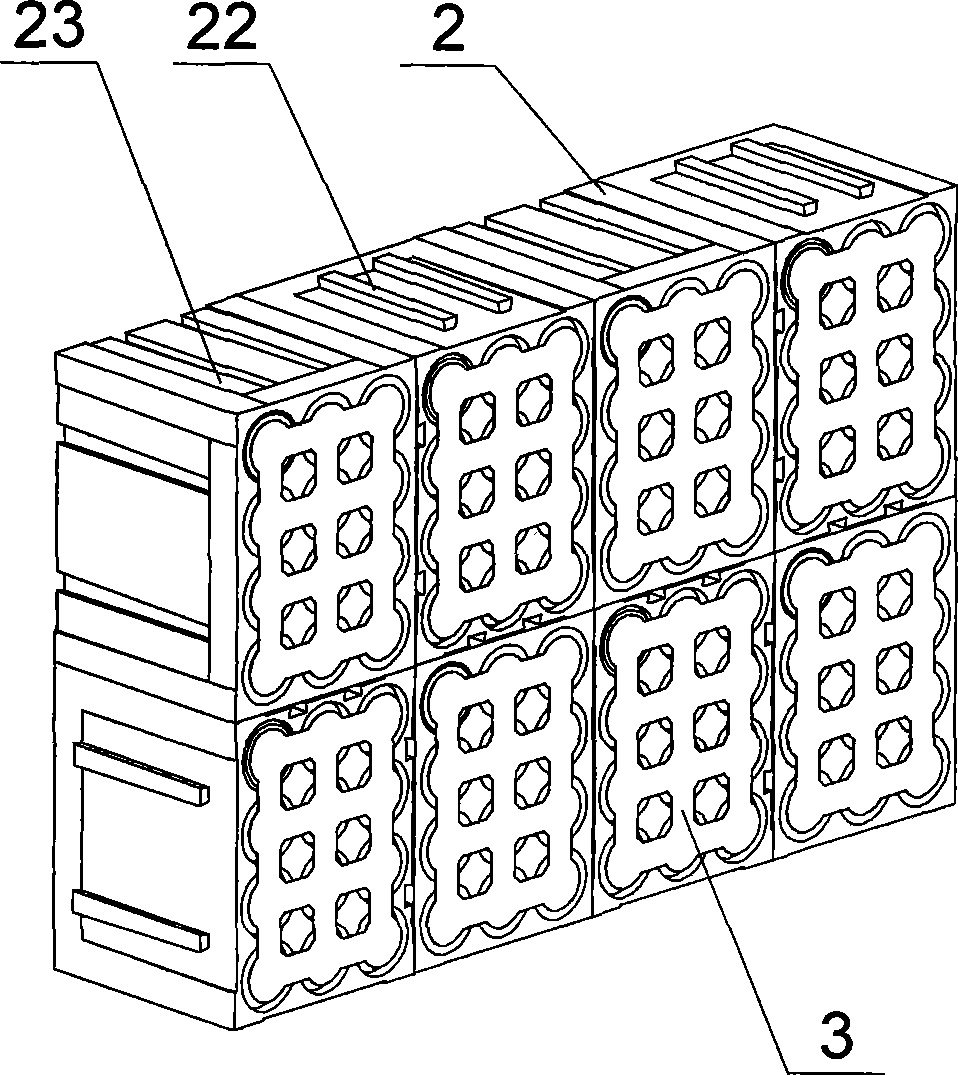

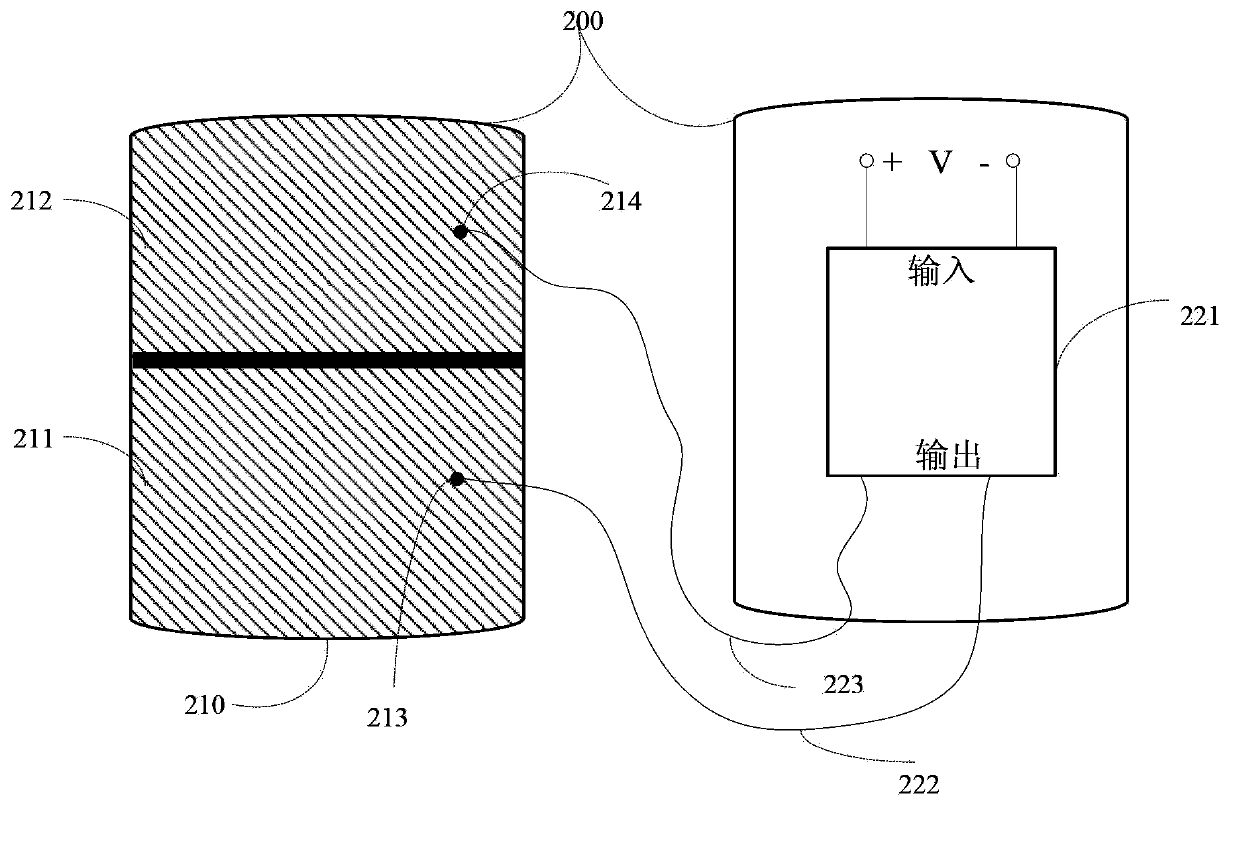

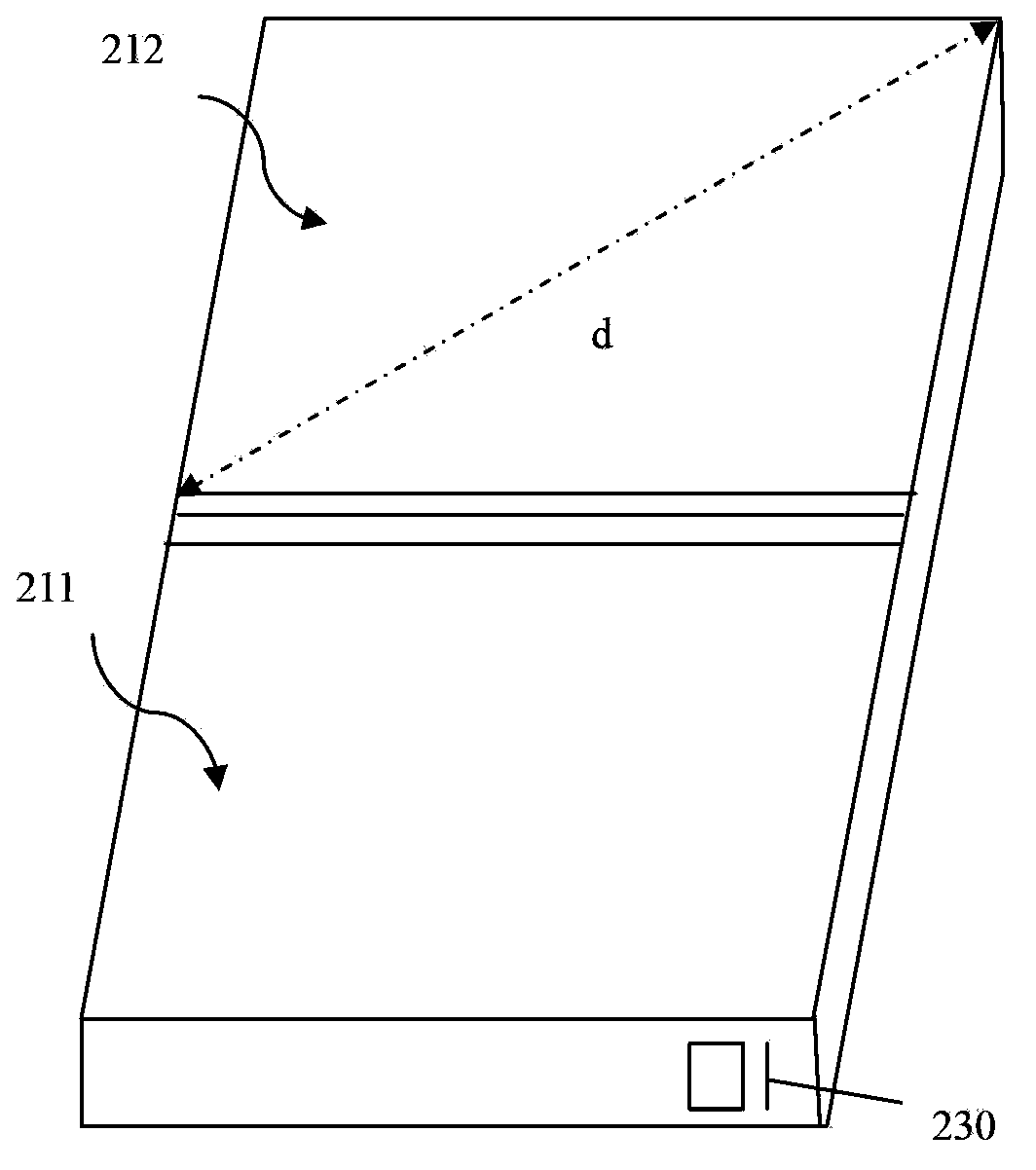

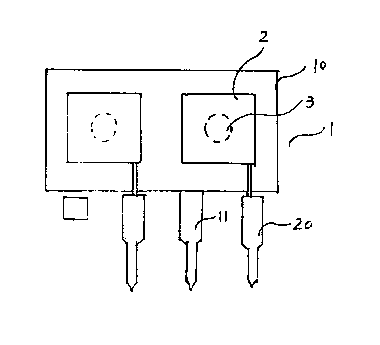

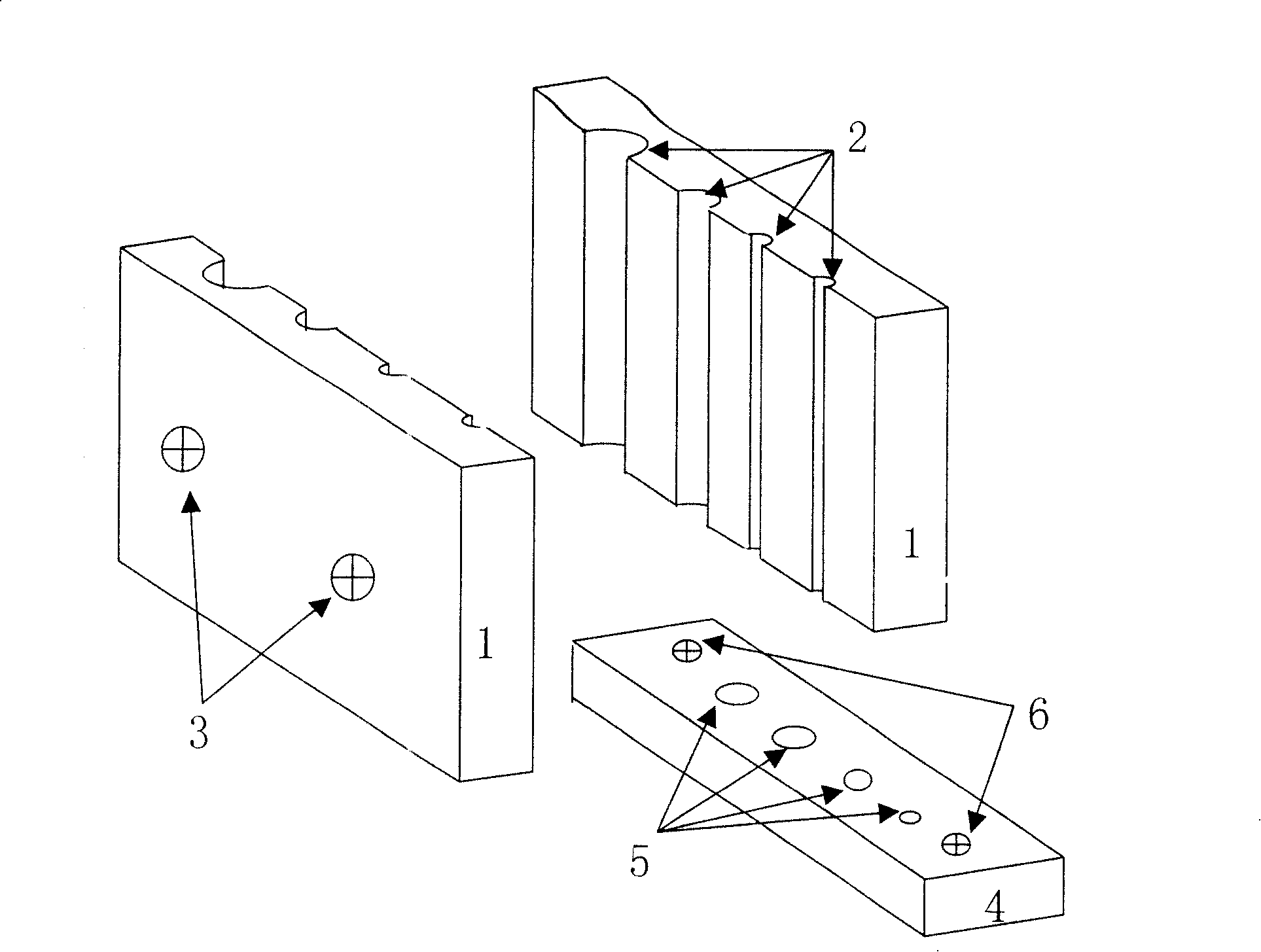

Lithium ionic cell module and cell set

ActiveCN101504973AAvoid feverAvoid fireSecondary cellsCell component detailsEngineeringLithium-ion battery

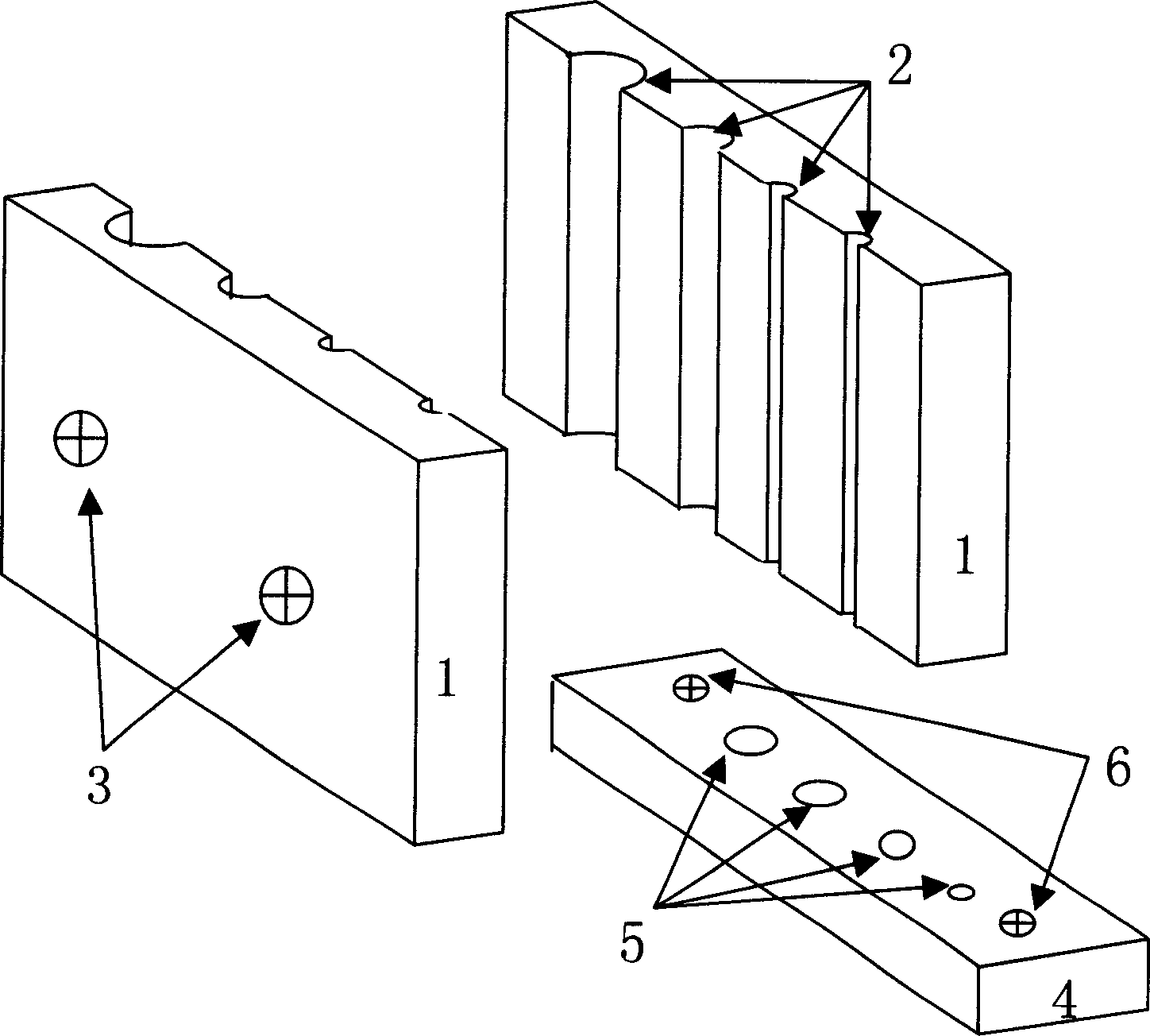

The invention discloses a lithium ion battery module with simple structure, high safety and good reliability, and a battery pack comprising the lithium ion battery module. The lithium ion battery module comprises monomer rechargeable lithium ion batteries (1) and a shell (2) made from a high-temperature resistant strong-toughness flame retardant material, wherein through holes (21) are formed between a front bottom surface and a back bottom surface of the shell (2) and are arranged in arrays, and each through hole is fixed provided with one of the monomer rechargeable lithium ion batteries (1). The lithium ion battery module and the battery pack can be widely applied to the field of power supplies.

