Lithium-ion battery separator, and preparation method and application thereof

A lithium-ion battery, separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of battery cycle performance consistency and reliability instability, safety performance needs to be further improved, etc., to achieve thermal shrinkage area It is not easy to expand, and it is beneficial to improve the stability and safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

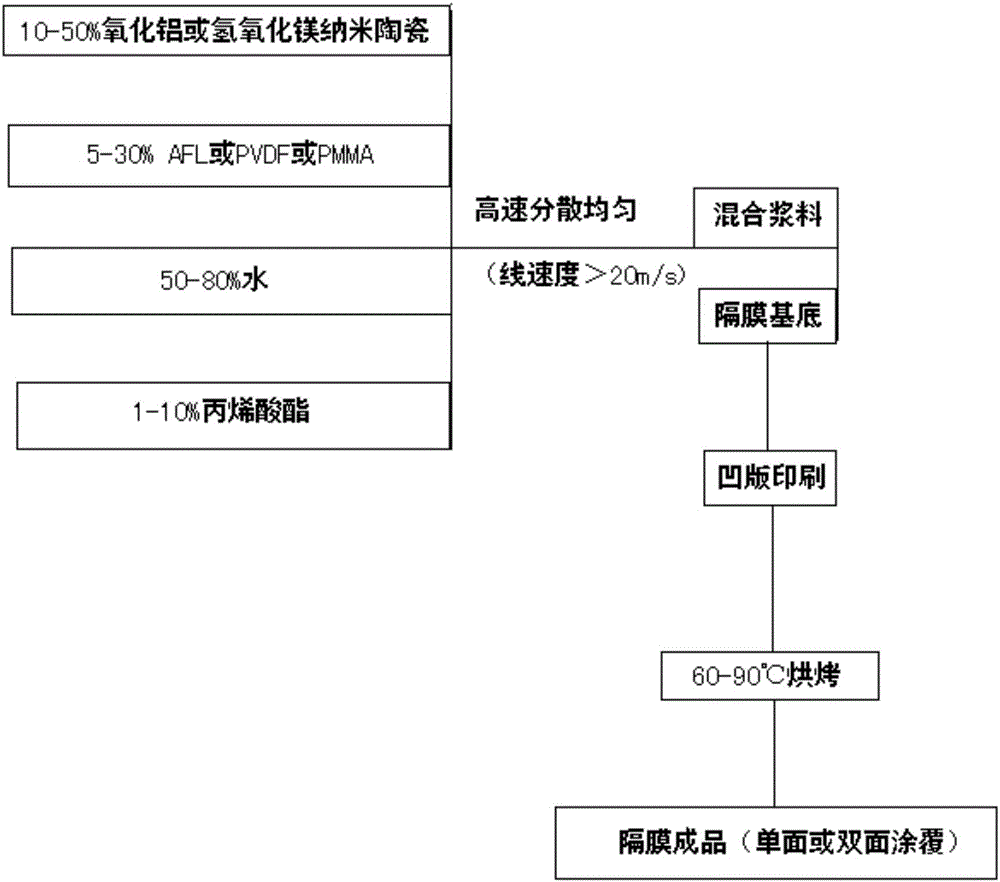

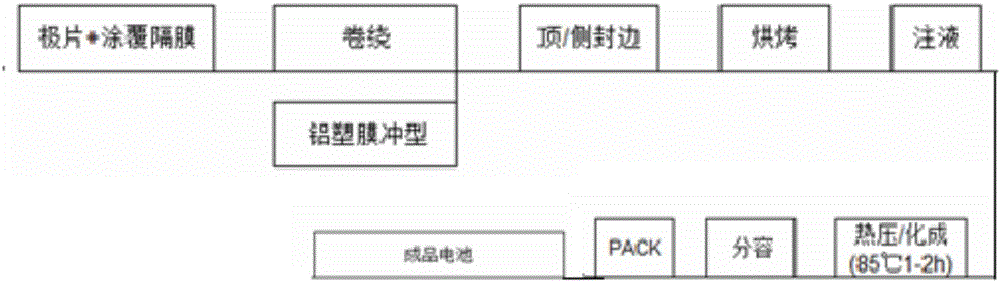

[0061] In the present invention, the method of compounding the water-based functional layer on the surface of the diaphragm substrate may be a coating method, or other methods capable of forming a coating. Specifically, an embodiment of the present invention provides a method for preparing a lithium-ion battery separator, comprising the following steps:

[0062] Coating the inorganic nano-ceramic slurry and the water-based functional binder slurry on one or both sides of the separator substrate respectively, and drying to form an inorganic nano-ceramic layer and a water-based functional binder layer respectively to obtain a lithium-ion battery separator; the water-based The functional binder slurry includes a water-based functional binder and water;

[0063] Alternatively, the mixed slurry is coated on one or both sides of the separator substrate, and dried to form a mixed material layer to obtain a lithium ion battery separator; the mixed slurry includes inorganic nano-cerami...

