Patents

Literature

49results about How to "Less prone to disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

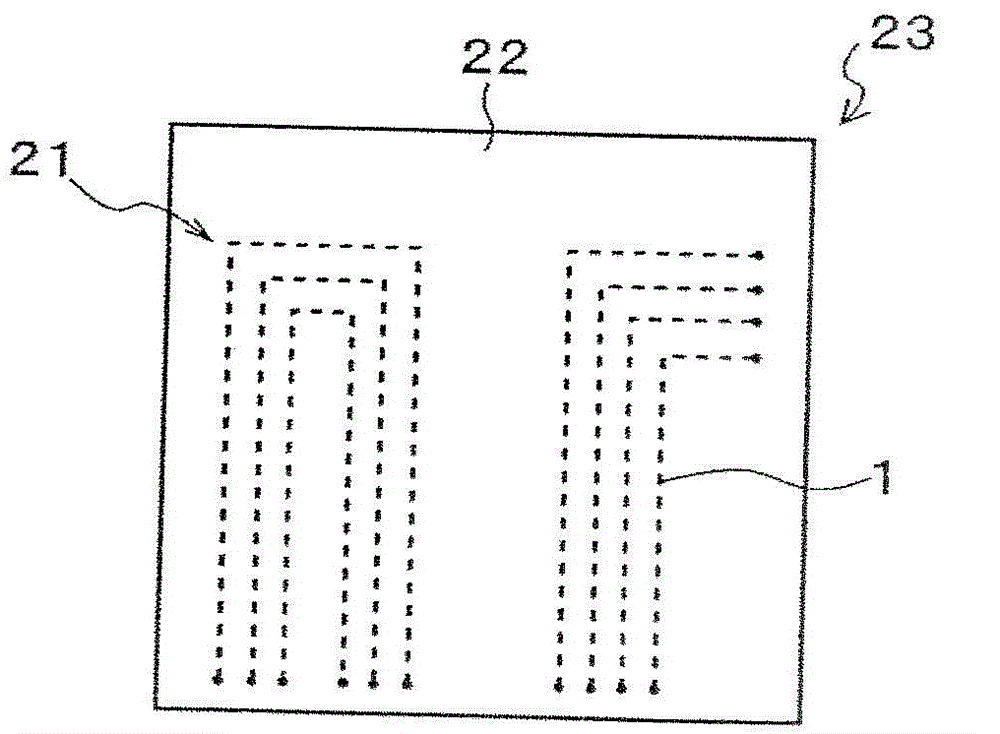

Capacitance type touch screen and manufacturing method thereof

InactiveCN101630215AImprove continuityLess prone to disconnectionInput/output processes for data processingElectrical resistance and conductanceCapacitance