Owner:珠海市嘉德电能科技有限公司

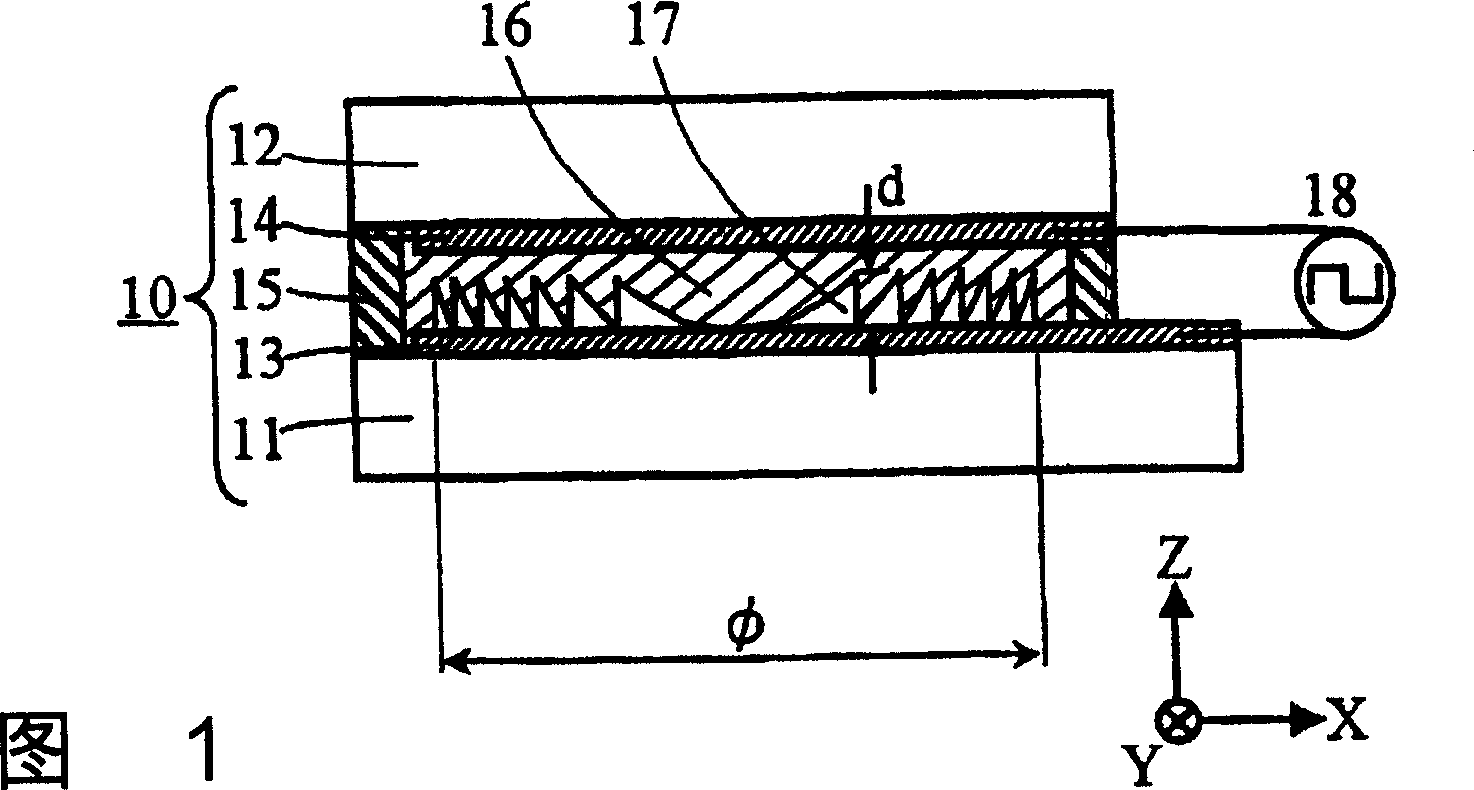

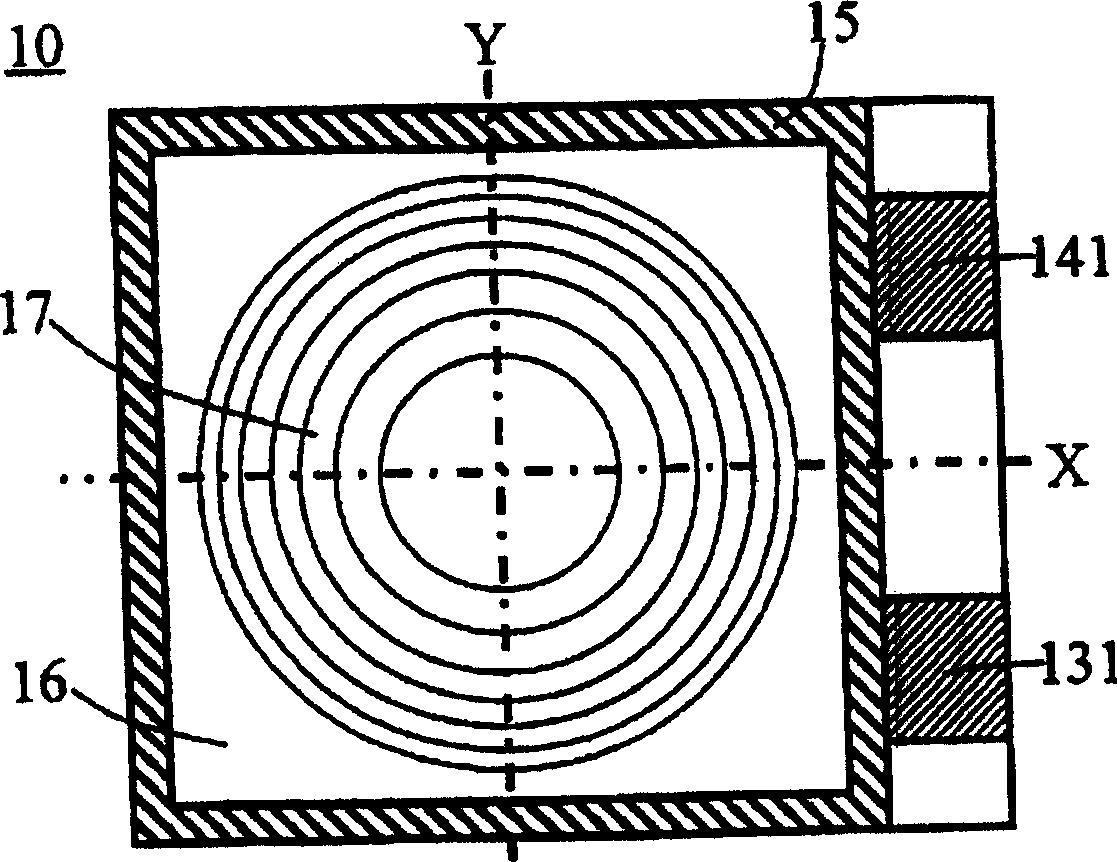

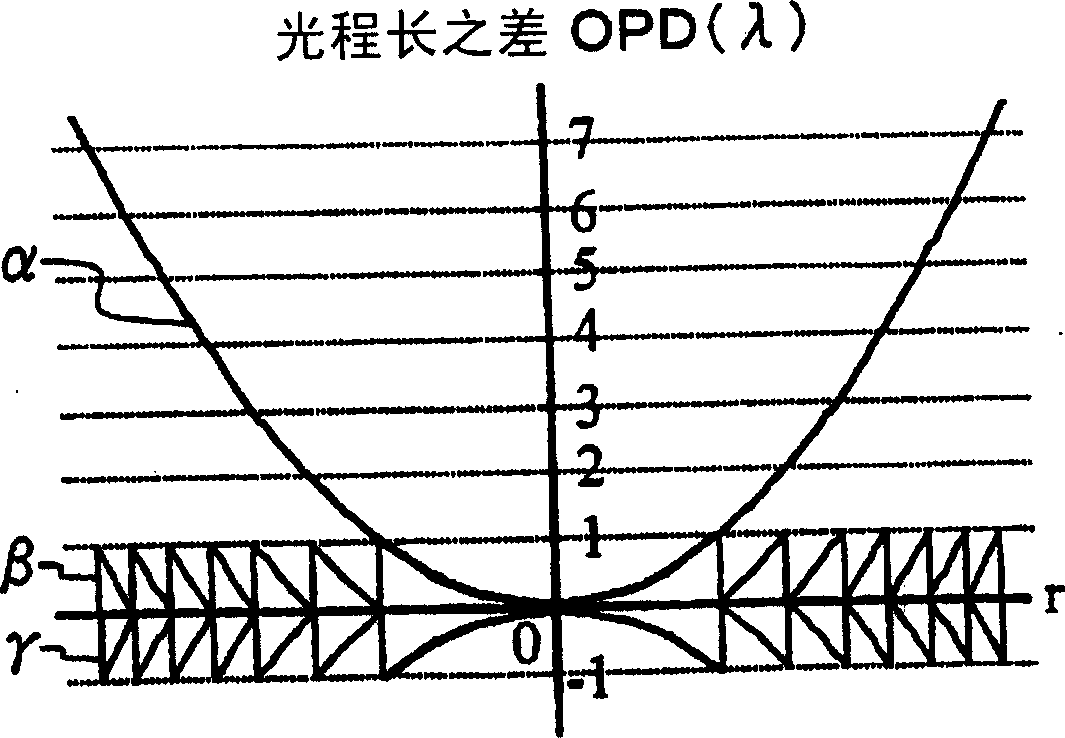

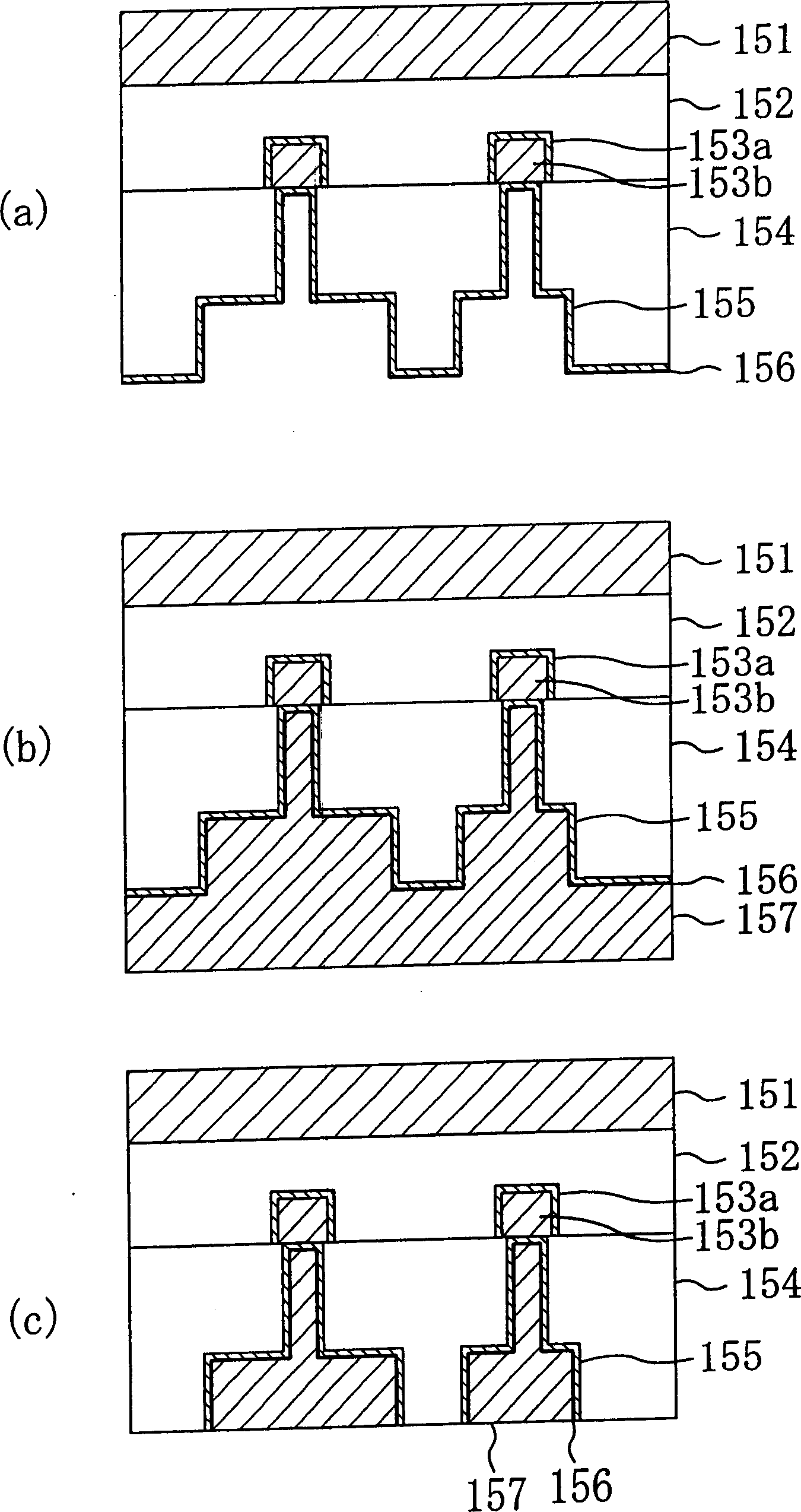

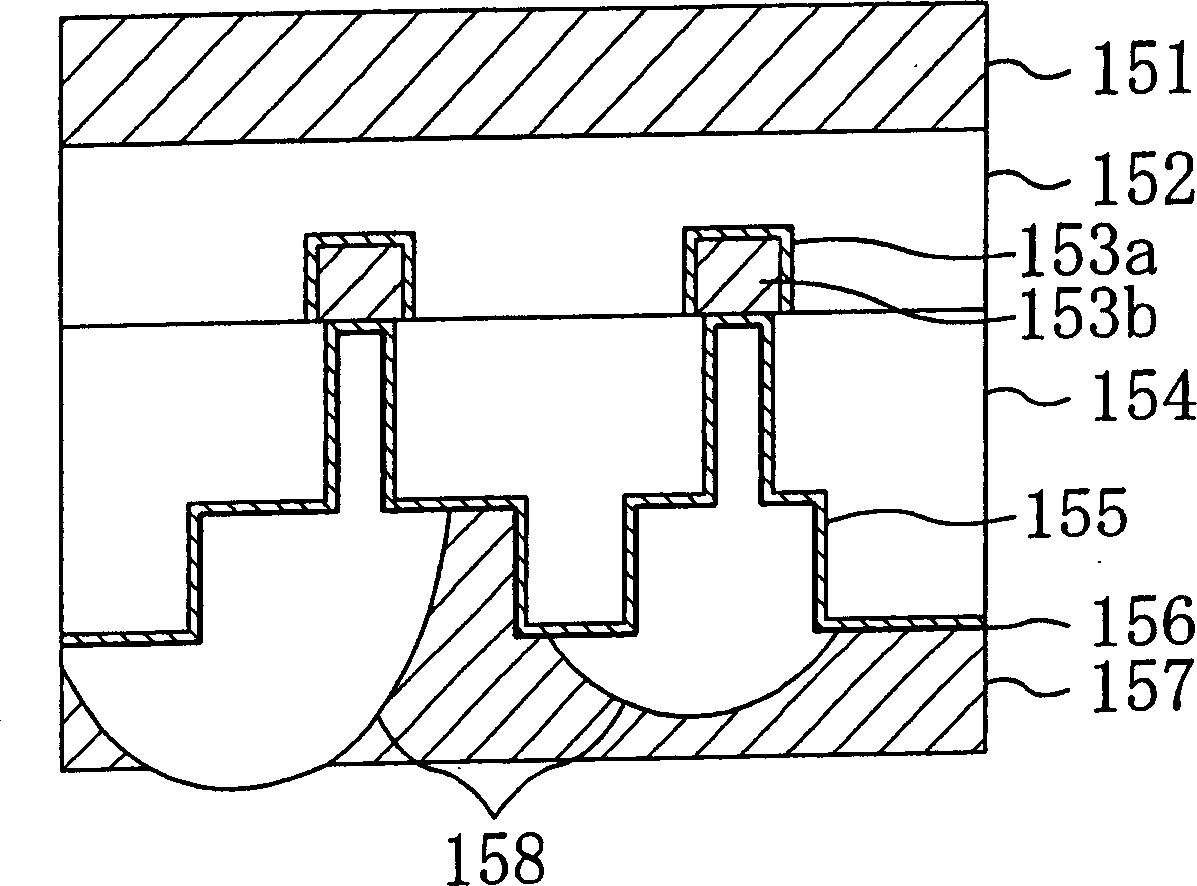

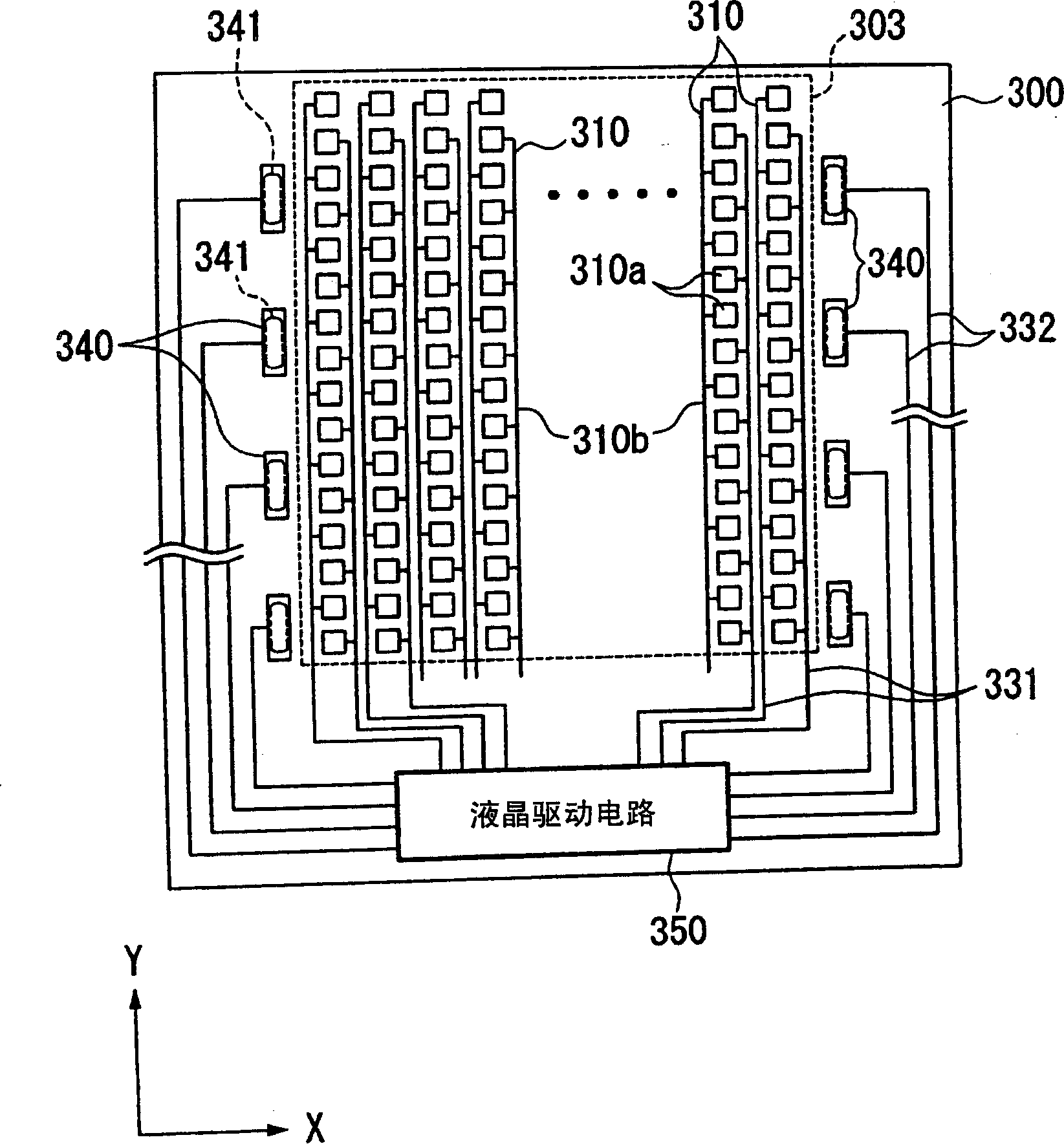

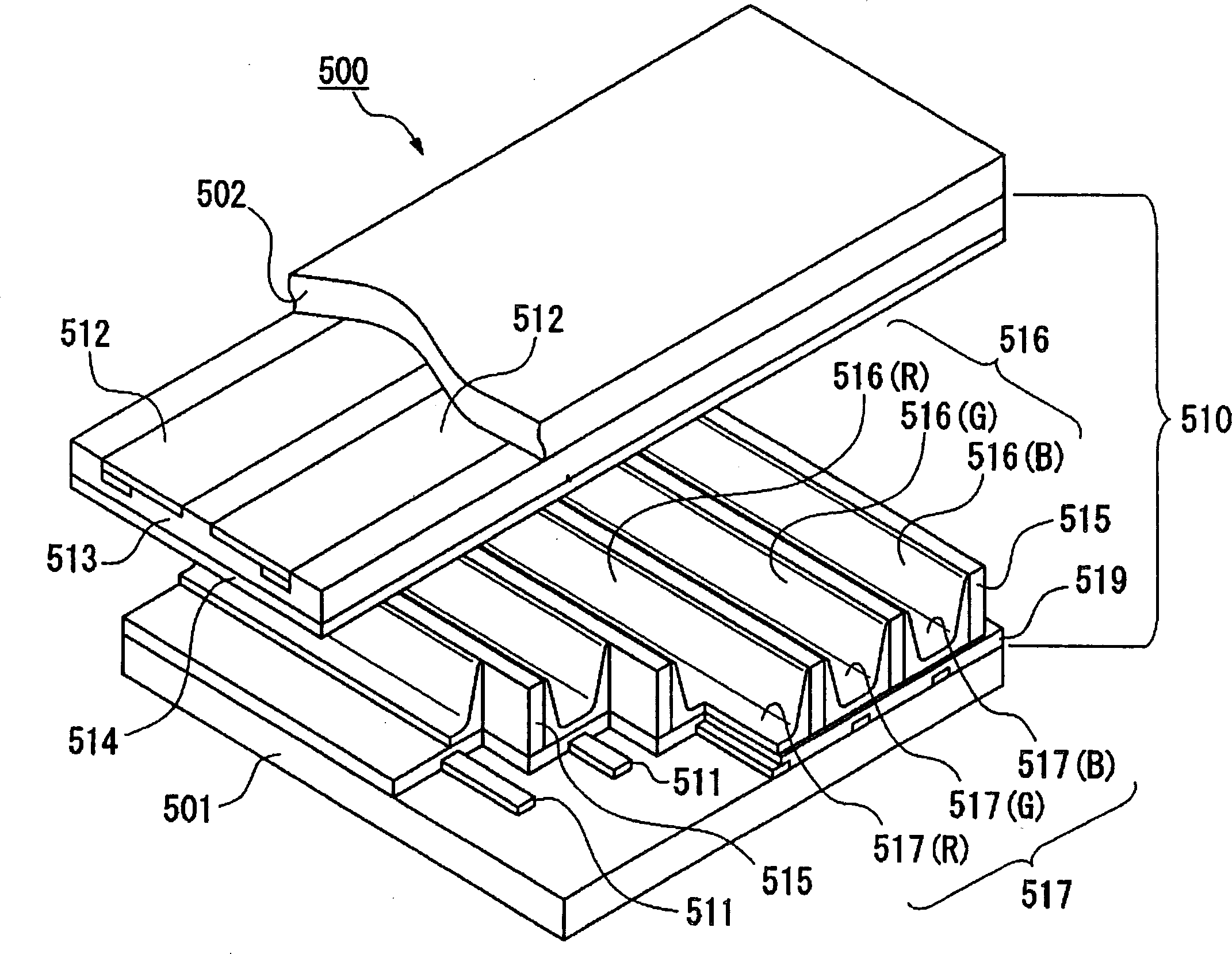

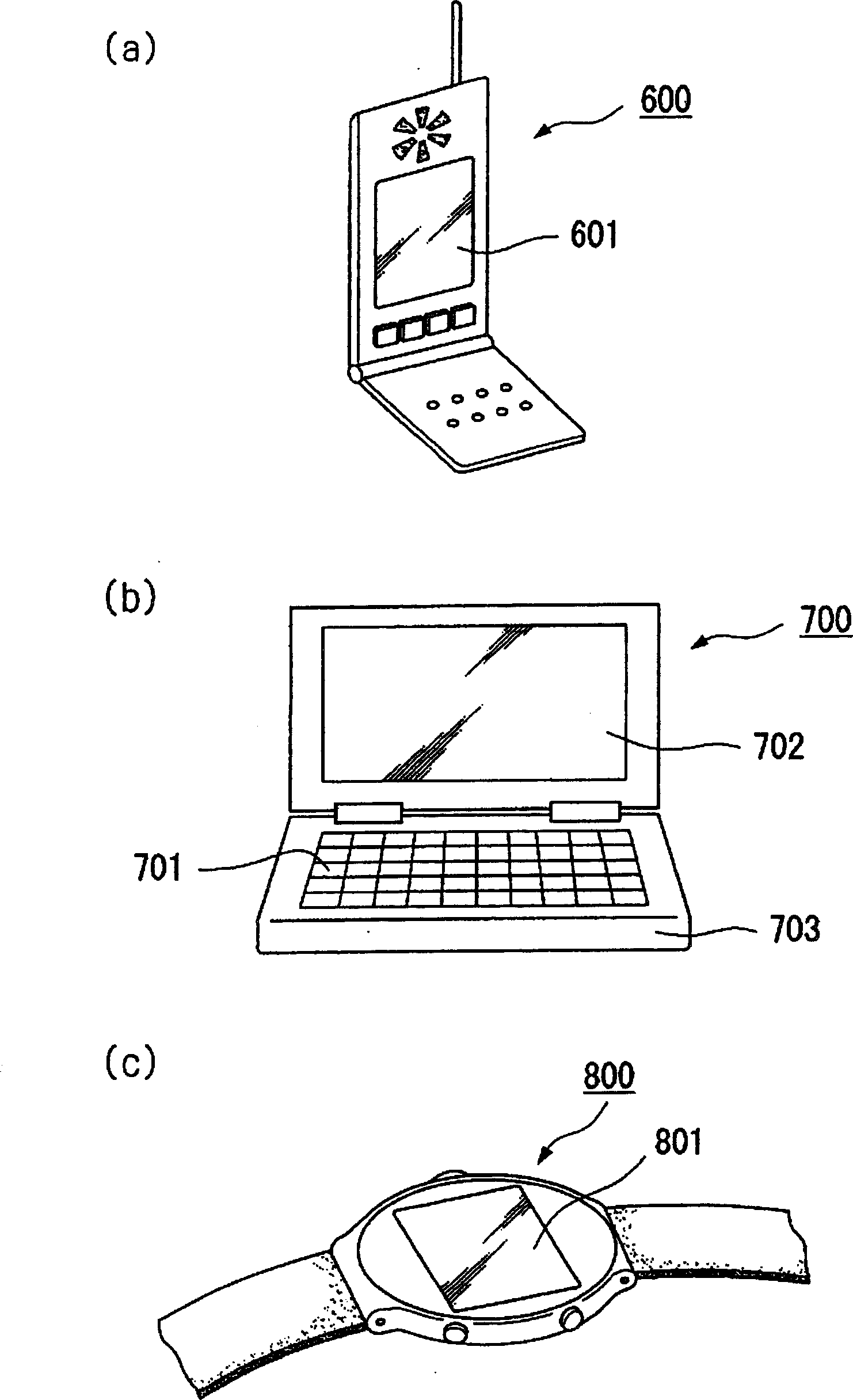

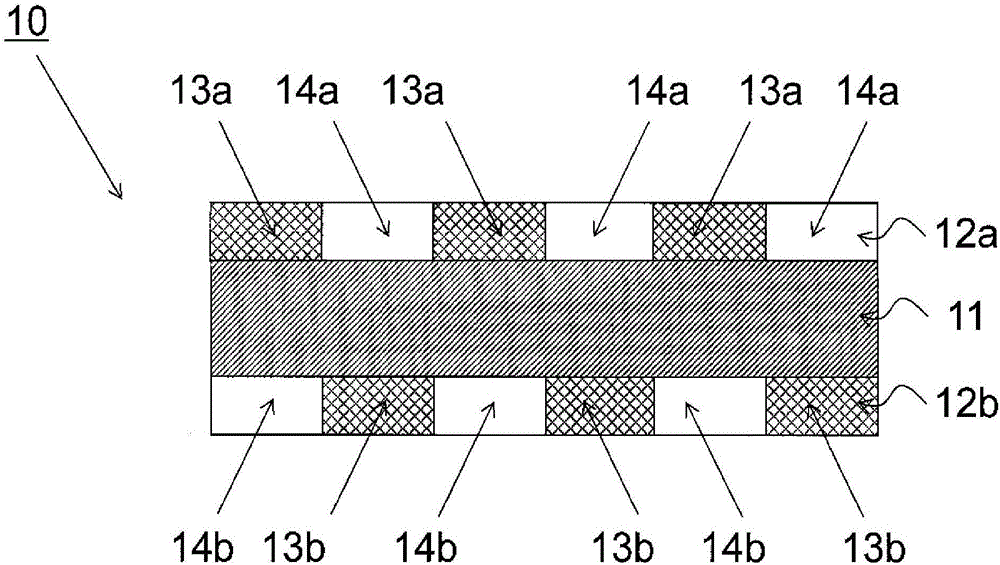

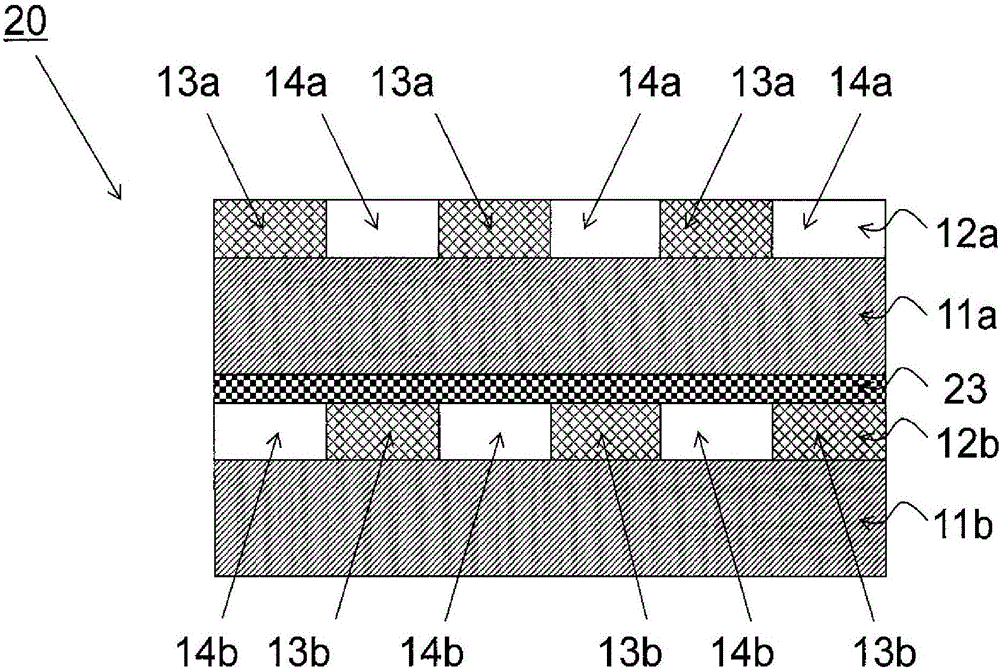

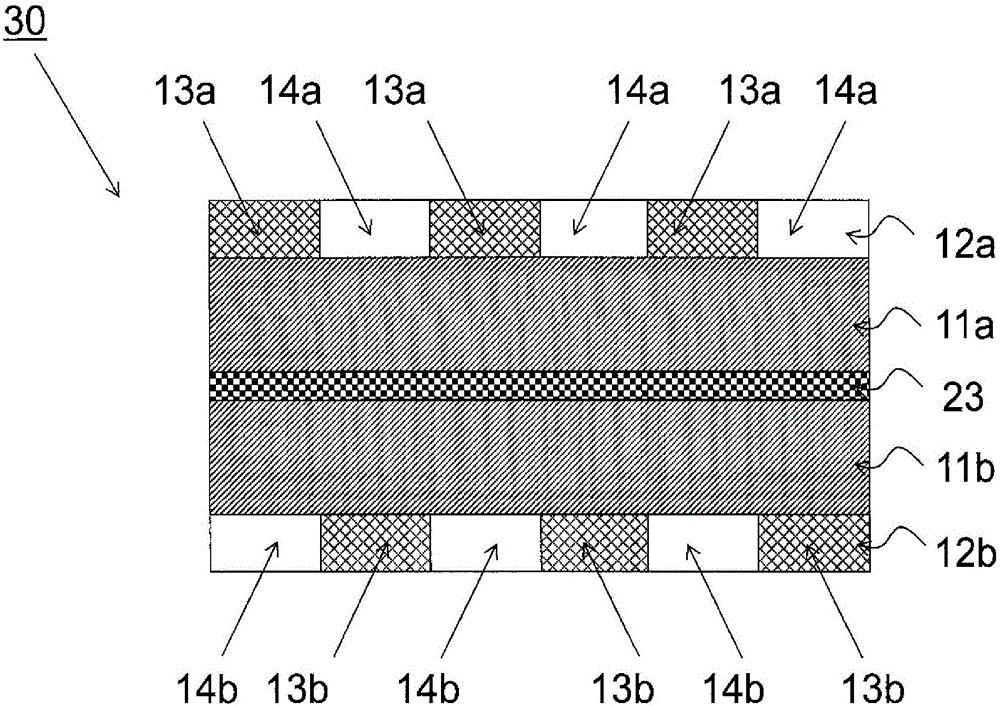

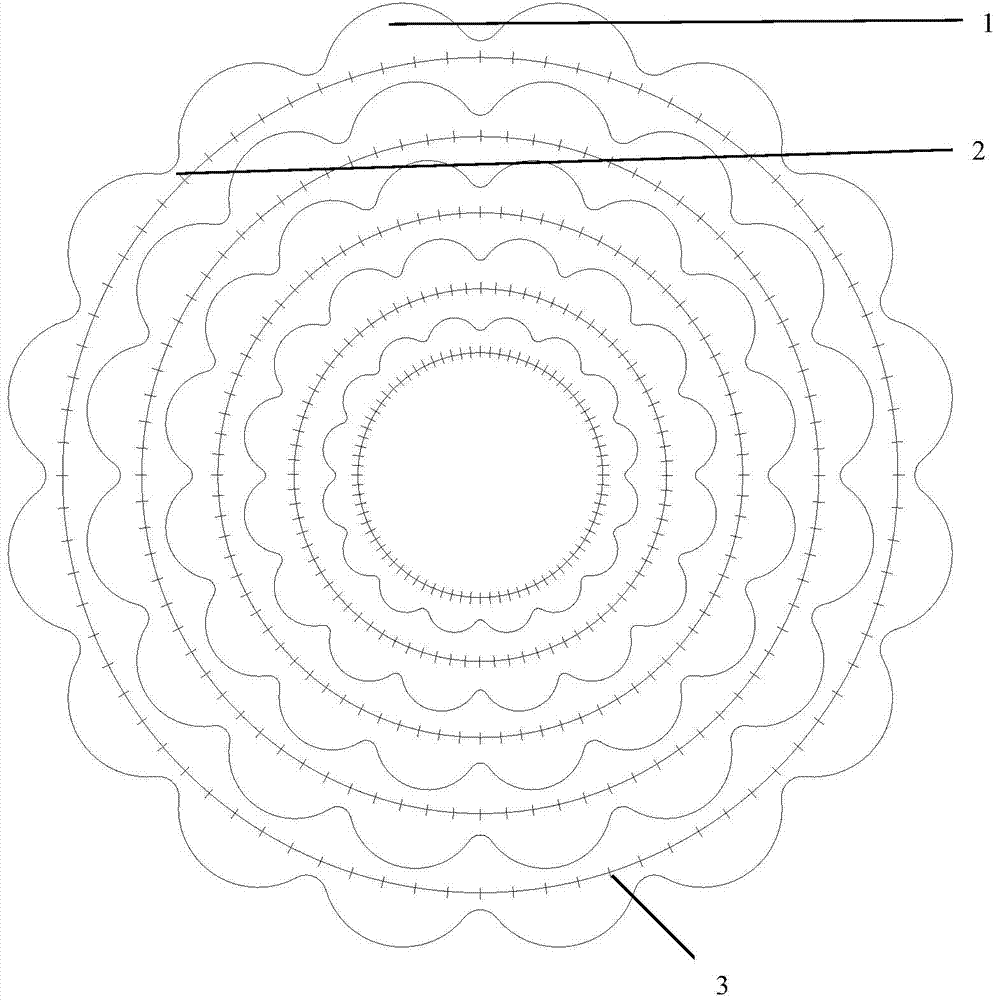

Liquid crystal lens element and optical head device

InactiveCN1914674AReduce thicknessImprove uniformityOptical beam sourcesRecord information storageOptical pickupOptical axis

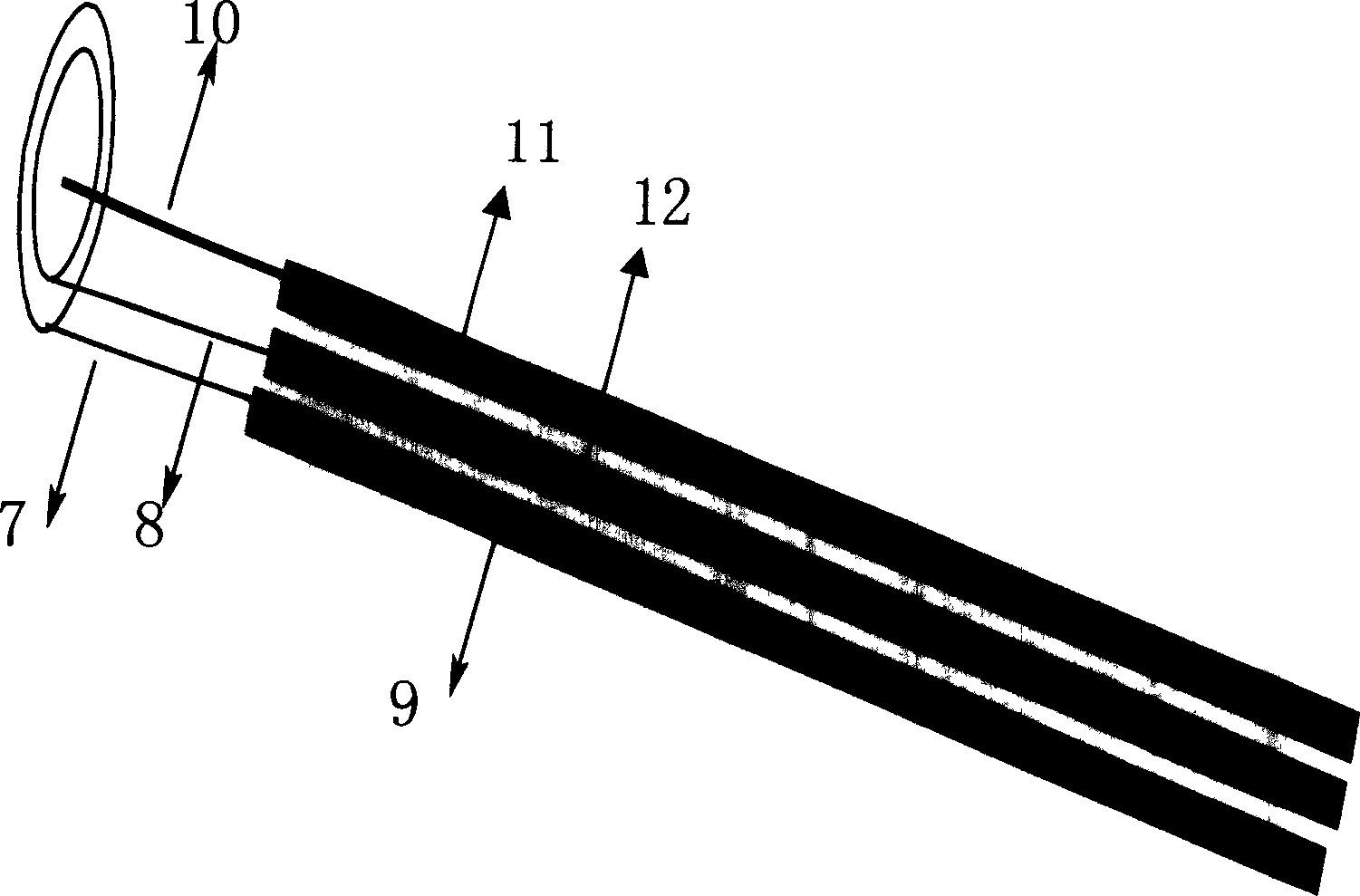

The present invention provides liquid crystal lens element comprising no movable part, having a small size, having a lens function capable of being subjected to stable spherical aberration correction including the power component corresponding to the focus variation of the incident light. The liquid crystal lens element has a variable focal length to the light transmitted through a liquid crystal(16) interposed between a pair of transparent substrates(11, 12). The variable focal length can be varied with the voltage applied to the liquid crystal(16). The liquid crystal lens comprises transparent electrodes(13, 14) provided to