Embodiment 1

[0102] In terms of mass fraction, 10% of alumina nano-ceramic powder, 30% of water-based functional binder AFL (Japan ZEON company, model BM-2509), 1% of acrylate and 59% of water were mixed in a 25m The line speed of / s disperses evenly at high speed to obtain a mixed slurry;

[0103] The mixed slurry was coated on one side of the separator substrate by a gravure printing process, and baked at a temperature of 90° C. to obtain a lithium-ion battery separator with a coating thickness of 3 μm.

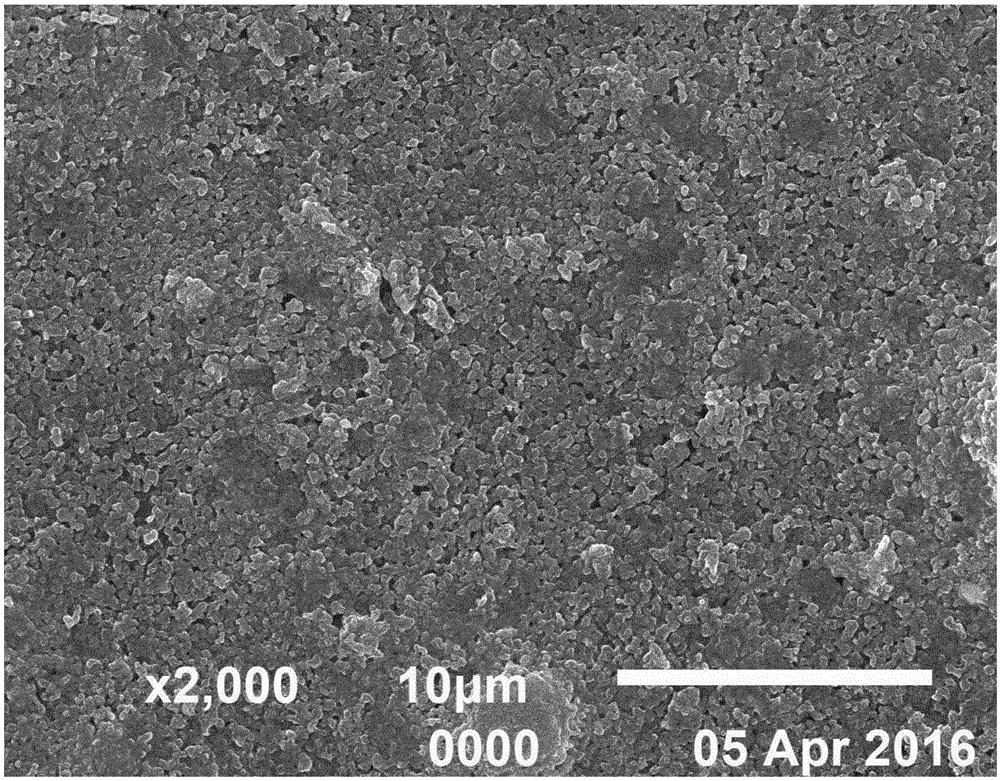

[0104] Carry out scanning electron microscope analysis (SEM) to described coating, its scanning electron microscope picture is as follows image 3 as shown, image 3 SEM photo of the membrane surface coating provided in Example 1.

Embodiment 2

[0106] In terms of mass fraction, 50% magnesium hydroxide nano-ceramic powder, 5% PMMA (Chengdu Yindile Company, model LA133), 10% acrylic ester and 35% water were mixed, and a 25m / s line The speed is high and the dispersion is uniform, and the mixed slurry is obtained;

[0107] The mixed slurry was coated on both sides of the separator substrate by a gravure printing process, and baked at a temperature of 60° C. to obtain a lithium-ion battery separator with a coating thickness of 3 μm.

[0108] Carry out scanning electron microscope analysis (SEM) to described coating, its scanning electron microscope picture is as follows Figure 4 as shown, Figure 4 SEM photo of the membrane surface coating provided for Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com