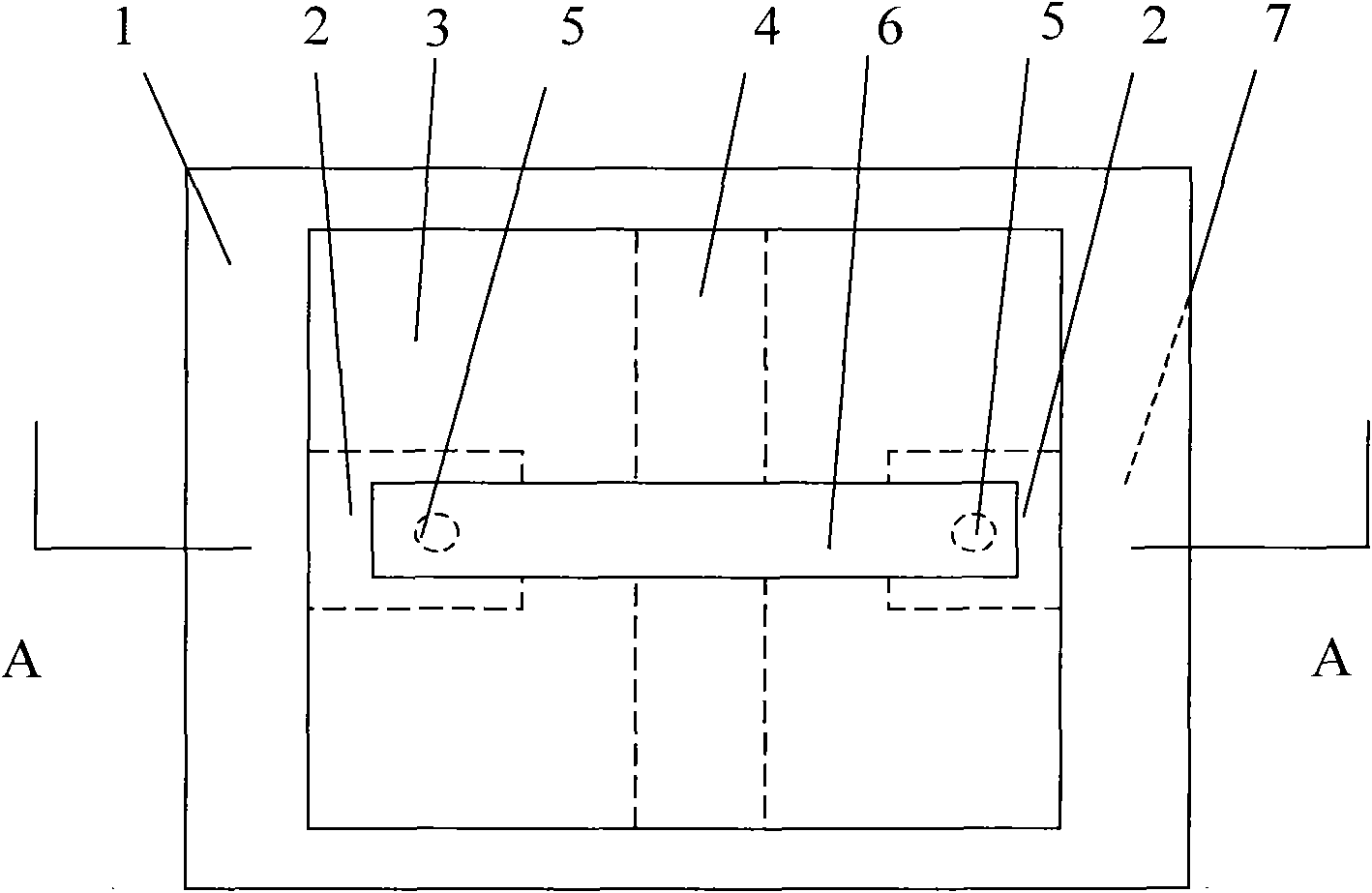

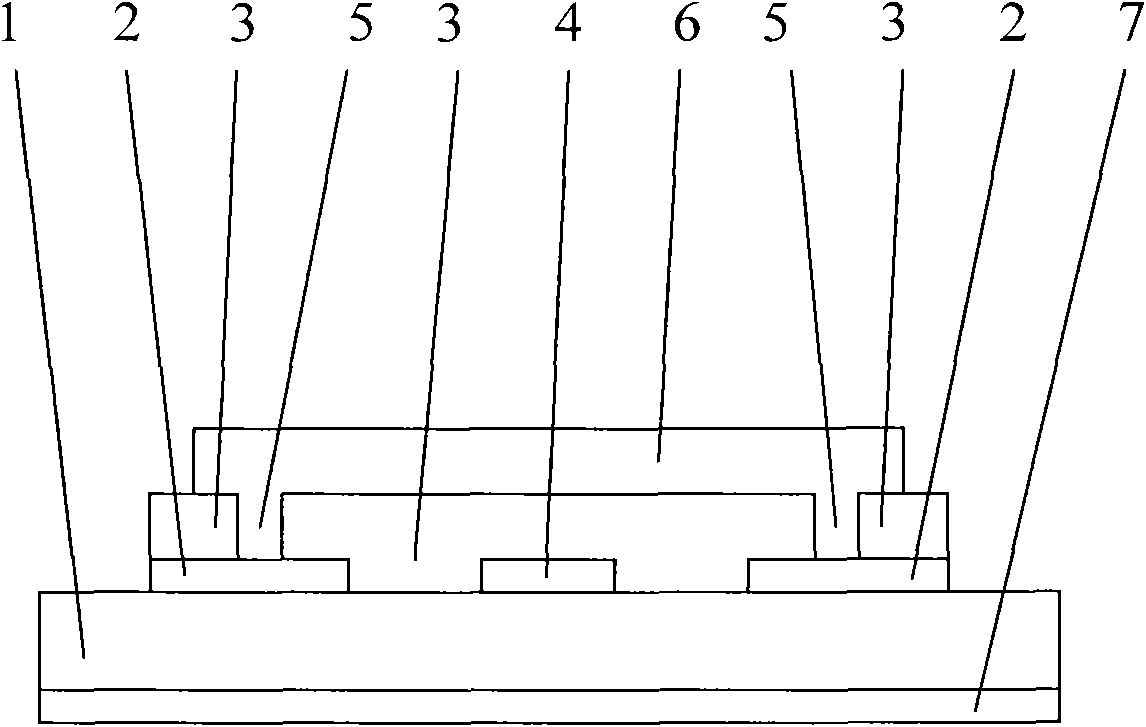

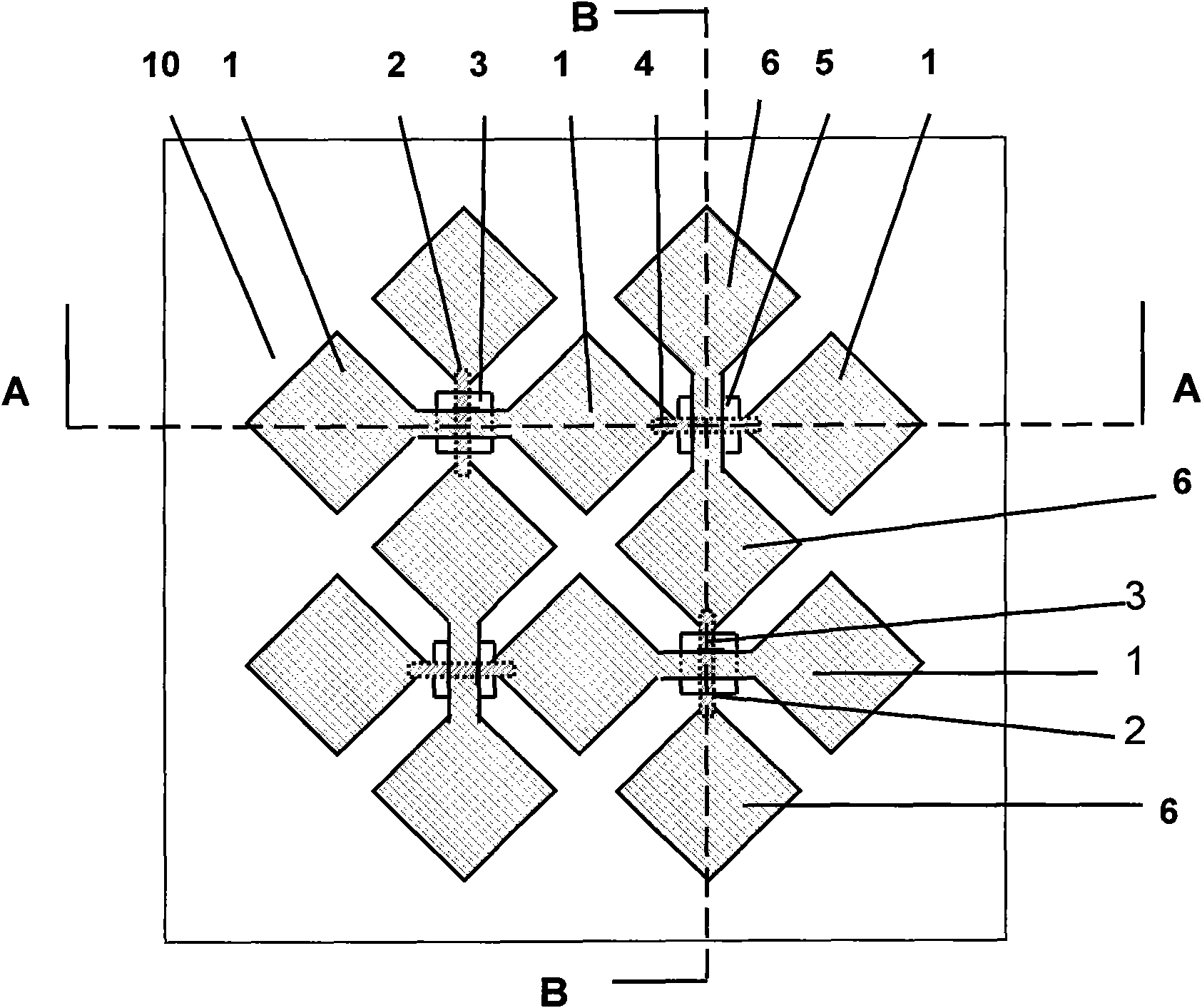

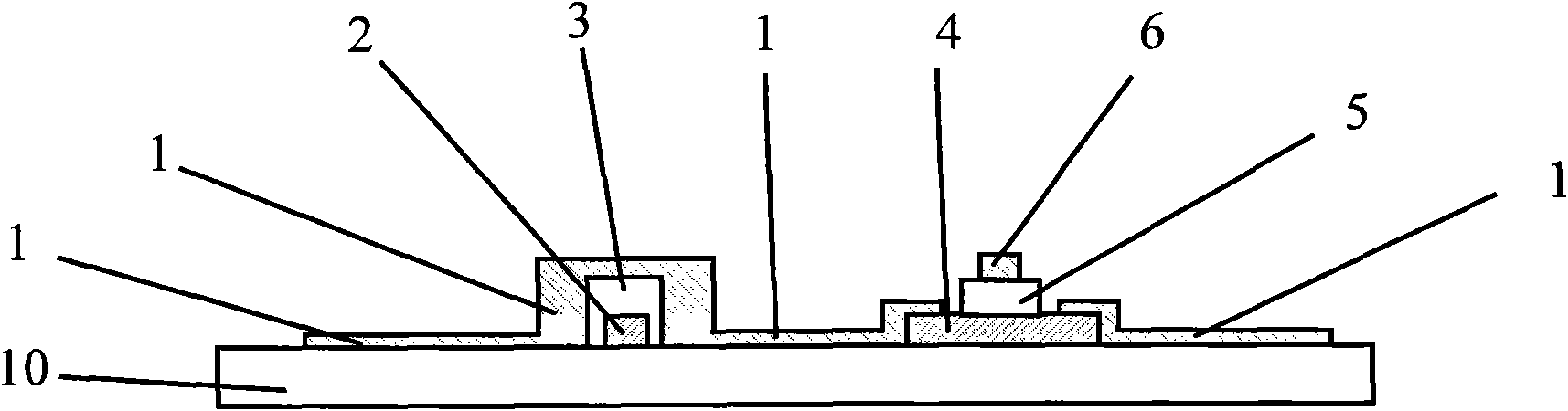

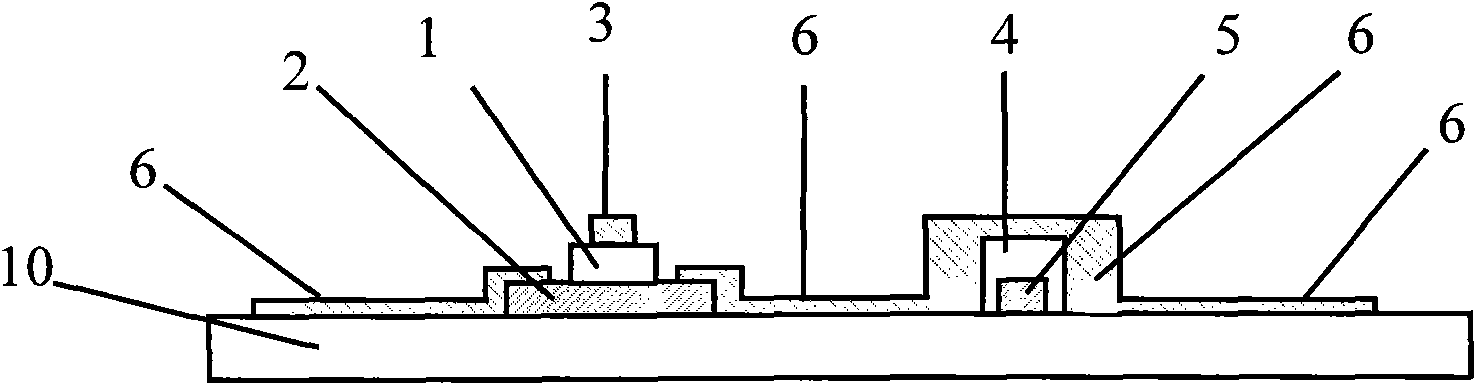

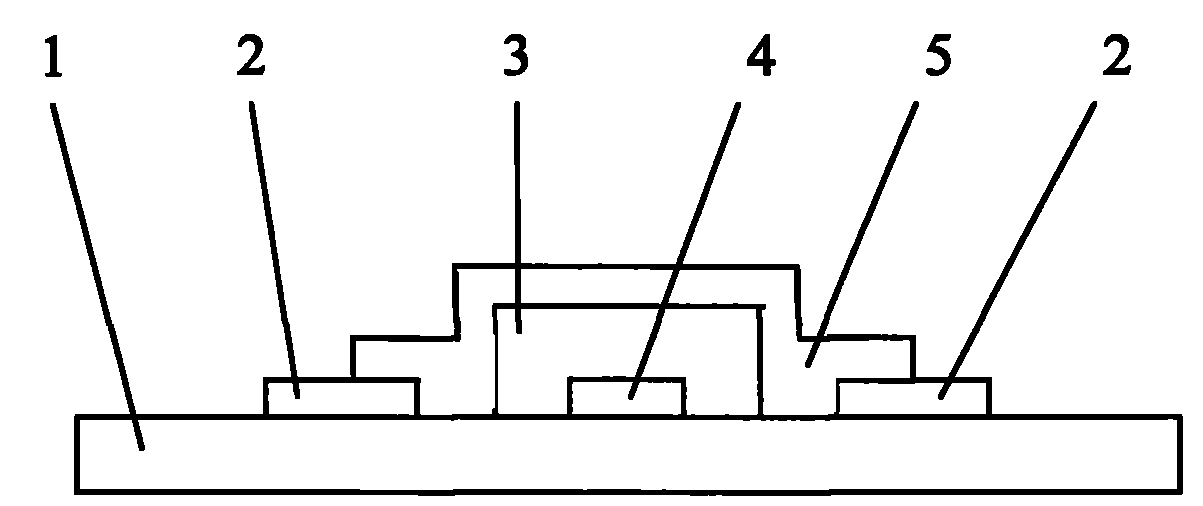

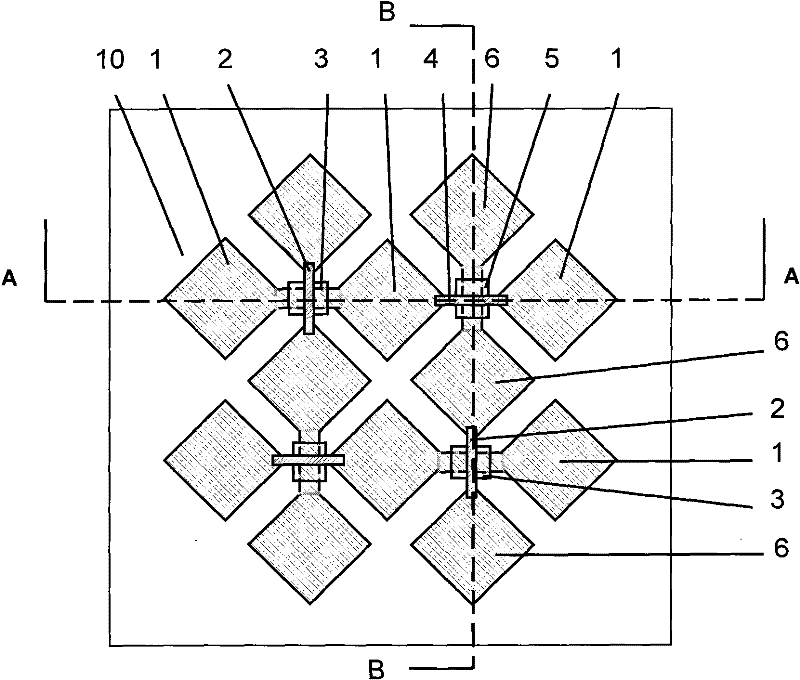

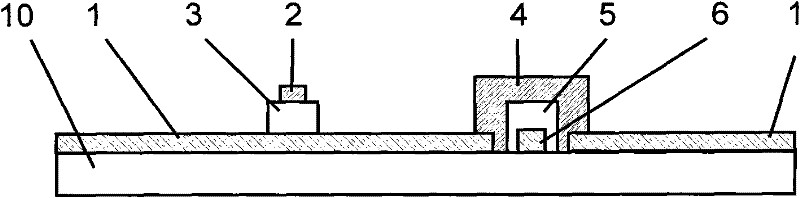

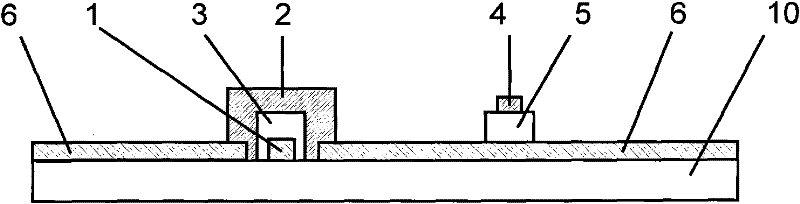

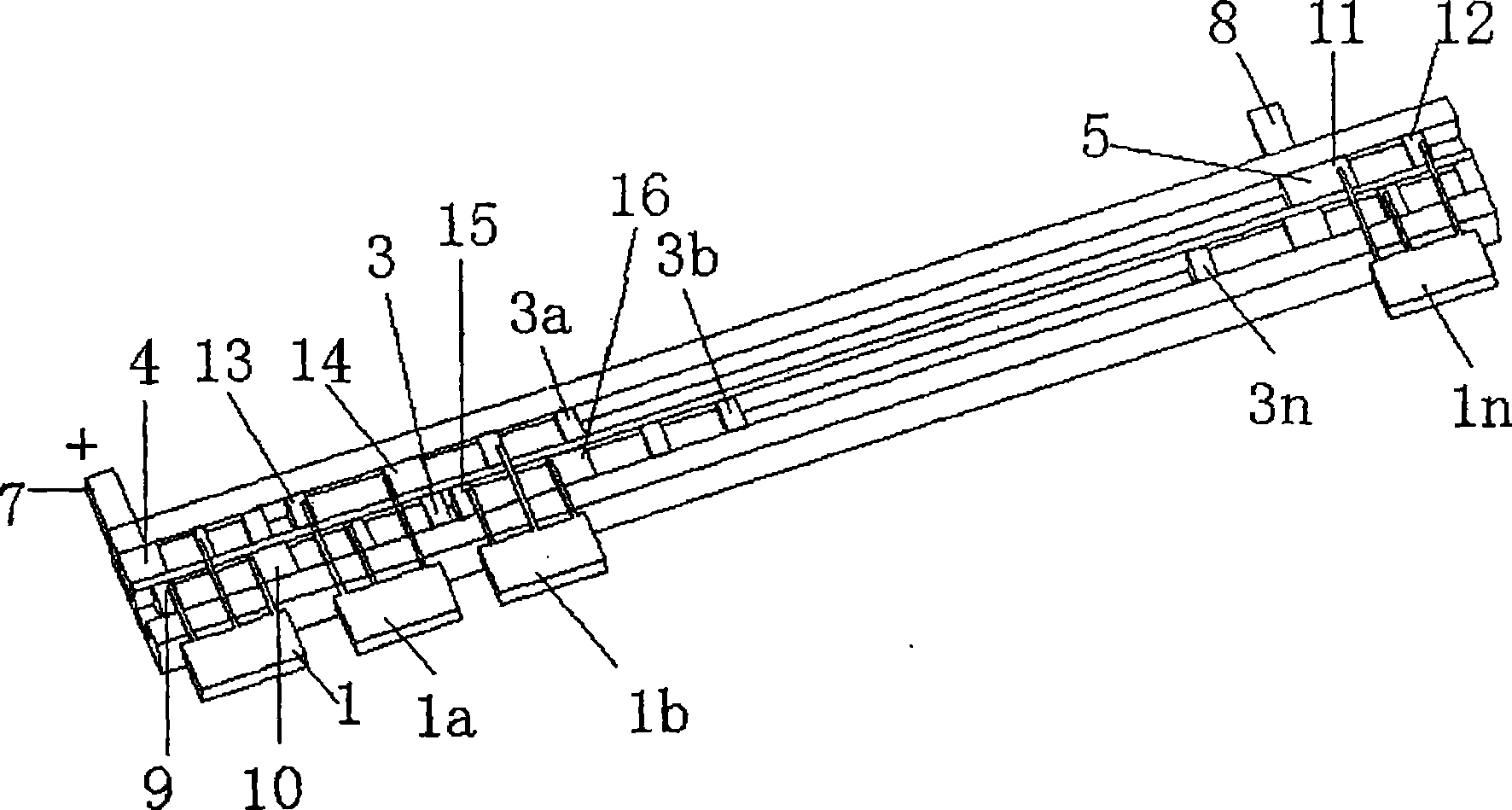

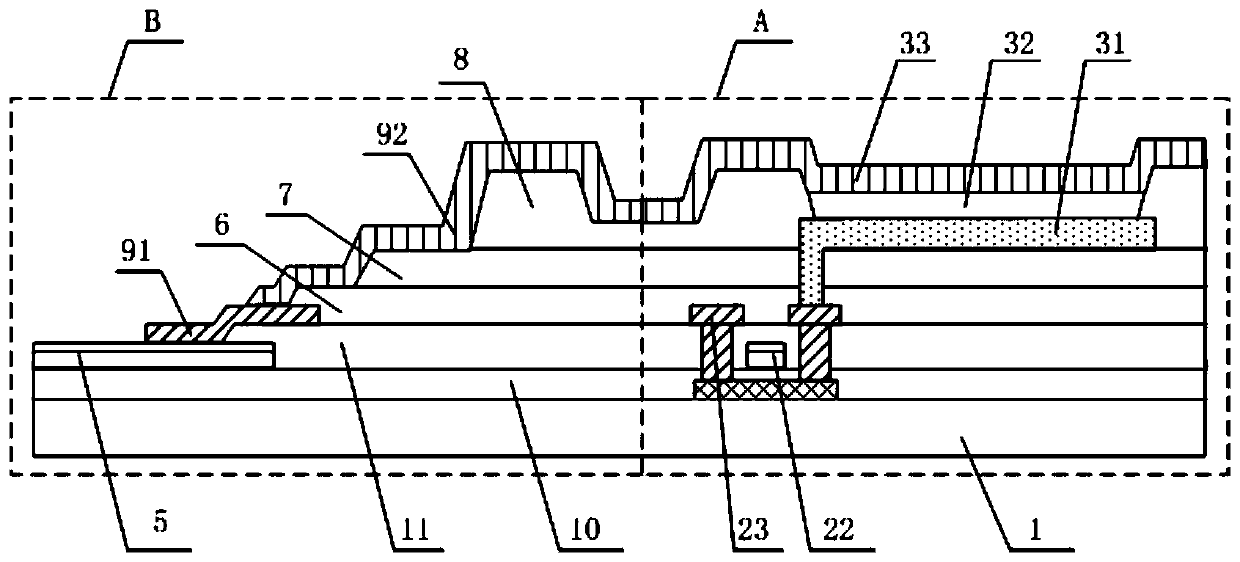

The invention relates to a capacitance type touch screen and a manufacturing method thereof. The capacitance type touch screen comprises a substrate, two sets of transparent conducting films of conducting wires, an insulating film and a metal bridging beam film. In the two sets of conducting wires, the first set of transparent conducting films are continuously arranged, and the second set of transparent conducting films are piecewise arranged by using the transparent conducting films of the first set as intervals. The insulating film covers the surfaces of the two sets of transparent conducting films, and the insulating film above each film section of the second set of transparent conducting films comprises a through hole. The metal bridging film is attached on the insulating film, crosses the first set of transparent conducting films and is connected with the second set of transparent conducting films which are arranged at intervals on both sides of the first set of transparent conducting films by passing through the through hole on the insulating film so as to form the continuous second conducting wires. The method comprises the following steps: manufacturing the first set of transparent conducting films, the second set of transparent conducting films, the insulating film and the metal bridging film to achieve the structure of the touch screen. The invention adopts the metal bridging film, thereby improving the continuity of the second set of conducting wires, reducing the resistance of the second set of conducting wires and the color difference of the touch screen and improving the performance of the touch screen and the product quality.

Owner:SHENZHEN LAIBAO HI TECH

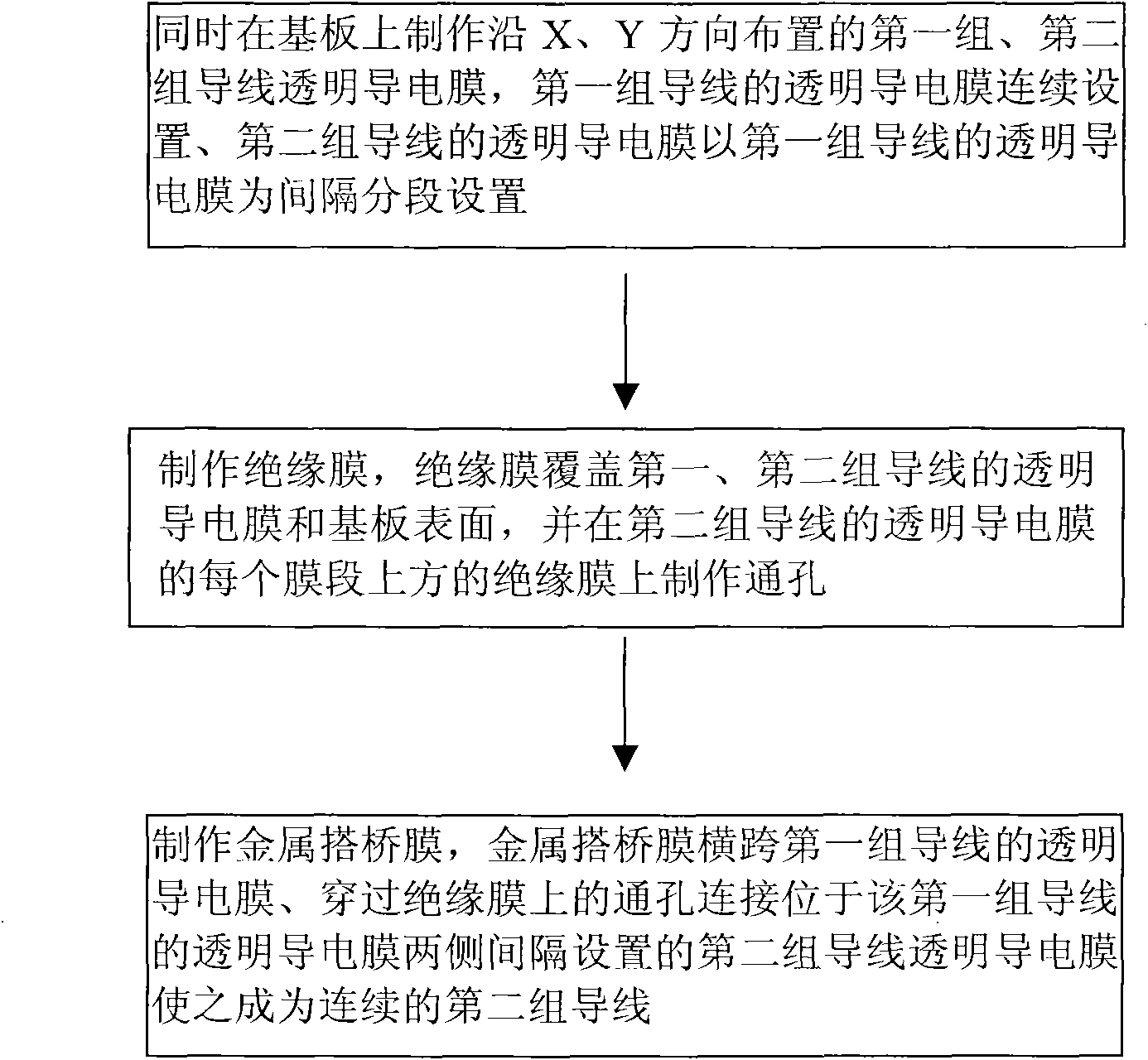

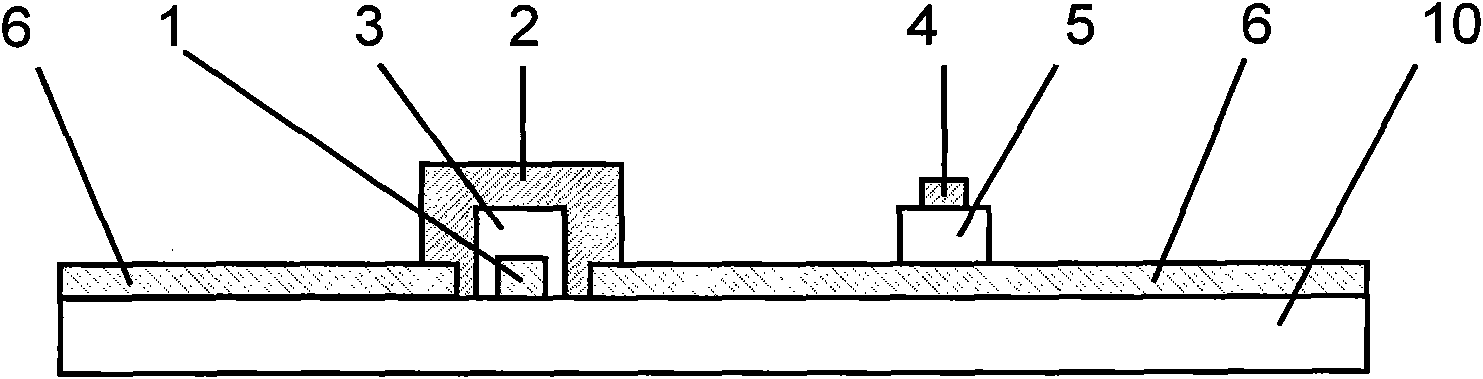

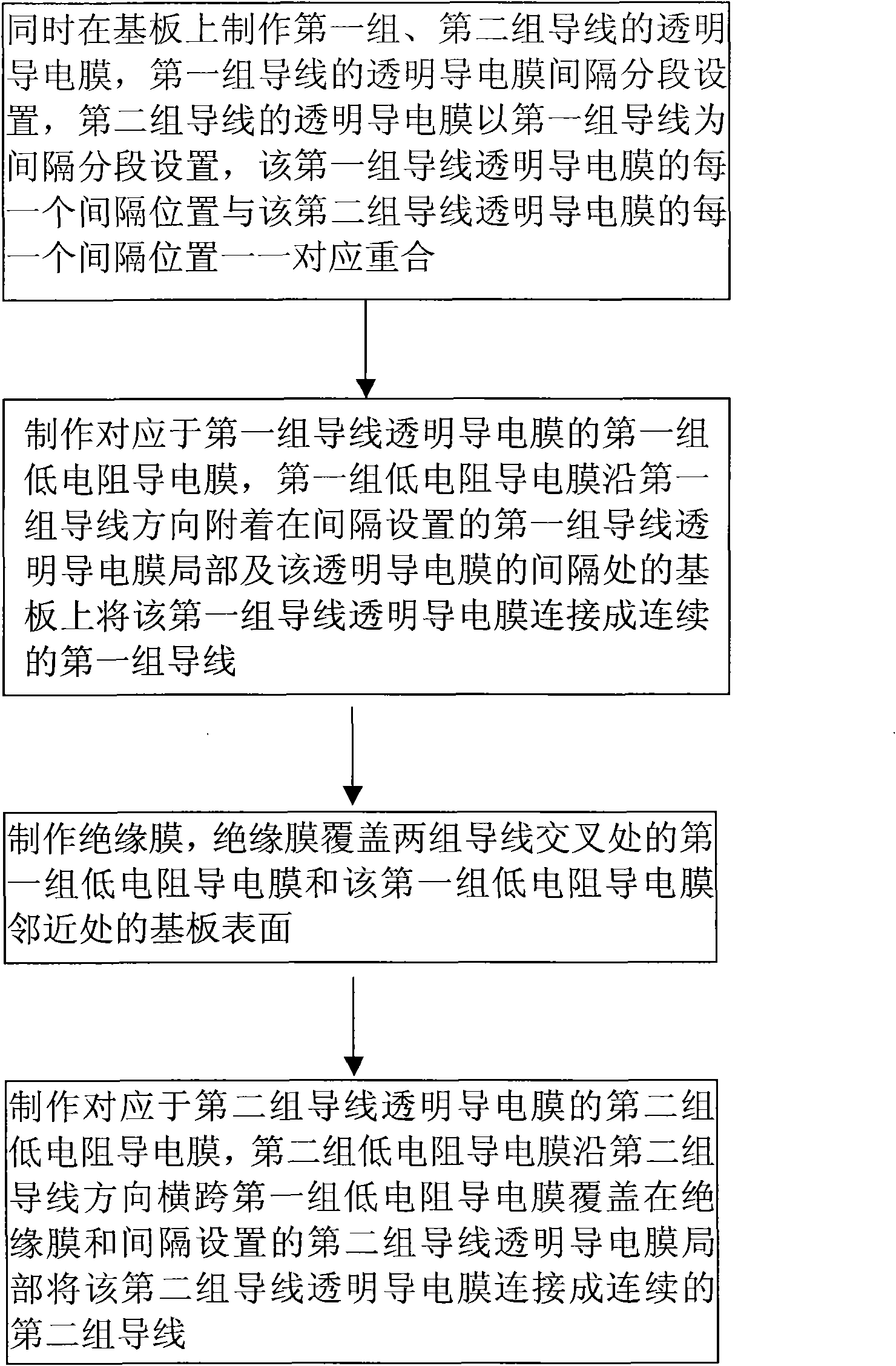

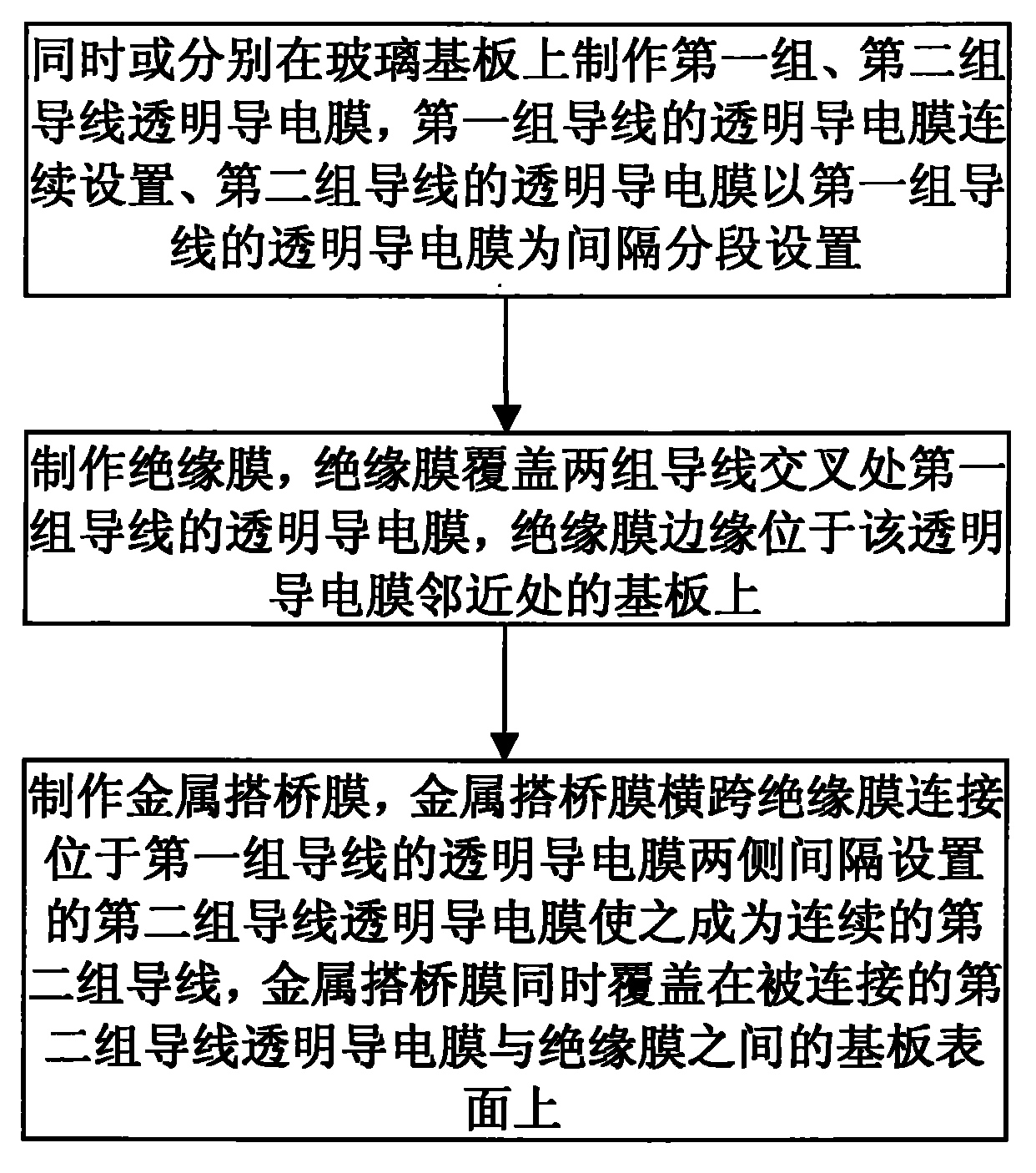

Wiring method and manufacturing method of capacitive touch screen

ActiveCN101634922AImprove product qualityAvoid chromatic aberrationInput/output processes for data processingElectrical resistance and conductanceEngineering