the respective transparent substrates(11, 12) and used to apply a voltage to the liquid crystal(16) and an irregular part(17) which has a serrated cross section and a rotational symmetry with respect to the optical axis and is formed of a transparent material on one side of the transparent electrode(13). The liquid crystal(16) is placed at least in the recesses of the irregular part(17) so as to vary the substantial index of refraction of the liquid crystal(16) depending on the applied voltage.

Owner:ASAHI GLASS CO LTD

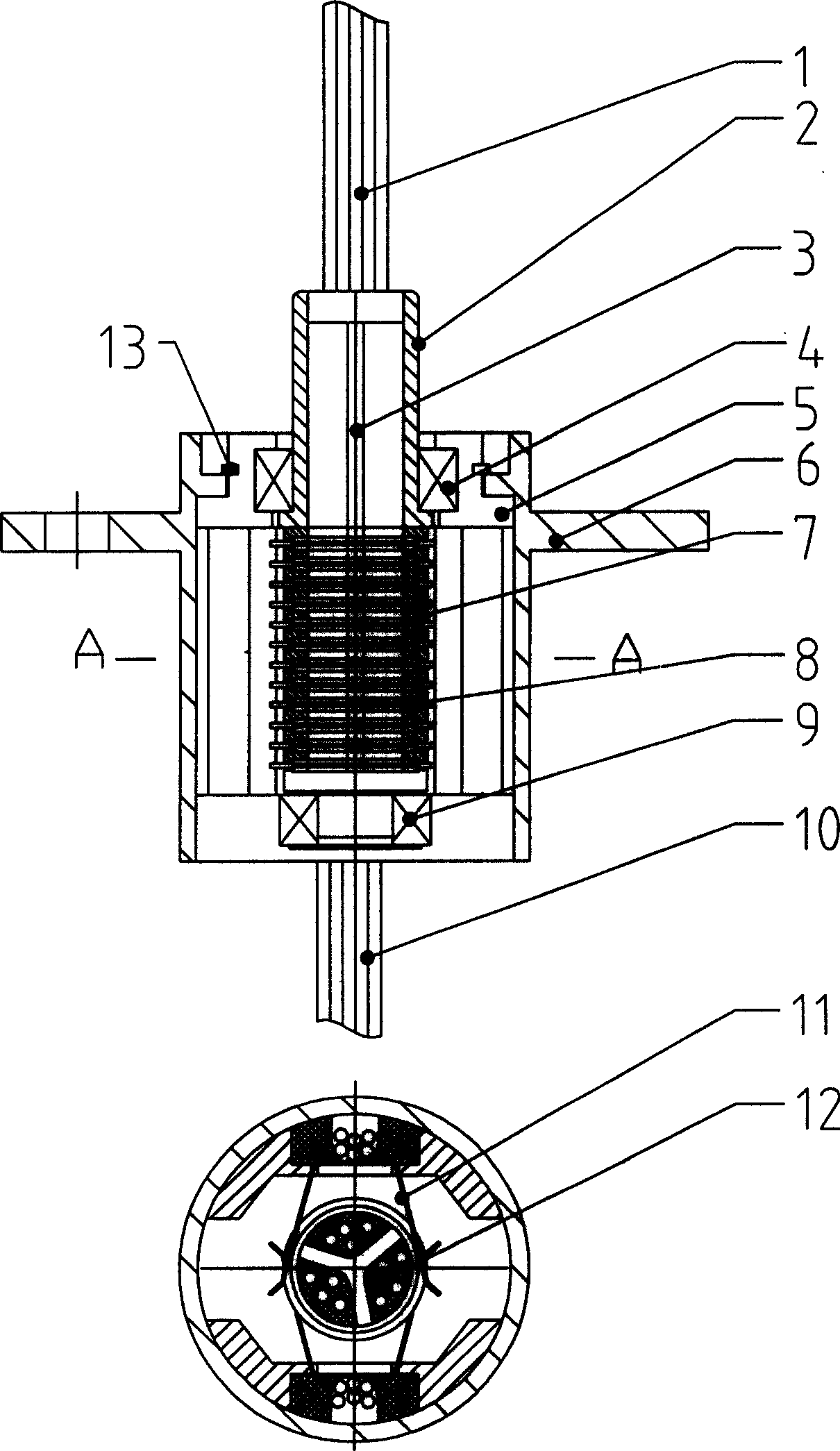

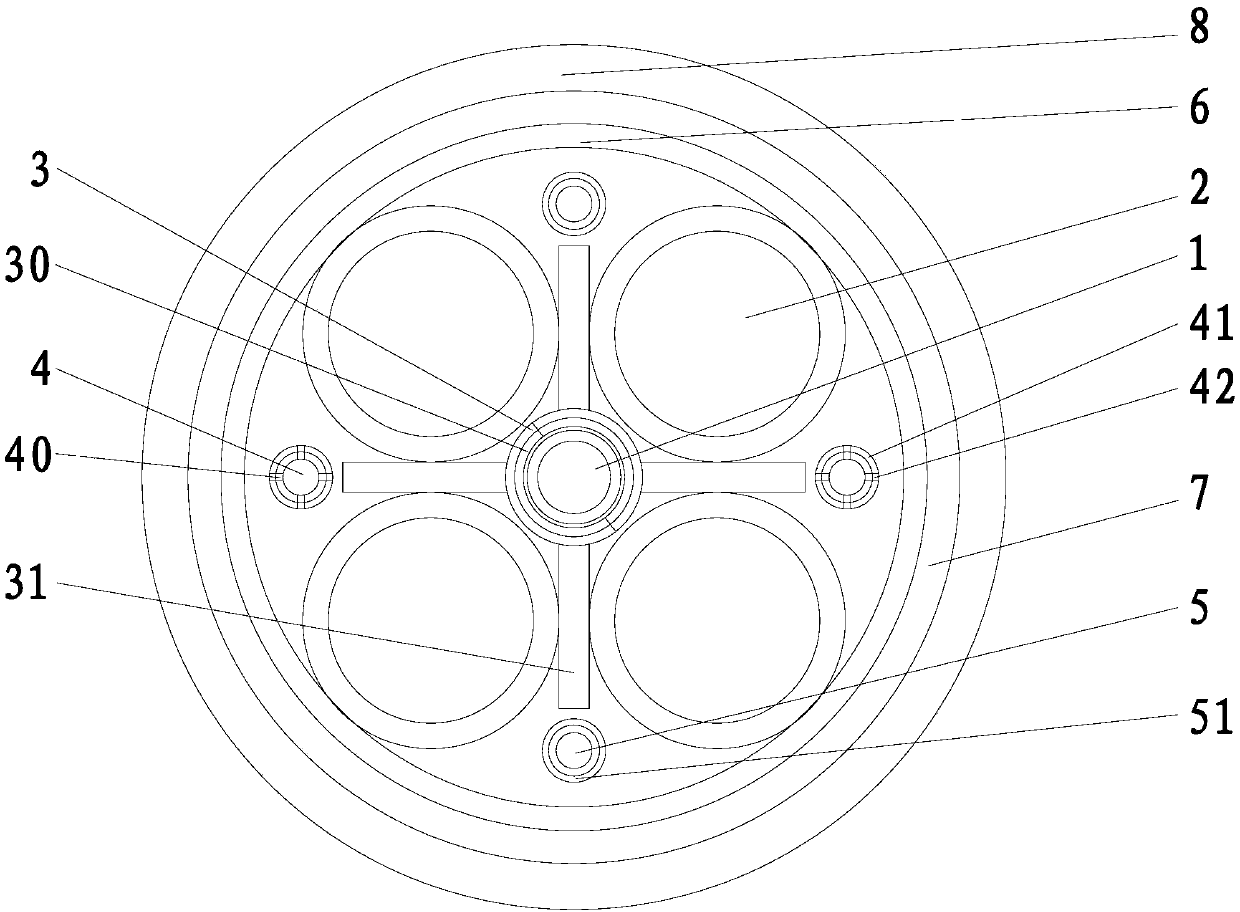

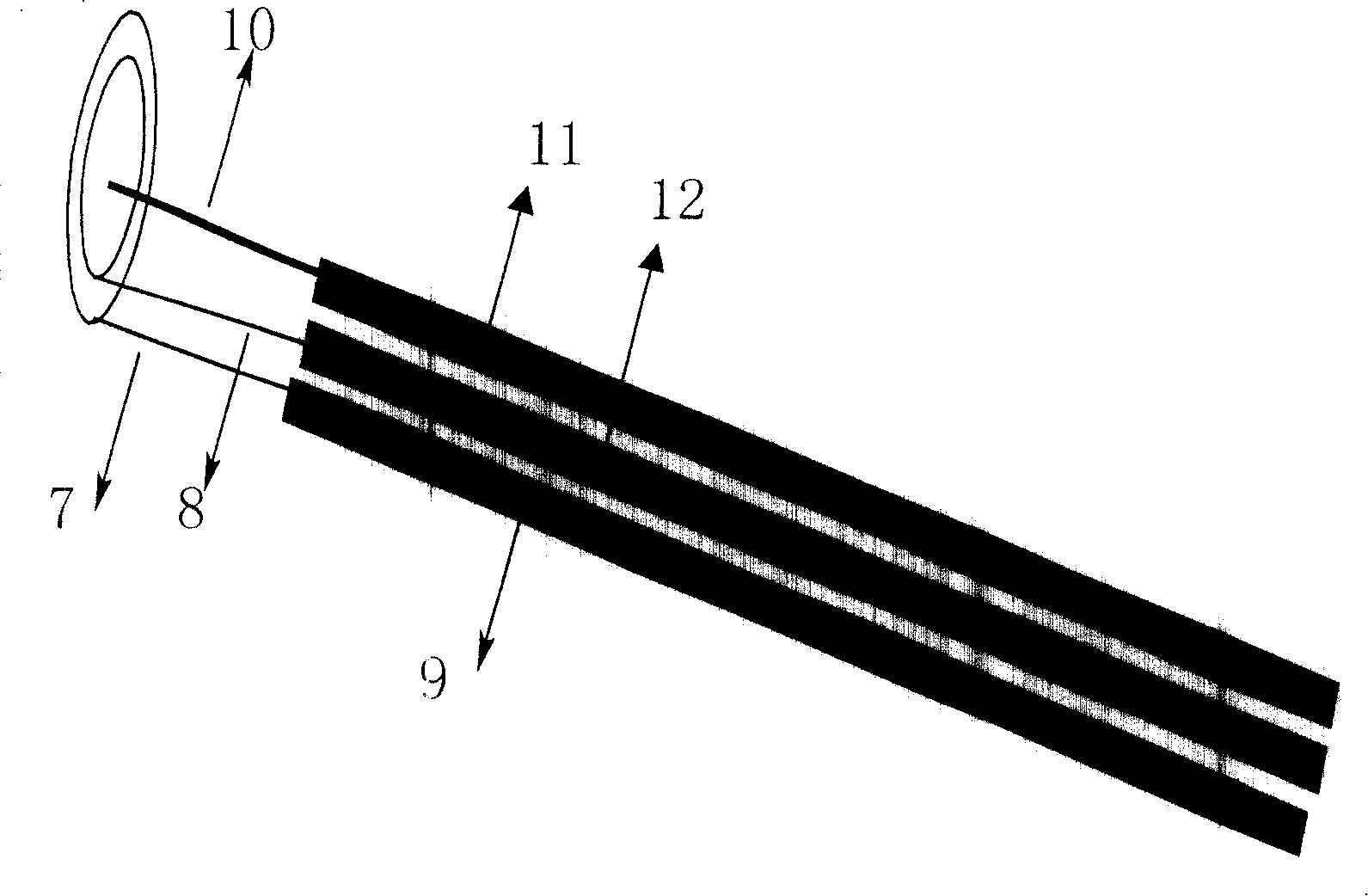

Laminated conductive rotary slip ring and producing process

InactiveCN1614830AReform processNot prone to displacement contactRotary current collectorSlip-rings manufactureEngineeringInjection moulding

The invention relates to a revolving and slip ring type circuit connector. It consists of spindle, insulating piece, conducting ring, bearing shell. The insulation piece and conducting ring with wire each sleeves on the triangle major axis. Then the bearing shell is sleeved and the dung is injected. The conducting revolving axis is easily made. The invention divides the conducting revolving axis into several individual component parts and changes the injection mould technology into lamination adhesive bonding technology.

Owner:刘磊 +1

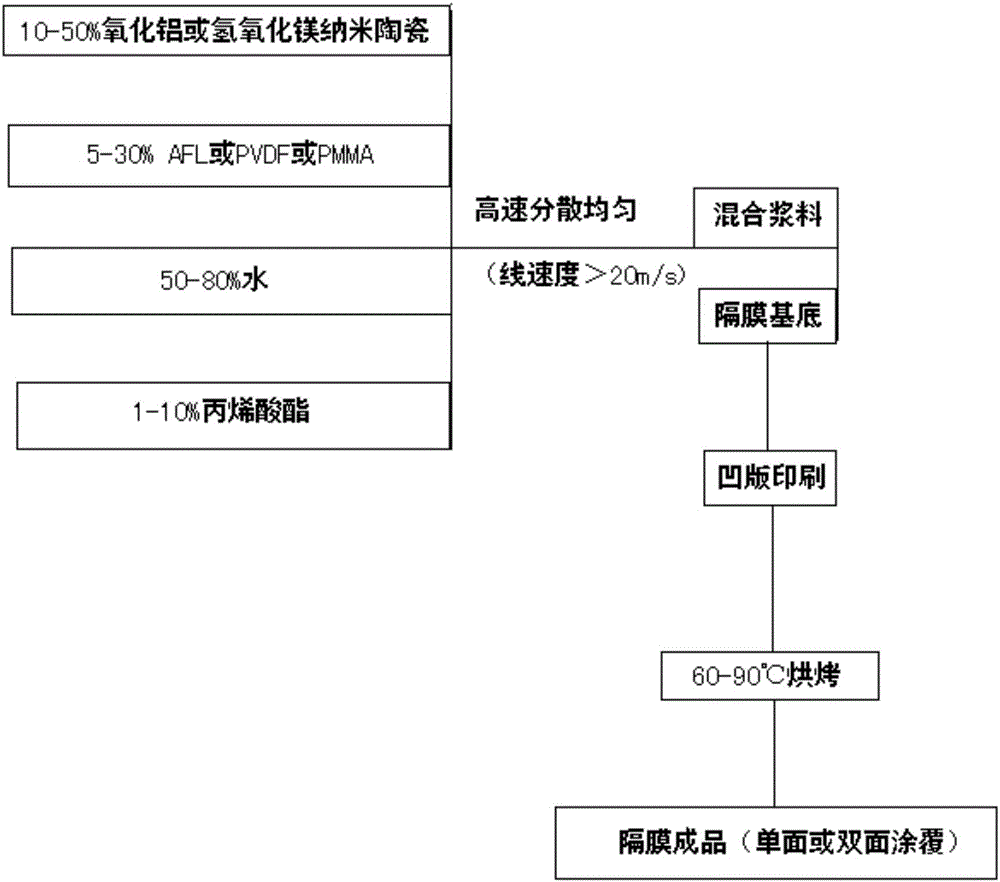

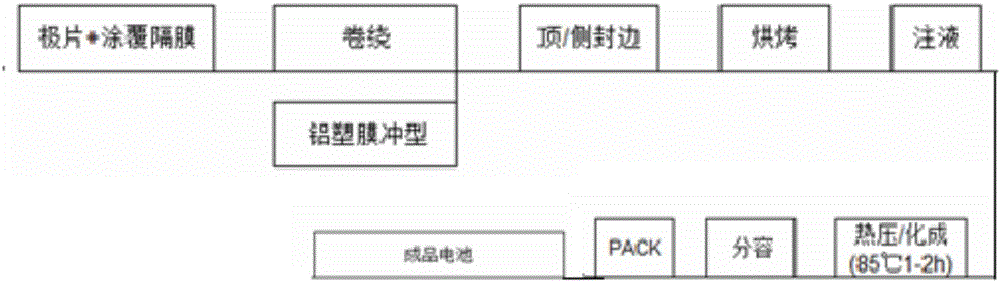

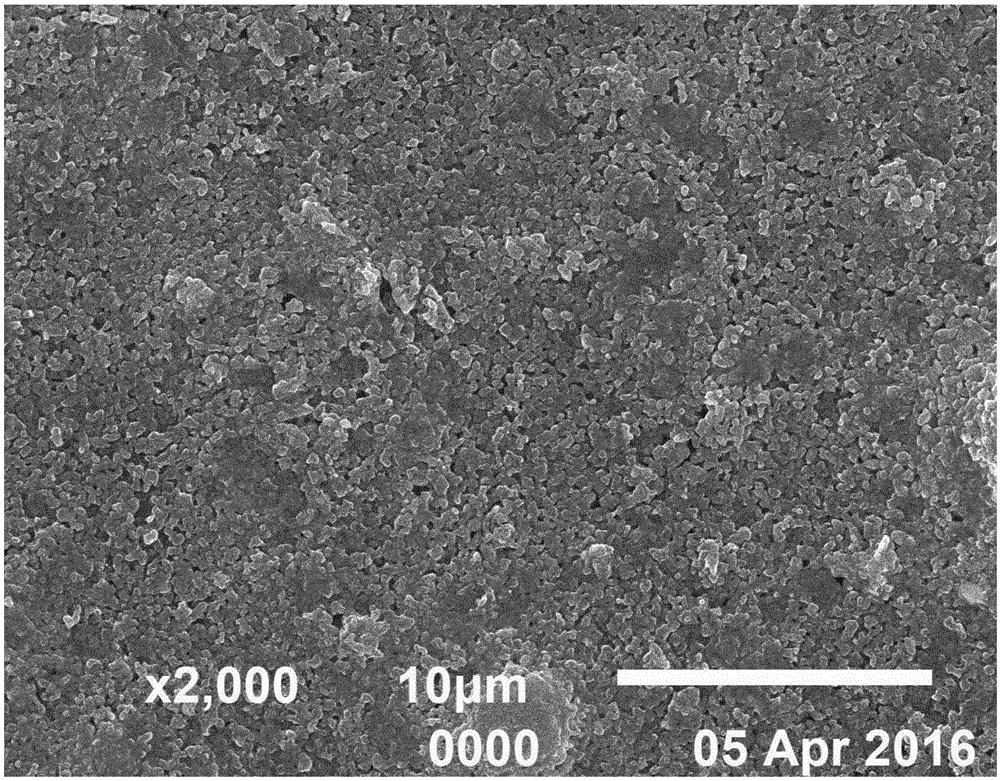

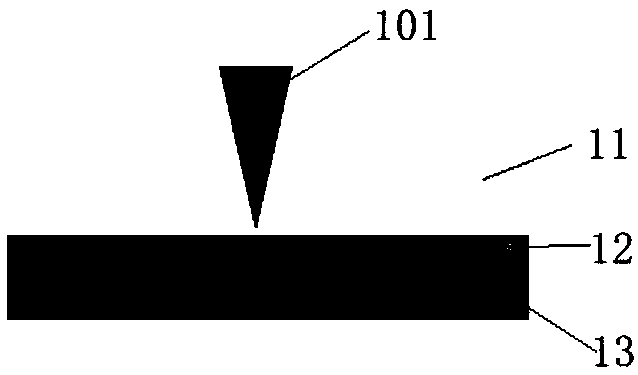

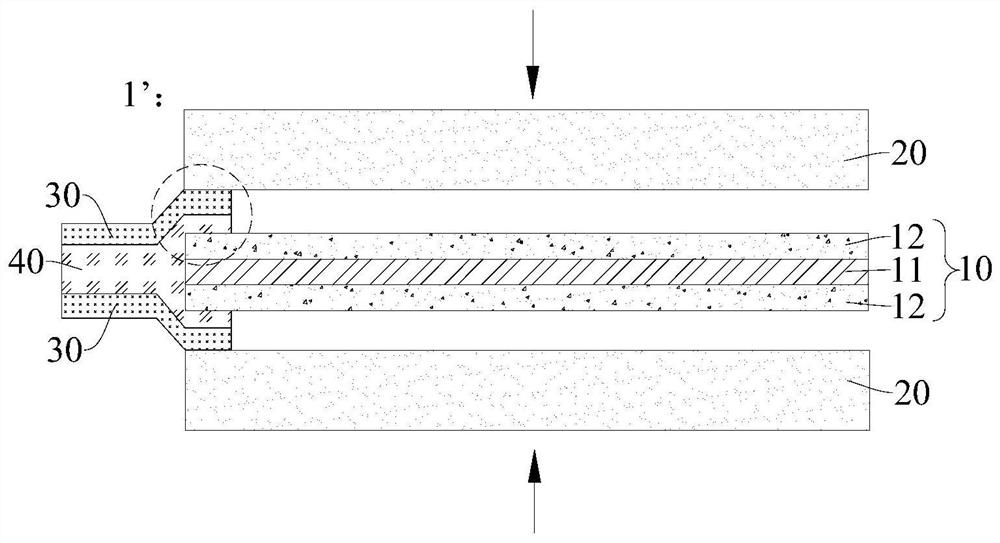

Lithium-ion battery separator, and preparation method and application thereof

ActiveCN106207059AImprove securityHeat shrinkable area expandsFinal product manufactureSecondary cellsCyclic processSafety testing

The invention provides a lithium-ion battery separator, and a preparation method and application thereof. The lithium-ion battery separator comprises a separator substrate and an aqueous function layer composited on the surface of the separator substrate. The aqueous function layer is equipped with multiple micropores. The aqueous function layer has viscidity. When the separator provided by the embodiment of the invention is applied to a polymer lithium-ion battery, a partial lithium separation phenomenon will not occurs in a cycle process and deformation or a relatively high expansion phenomenon will not occur in a battery pole group, thereby facilitating stability of cycle life. Moreover, the heat contractility of the separator is improved. The separator and an electrode are adhered together well with the combination of effects such as the viscidity of the aqueous function layer. In a safety test process or when the battery is abused such as the fact that the battery is punctured, extruded, twisted and bended, or when the battery is used in a high temperature environment for a long time, the safety performance of the battery can be greatly improved.

Owner:LENOVO (BEIJING) CO LTD

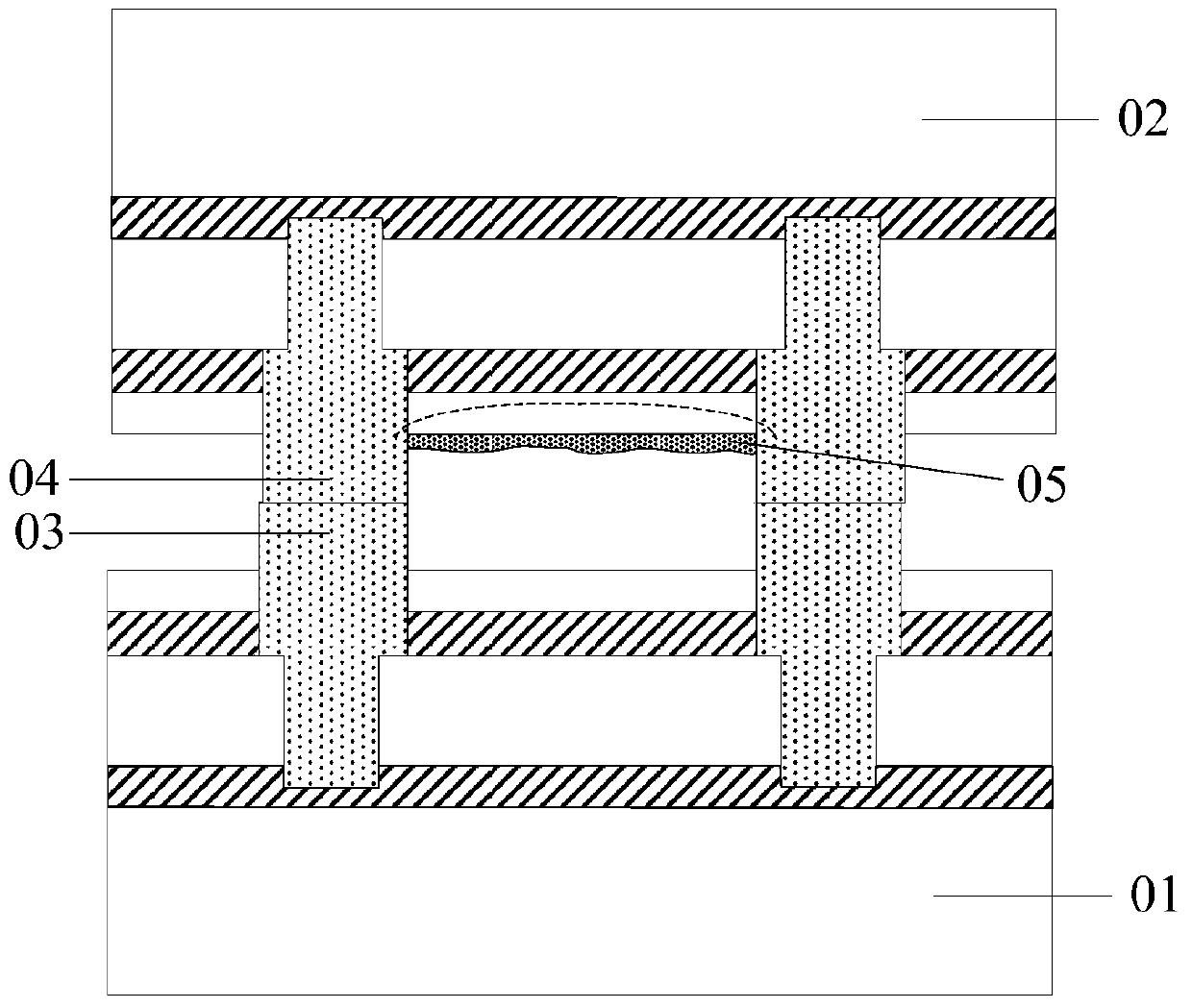

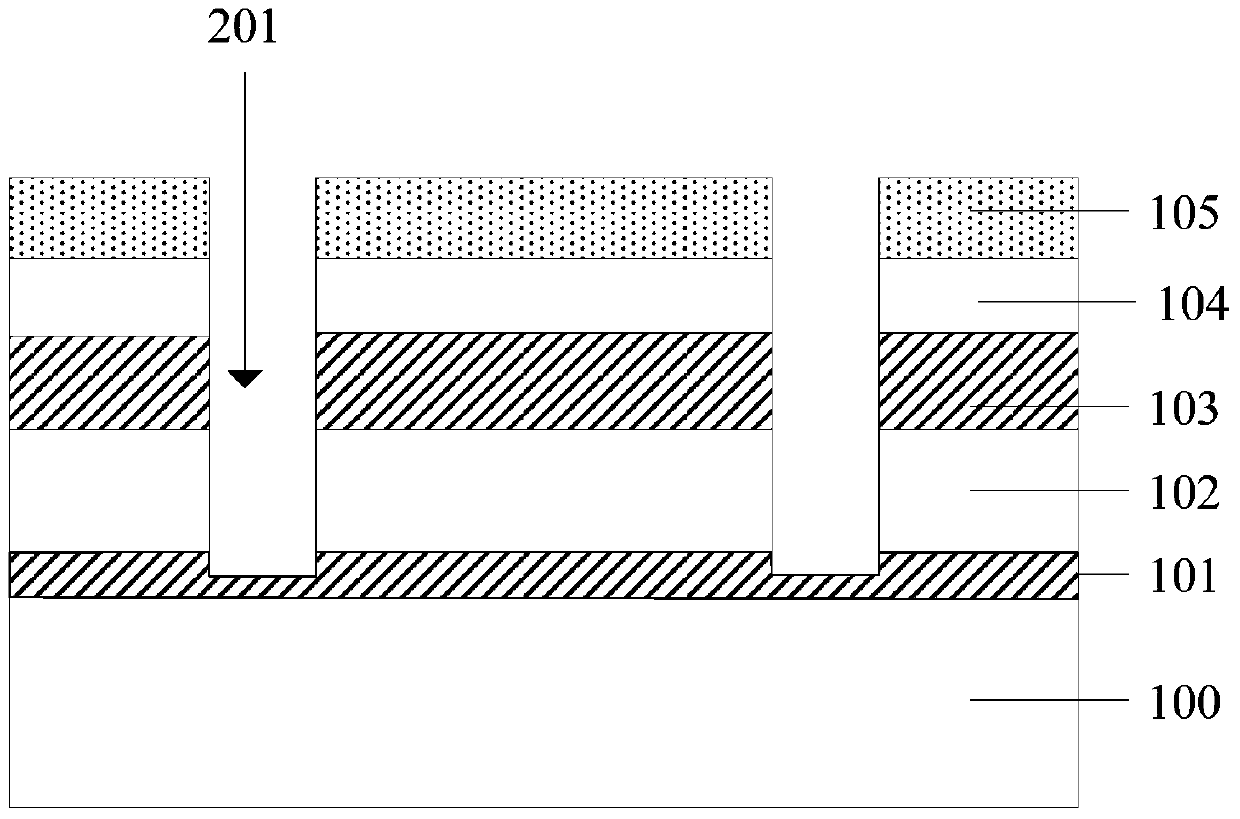

Wafer bonding method and wafer bonding structure

ActiveCN105513983AReduced risk of short circuitsNot easy to short circuitSemiconductor/solid-state device detailsSolid-state devicesEngineeringOxide

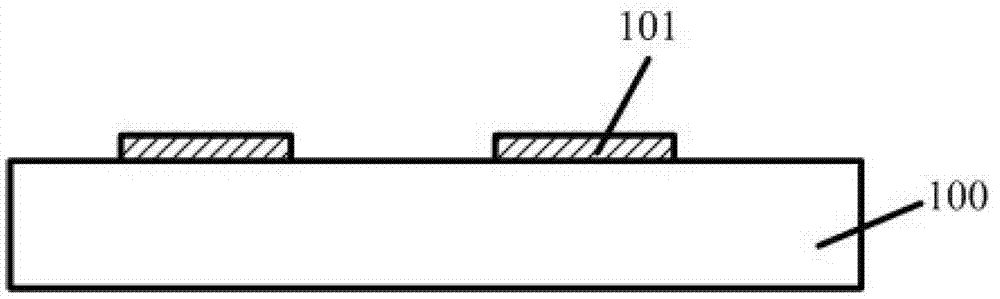

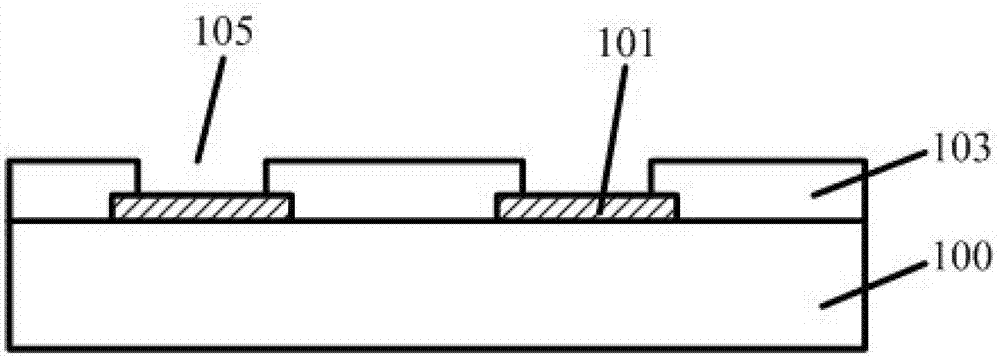

The invention provides a wafer bonding method and a wafer bonding structure. The wafer bonding method is characterized in that before the wafer bonding processing, an interlayer dielectric layer is formed on a wafer, and the interlayer dielectric layer comprises a first dielectric layer and an insulation layer, which are formed sequentially; an interconnection structure can be formed in the interlayer dielectric layer, and a part of the interconnection structure is protruded from the surface of the interlayer dielectric layer, and is a bonding end of the interconnection structure; and side walls are formed on the side walls of the bonding end. The wafer bonding method and the wafer bonding structure are advantageous in that the insulation layer is used to completely cover the surface of the interlayer dielectric layer, and the side walls are used to cover the side walls of the bonding end; after the bonding processing of a plurality of wafers, the adjacent bonding ends are provided with the insulation layers and the side walls for the isolation, and the short circuit is not easy to occur; and in addition, under the protection of the side walls, the bonding ends are not exposed in the external environment, and the oxide is not easy to form under the influence of the oxygen and the water vapour, and at the same time, the short circuit risk can be reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

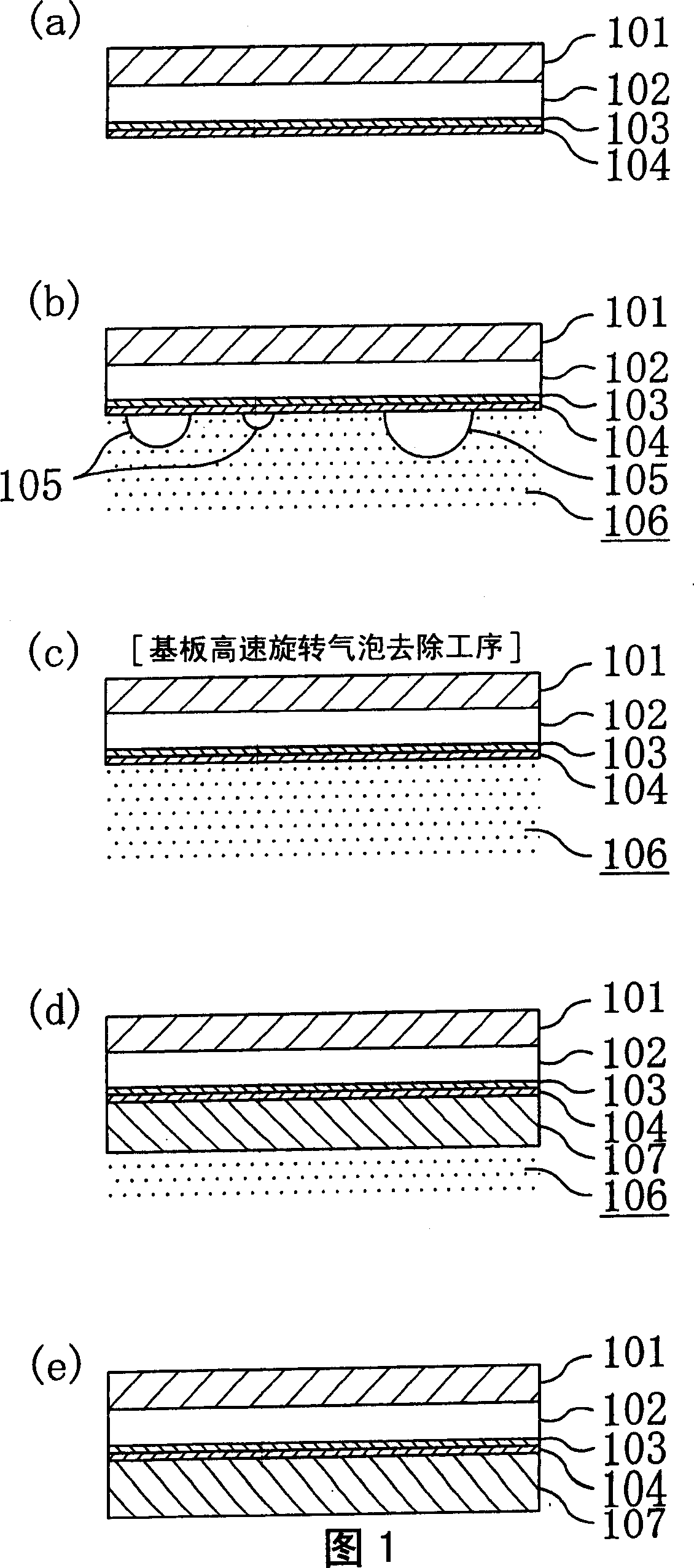

Filming method of substrate and filming appts.

InactiveCN1480988AImprove reliabilityImprove wettabilityCellsSemiconductor/solid-state device manufacturingMetallurgyCoating

Owner:PANASONIC CORP

Preparation method of electrochemical combined electrode

This invention relates to a method for processing electrochemical combination electrodes sealed by the nm flexible epoxy resin material including: 1, inserting a working electrode matrix material into a conductive support copper rod wrapped with an insulation pyrocondensed tube, a hole Ag reference electrode is welded to the support copper rod, the bottom of a hole Pt counter-electrode is welded to the support copper rod, the hole Ag reference electrode, the hole Pt counter-electrode and the working electrode matrix are arrayed from inside to outside with the working electrode at the middle, the tops of which are at a same plane, the support copper rods of them are fixed by a pyrocondensed tube and put into a die set and fixed, 2, casting the nm flexible epoxy resin material onto the die set to deaerate and cure it, 3, taking out the electrode after cooling it and polishing it.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

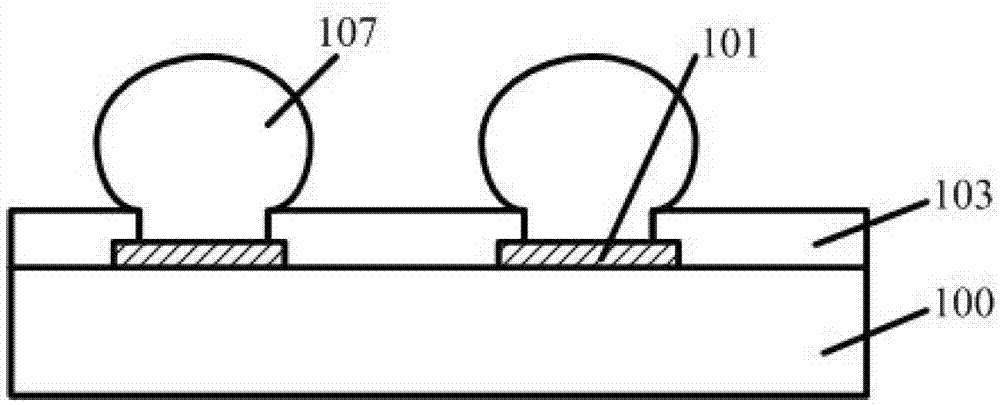

Packaging element of semiconductor device

ActiveCN102931164ANot prone to short circuitImprove performanceSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSolder ball

Discloses is a packaging element of a semiconductor device. The packaging element comprises a chip, a passivation layer, salient points and solder balls. Pads and integrated circuits are arranged on the surface of the chip and electrically connected; the passivation layer is placed on the surface of the chip and provided with openings which expose part of the pads; the salient points are arranged on the surfaces of the pads, and the sizes of the salient points are smaller than those of the openings; and the solder balls cover the tops and side walls of the salient points and the bottoms of the openings. The packaging element of the semiconductor device is not easy to short circuit, high in bonding strength between the solder balls and the salient points and stable in performance.