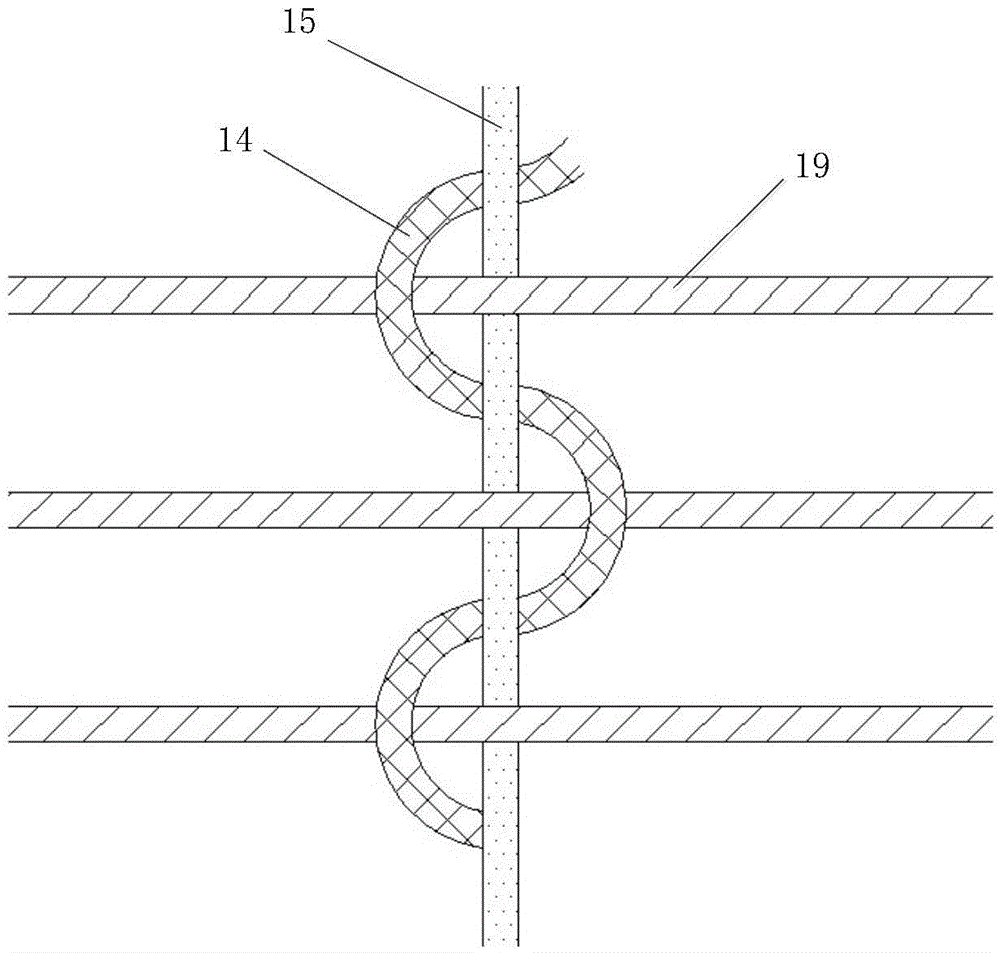

The invention relates to a wiring method and a manufacturing method of a capacitive touch screen, wherein the wiring method comprises the step of arranging two groups of wire transparent conducting films in X and Y directions, an insulating film and a bridging film on a basal plate, wherein the surface resistance of the bridging film is lower than the surface resistance of the transparent conducting films, an intersection structure of the transparent conducting films in the two directions comprises continuous connection and bridging connection, wherein the continuous connection structure is a continuation of transparent conducting film material at two sides of the intersection point, and the bridging connection structure has the structures that the transparent conducting film in X or Y direction is continuously connected and positioned on the basal plate at the intersection point, the transparent conducting film in the other direction is disconnected at the intersection point, the insulating film is covered on the transparent conducting films that are continuously connected at the intersection part, and the bridging film stretches over the transparent conducting films that are continuously connected at the intersection point and is covered on the insulating film and connected with the transparent conducting film disconnected at the intersection point; and the method comprises the step of manufacturing two groups of wire conducing film, the insulating film and the bridging film. The invention can avoid color difference and improve the sensitivity, the standard ratio and the quality of the touch screen.

Owner:SHENZHEN LAIBAO HI TECH

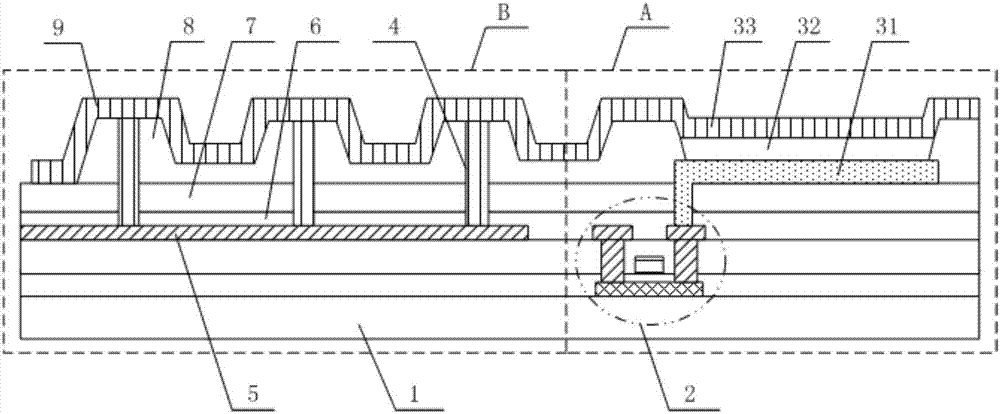

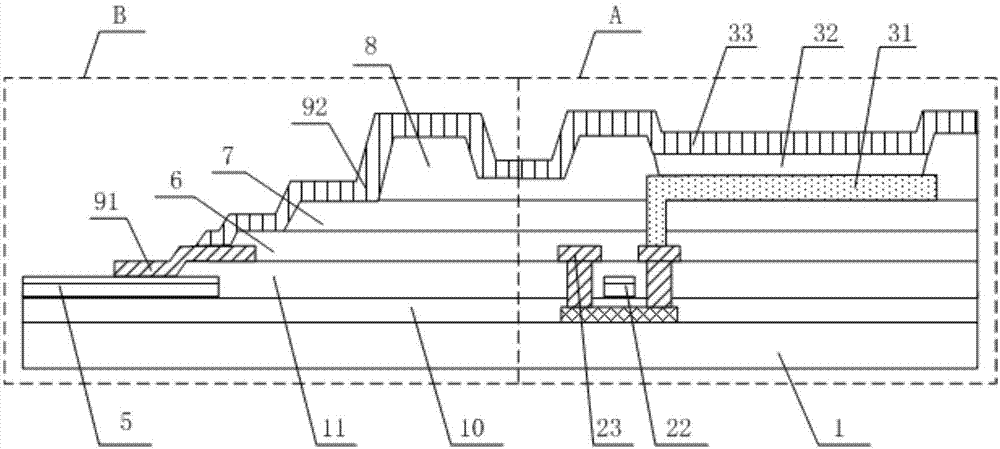

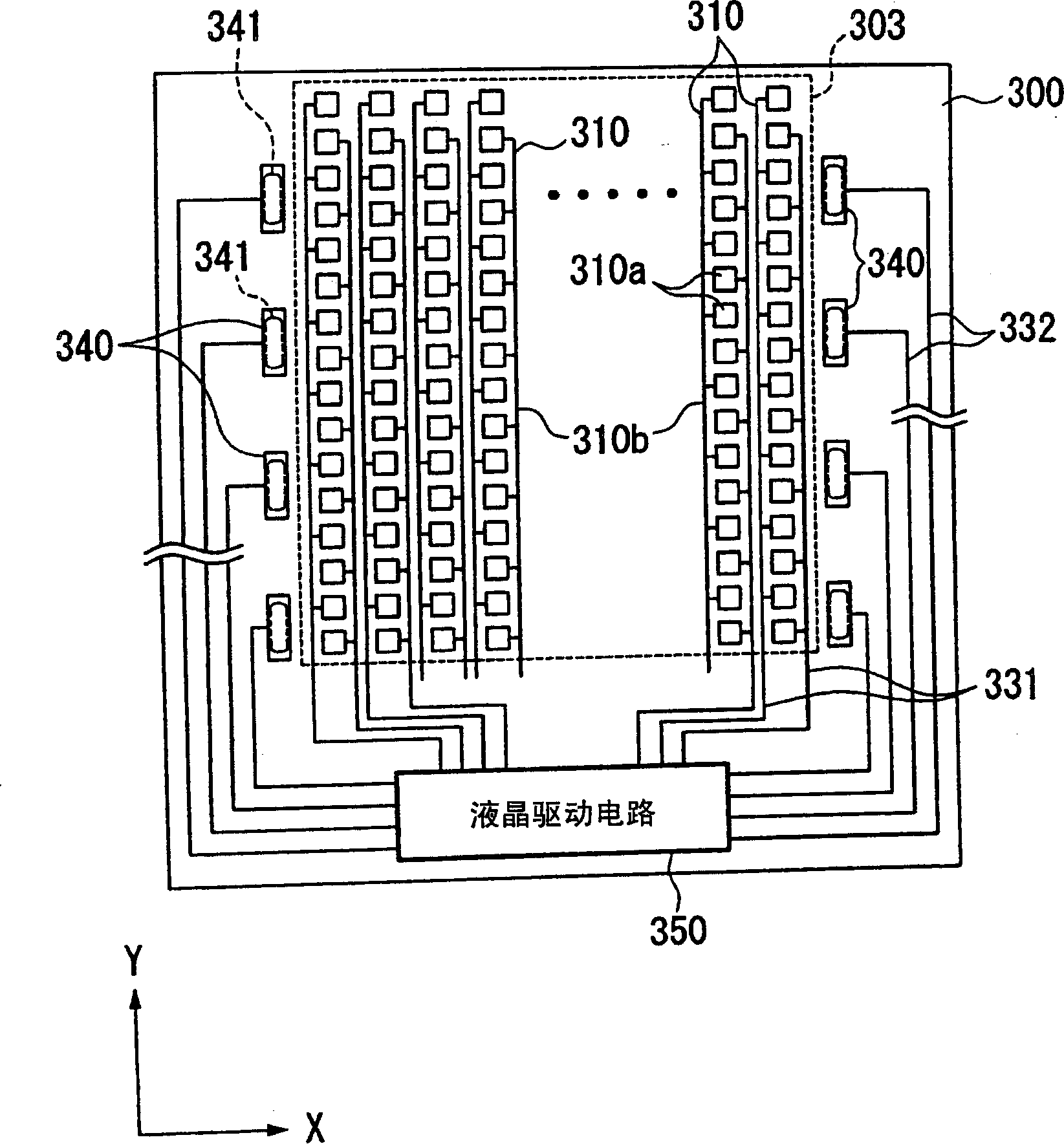

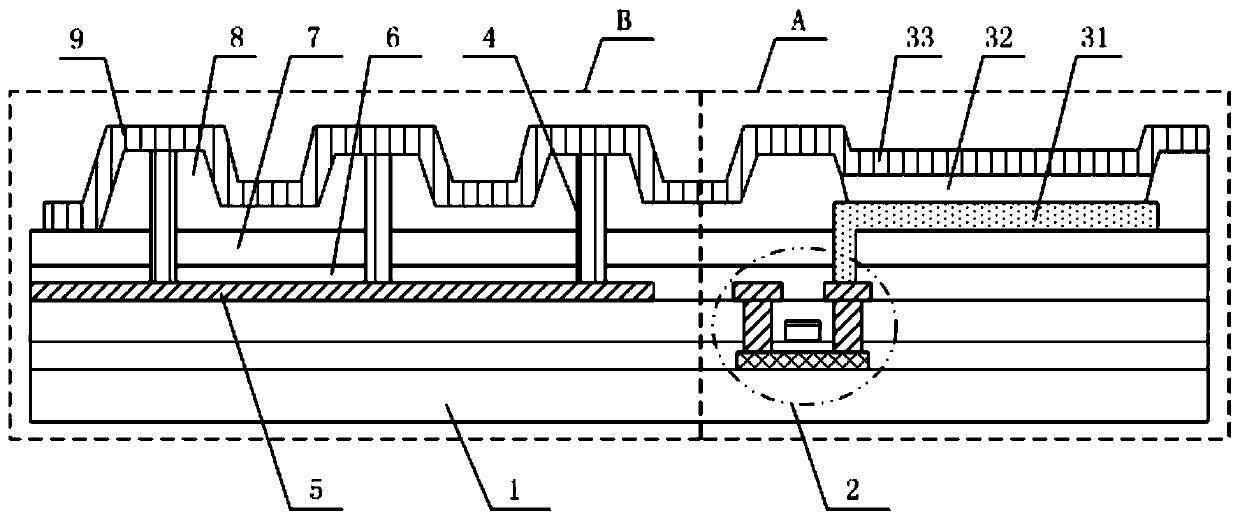

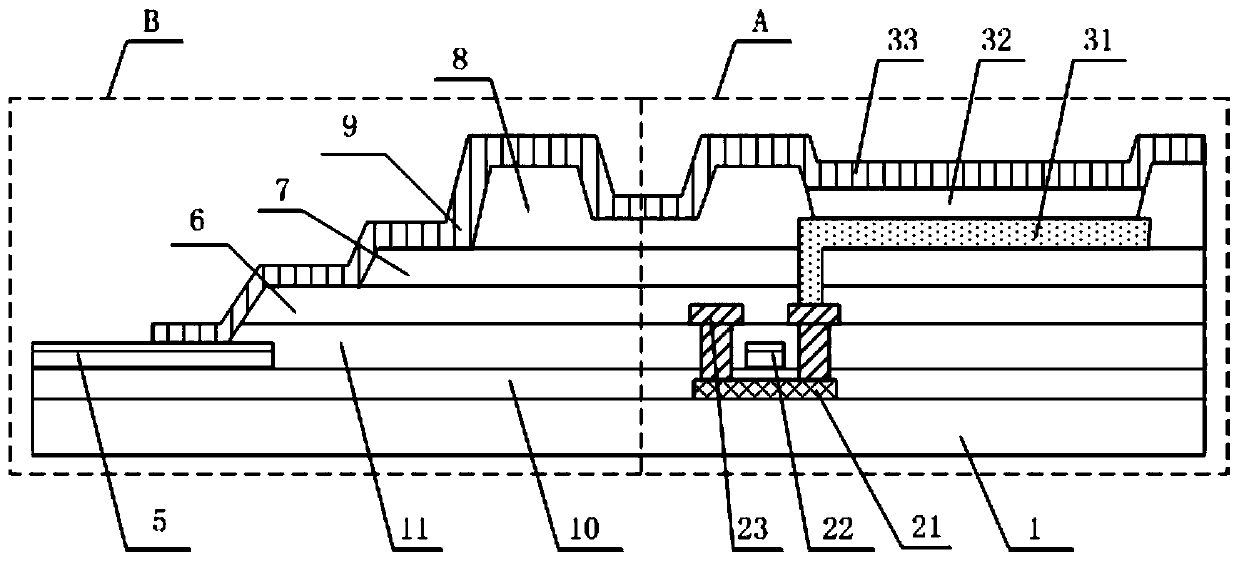

OLED substrate and manufacturing method and display apparatus

ActiveCN107452780AThe process is simple and reliableLess prone to disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSignal lines

The invention discloses an OLED substrate and a manufacturing method and a display apparatus, relates to the technical field of display, and aims to solve the problem of easy wire breaking of an electrode lead so as to ensure normal display of the OLED display apparatus. The OLED substrate comprises an array substrate with a display region and a peripheral wiring region; multiple OLEDs in array arrangement are arranged in the display region; each OLED comprises an upper electrode and a lower electrode arranged oppositely, and an OLED light emitting layer positioned between the upper electrode and the lower electrode, and the lower electrode is formed on the surface of the array substrate; the peripheral wiring region is provided with a functional film layer and a signal line; the functional film layer partially covers the signal line; an electrode lead is arranged on the surface of the edge of the functional film layer; and one end of the electrode lead is connected with the part, not covered by the functional film layer, of the signal line, while the other end is connected with the corresponding upper electrode. The OLED substrate provided by the invention is used for OLED display.