Owner:NANTONG FUJITSU MICROELECTRONICS

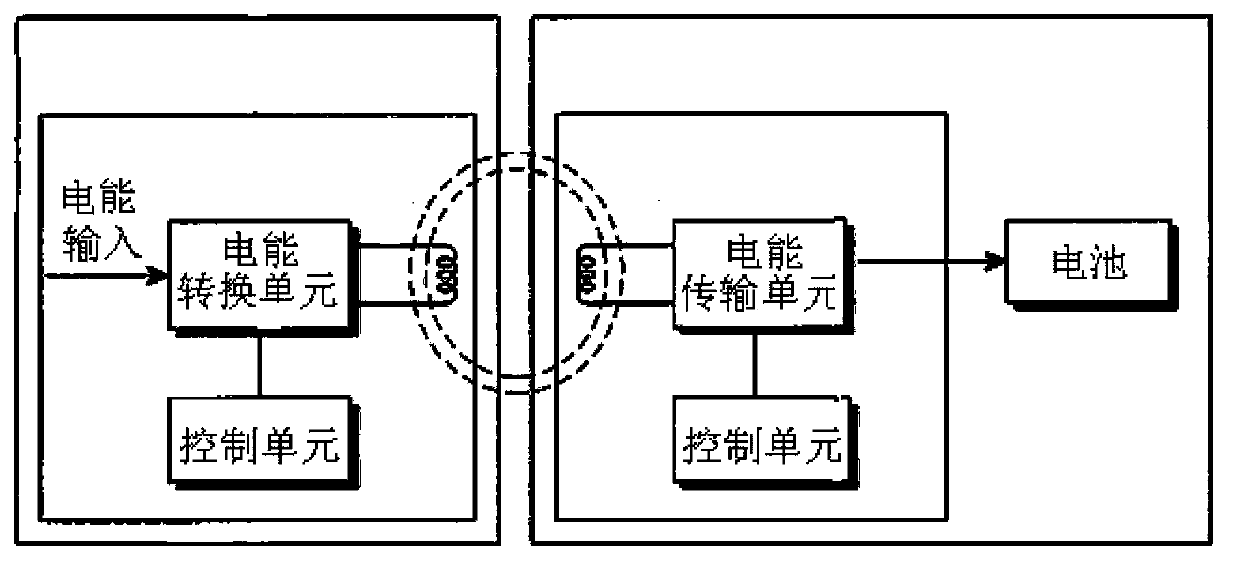

Charging system and charging base of electronic equipment

InactiveCN103683365ANo effect on lifespanNot prone to short circuitBatteries circuit arrangementsElectric powerElectricityElectrical battery

The invention discloses a charging system of electronic equipment and a charging base of the electronic equipment. The charging base comprises the following components of: a power source input interface which is used for connecting an external power source supplying device; a control unit of which the input end is connected with the power source input interface; and an electrode which comprises a first electrode plate and a second electrode plate, wherein the first electrode plate is connected with a first output end of the control unit, and the second electrode plate is connected with a second output end of the control unit. With the charging system and the charging base of the electronic equipment of the invention adopted, charged equipment can directly contact with the charging base, such that power transmission can be realized, and a charging process of the charged equipment can be accomplished, and in the charging process, power conversion efficiency is high, and no heat is emitted, and the service life of a battery will not be affected; with direct charging realized, a charging speed can be very fast; electromagnetic and magnetoelectric conversion devices are not required to be set, and therefore, the product is low in cost and convenient to carry; and at the same time, short-circuiting will not occur between the electrode plates, and charging is safe, and a requirement for a setting position of a charging electrode of the charged equipment is low.

Owner:荆涛

Surface treating method and film pattern forming method

InactiveCN1905782AGood electrical conductivityLess prone to disconnectionAntenna supports/mountingsSemiconductor/solid-state device manufacturingOptoelectronicsUltraviolet irradiation

The invention provides a surface treatment method by which a substrate with desired uniform lyophilicity is obtained in order to enhance the formation of a film pattern by an ink-jet process; a surface-treated substrate obtained by the surface treatment; and a method of forming a film pattern. A surface of a substrate is subjected to lyophobic treatment by forming a self-assembled layer composed of organic molecules. The lyophobicity is then modified by ultraviolet irradiation or the like to obtain desired lyophobicity.

Owner:SEIKO EPSON CORP

Printing ink with high adhesive force

The invention relates to a printing ink with high adhesive force. The printing ink comprises following ingredients, by weight, 30 to 50 parts of a base resin, 5 to 15 parts of an auxiliary resin, 0.5 to 2.0 parts of an adhesive, 0.5 to 2.0 parts of a thickening agent, and 21 to 44 parts of an organic solvent. Compared with existing products, adhesive force of the printing ink is excellent high.

Owner:SHANGHAI DEMAN ELECTRONICS TECH

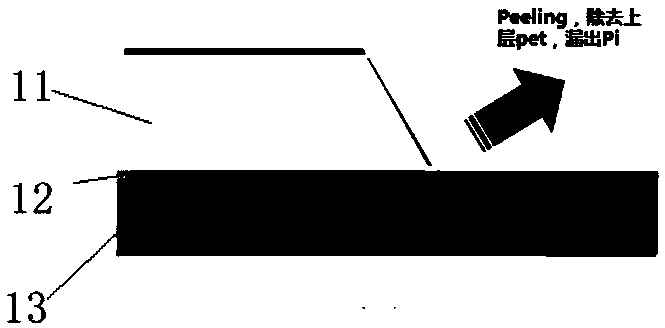

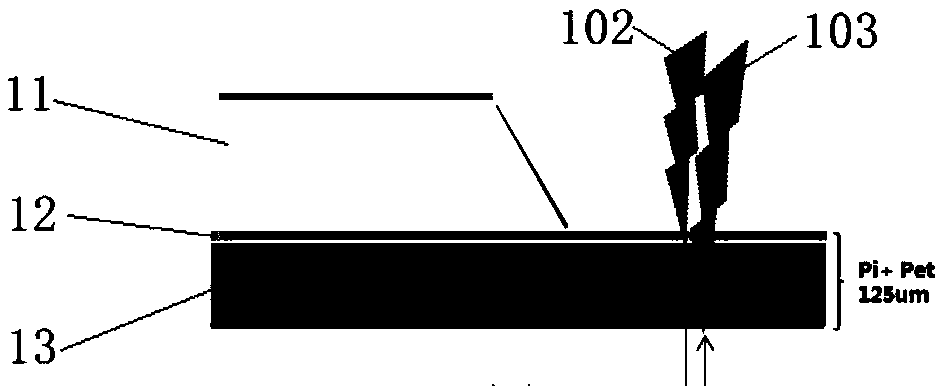

Laser cutting method and laser cutting device of flexible screen

InactiveCN109434307AImprove yield rateNot prone to short circuitLaser beam welding apparatusTectorial membraneSurface layer

The invention is belongs to the technical field of laser cutting of flexible screens, and discloses a laser cutting method and laser cutting device of a flexible screen. The laser cutting method comprises the following steps that a flexible screen is tiled and fixed to a workbench; a first laser cuts a protective film layer of a surface layer of the flexible screen along a first processing track;the protective film layer is torn and removed to expose a circuit layer; laser slotting is carried out on the circuit layer by a second laser to form a circuit removal groove; and the flexible screenis cut off along the path of the circuit removal groove. According to the laser cutting method and laser cutting device of the flexible screen, the protective film layer is firstly removed, and afterthe circuit removal groove is formed in the circuit layer, a control system controls a second laser device or a third laser device to cut off the flexible screen along the path of the circuit removalgroove, so that the influence of laser thermal effect on a circuit is reduced, the circuit short in a terminal area of the circuit layer is avoided, the yield of the flexible screen is improved, and the production cost is reduced.

Owner:HANS LASER TECH IND GRP CO LTD

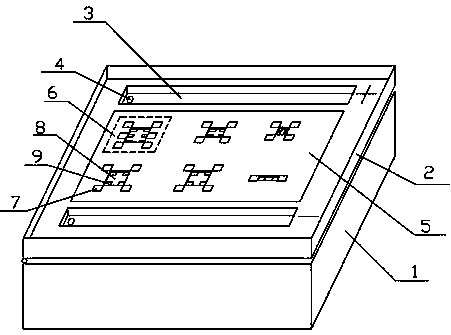

LED lamp pin polarity detection apparatus

The invention discloses an LED lamp pin polarity detection apparatus. The apparatus comprises au upper box body and a lower box body, wherein the upper box body is arranged at the upper portion of the lower box body, a through hole is arranged between the upper box body and the lower box body, the lower box body is internally provided with a power source, the positive lead wire and the negative lead wire of the power source are outputted to the upper box body through the through hole, the upper box is internally provided with an LED lamp assembly, the LED lamp assembly comprises LED lamp pin contact welding pads corresponding to LED lamp pins, and the two different LED lamp pin contact welding pads are respectively contacted through the positive output lead wire and the negative output lead wire of the power source so as to determine polarities of the LED lamp pins and a corresponding LED lamp color. According to the invention, the power source is arranged in the lower box body, and the LED lamp assembly is arranged in the upper box body so that the detection of the polarities of the LED lamp pins is facilitated, the apparatus is not easily lost during a use process, and the apparatus can be reused.

Owner:佛山市顺德区科测技术服务有限公司

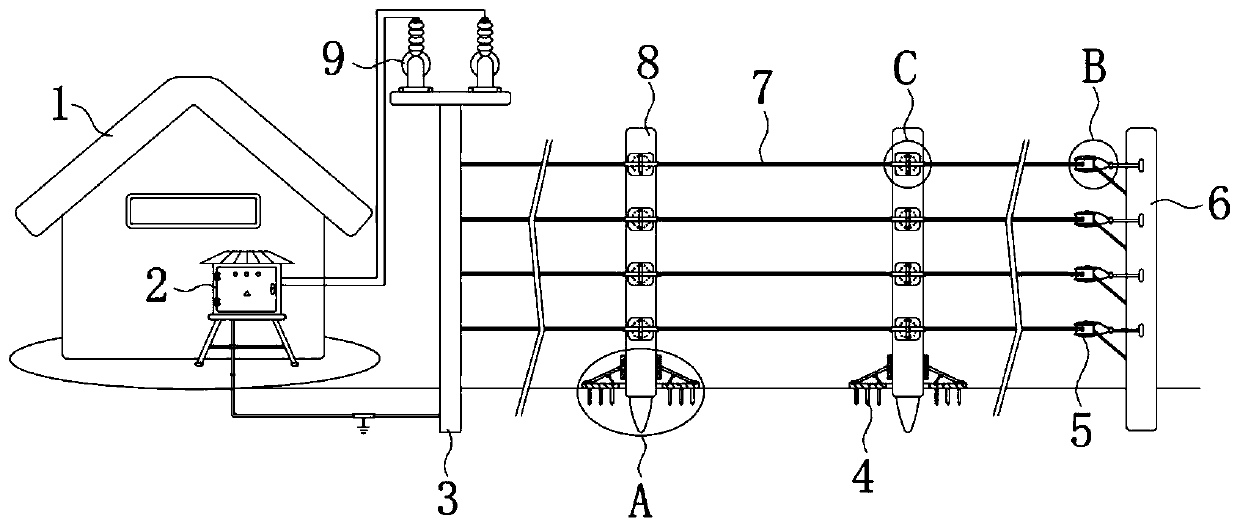

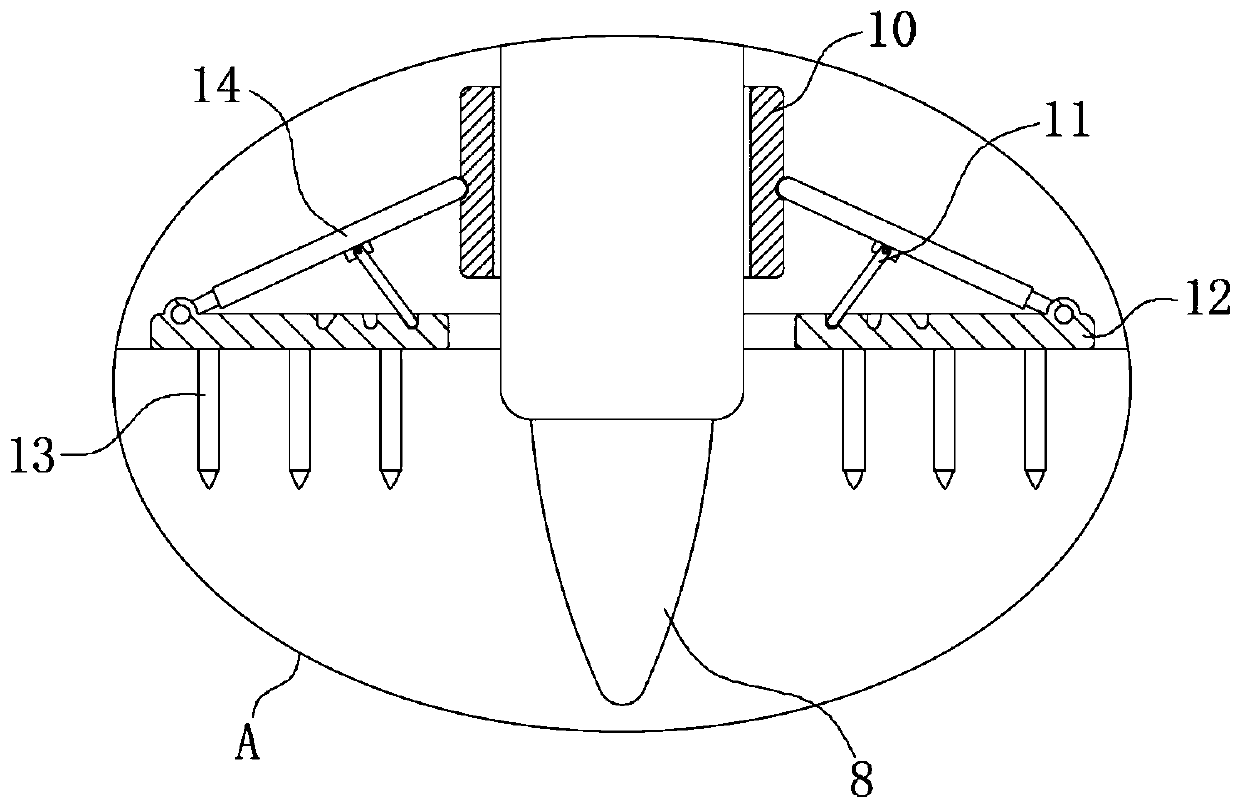

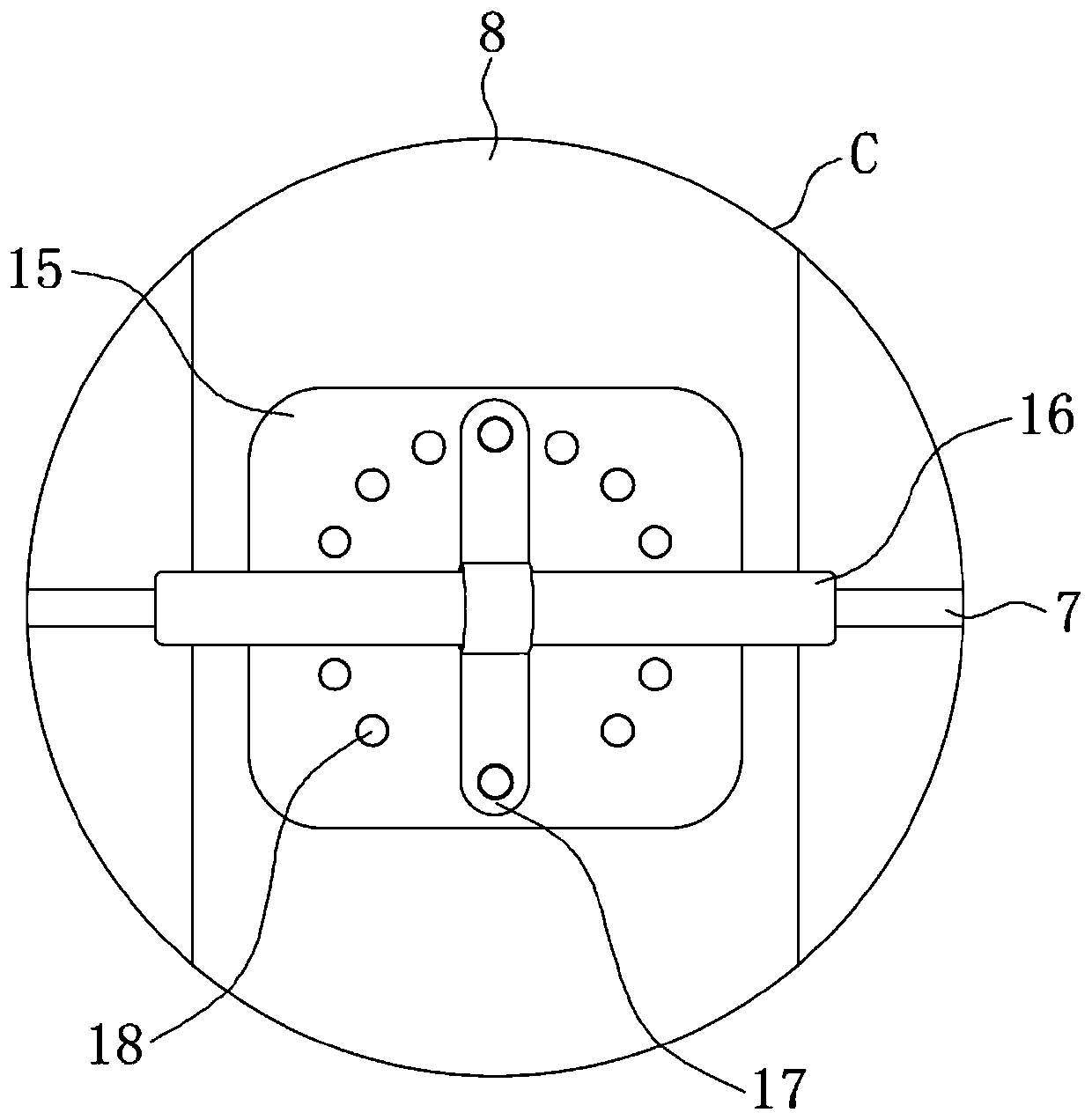

Wearable device-based electronic fence for livestock breeding and husbandry method of wearable device-based electronic fence

ActiveCN110959539AReduce the number of shocksIncrease flow ratePasturing equipmentAnimal repellantsAnimal scienceCrop livestock

The invention discloses a wearable device-based electronic fence for livestock breeding. The wearable device-based electronic fence includes a wearable device, a main control room, an electronic fencehost, a wiring rod, a plurality of bearing rods and a terminal rod, wherein a serial closed loop is formed among the wiring rod, the bearing rods and the terminal rod through four alloy wires. The invention also discloses a husbandry method of the wearable device-based electronic fence for livestock breeding. The husbandry method includes the following steps: S1, inputting information; S2, performing real-time positioning, S3, adopting electric shock for warning; and S4, performing statistical analysis. The wearable device-based electronic fence has a reasonable structure, and though arrangement of a warning mechanism, livestock is expelled by shape whistles which are produced by the warning mechanism when the livestock approaches the electronic fence, so that the number of the electric shocks applied to the livestock is reduced; and if the livestock ignores the whistles and continues to go near the electronic fence, the electric shocks are applied to the livestock, and therefore thelivestock produces a conditioned reflex through the action of the whistles and electric shocks, and then goes away from the position of the electronic fence actively.

Owner:山东筑安农牧科技股份有限公司 +1

Transparent conductive laminated body and touch panel provided with transparent conductive laminated body

InactiveCN106104444ANot prone to short circuitLess prone to malfunctionNanotechConductive layers on insulating-supportsHigh humidityOptoelectronics

Provided are: a transparent conductive laminated body wherein malfunction does not occur at high temperatures and high humidity; and a touch panel that is provided with the transparent conductive laminated body. The transparent conductive laminated body is provided with: a transparent base material; and a transparent electrode layer, which is laminated on one surface or both surfaces of the transparent base material, and which contains a resin. The transparent electrode layer includes a plurality of conductive regions having a fibrous metal, and a plurality of nonconductive regions, and the thickness of the transparent electrode layer is 30-150 nm.

Owner:TOPPAN INC

Alkali soluble resin and photosensitive resin composition containing the same

InactiveCN103509151AImprove chemical resistanceExcellent sensitivity and adhesionOptical filtersPhotosensitive materials for photomechanical apparatusFlat panel displayPhotoresist

The invention relates to an alkali soluble resin containing a repetitive unit represented by the following chemical formula 1, and a photosensitive resin composition and a colored photosensitive resin composition containing the same, wherein physical properties, such as adhesivity, chemical resistance, developability, sensitivity, strength or elasticity, of the alkali soluble resin are excellent, and the alkali soluble resin is suitable for photoetching material for a panel display, such as a columnar spacer, a color filter, a color resist, a photoresist and so on.

Owner:DONGWOO FINE CHEM CO LTD

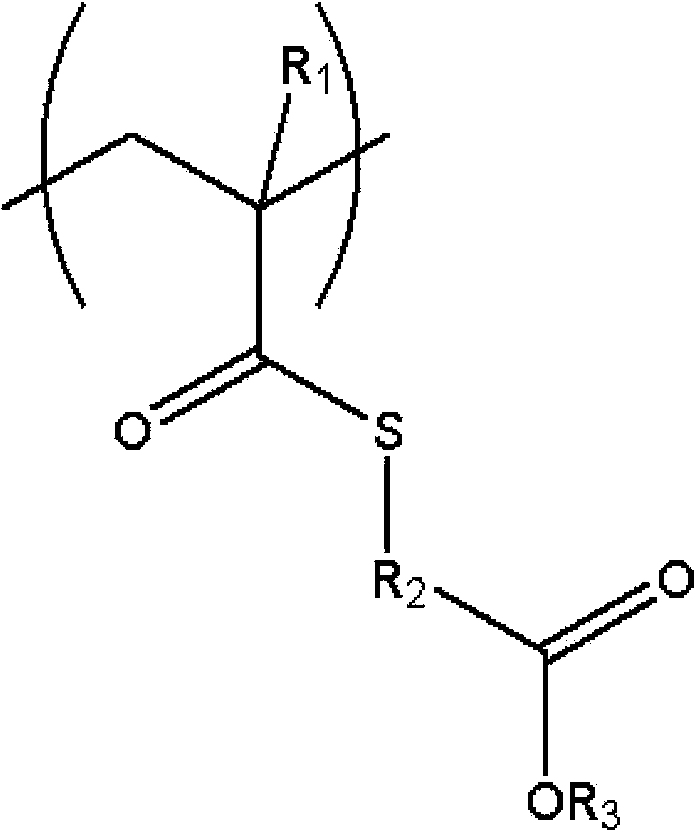

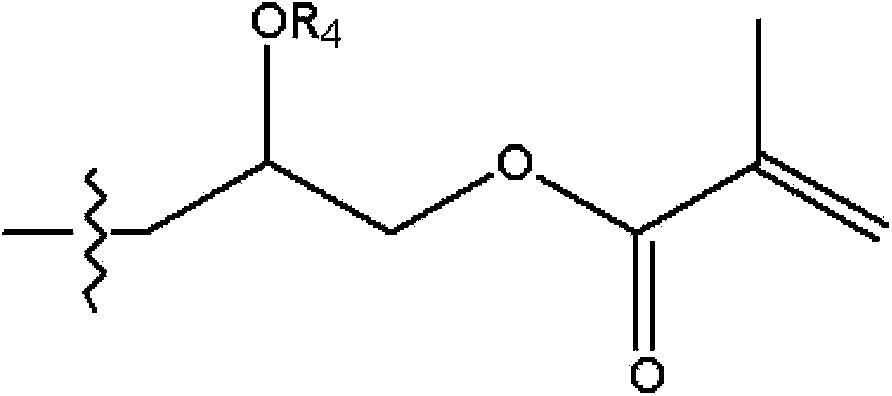

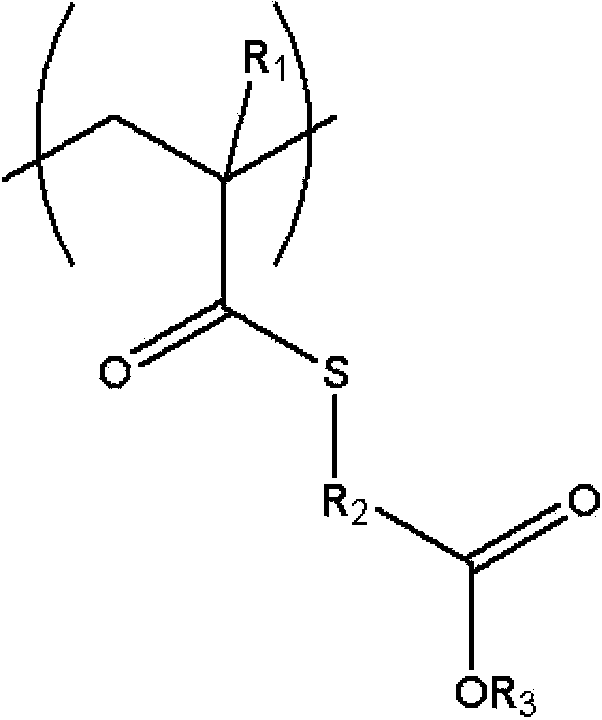

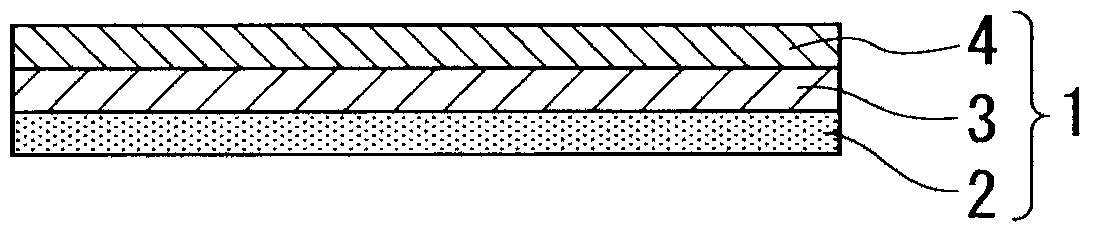

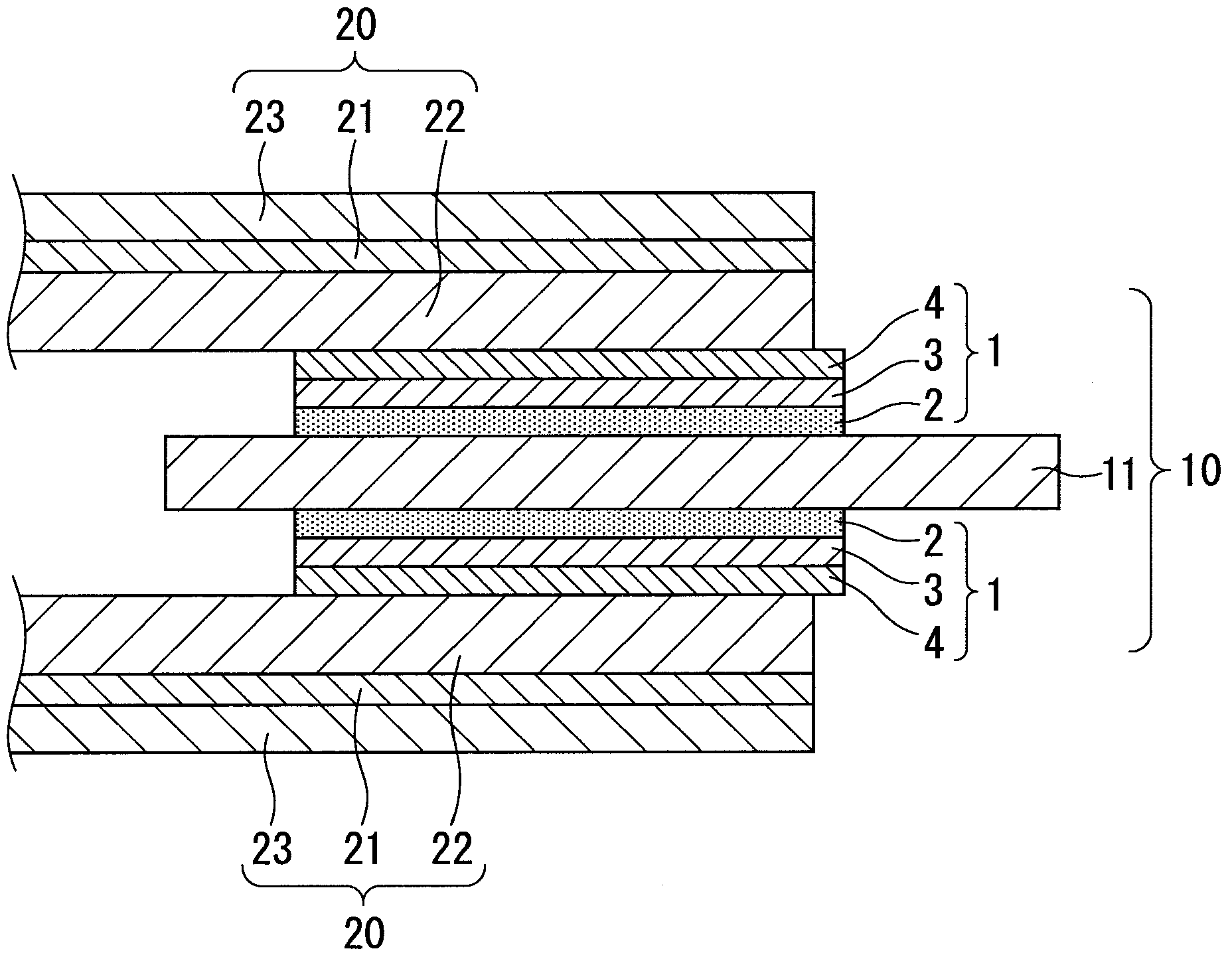

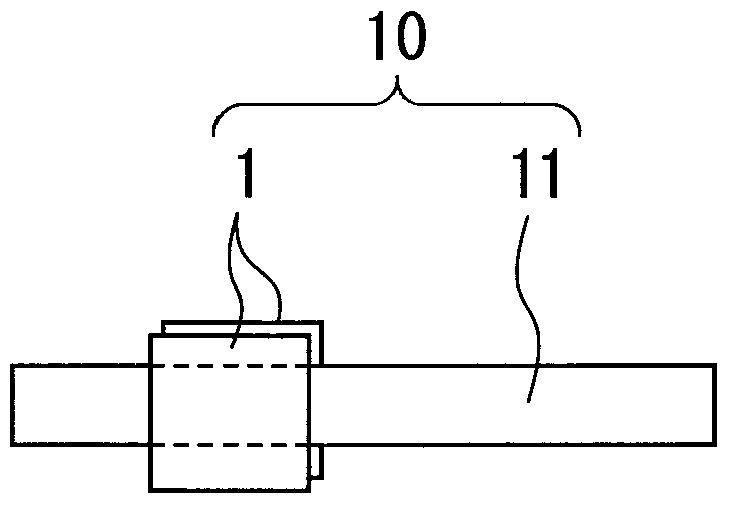

Process for producing sealing film, and sealing film

ActiveCN103222084ANot prone to short circuitImprove joint strengthSynthetic resin layered productsDouble layer capacitorsMolten stateChemical Linkage

A process for producing a sealing film (1) to be interposed between each electrode (11), as a power-generating element, that has been introduced into a bag (20) and the edge of the bag (20), the process comprising: a melt kneading step in which both an acid-modified polyolefin resin A to which a carboxylic acid has been grafted and a resin B having functional groups capable of reacting with the carboxy groups of the resin A are melted and kneaded together to thereby chemically bond the carboxy groups of the resin A to the functional groups of the resin B and convert the resins into a resin C; a heat-resistant-layer formation step in which the resin C is formed into a layer to form a heat-resistant layer (3); an adhesive-layer formation step in which a carboxylic-acid-modified polyolefin resin D is formed into a layer to form an electrode adhesion layer (2) which adheres to electrodes; and a laminating step in which the heat-resistant layer (3) and the electrode adhesion layer (2) are directly laminated to each other when the resin C and / or the resin D is in a molten state.

Owner:FUJIMORI KOGYO CO LTD

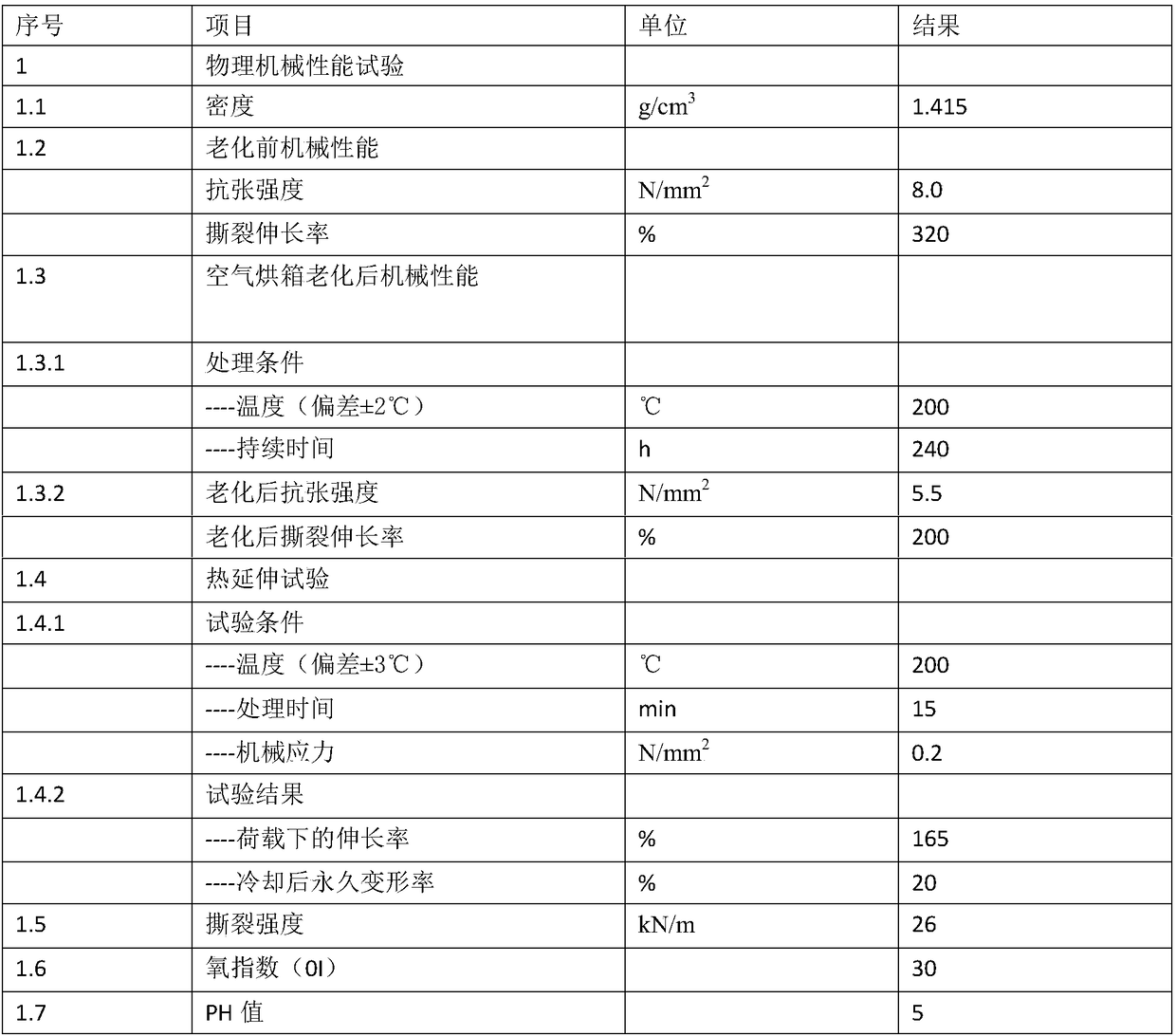

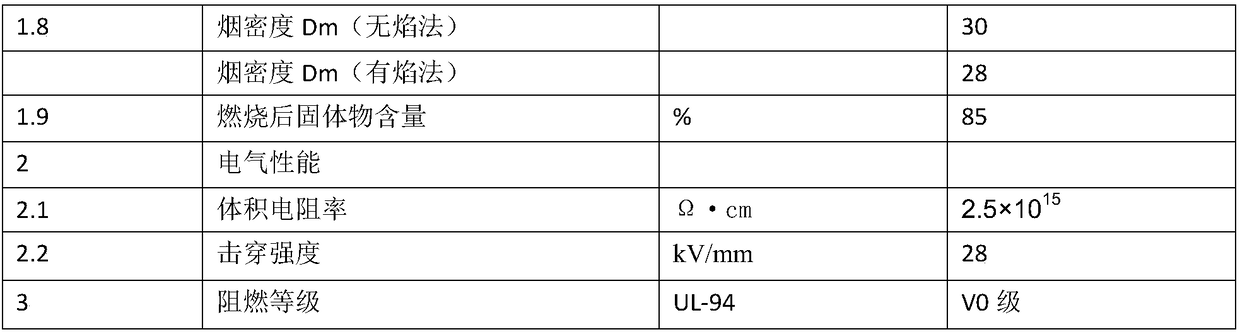

Preparation method of flame-retardant ceramic silicone rubber for safety cables

InactiveCN109021576AGuaranteed uptimeGuaranteed to workPlastic/resin/waxes insulatorsPolymer scienceFumed silica

The invention discloses a flame-retardant ceramic silicone rubber for safety cables. The flame-retardant ceramic silicone rubber is prepared from, by weight, 100 parts of methyl vinyl polysiloxane, 30-60 parts of fumed silica, 1-5 parts of hydroxy silicone oil, 0.1-1 part of dimethyldiethoxysilane, 1-5 parts of polyvinyl hydroxy silicone oil, 0.5-5 parts of a heat conduction filler, 30-80 parts ofceramifying powder, 1-5 parts of titanium dioxide, 0.5-5 parts of a special mold release agent, 1-10 parts of vinyltriethoxysilane, 1-5 parts of alumina and 0.001-0.1 part of platinum. The inventionalso discloses a preparation method of the flame-retardant ceramic silicone rubber for safety cables. The ceramic silicone rubber has good mechanical properties, and can be sintered to form a hard ceramic body when ablated by an open fire in order to isolate flame and prevent fire, so the normal operation of a line under a fire condition is ensured, short circuit and other secondary disasters arenot prone to occur, and the normal operation of electricity and communication is ensured.

Owner:镇江创达新材料科技有限公司

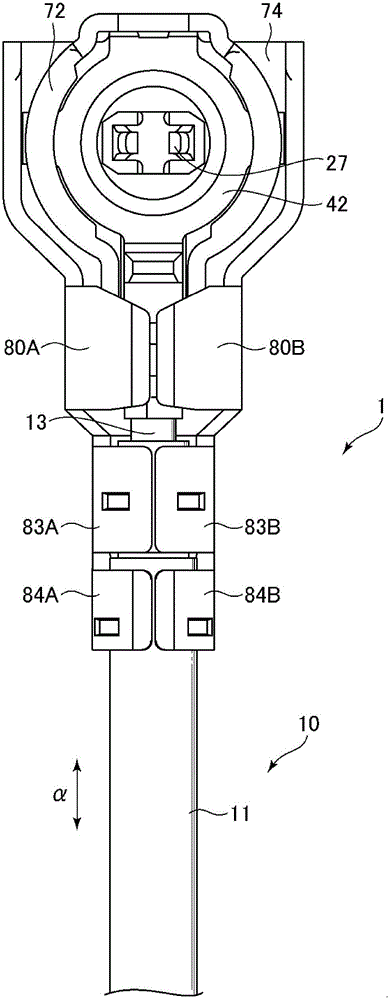

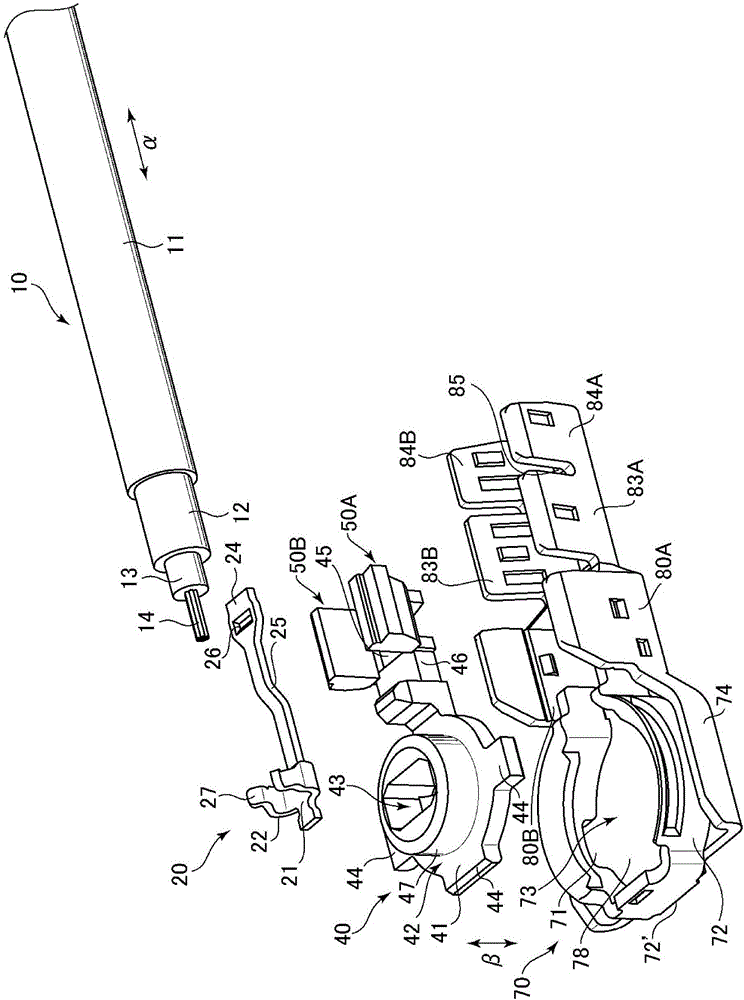

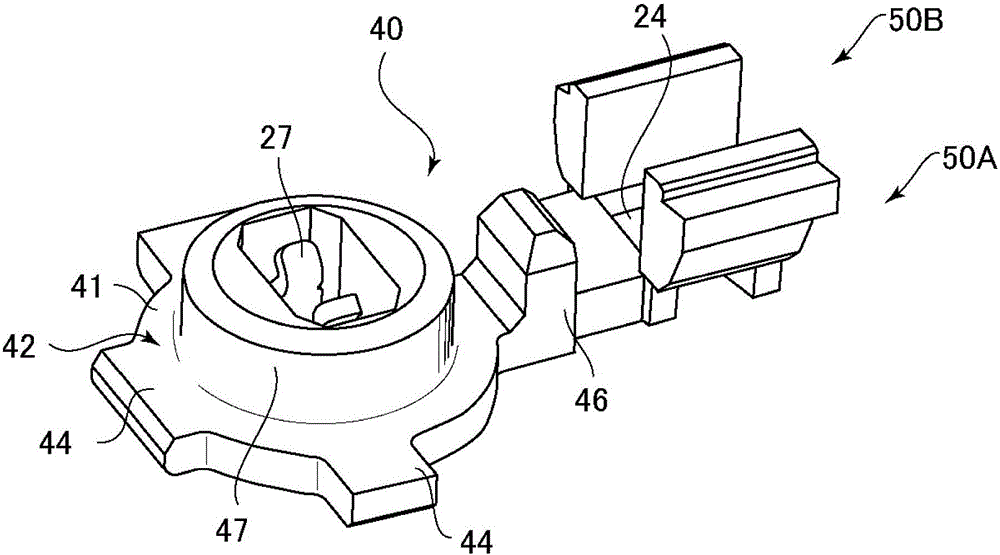

Coaxial connector

ActiveCN106025734AImpedance characteristics are stableNot prone to short circuitContact member manufacturingElectrically conductive connectionsElectrical conductorMechanical engineering