Owner:BOE TECH GRP CO LTD

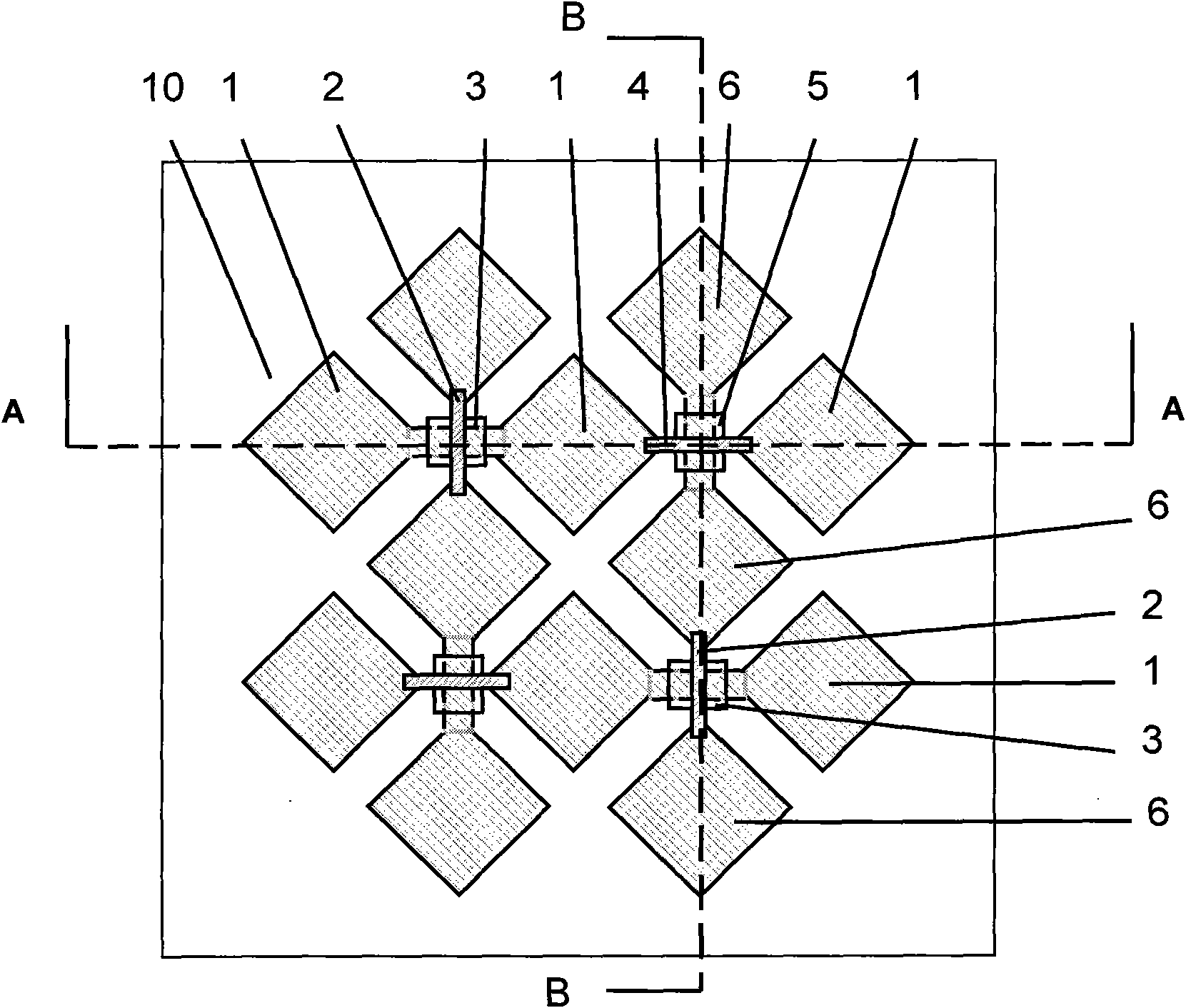

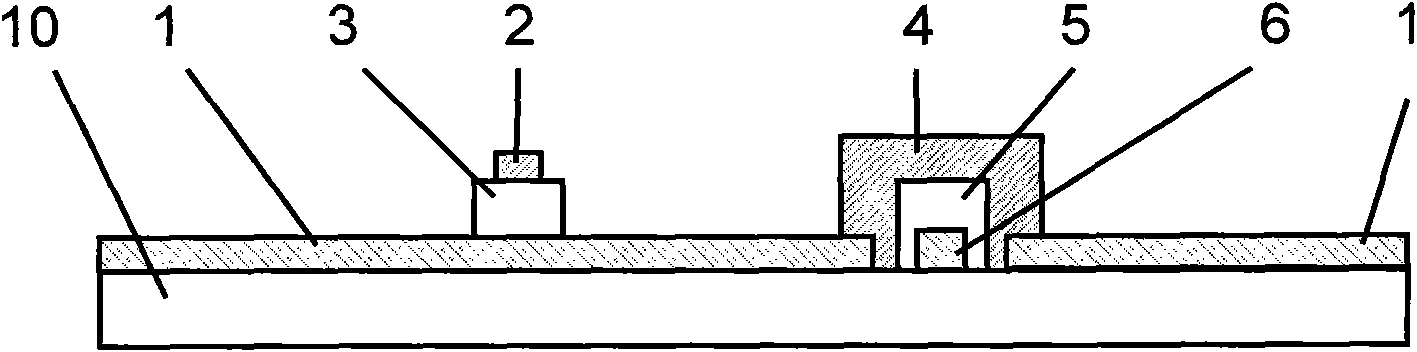

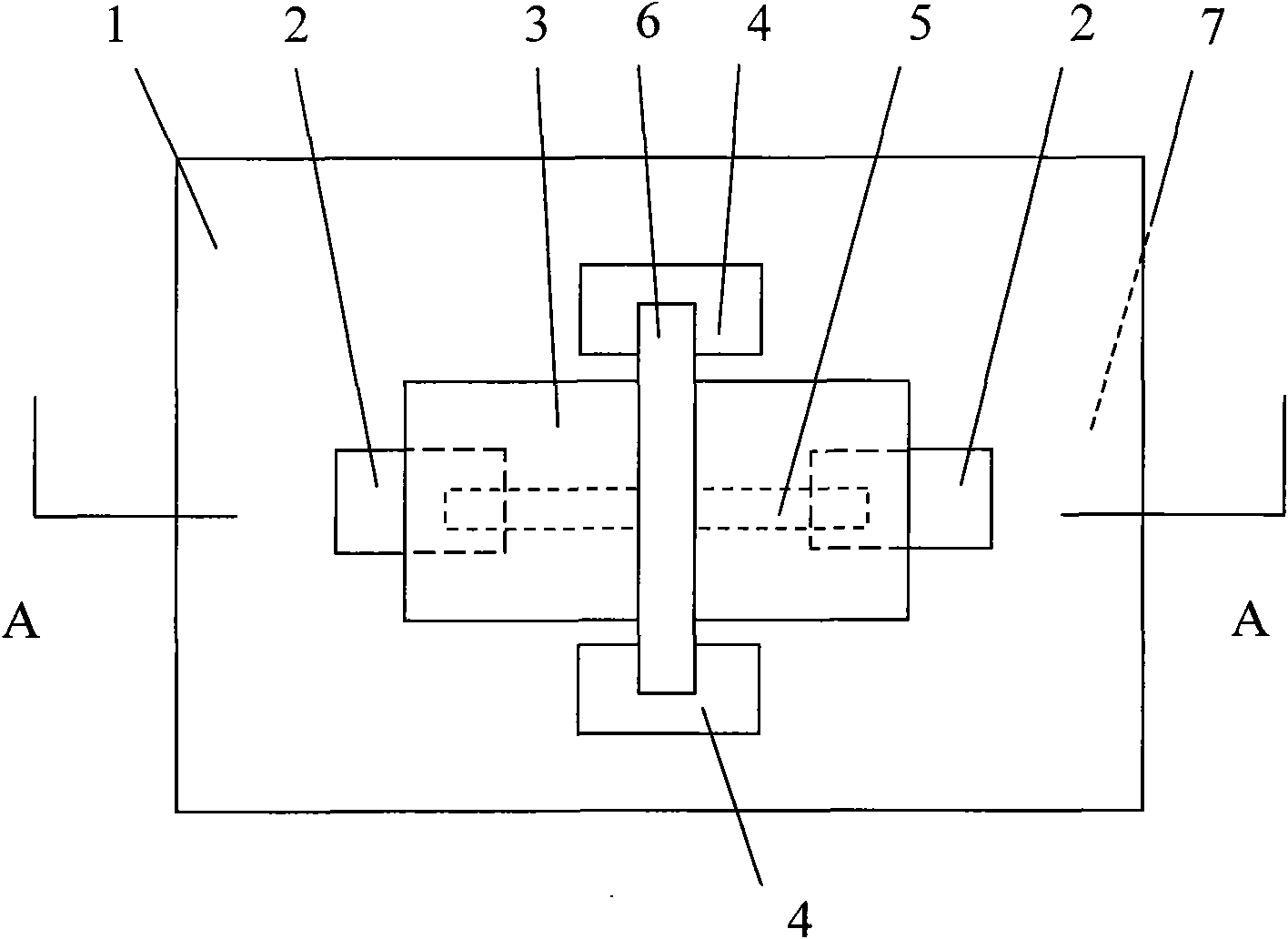

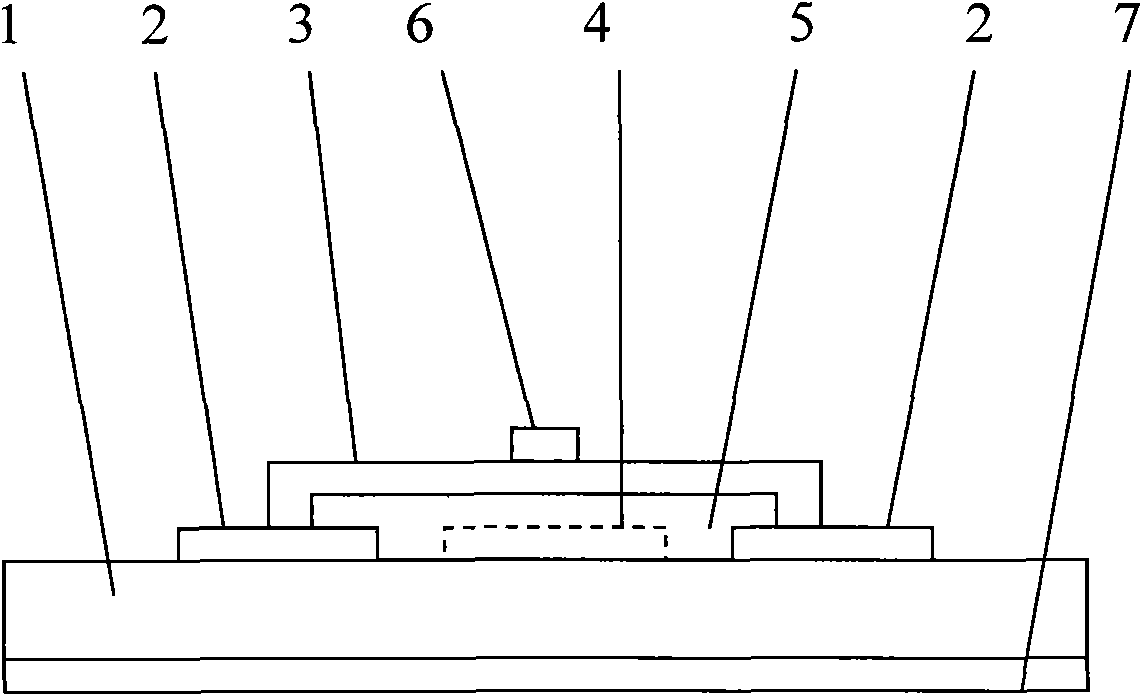

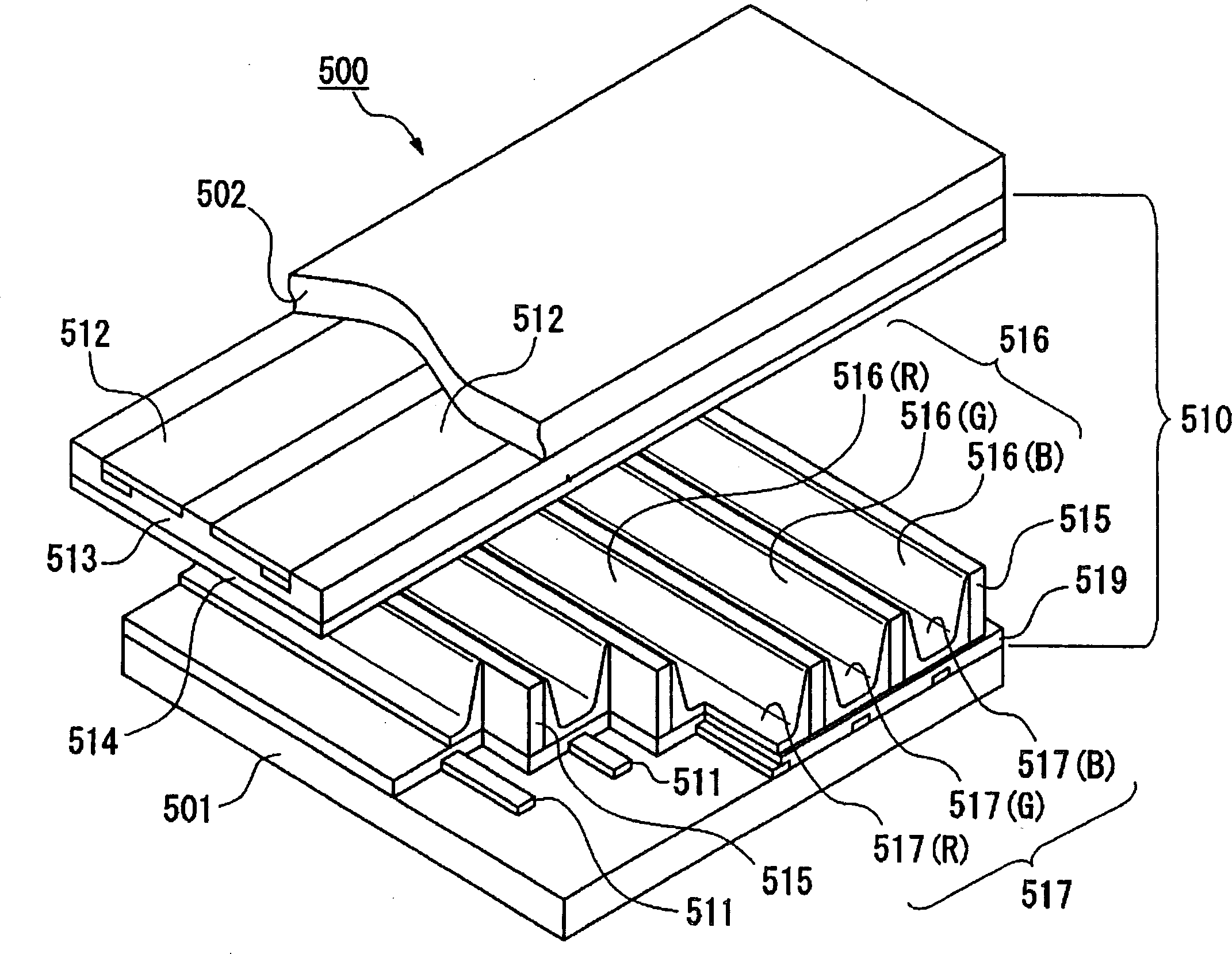

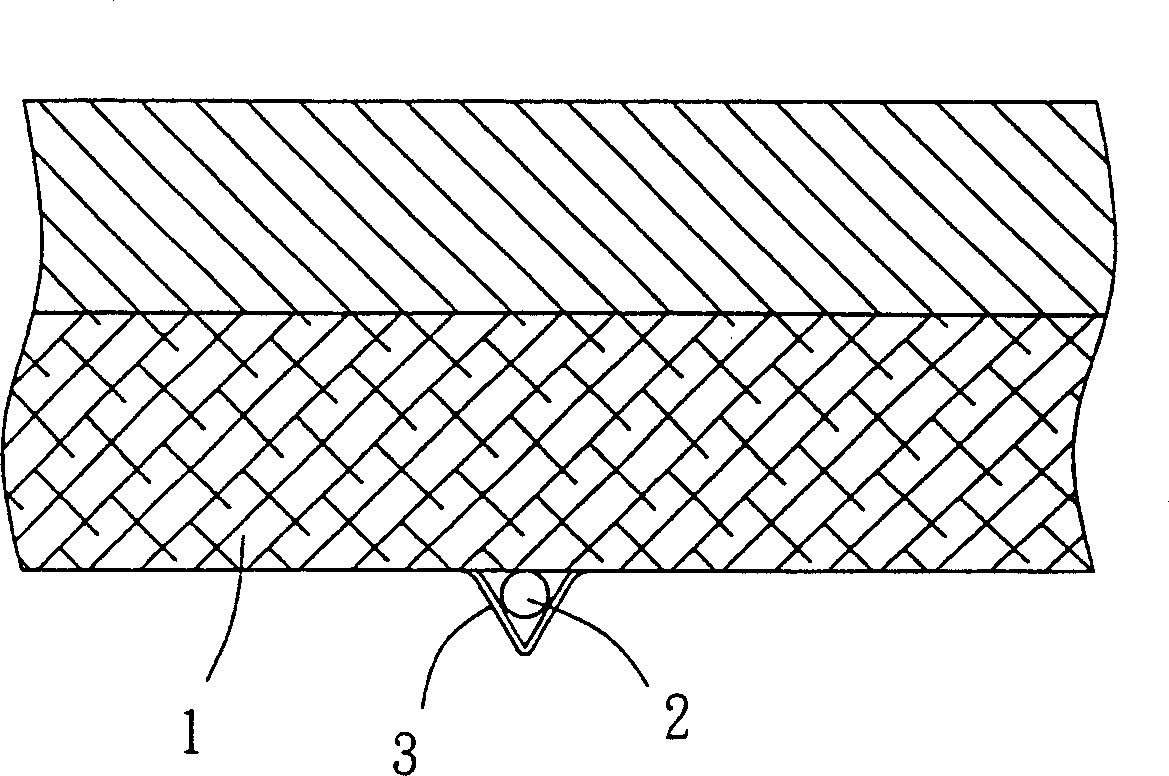

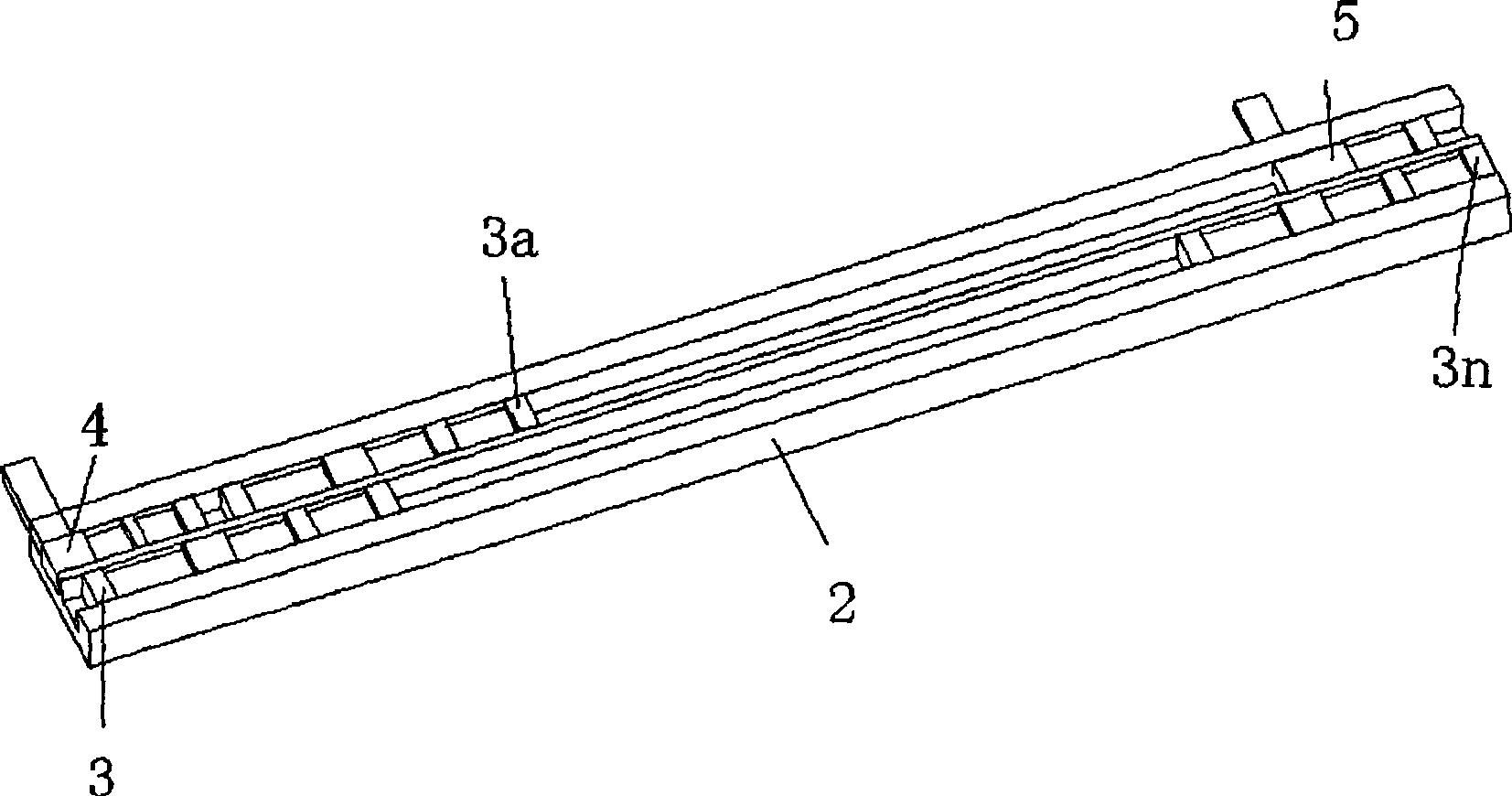

Capacitance touch screen and method for preparing the same

ActiveCN101587408AImprove continuityLess prone to disconnectionInput/output processes for data processingElectrical resistance and conductanceCapacitance

Capacitance touch screen and method for preparing the same, the touch screen includes a substrate, two sets of wire transparent conductive films, an insulation film, and two sets of low-resistance conductive film, two sets of transparent conductive films are disposed sectionally in interval and two sets of transparent conductive films are coincided corresponding to each other at every interval position; a first low-resistance conductive film connects with its transparent conductive film along direction of the first set of wires to form a continous set of wires, a second low-resistance conductive film crosses the first low-resistance conductive film along direction of the second set of wires to connect its transparent conductive film to form a second continous set of wires. An insulation film is disposed between two sets of low-resistance conductive films and covers surface of substrate adjacent to the first set of low-resistance conductive film, the second low-resistance conductive film covers the insulation film. The method produces the first, second set of transparent conductive films, an insulation film and low-resistance conductive film on the substrate step by step to implement the touch screen structure. The wires according to the invention are not easy to break which reduces resistance of wires, reduces chromatic aberration and electrical interference, and improves performance and quality of products.