Owner:HIROSE ELECTRIC GROUP

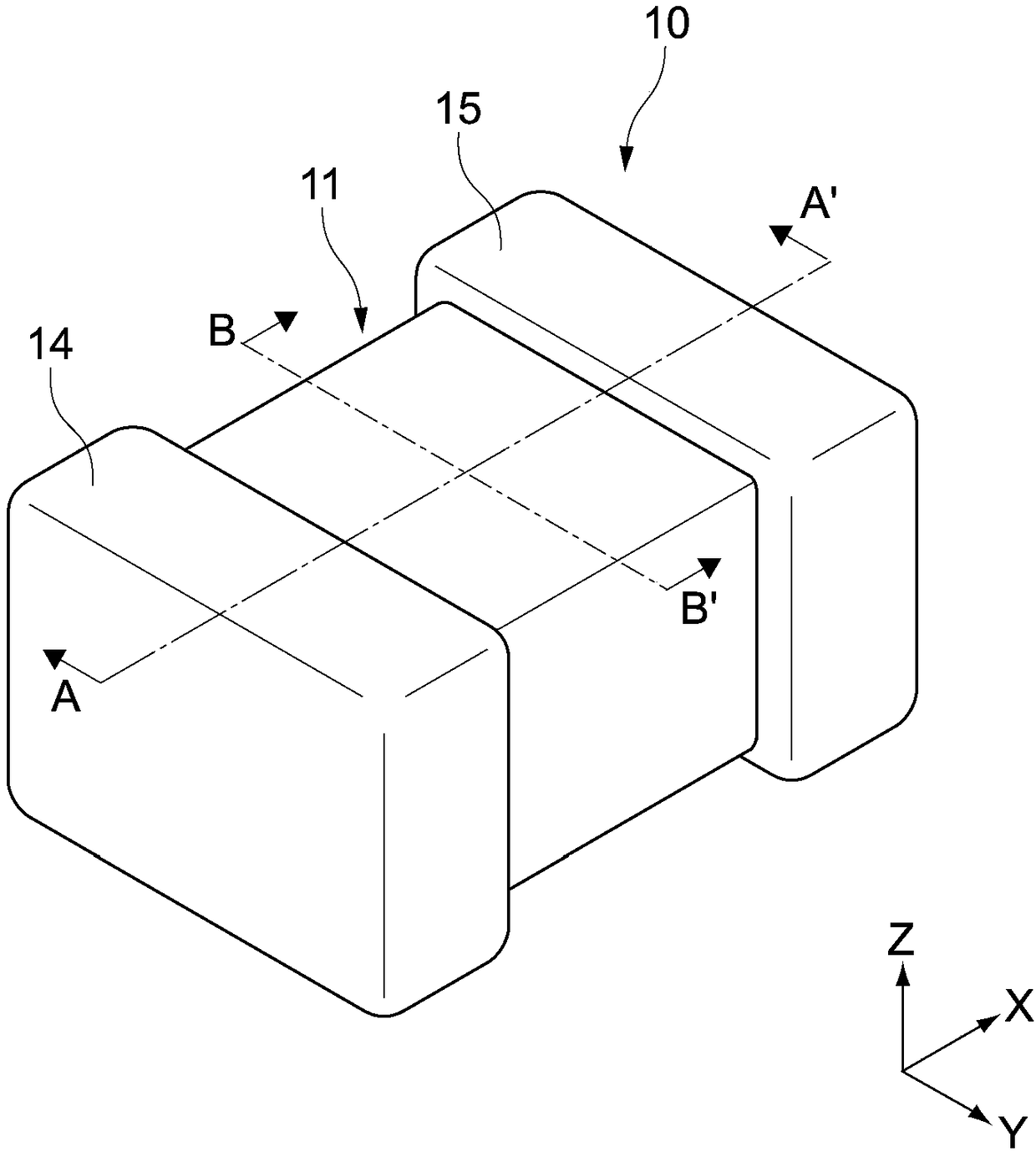

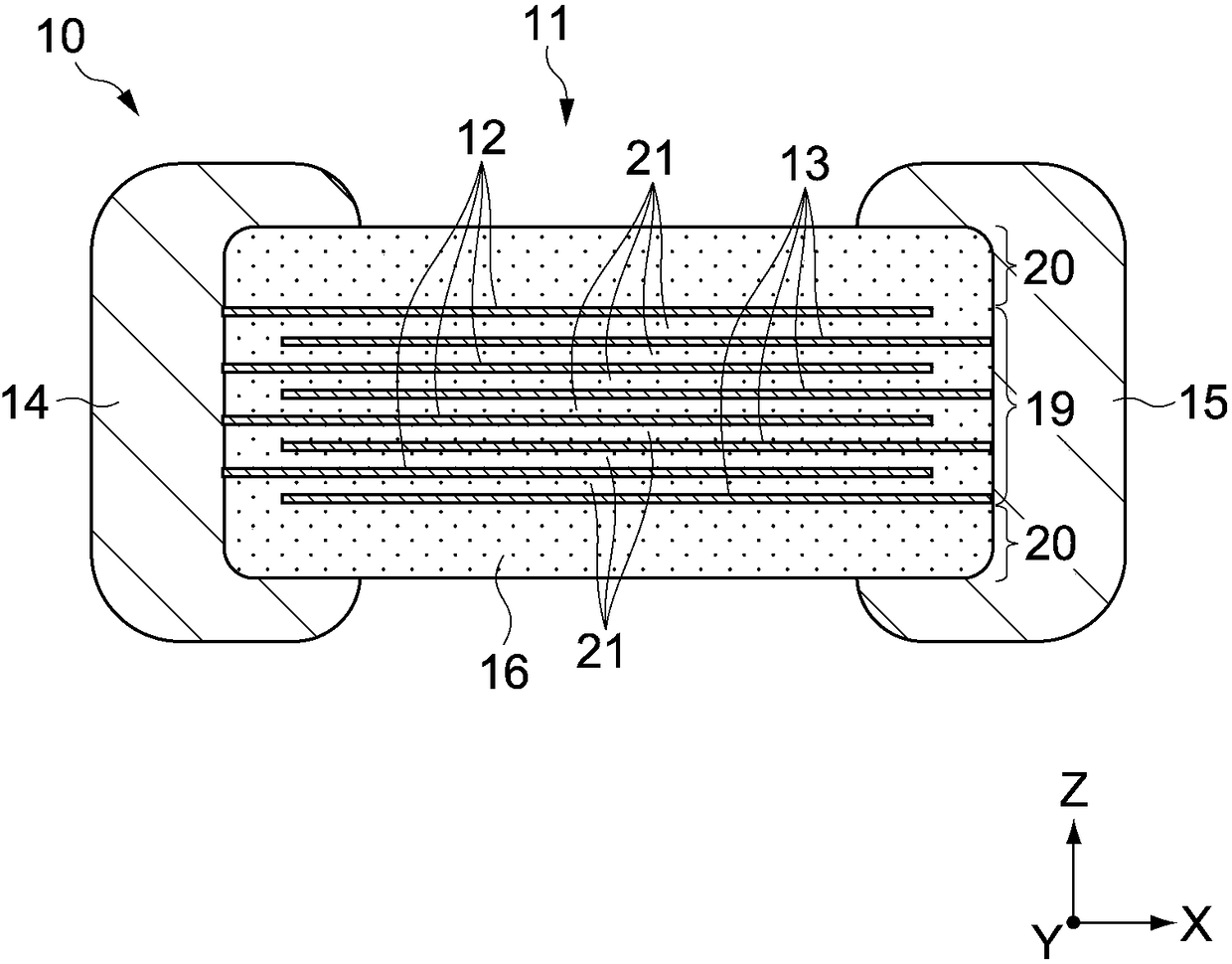

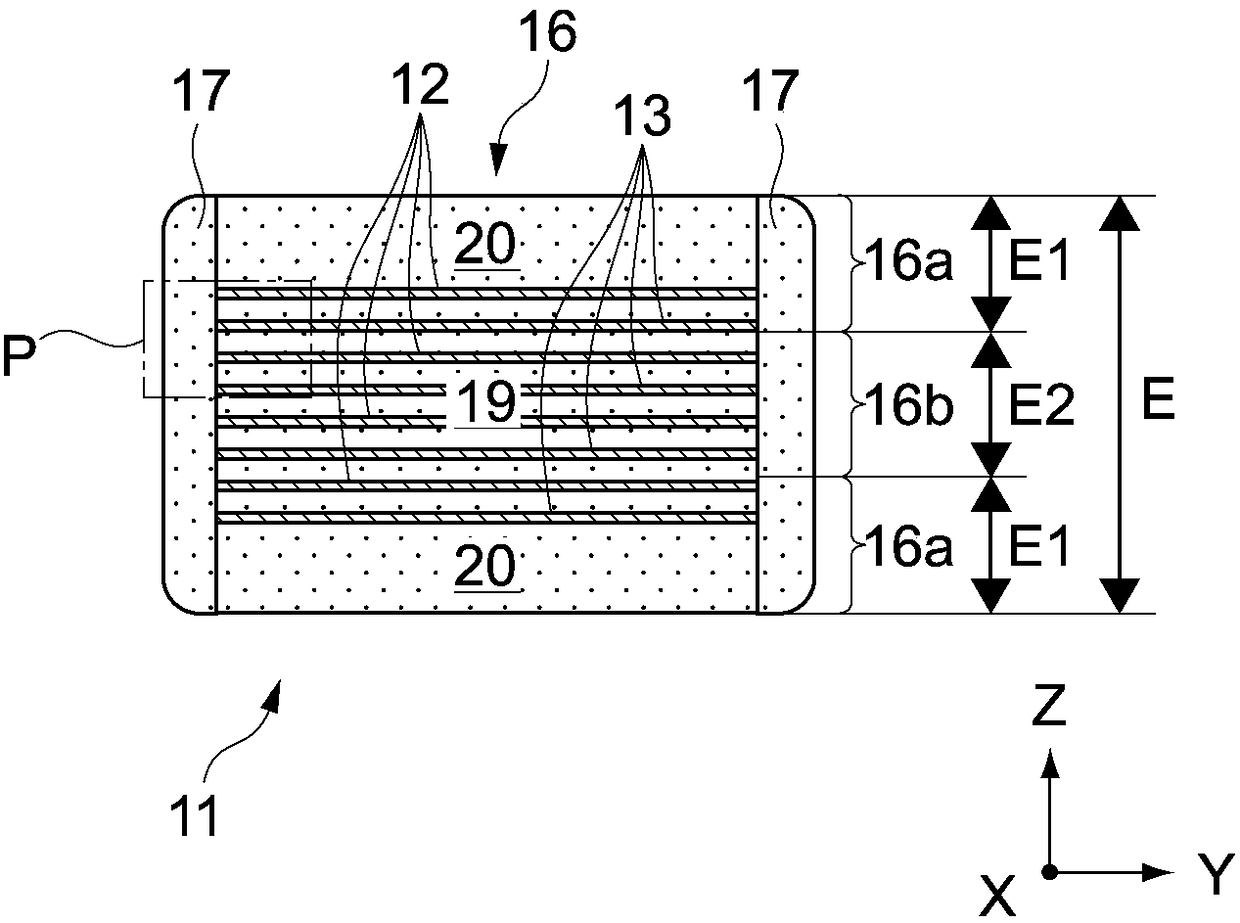

Multi-layer ceramic capacitor

ActiveCN108695070ANot prone to short circuitFixed capacitor electrodesFixed capacitor dielectricSurface layerMetallurgy

The invention provides a multi-layer ceramic capacitor in which short circuit between internal electrodes does not easily occur even if the average thickness of ceramic layers is set to be below 0.4 [mu]m. The multi-layer ceramic capacitor includes a multi-layer unit and a side margin. The multi-layer unit includes ceramic layers laminated in a first direction, internal electrodes disposed betweenthe ceramic layers, a main surface oriented in the first direction, a surface layer portion in a range from the main surface to a predetermined depth, and a center portion adjacent to the surface layer portion in the first direction. The side margin covers the multi-layer unit from a second direction orthogonal to the first direction. The ceramic layers have an average dimension that is 0.4 [mu]mor less in the first direction. Each of the internal electrodes includes an oxidized region adjacent to the side margin. The oxidized region in the surface layer portion has a dimension in the seconddirection that is equal to or more than twice the average dimension of the ceramic layers in the first direction.

Owner:TAIYO YUDEN KK

Cable safe in use

InactiveCN107633909ANot prone to short circuitEnsure safetyInsulated cablesInsulated conductorsEngineeringSecond ancillary

The invention discloses a cable safe in use. The cable comprises an outer sheath, a wrapping layer and a stranded cable body, which are arranged in sequence from the outside in. The stranded cable body is formed by support frames, a center cable core, peripheral cable cores, first auxiliary flexible pipes and second auxiliary flexible pipes. The center cable core is sleeved by the plurality of support frames. Each support frame is formed by a center ring and baffle plates. The center ring is sleeved on the center cable core; and the center ring is peripherally and fixedly provided with the plurality of baffle plates. The peripheral cable cores are distributed around the center cable core. The peripheral cable cores are separated by the baffle plates. Gaps between the peripheral cable coresare provided with the plurality of first auxiliary flexible pipes and the second auxiliary flexible pipes. The first auxiliary flexible pipes and the second auxiliary flexible pipes are arranged inside the cable, so that the inner portion of the cable can be cooled effectively, and meanwhile, fire inside the cable can be put out when necessary.

Owner:JIAXING AOYIPU DATA CABLE

Electromagnetic interference prevention overvoltage protection device

InactiveCN103474405AIncreased ability to withstand current and powerNot prone to short circuitSemiconductor/solid-state device detailsSolid-state devicesCapacitanceOvervoltage

The invention discloses an electromagnetic interference prevention overvoltage protection device. The device comprises a semiconductor packaging framework and an overvoltage protection chip arranged on the semiconductor packaging framework. The device is characterized in that the overvoltage protection chip is three P-N junctions so as to form a double-end four-layer bidirectional symmetrical structure; each group is successively doped with N2, P2, N1 and P1 four layer overvoltage protection circuits from top to bottom and is connected in series with a low capacitance surge protector and an electromagnetic interference suppression circuit. As an improvement, a carrier of the semiconductor framework is provided with a convex point seat which is mutually and electrically connected with a pedestal. The convex point seat is connected with the semiconductor overvoltage protection chip so that a right side of the chip is connected with a pin on the semiconductor framework through using a lead. The device of the invention has the advantages that the structure is simple; usage is reliable; surge prevention and electromagnetic interference prevention functions are possessed.

Owner:江苏晟芯微电子有限公司

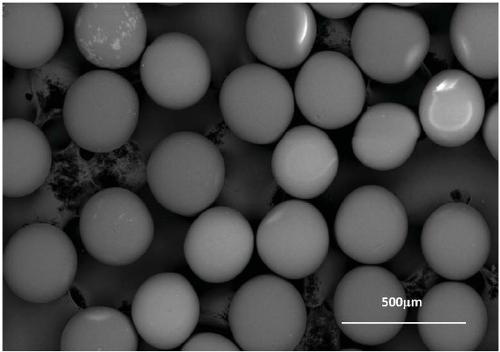

Method for sodium alginate microsphere adsorbent through emulsion polymerization process

InactiveCN109351350AUniform sizeHigh mechanical strengthIon-exchange process apparatusOther chemical processesIonEmulsion

The invention discloses a method for a sodium alginate microsphere adsorbent through an emulsion polymerization process and belongs to the technical field of metal ion adsorption. The method includes:sufficiently mixing chemically modified sodium alginate solution, calcium carbonate, paroline and Span 85 surfactant to form an emulsion, adding glacial acetic acid to release calcium ions, and generating sodium alginate microspheres during high-speed stirring. The sodium alginate microspheres different in grain size and narrow in grain size distribution can be prepared by adjusting agent consumption and stirring condition. Compared with conventional adsorbents taking sodium alginate as a raw material, the microsphere adsorbent prepared by the method has the advantages of uniform size, high mechanical strength and high selective adsorptivity. The microsphere adsorbent has high selectivity to heavy metal in acidic conditions, has high selectivity to heavy metal in acidic to neutral conditions and can be successfully filled and applied in a fixed bed adsorption column, thereby having good industrial application prospect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

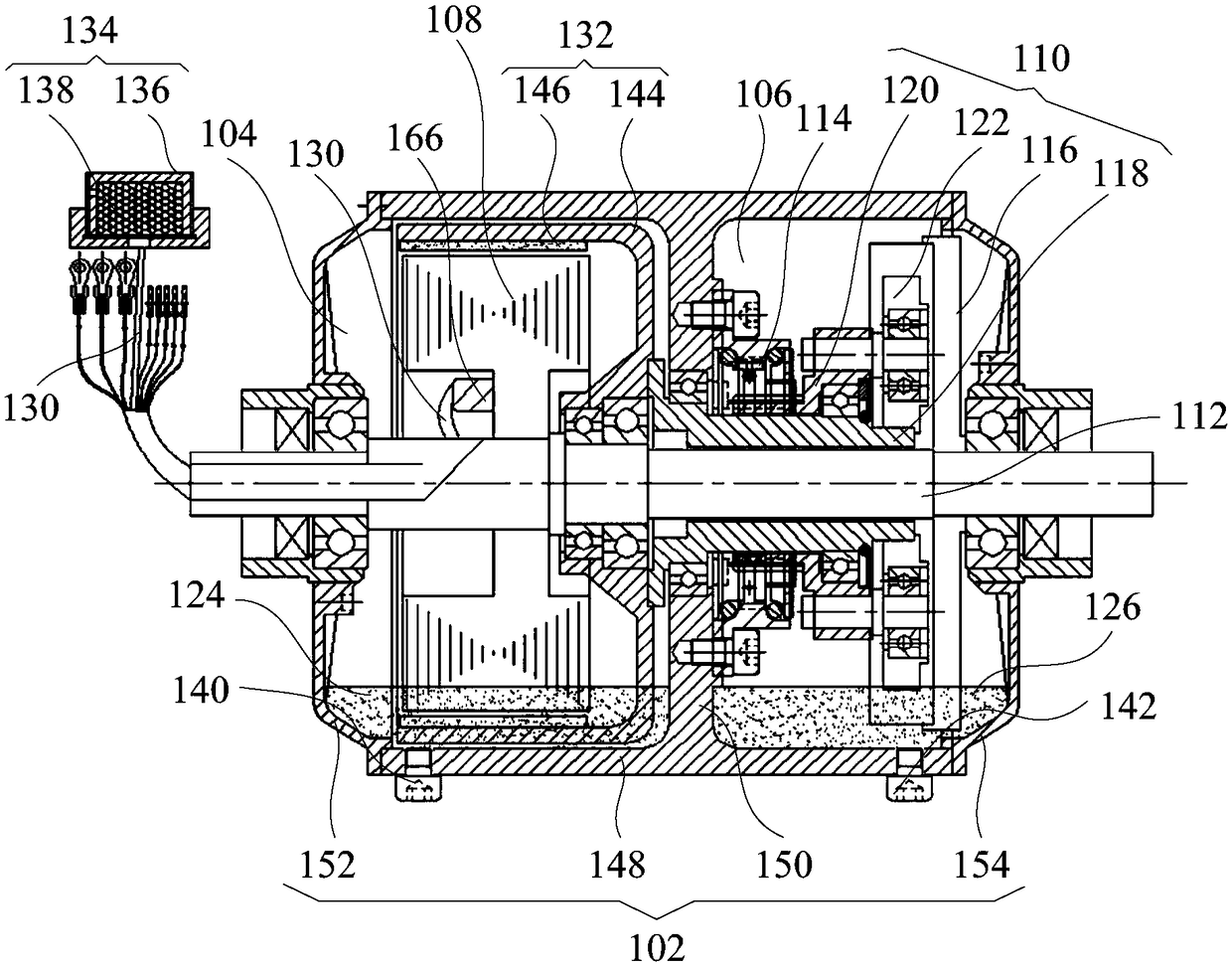

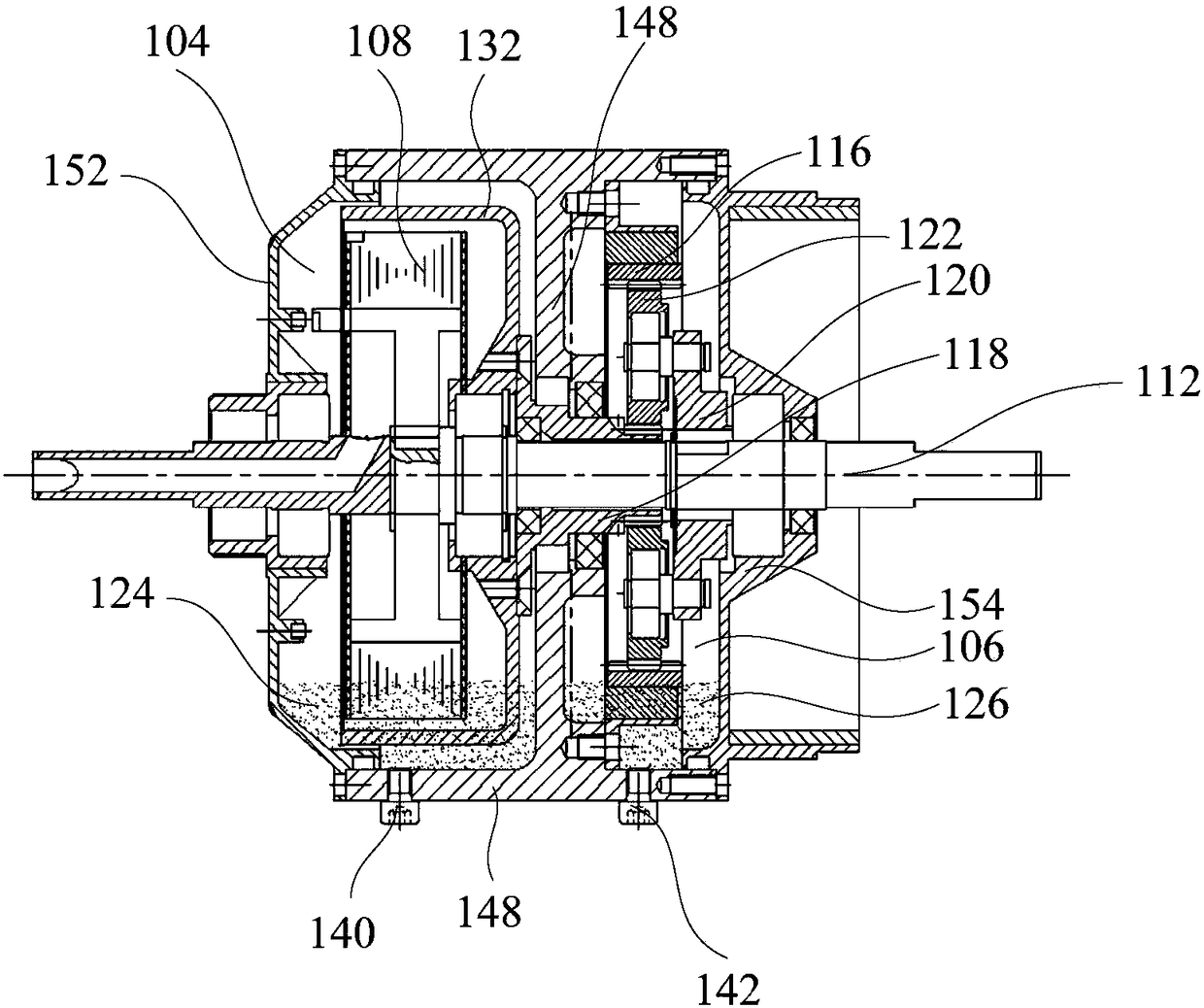

Gear motor

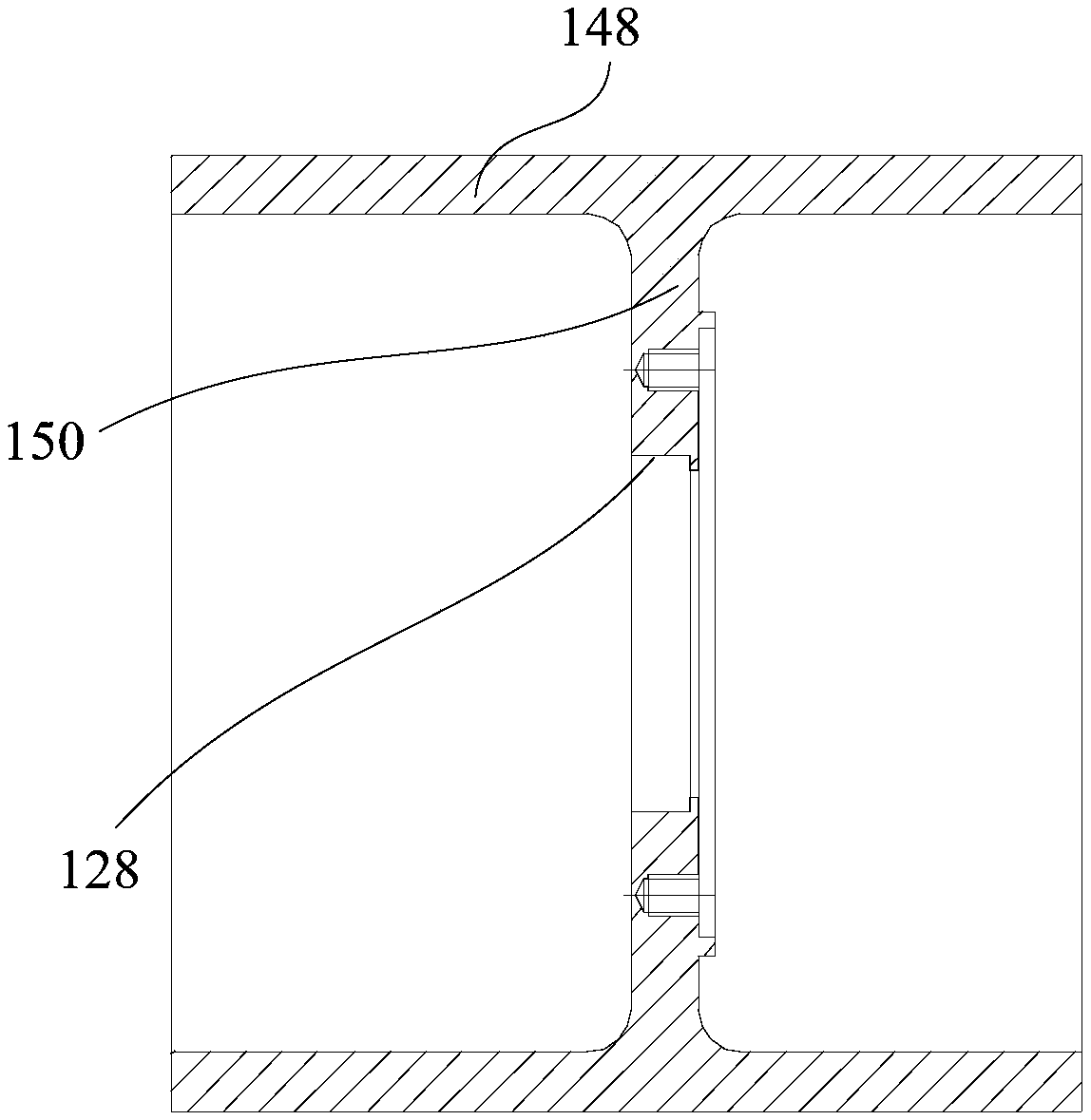

PendingCN108768067ANot prone to short circuitLess prone to leakageMechanical energy handlingCooling/ventillation arrangementGear wheelAccelerated aging

The invention provides a gear motor. The gear motor comprises a shell, a motor shaft, a motor assembly and a gear reduction mechanism, wherein a first installation cavity, a second installation cavityand an installation hole for communicating the first installation cavity and the second installation cavity are arranged in the shell; the motor shaft is arranged in the installation hole in a sleeved mode, at least one end of the motor shaft extends out of the shell, and the motor shaft and the shell can rotate relative to each other; the motor assembly is arranged in the first installation cavity, the motor assembly comprises a stator winding assembly and a rotor assembly, wherein the stator winding assembly is fixed on a motor shaft, and the rotor assembly is arranged outside the stator winding assembly in a sleeved mode; the gear reduction mechanism is arranged in the second installation cavity, the input end of the gear reduction mechanism penetrates through the installation hole andis connected to the rotor assembly, and the output end of the gear reduction mechanism is connected to the shell. According to the technical scheme, the motor assembly and the gear reduction mechanism are not prone to influence each other, so that the accelerated aging of the gear reduction mechanism is not easily caused due to the fact that the temperature rise of the motor assembly is too high,and the situation that lubricating oil on the gear reduction mechanism intrudes into the motor assembly is avoided.