Owner:SHENZHEN LAIBAO HI TECH

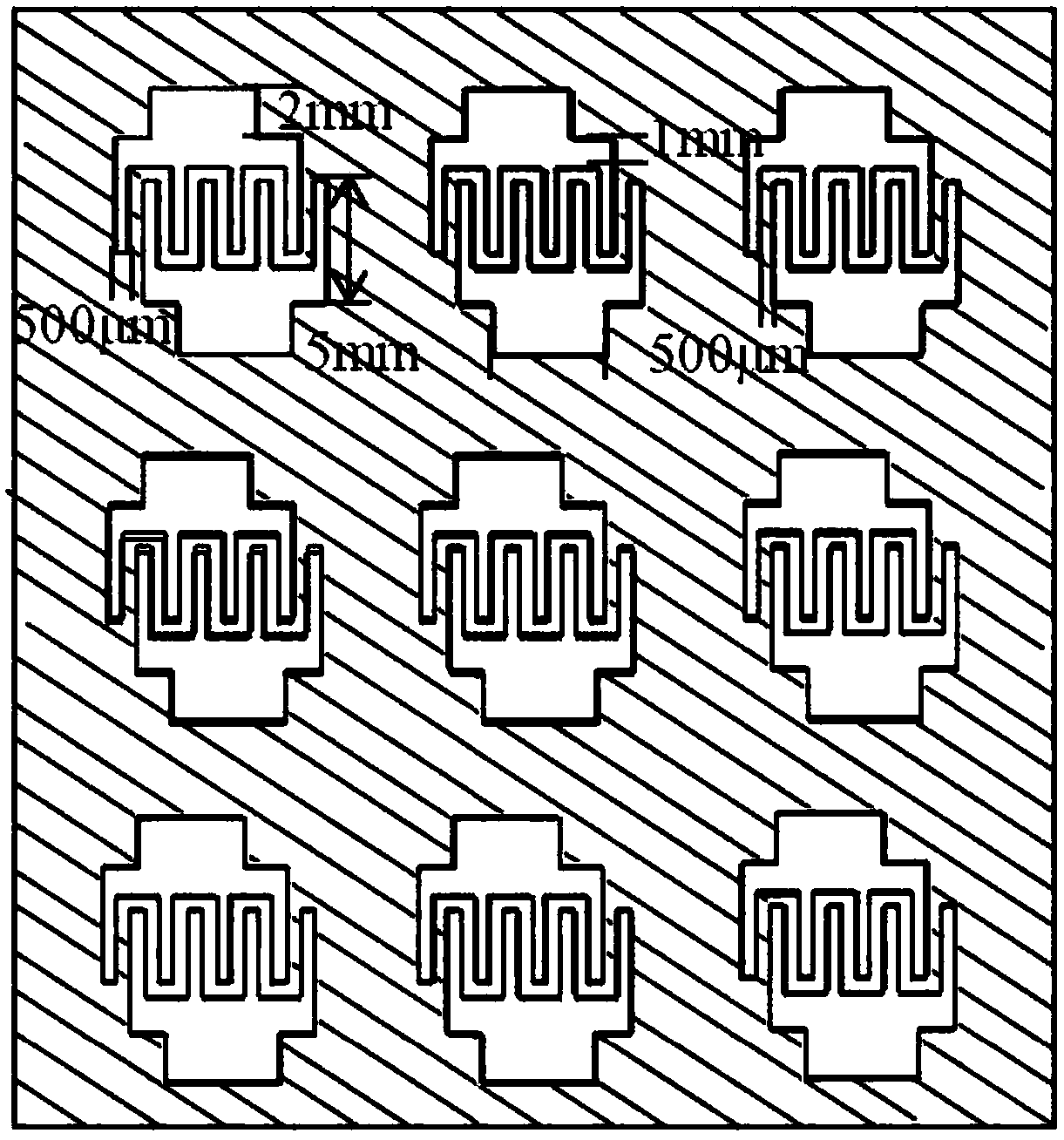

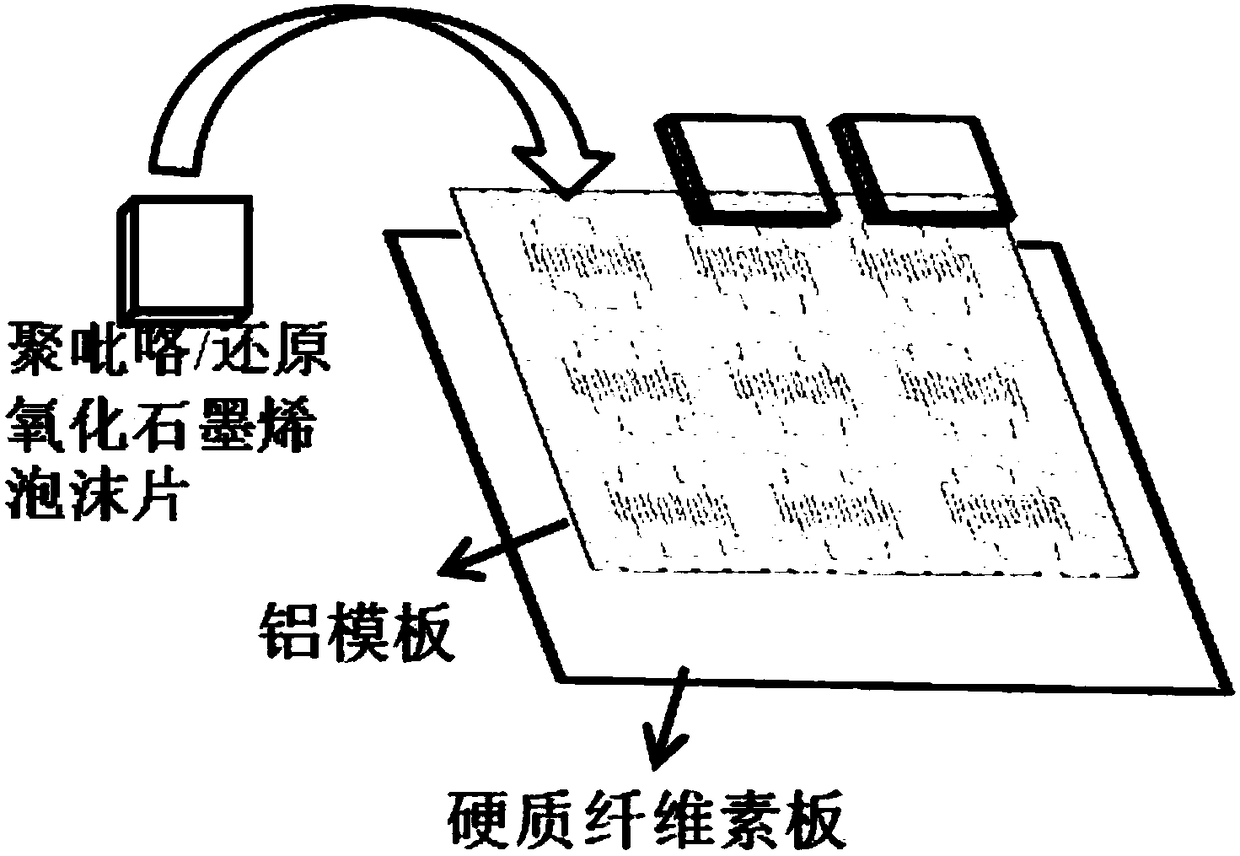

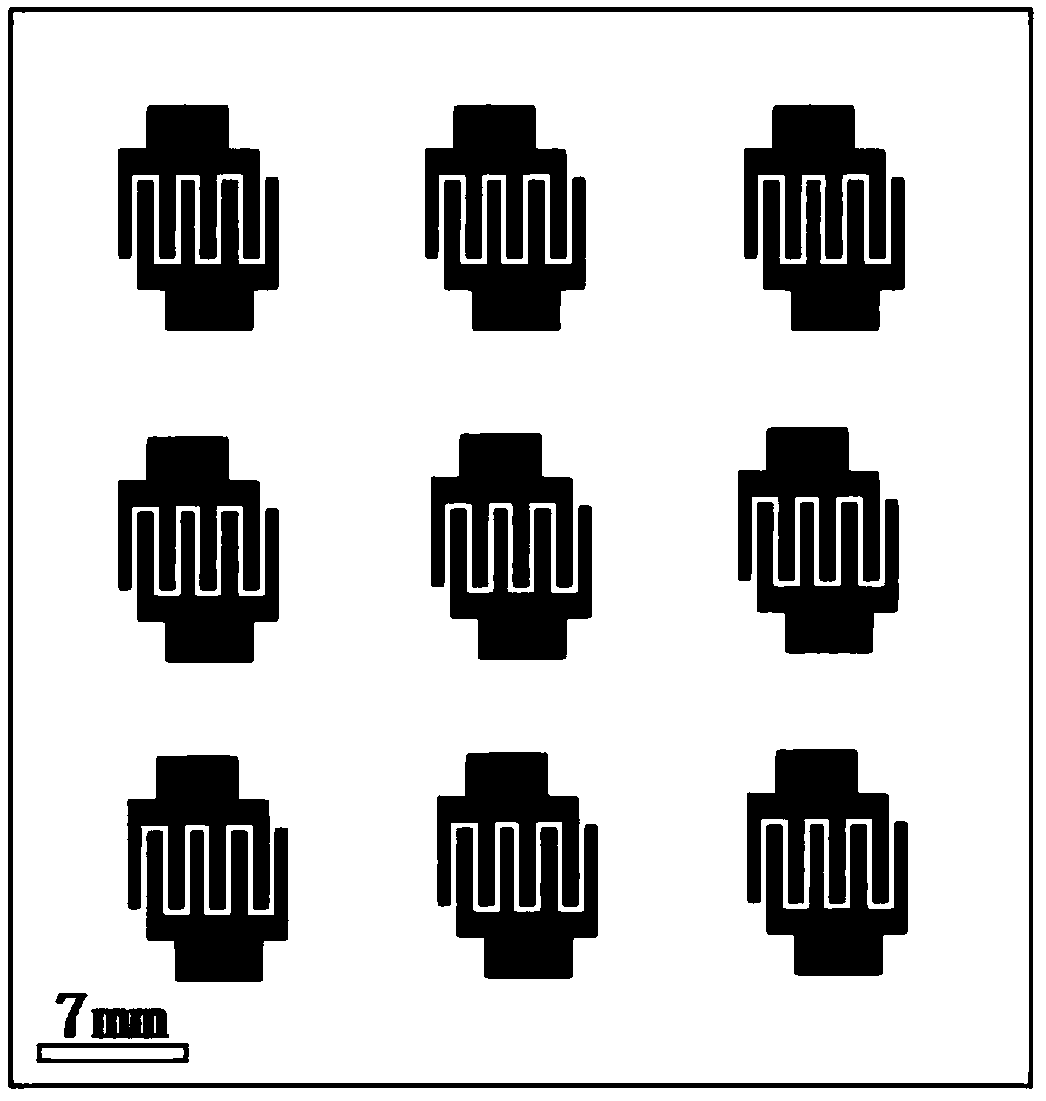

Manufacturing method of foldable paper-based micro supercapacitor

ActiveCN108447695AImprove Capacitive PerformanceIncrease migration rateHybrid capacitor electrodesHybrid/EDL manufactureSolid state electrolytePorosity

The invention relates to a manufacturing method of a foldable paper-based micro supercapacitor and belongs to the technical field of a micro energy storage device. The method comprises steps that a graphene or graphene composite electrode is imprinted onto a paper substrate through utilizing the template imprinting technology, the solid electrolyte is coated to the electrode, and the micro supercapacitor is manufactured on the paper substrate. The sheet-like graphene or graphene composite is imprinted through the template on the paper substrate to make the outline of the electrode clear and connectivity good, porosity and the water absorption property of the paper are utilized to ensure stability of the graphene or graphene composite electrode on the paper, foldability and flexibility of the paper are utilized to make the manufactured micro supercapacitor have good flexibility and foldability, wind energy collection and utilization and output of different voltages and currents can be realized, moreover, the manufacturing process is simple, operability is high, cost is low, and large scale manufacturing is realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

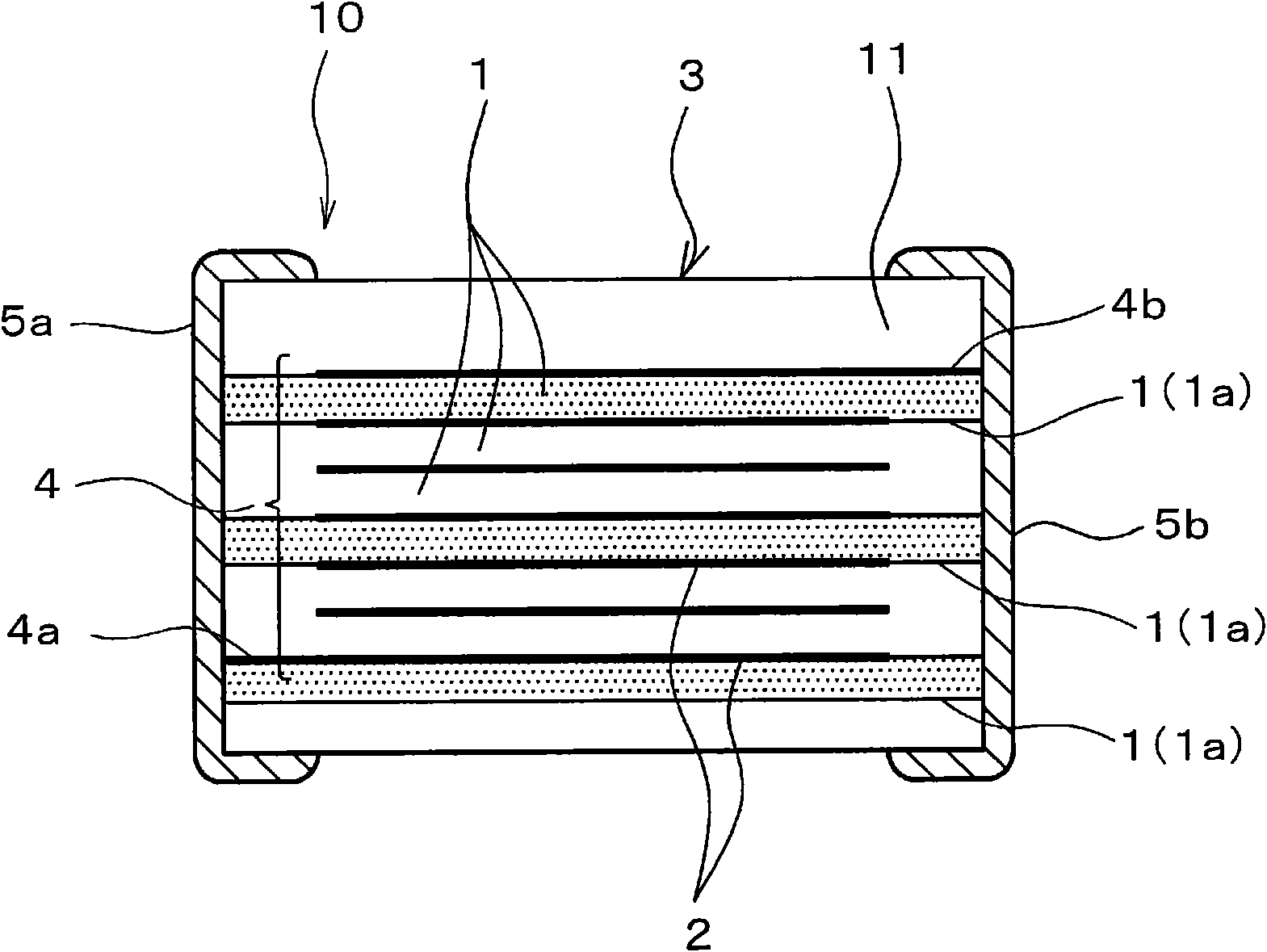

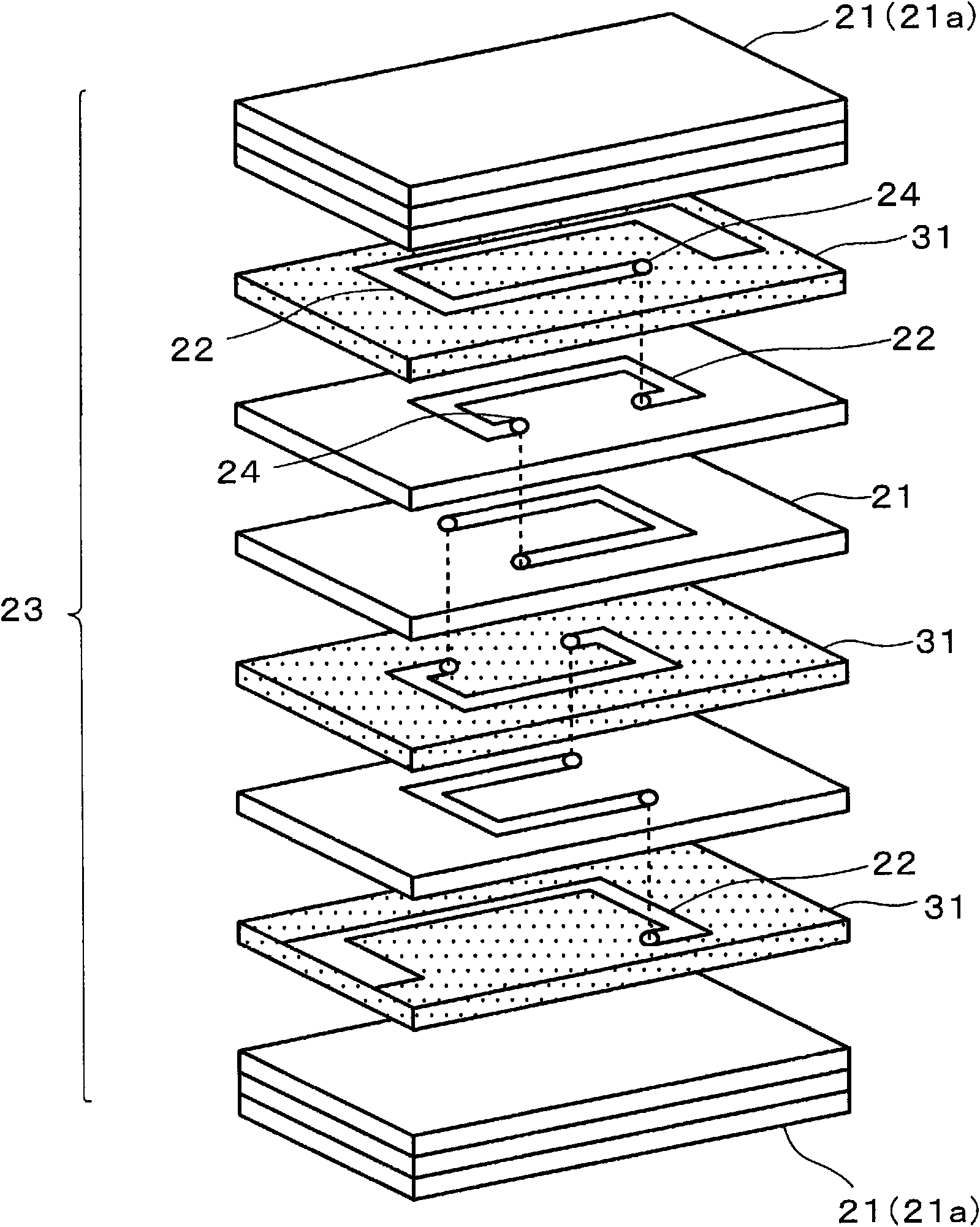

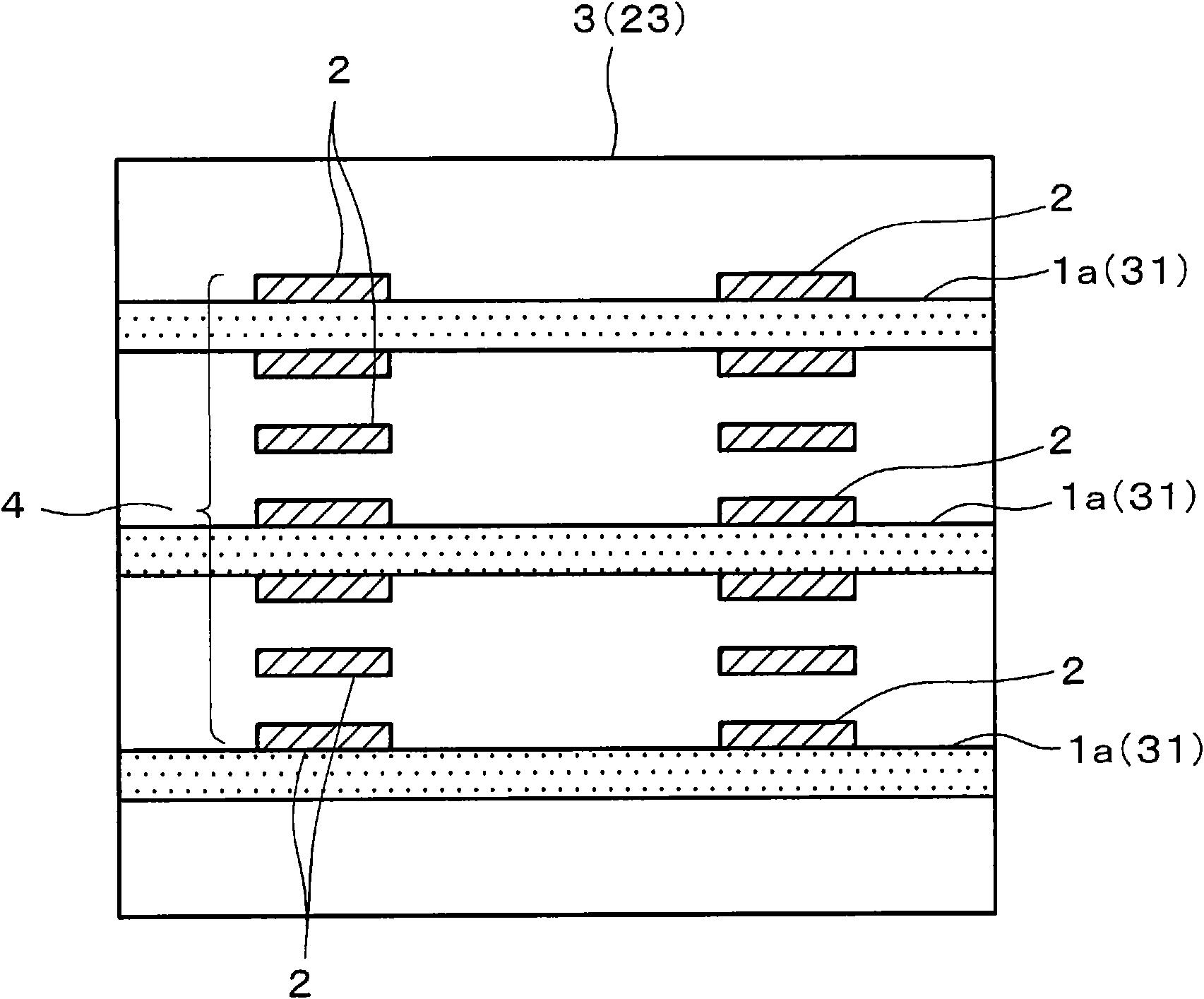

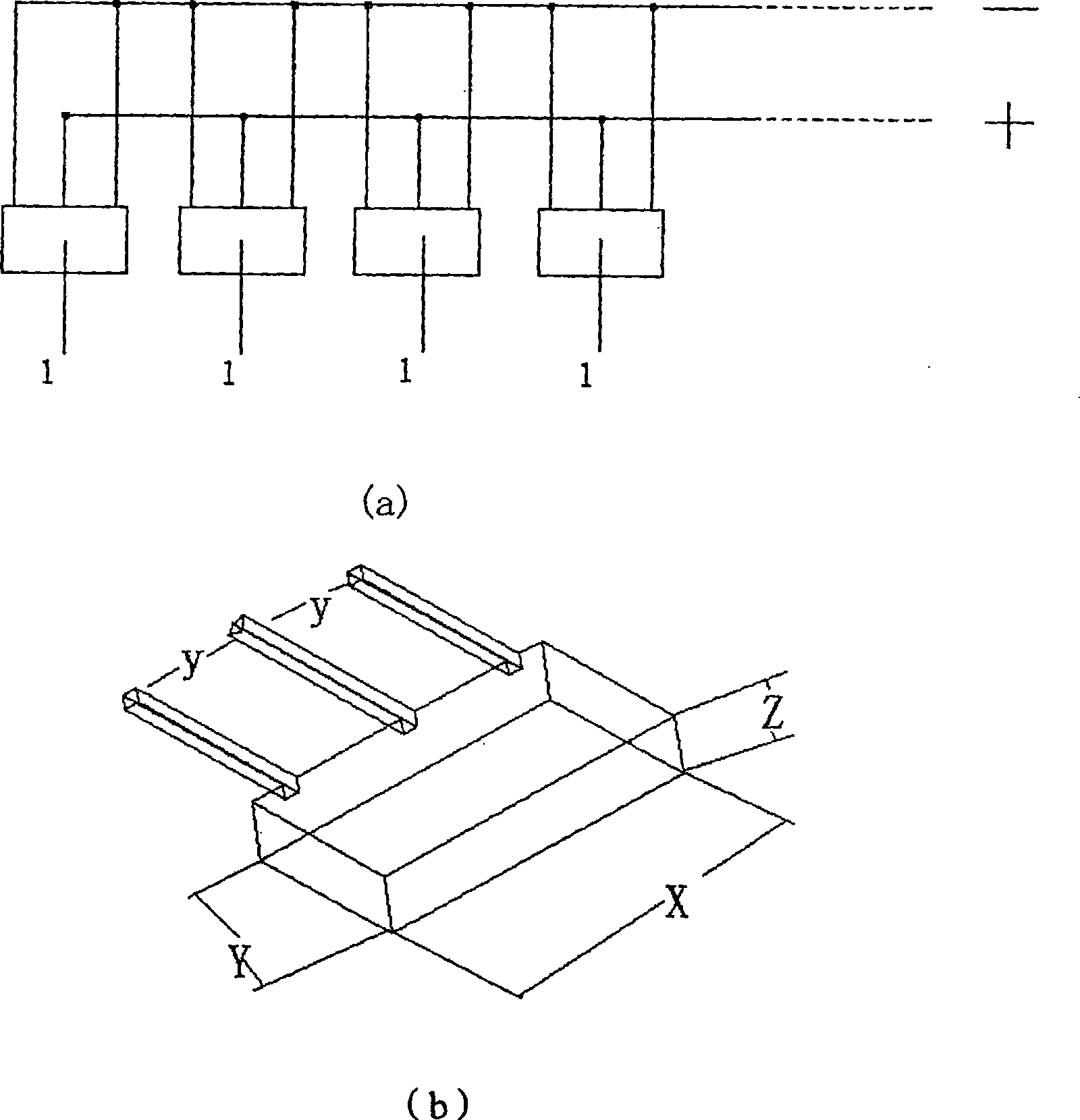

Stacked coil device and manufacturing method thereof

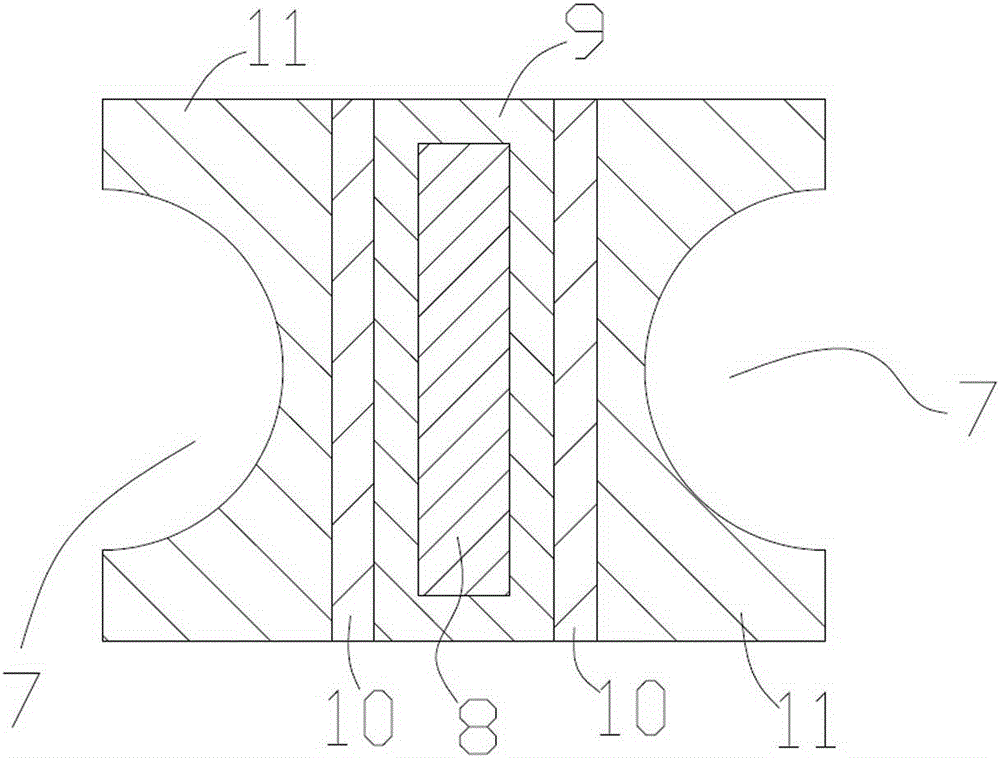

InactiveCN101651007AImprove featuresStress reliefTransformers/inductances coils/windings/connectionsCoils manufactureElectrical conductorInternal stress

The present invention provides a high characteristic and high reliability stacked coil device which alleviates the internal stress problem and does not form gap between the magnetic body ceramic layerand the internal conductor. The structure includes a magnetic body ceramic layer (1a). The magnetic body ceramic layer (1a) has a region with the pore space area rate of 6 to 20% from the flank of the magnetic body ceramic component (3) to the internal conductor. The structure has multiple layers of the magnetic body ceramic layer having a region with the pore space area rate of 6 to 20%. In thestructure, the gap does not exist on the interface of the internal conductor and the interface of the magnetic body ceramic surrounding the internal conductor, and the interface of the internal conductor is separated from the interface of the magnetic body ceramic. The flank of the magnetic body ceramic component is soaked through a region of the magnetic body ceramic layer with the pore space area rate of 6 to 20%, so that the acidic solution arrives in the interfaces of the internal conductor and the magnetic body ceramic surrounding the internal conductor, to cut off the combination of theinterface of the internal conductor and the interface of the interface of the magnetic body ceramic surrounding the internal conductor.

Owner:MURATA MFG CO LTD

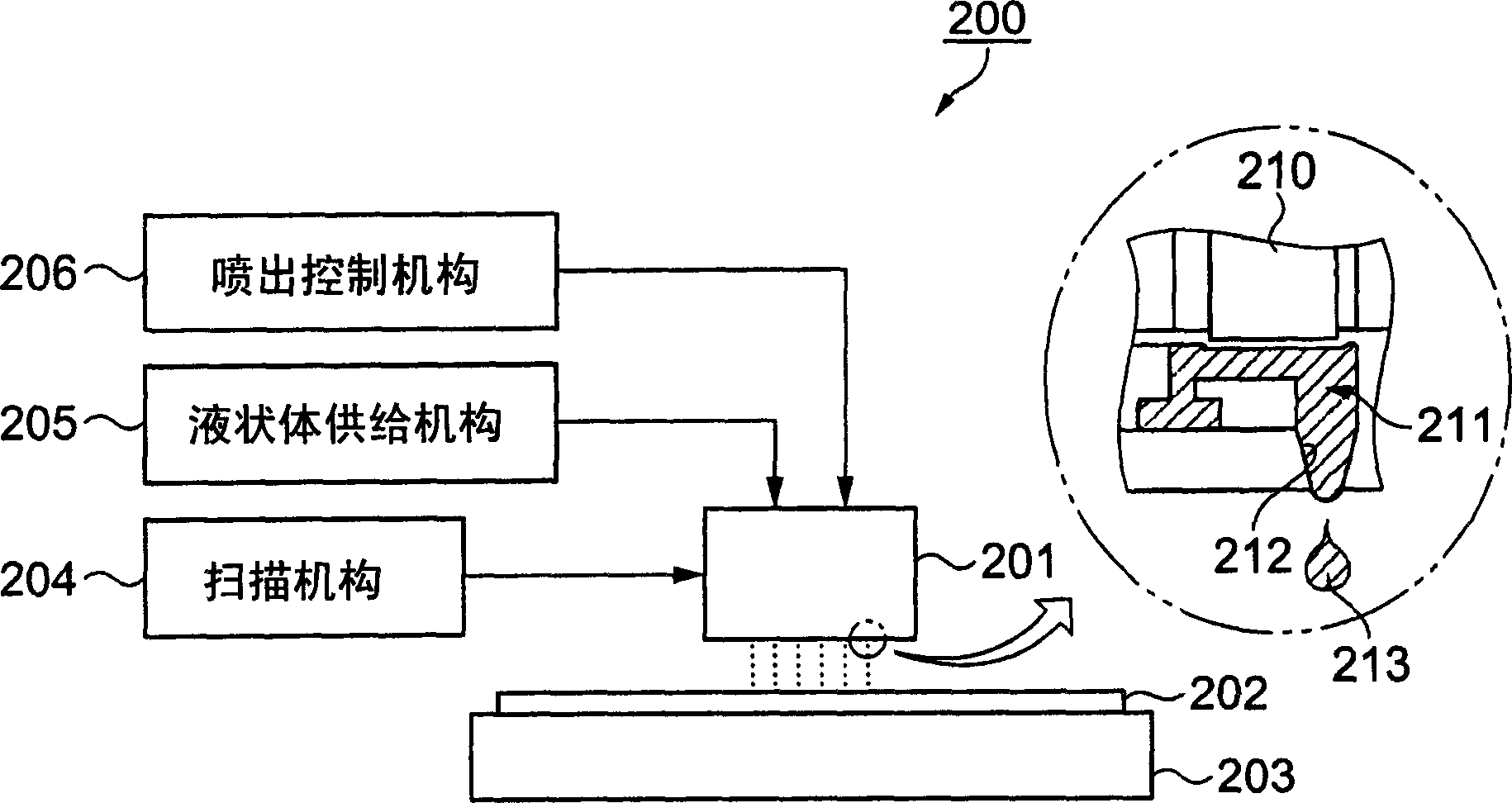

Surface treating method and film pattern forming method

InactiveCN1905782AGood electrical conductivityLess prone to disconnectionAntenna supports/mountingsSemiconductor/solid-state device manufacturingOptoelectronicsUltraviolet irradiation

The invention provides a surface treatment method by which a substrate with desired uniform lyophilicity is obtained in order to enhance the formation of a film pattern by an ink-jet process; a surface-treated substrate obtained by the surface treatment; and a method of forming a film pattern. A surface of a substrate is subjected to lyophobic treatment by forming a self-assembled layer composed of organic molecules. The lyophobicity is then modified by ultraviolet irradiation or the like to obtain desired lyophobicity.