Owner:ZHEJIANG LUYUAN ELECTRIC VEHICLE

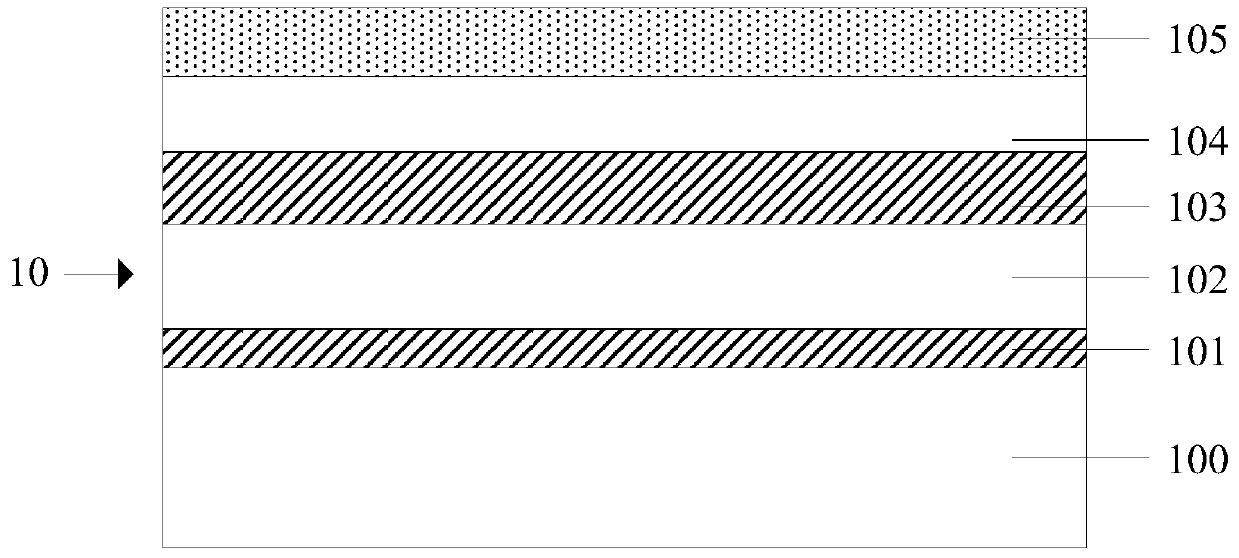

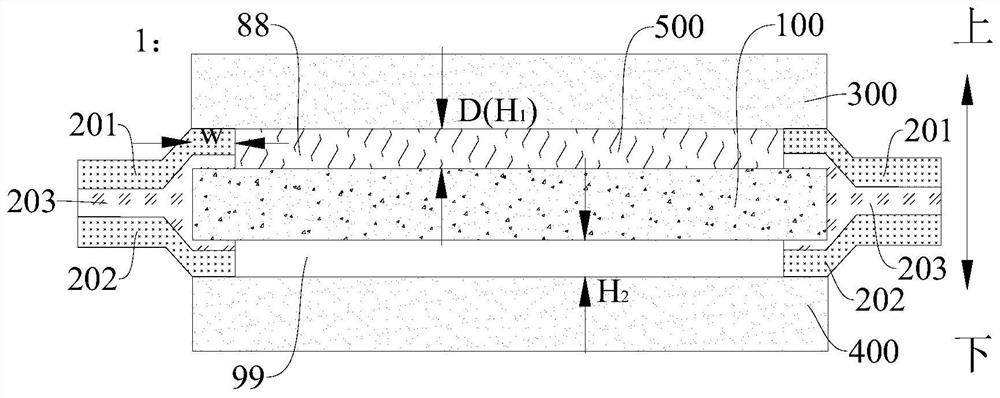

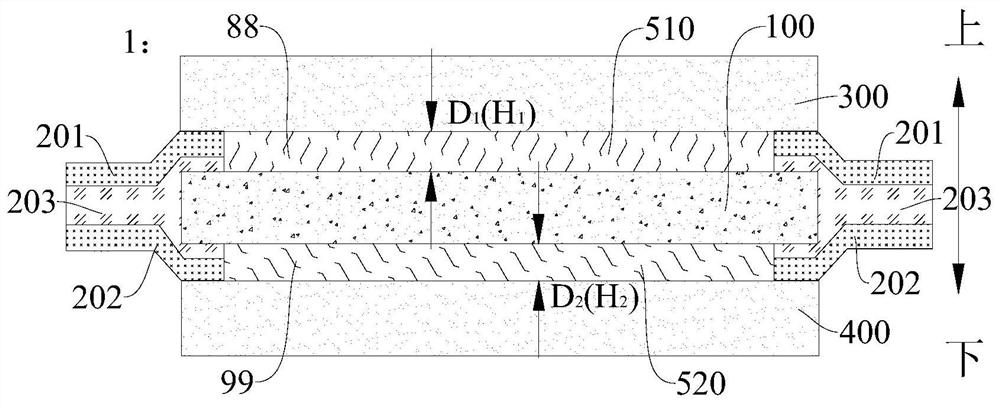

Packaging structure of fuel cell membrane electrode assembly and manufacturing method and application thereof

InactiveCN112242538AAdvantages of package structureNot easy to damageFinal product manufactureFuel cellsFuel cellsPtru catalyst

The invention discloses a packaging structure of a fuel cell membrane electrode assembly and a manufacturing method and application thereof. The invention provides the packaging structure of the membrane electrode assembly and the manufacturing method and application thereof. The packaging structure comprises the membrane electrode assembly; a sealing frame which comprises a first closed annular frame and a second closed annular frame which are in lap joint with the outer edge of the membrane electrode assembly and are connected through a bonding layer; a first gas diffusion layer which is arranged on the upper surface of the sealing frame, wherein a first accommodating space is defined by the first gas diffusion layer, the sealing frame and the membrane electrode assembly; a second gas diffusion layer which is arranged on the lower surface of the sealing frame, wherein a second accommodating space is defined by the second gas diffusion layer, the sealing frame and the membrane electrode assembly; a third gas diffusion layer which is arranged in at least one of the first containing space and the second containing space, wherein when the third gas diffusion layer is arranged in thefirst containing space, the thickness of at least one part is the same as the height of the first containing space. When arranged in the second containing space, at least one part of the thickness isthe same as the height of the second containing space. The catalyst layer in the packaging structure is not easy to degrade, short circuit is not easy to occur, gas exchange is not easy to occur at two sides of the membrane electrode assembly, and the performance is better.

Owner:FTXT ENERGY TECH CO LTD

Solid electrolyte, solid lithium ion battery and preparation method of solid lithium ion battery

ActiveCN111193066AImprove ionic conductivityImprove stabilitySecondary cellsSolid state electrolytePolyethylene oxide

The invention discloses a solid electrolyte, a solid lithium ion battery and a preparation method of the solid lithium ion battery. The solid electrolyte is a quaternary solid polymer electrolyte formed by crosslinking polyethylene oxide, bis(trifluoromethylsulfonyl)imide, branched chain polymethyl methacrylate and silicon dioxide in a molar ratio of (8-10): (1-2): (2-3): (1-2) under photo-initiation, and is a solid electrolyte adapted to a 4V high-voltage positive electrode material. The solid lithium ion battery comprises a 4V-grade elastic positive electrode layer, a solid electrolyte layerand an elastic negative electrode layer which are packaged by packaging films, and is an elastic solid lithium ion battery with 4V high-voltage output.

Owner:QINGDAO UNIV OF SCI & TECH

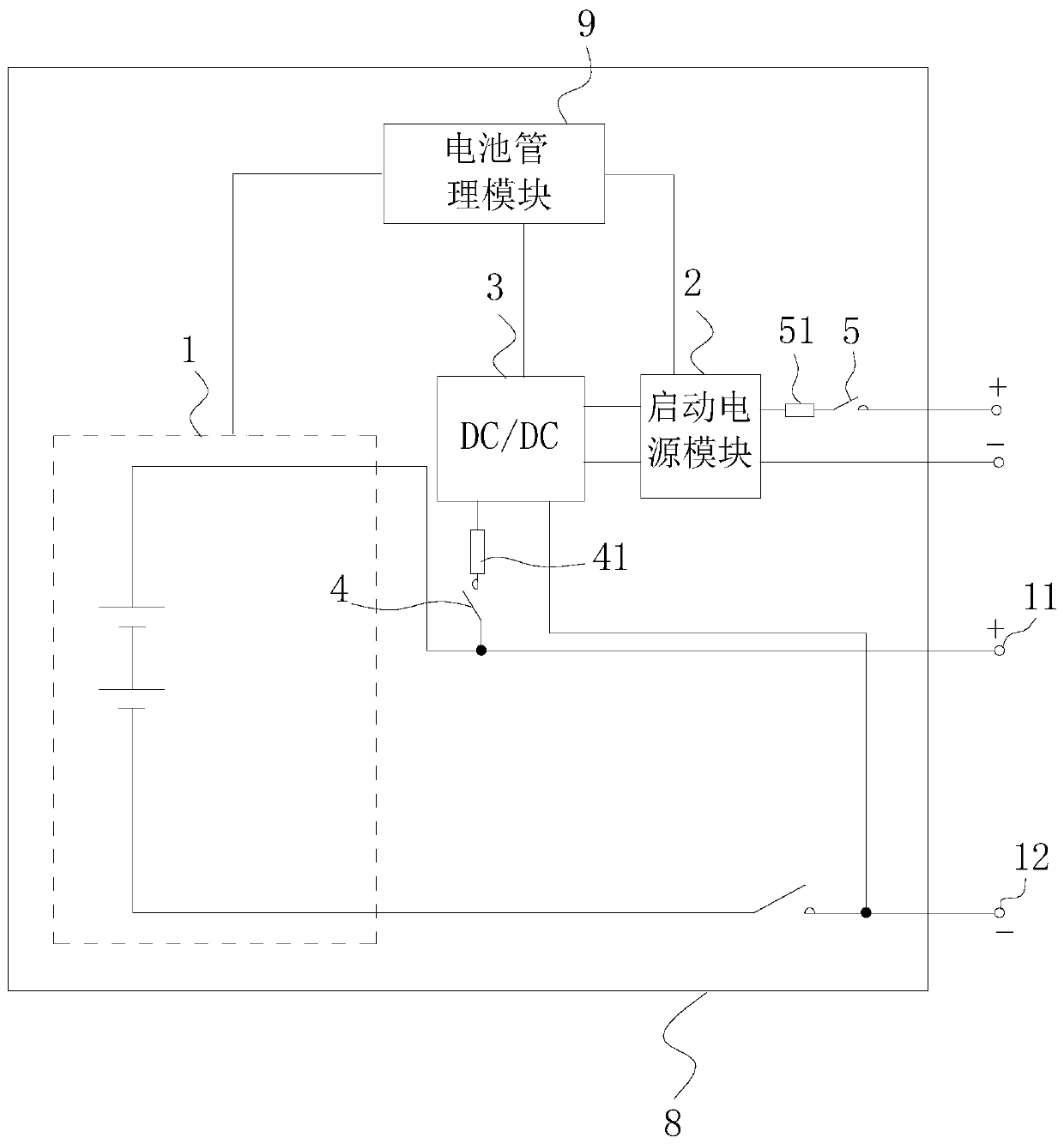

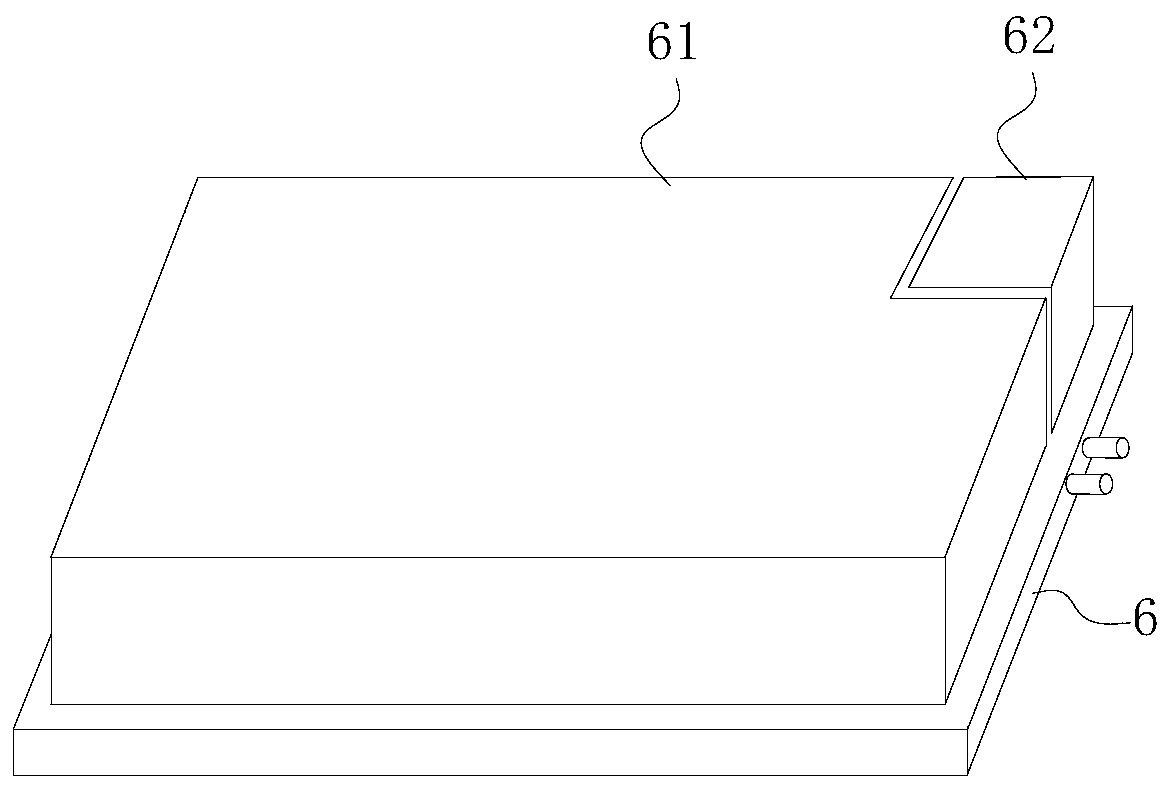

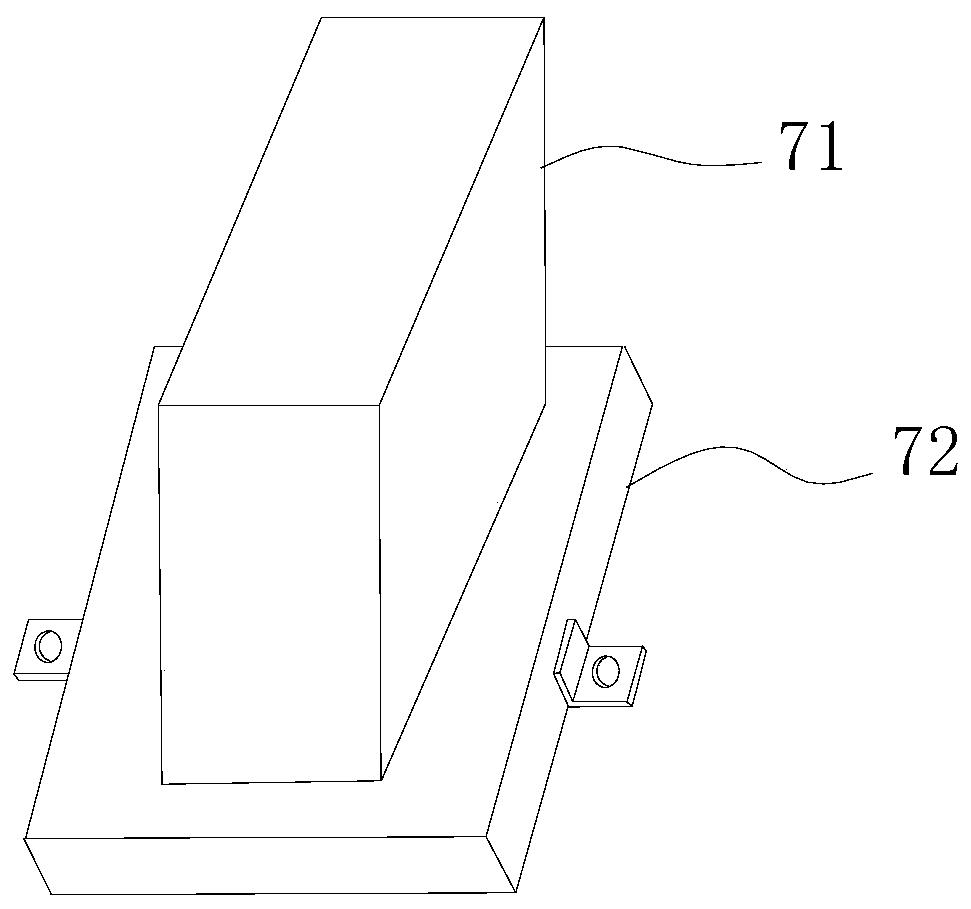

New energy automobile double-source output power battery pack

PendingCN109795370AExtend your lifeEnergy density has little effectElectric devicesElectric powerElectricityPower battery

The invention provides a new energy automobile double-source output power battery pack. The new energy automobile double-source output power battery pack comprises a power battery module, a starting power source module, a bidirectional DC / DC (direct current / direct current) module and a battery management module, which are all arranged in one power battery pack box; the power battery module is electrically connected to the high-voltage end of the bidirectional DC / DC module; the starting power source module is electrically connected with the low-voltage end of the bidirectional DC / DC module; thebattery management module is used for detecting stored energy of the power battery module and the starting power source module; when the stored energy of the power battery module is lower than a first preset value and the stored energy of the starting power source module is higher than a second preset value, the battery management module controls the bidirectional DC / DC module to discharge electricity from the starting power source module to the power battery module to achieve rapid charging of the power battery module with the starting power source module.

Owner:深圳众鼎知识产权创新发展有限公司

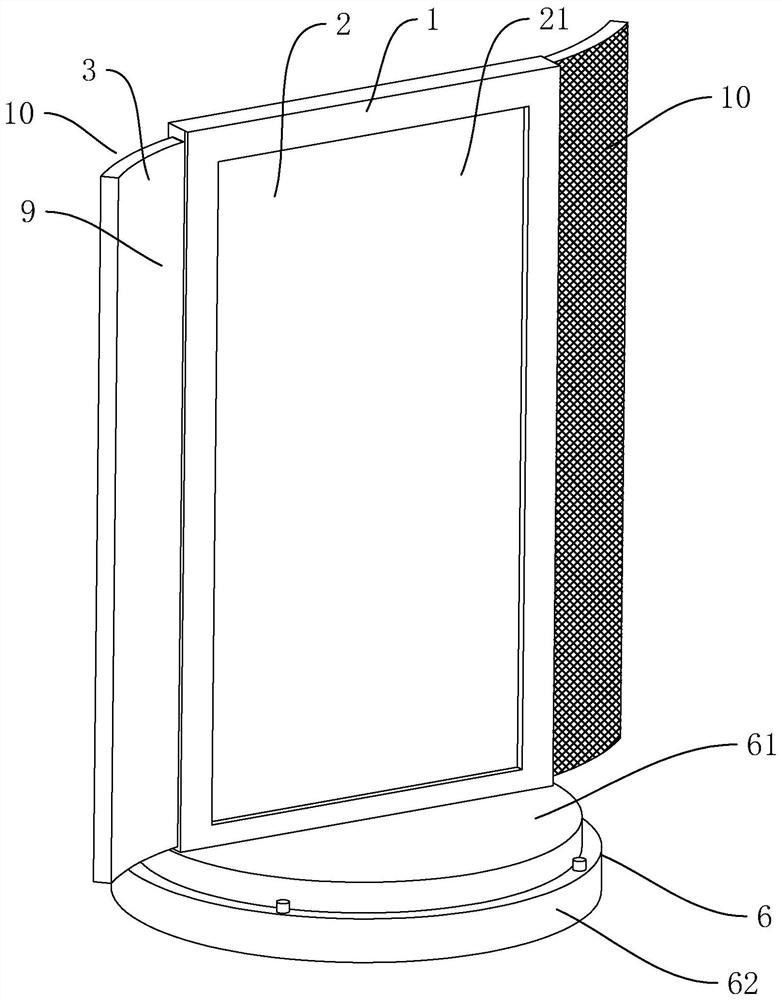

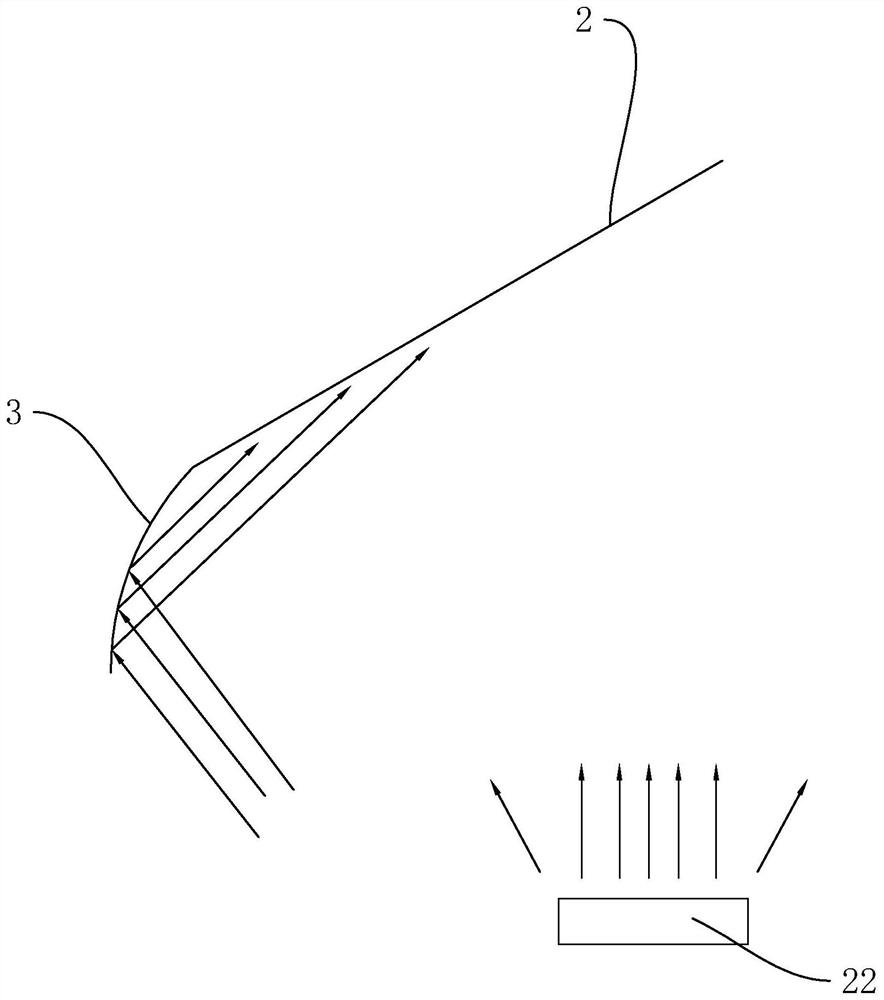

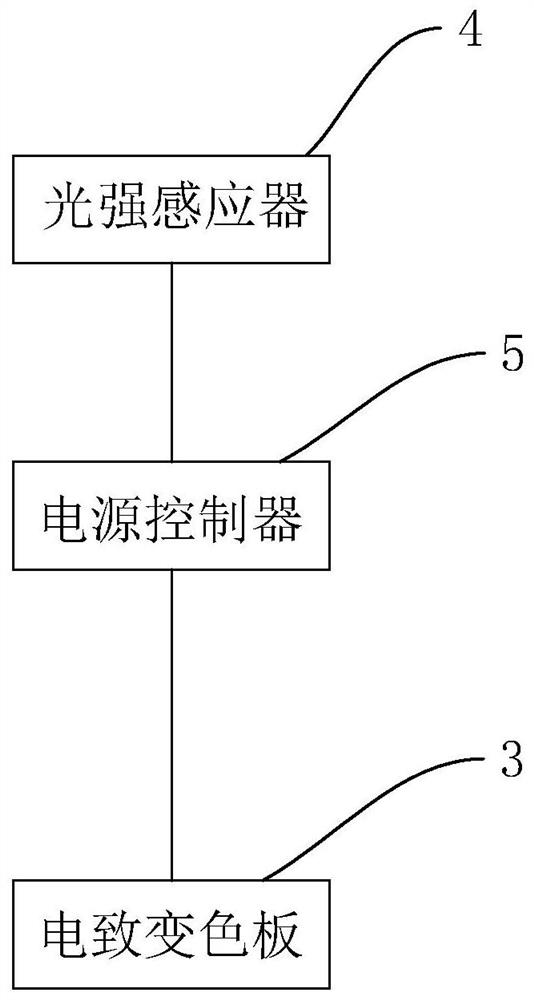

Photovoltaic anti-glare panel

ActiveCN112681166ANormal anti-glare effectReduce occlusionBatteries circuit arrangementsProtective constructionElectrochromismMaterials science

The invention relates to a photovoltaic anti-glare panel which comprises a frame and a photovoltaic module arranged in the frame, an electrochromic plate is installed on the outer side wall of the frame, a light intensity sensor and a power supply controller connected to the output end of the light intensity sensor are further arranged on the frame, and the power supply controller is connected to the electrochromic plate and pre-provided with a color changing threshold value. When a detection signal output to the power supply controller by the light intensity sensor is greater than or equal to a threshold value, the power supply controller controls the electrochromic plate to be in a light transmission state; and when the detection signal output to the power supply controller by the light intensity sensor is smaller than the threshold value, the power supply controller controls the electrochromic plate to be converted into a shading state. The photovoltaic anti-glare panel not only can output large electric energy in the daytime, but also can collect car lamp light for power generation at night.

Owner:广州北环智能交通科技有限公司 +2

Preparation method of electrochemical combined electrode

This invention relates to a method for processing electrochemical combination electrodes sealed by the nm flexible epoxy resin material including: 1, inserting a working electrode matrix material into a conductive support copper rod wrapped with an insulation pyrocondensed tube, a hole Ag reference electrode is welded to the support copper rod, the bottom of a hole Pt counter-electrode is welded to the support copper rod, the hole Ag reference electrode, the hole Pt counter-electrode and the working electrode matrix are arrayed from inside to outside with the working electrode at the middle, the tops of which are at a same plane, the support copper rods of them are fixed by a pyrocondensed tube and put into a die set and fixed, 2, casting the nm flexible epoxy resin material onto the die set to deaerate and cure it, 3, taking out the electrode after cooling it and polishing it.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Corrugated wet-type electric dust remover anode

InactiveCN104722406AReduce voltageIncrease spacingElectrode constructionsTitanium alloyTitanium plate

The invention belongs to the field of environmental engineering and relates to a corrugated wet-type electric dust remover anode. The electric dust remover anode is a titanium plate or a titanium alloy plate. The thickness of the titanium plate or the titanium alloy plate is 2-4 mm; the titanium plate or the titanium alloy plate is pressed into a corrugated shape which is formed by up-down connection of a 30-degree arc and a semicircle with the diameter being 10-500mm. The corrugated wet-type electric dust remover anode has the advantages that due to adoption of a large-channel corrugated design, the dust depositing effect is effectively improved, the dust-depositing blind areas are solved, and the anode spacing is increased under the condition of not increasing the voltage, so that the occurrence of the short-circuit phenomenon is reduced, the quantity of anode plates is reduced and the expenditure is saved; and due to the corrugated design, the discharging and the dust deposition are divided into two areas, so that the problem that the power needs to be cut off when the existing wet-type electric dust remover is washed is effectively solved. Since the titanium plate or the titanium alloy plate is used as the dust remover anode, the problems that the existing anode is too heavy, the base frame cannot bear the weight and the anode is extremely easy to corrode are solved.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com