Owner:SEIKO EPSON CORP

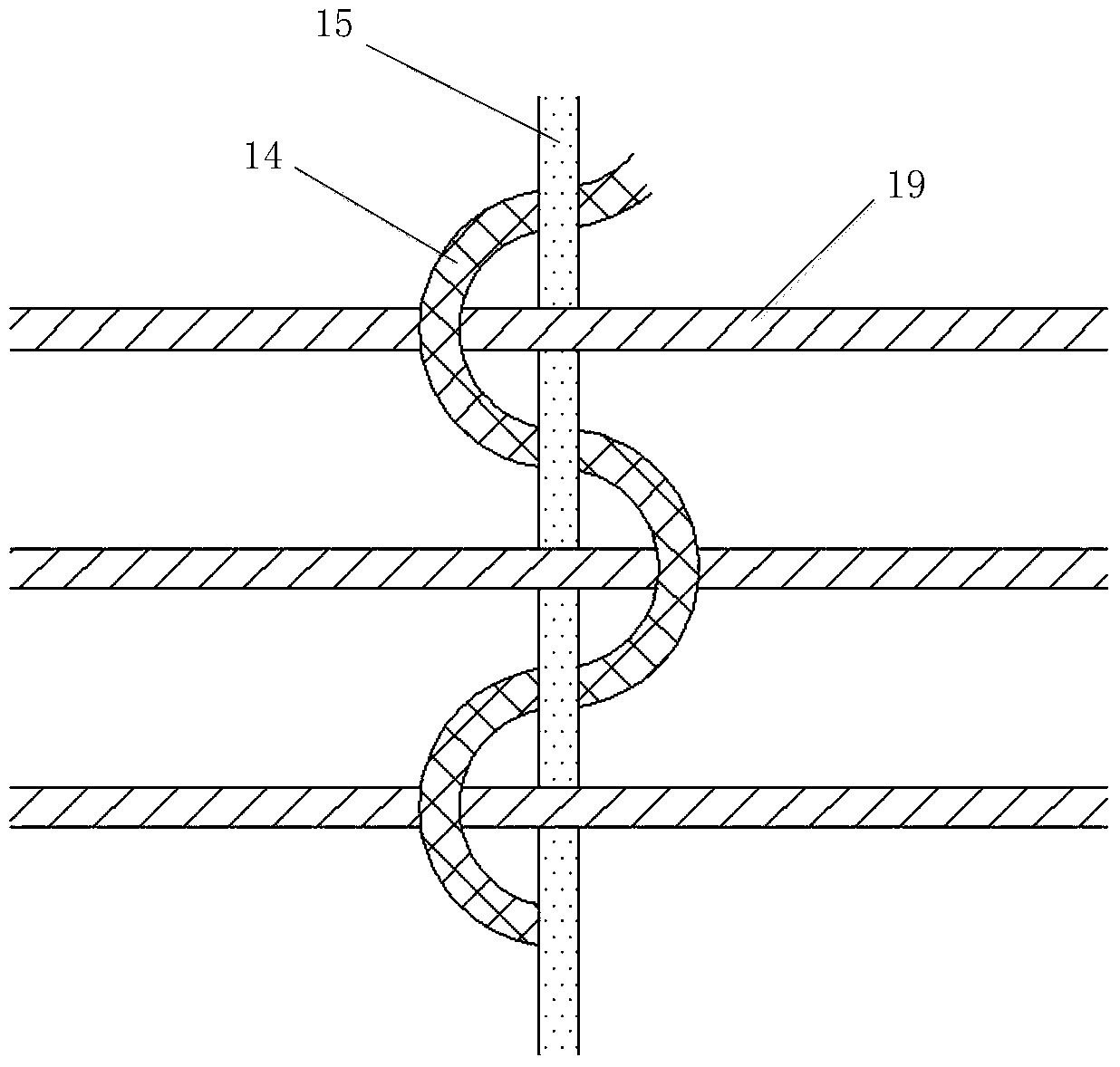

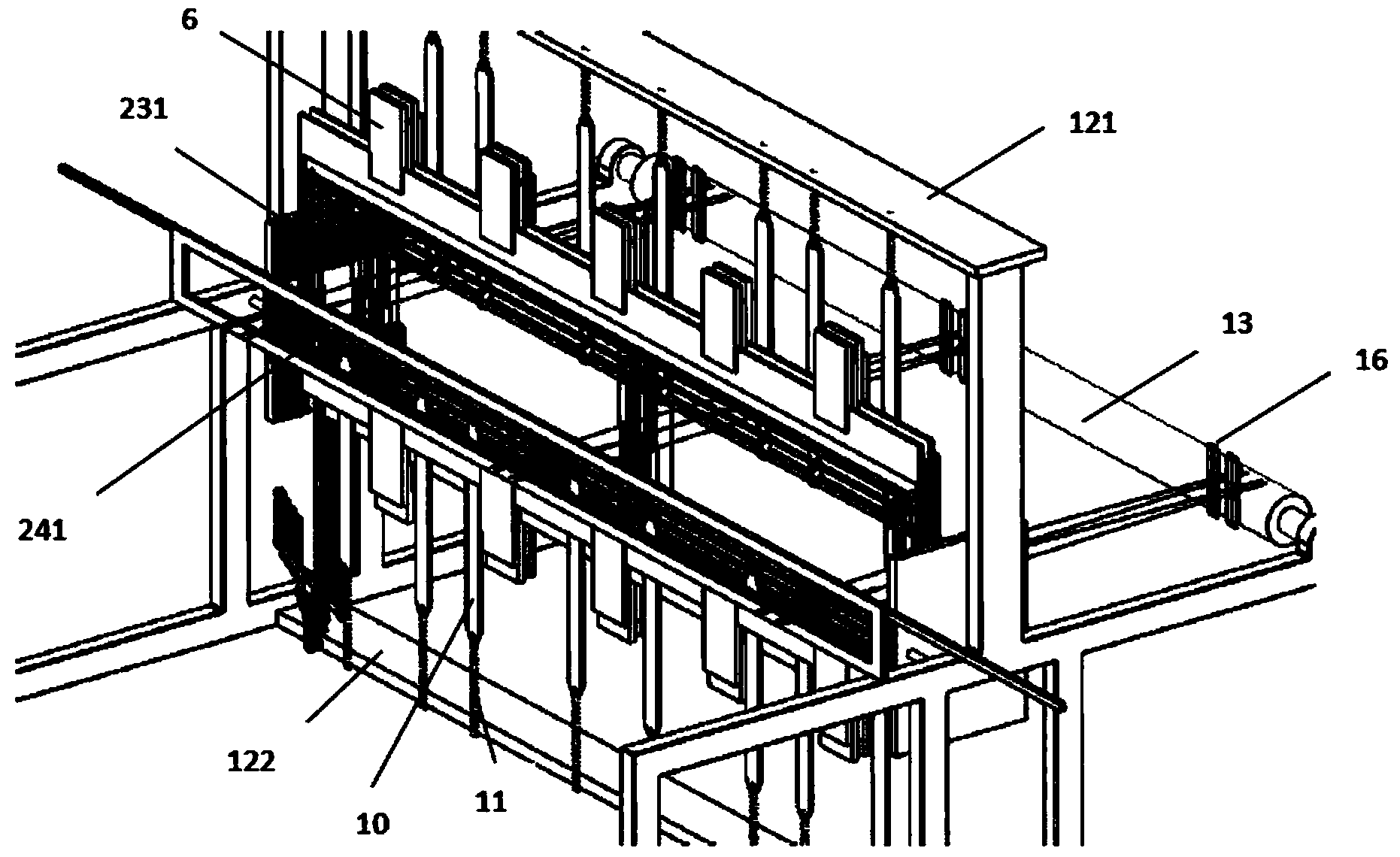

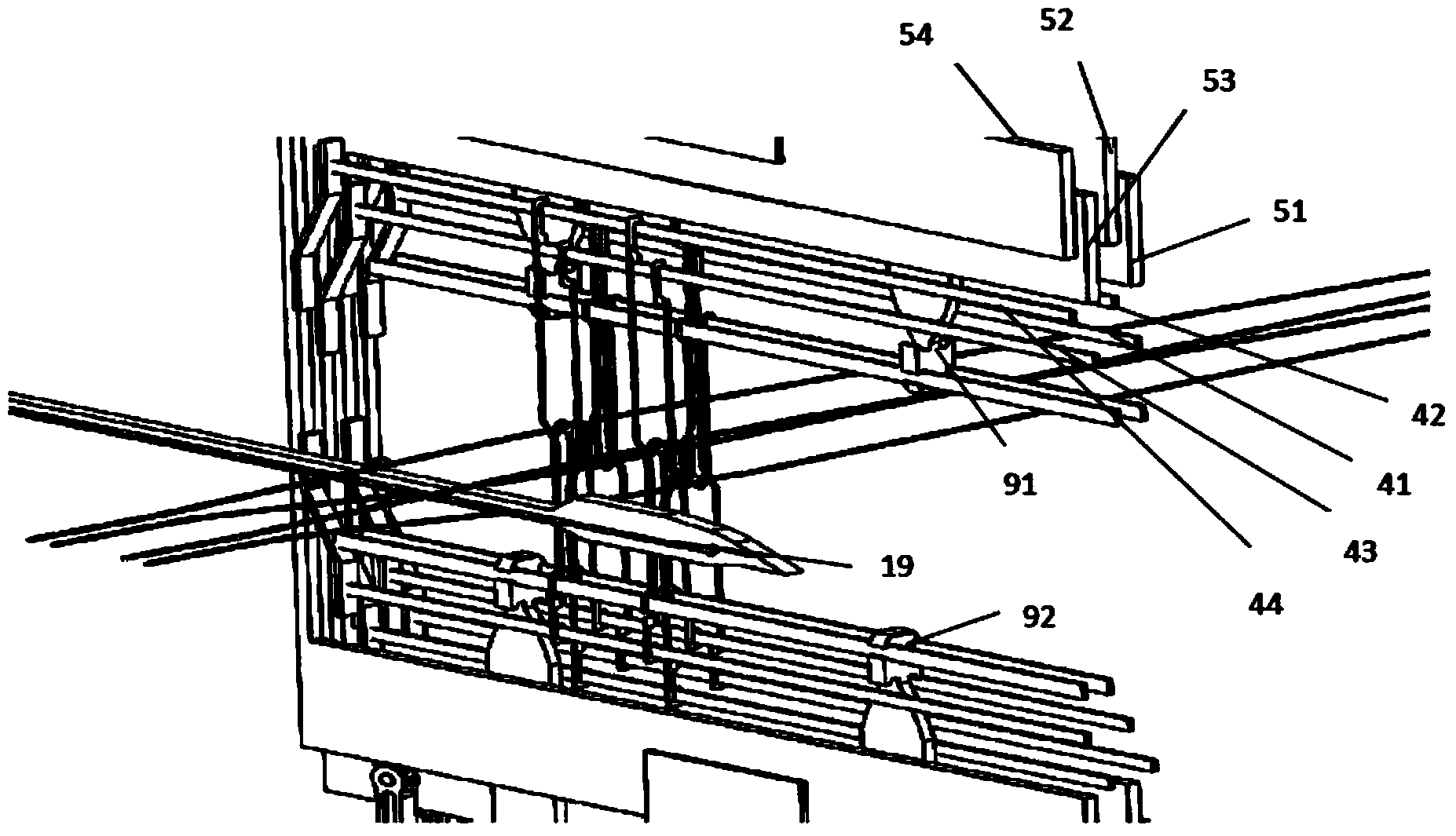

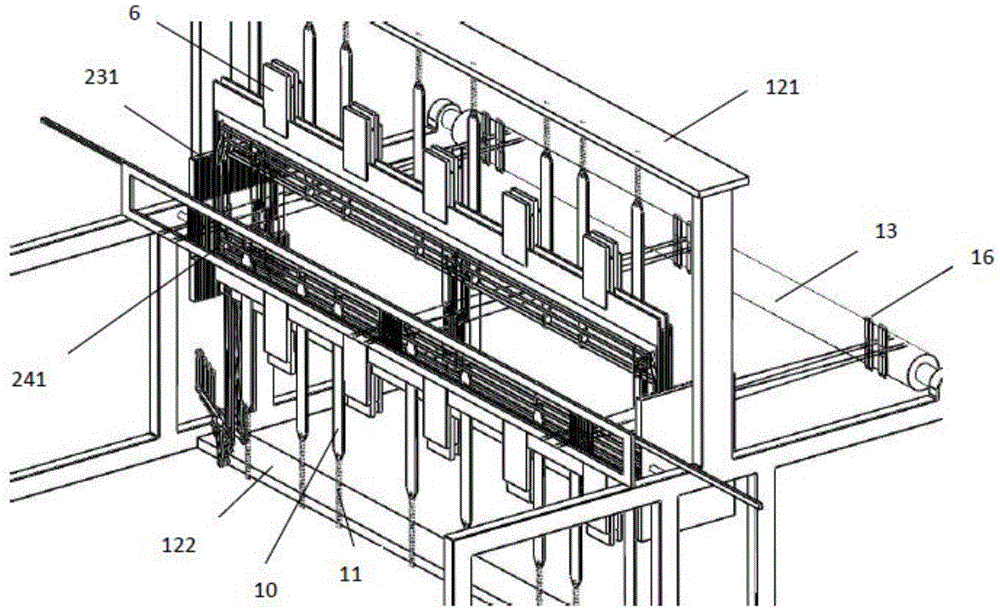

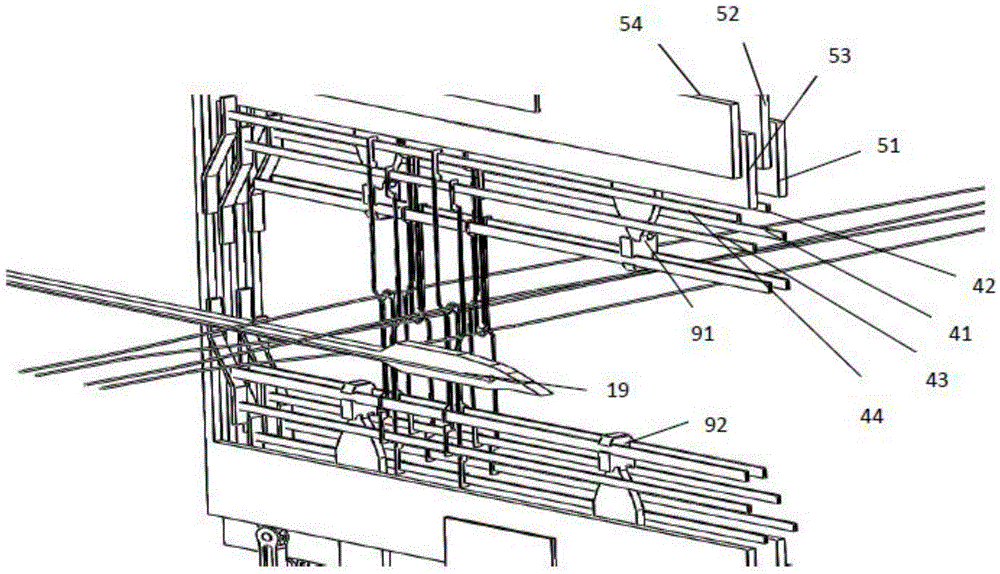

Device and method for controlling warp yarns of gauze cloth on loom

The invention discloses a device and a method for controlling warp yarns of gauze cloth on a loom, and belongs to the technical field of braiding equipments in the textile industry. The device comprises a plurality of heald frames, brackets, first healds, second healds, two-way brackets, linkages and multi-arm mechanisms, wherein the first healds and the second healds are mounted on the brackets front and back in pairs; the brackets are arranged in parallel side by side, and are connected with the heald frames; upper cross beams and lower cross beams of the brackets are respectively connected with a plurality of wooden frames; the heald frames are mounted in baffles on the two sides of the loom; the heald frames are connected with the linkages; the linkages are connected with the multi-arm mechanisms; the two-way brackets are arranged between the adjacent heald frames; the first healds and the second healds respectively pass through the two-way brackets; the two-way brackets are respectively connected with the upper cross beam and the lower cross beam of the loom through nylon pieces and springs. The invention further provides the method for controlling the warp yarns of the gauze cloth. The device and the method have the advantages that the device is suitable for the high-speed weaving of thick yarns, the opening is clear, the friction of yarns is avoided, and the structural design is simple and reasonable.

Owner:北京燕阳新材料技术发展有限公司

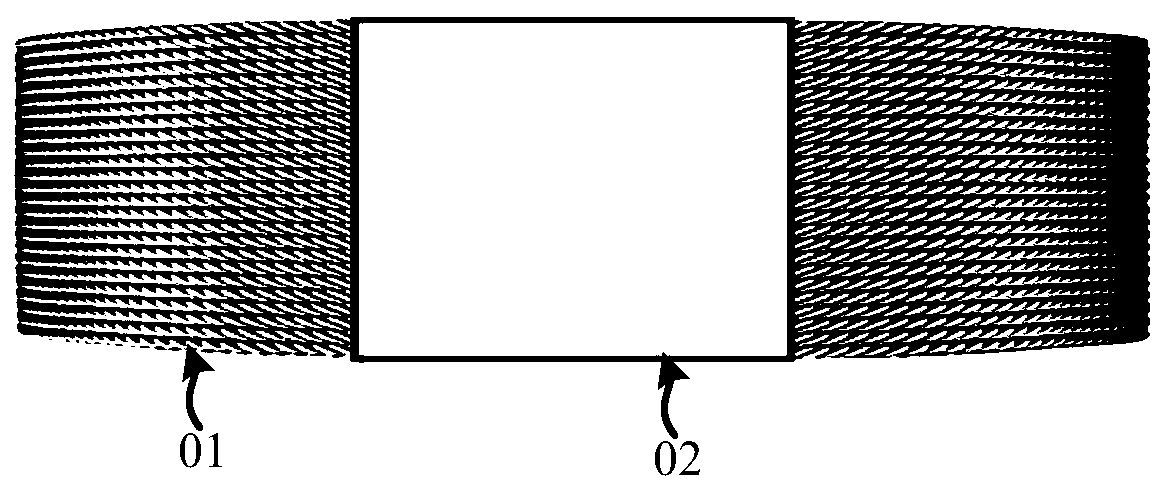

Wearable equipment fixing band and wearable equipment

ActiveCN110448013AGuaranteed wearing comfortImprove detection accuracyBraceletsWrist-watch strapsElectricityEmbedded system

Owner:HUAWEI TECH CO LTD

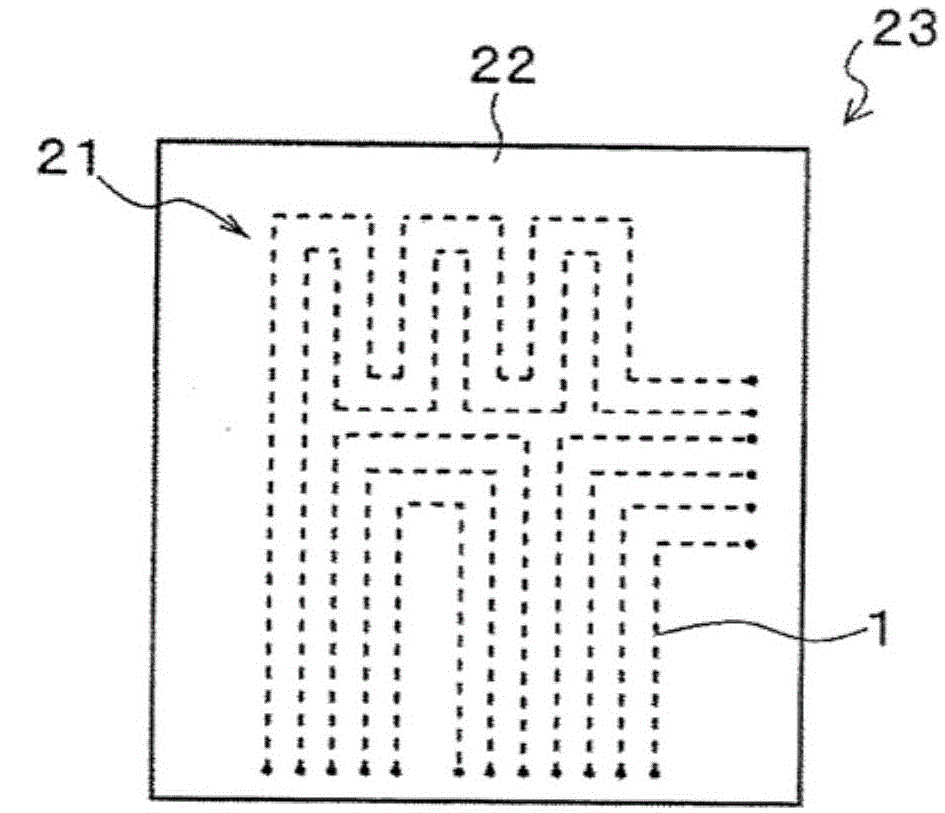

Wiring and manufacturing method of capacitive touch screen

ActiveCN101639749AImprove product qualityAvoid chromatic aberrationInput/output processes for data processingElectrical resistance and conductanceTransparent conducting film

The invention relates to a wiring and a manufacturing method of a capacitive touch screen, wherein the wiring comprises two groups of transparent conducting films on X and Y directions on a substrate,an insulating film and a connecting film, wherein the surface resistance of the connecting film is lower than the surface resistance of the transparent conducting films, an intersection structure ofthe transparent conducting films on the two directions adopts continuous connection and tunnel connection, wherein the continuous connection structure is a continuation of transparent conducting filmmaterials at two sides of the intersection point, and the tunnel connection structure is achieved as follows: the transparent conducting film on X or Y direction is continuously connected at the intersection point, and the transparent conducting film on the other direction is disconnected; the connecting film is sectionally arranged corresponding to the disconnected transparent conducting films atthe intersection point; the insulating film is covered at the middle part of the connecting film, the disconnected transparent conducting films are covered at the end part of the connecting film andthe substrate to form a continuous wire, and the transparent conducting films which are continuously connected at the intersection point stretch over the connecting film to be covered on the insulating film and the substrate. The manufacturing method comprises the step of manufacturing the connecting film, the insulating film and two groups of wire conducting films. The invention can avoid colordifference and improve the sensitivity, the standard ratio and the quality of the touch screen.

Owner:SHENZHEN LAIBAO HI TECH

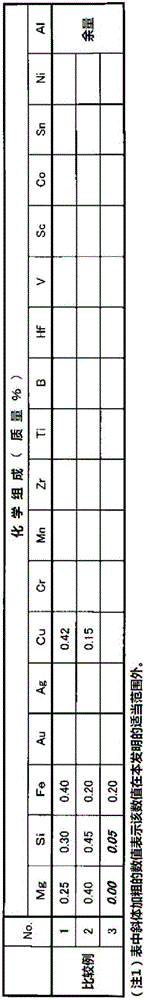

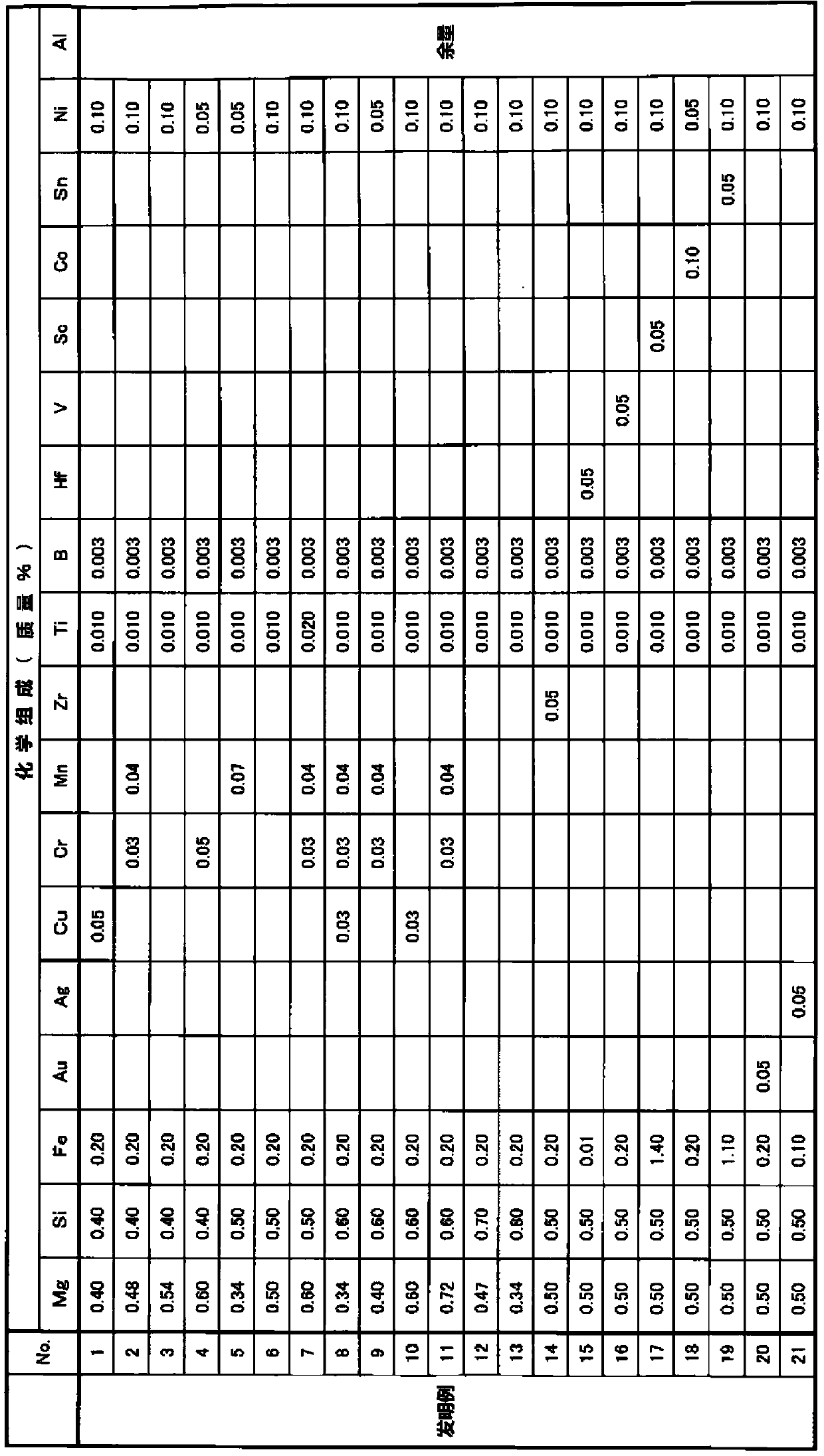

Aluminum alloy conductor wire, aluminum alloy twisted wire, sheathed electrical cable, wire harness, and method for manufacturing aluminum alloy conductor wire

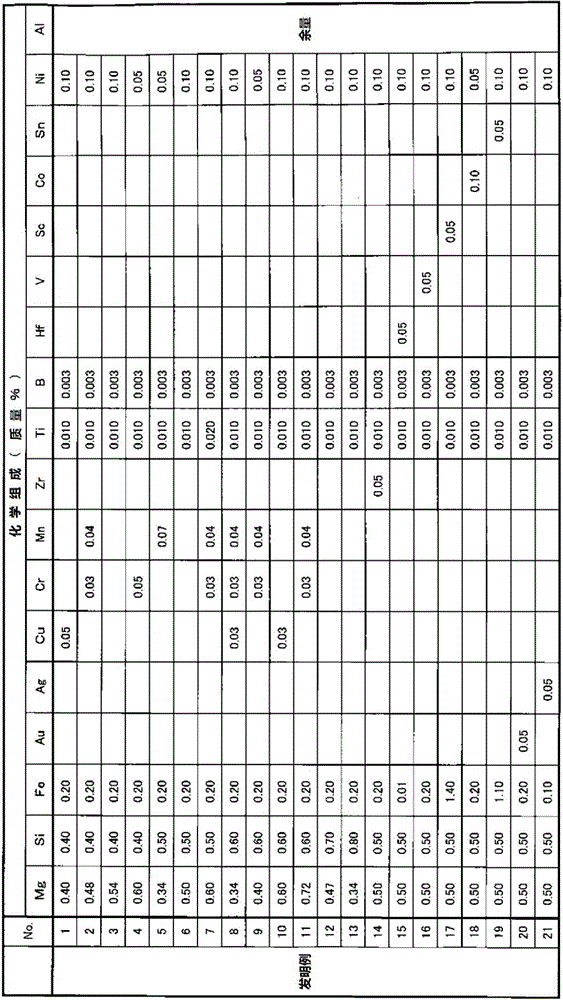

ActiveCN106605003AHigh strengthHigh tensile strengthSingle bars/rods/wires/strips conductorsApparatus for heat treatmentHigh intensityArea ratio

Provided is an aluminum alloy wire material having high strength and flexibility is minimally prone to breaking even when subjected to severe bending, such as that of 180 DEG. This aluminum alloy wire material has a composition of 0.1-1.0% by mass of Mg, 0.1-1.0% by mass of Si, 0.01-1.40% by mass of Fe, 0.000-0.100% by mass of Ti, 0.000-0.030% by mass of B, 0.00-1.00% by mass of Cu, 0.00-0.50% by mass of Ag, 0.00-0.50% by mass of Au, 0.00-1.00% by mass of Mn, 0.00-1.00% by mass of Cr, 0.00-0.50% by mass of Zr, 0.00-0.50% by mass of Hf, 0.00-0.50% by mass of V, 0.00-0.50% by mass of Sc, 0.00-0.50% by mass of Sn, 0.00-0.50% by mass of Co, and 0.00-0.50% by mass of Ni, with the remainder made up by Al and unavoidable impurities. The area ratio of a region in which the angle between the longitudinal direction of the aluminum alloy wire material and the <111> direction of the crystal is 20 DEG or less is 20-65%.

Owner:FURUKAWA ELECTRIC CO LTD +1

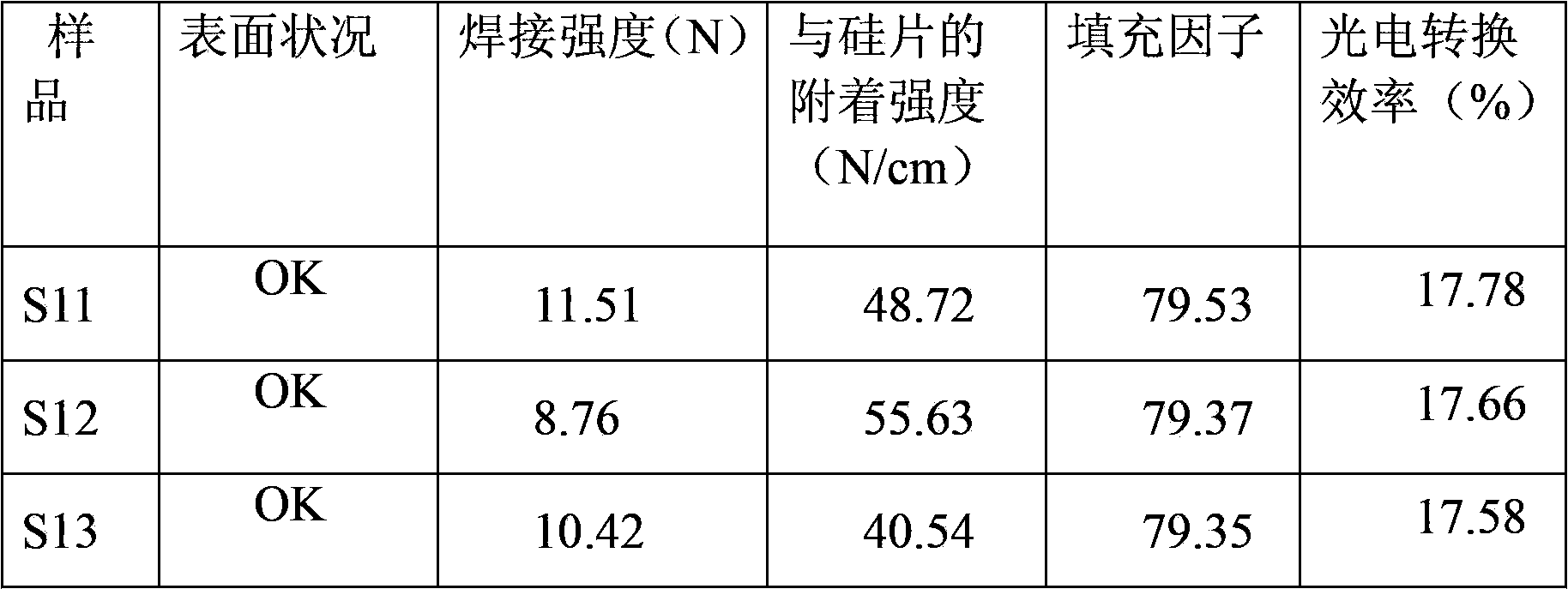

Silver conductive slurry used for solar cell, solar cell, and solar cell preparation method

ActiveCN103514972AIncrease light receiving areaReduce widthFinal product manufactureNon-conductive material with dispersed conductive materialSilicon alloySlurry

The invention provides silver conductive slurry used for solar cells, a solar cell, and a solar cell preparation method. The silver conductive slurry comprises a conductive phase, an inorganic binder and an organic carrier. The conductive phase contains 40 to 60% by weight of silver and silicon alloy powder, with the total amount of the silver conductive slurry being a reference. A prepared seed layer is smooth and low, no line breaking phenomenon tends to occur, a prepared electrode on the right side has a fine and smooth surface which has no nodes and holes, etc. Meanwhile, the silver conductive slurry exhibits high welding strength, can be firmly adhered to a silicon substrate, provides a basis for preparation of solar cells, and especially enables cell filling factors and the conversion efficiency to be greatly improved compared with conventional silver conductive slurry that is used for preparing a seed layer for a cell. Furthermore, the silver conductive slurry is easy to prepare, and simple in process and low in cost.

Owner:BYD CO LTD

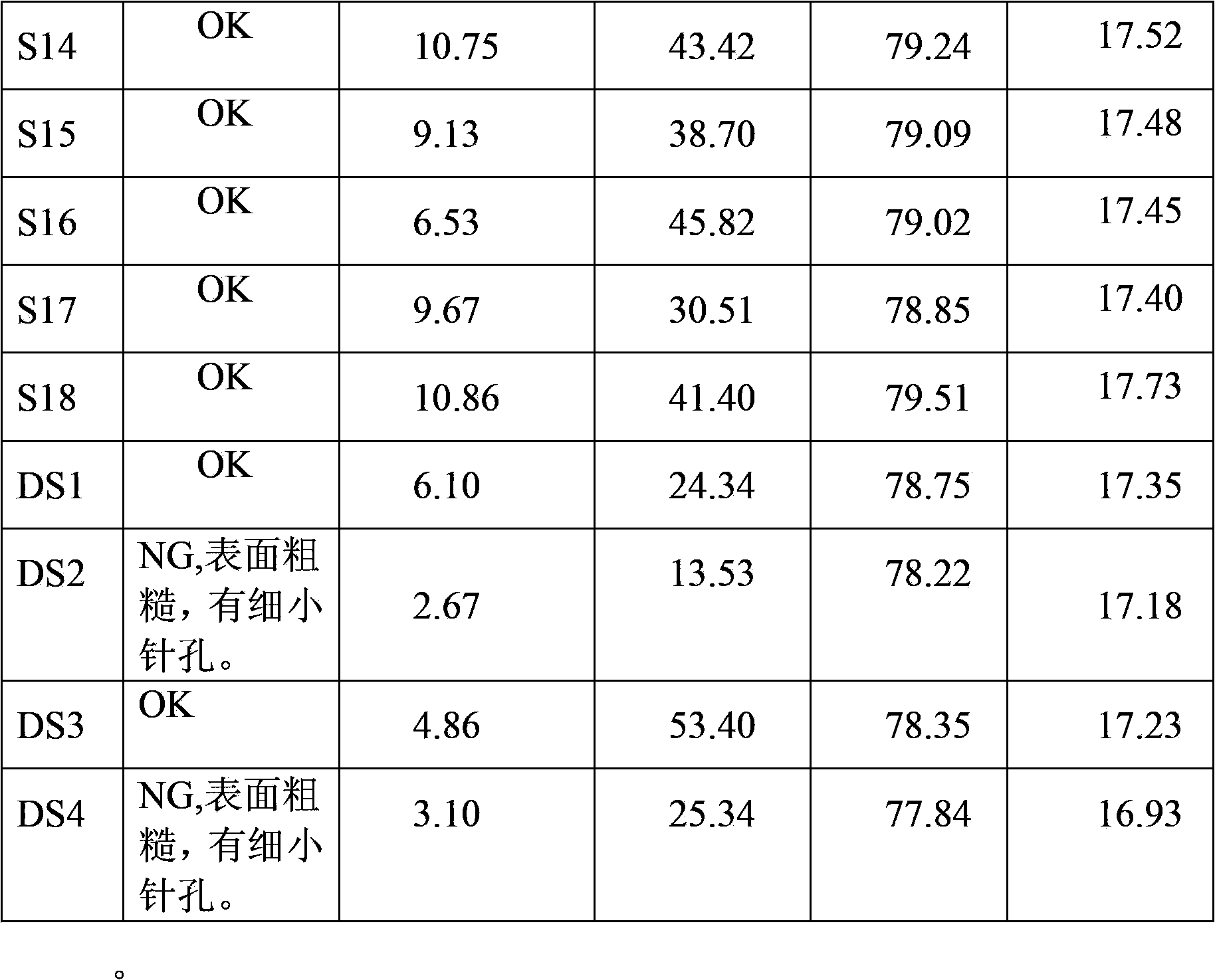

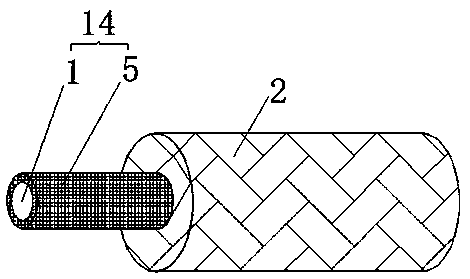

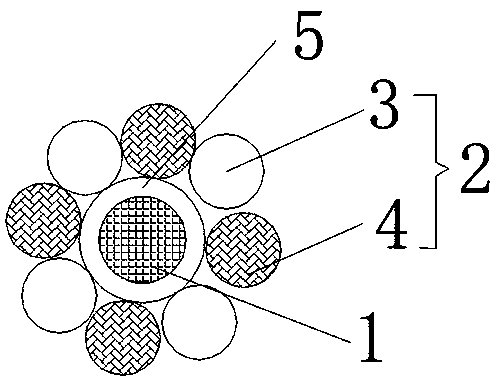

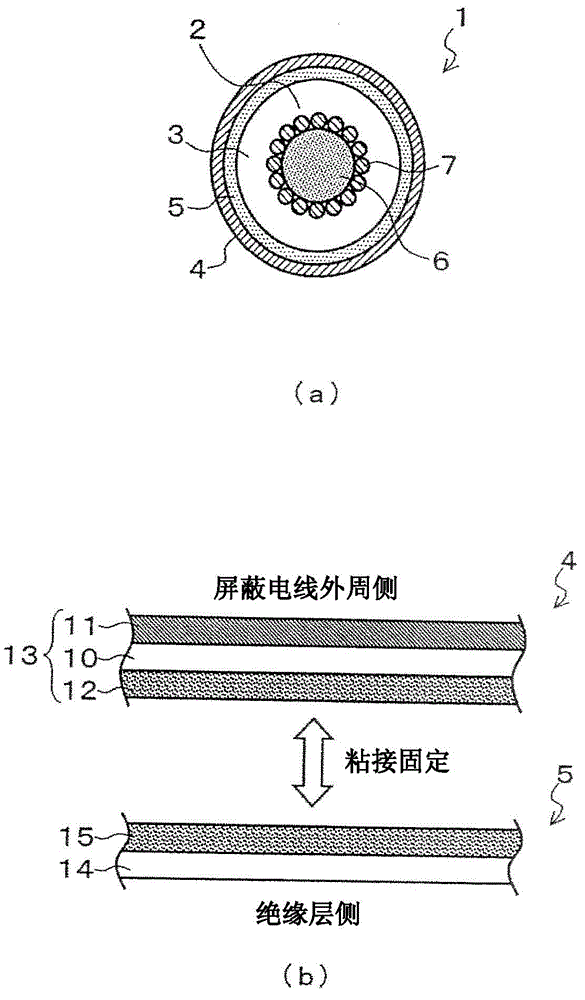

Electric wire, harness, electrical circuit, fabric, garment and sheet

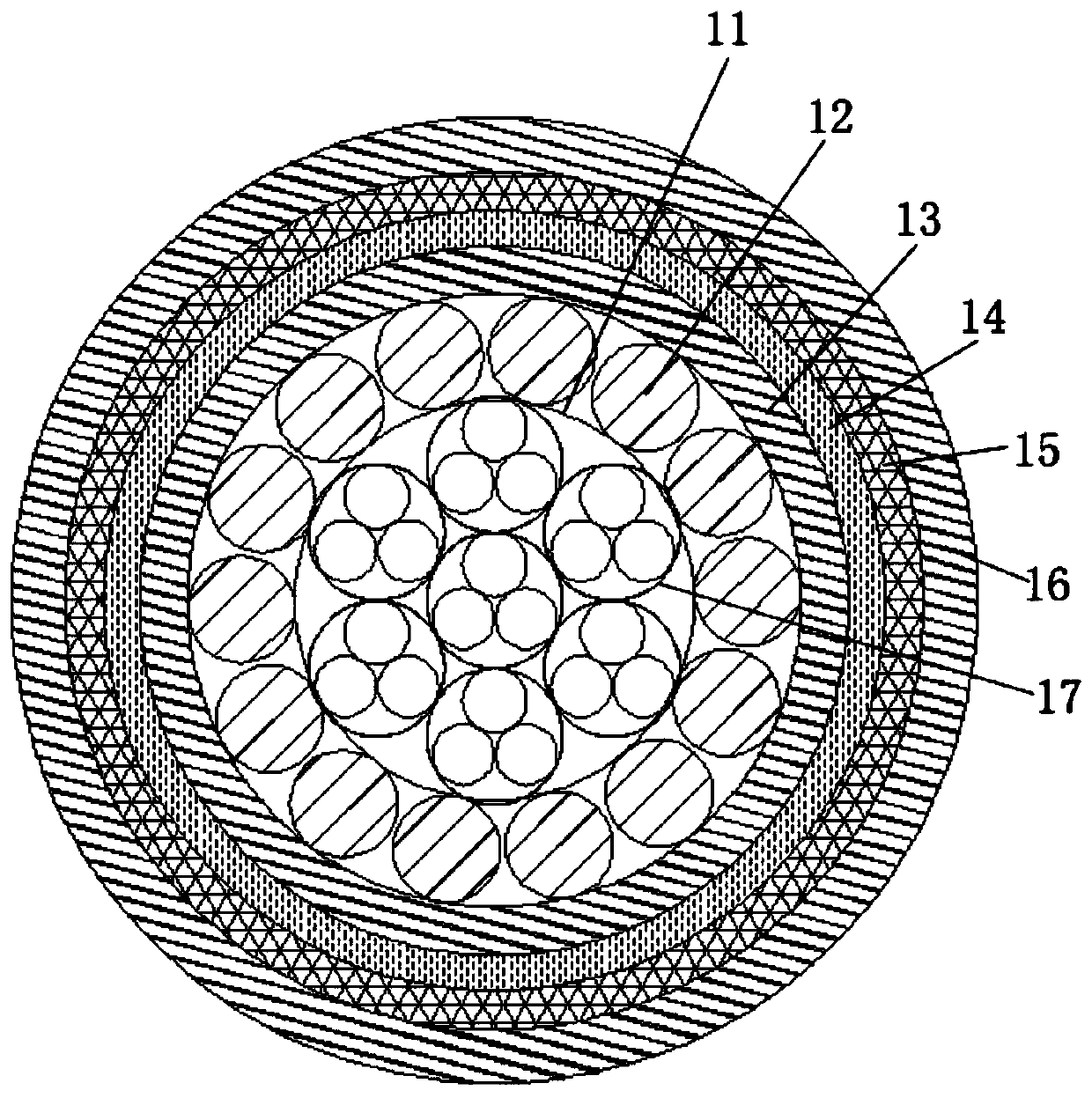

InactiveCN105097079ALess prone to disconnectionPlastic/resin/waxes insulatorsCommunication cablesFiberWire rod

An electric wire includes a center conductor, and an insulation layer formed on an outer periphery of the center conductor. The center conductor includes a high tensile-strength fiber and a plurality of metal strands wound around the high tensile-strength fiber.

Owner:HITACHI METALS LTD

Wiring and manufacturing method of capacitive touch screen

ActiveCN101639749BImprove product qualityAvoid chromatic aberrationInput/output processes for data processingContinuationEngineering

Owner:SHENZHEN LAIBAO HI TECH

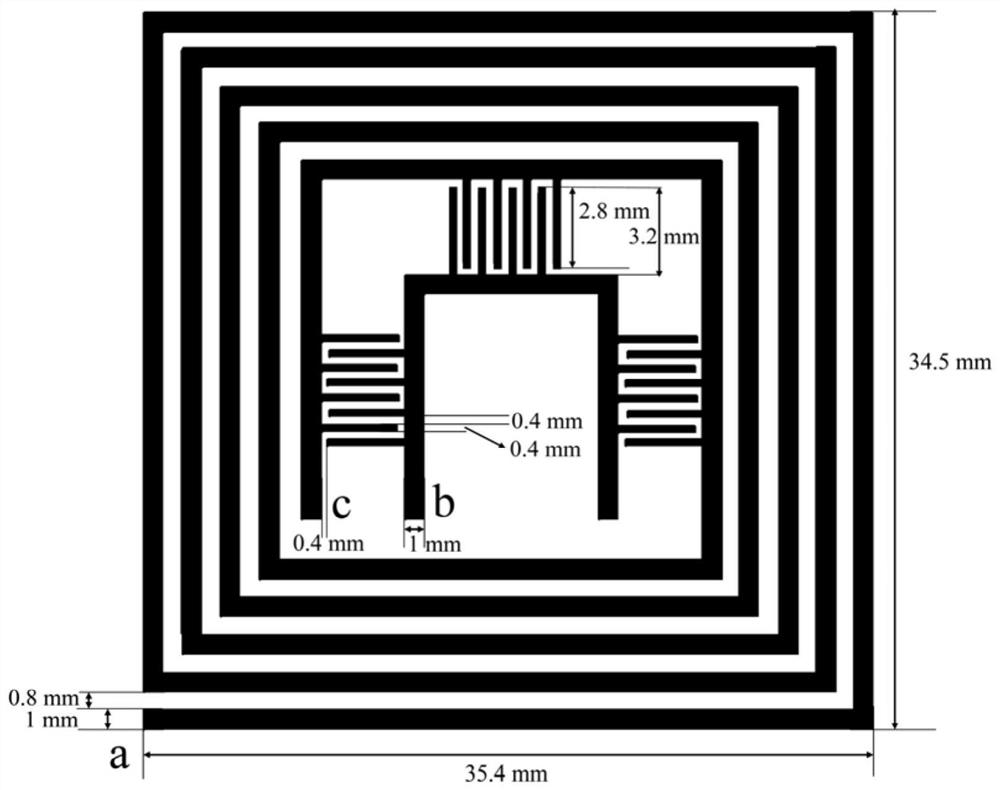

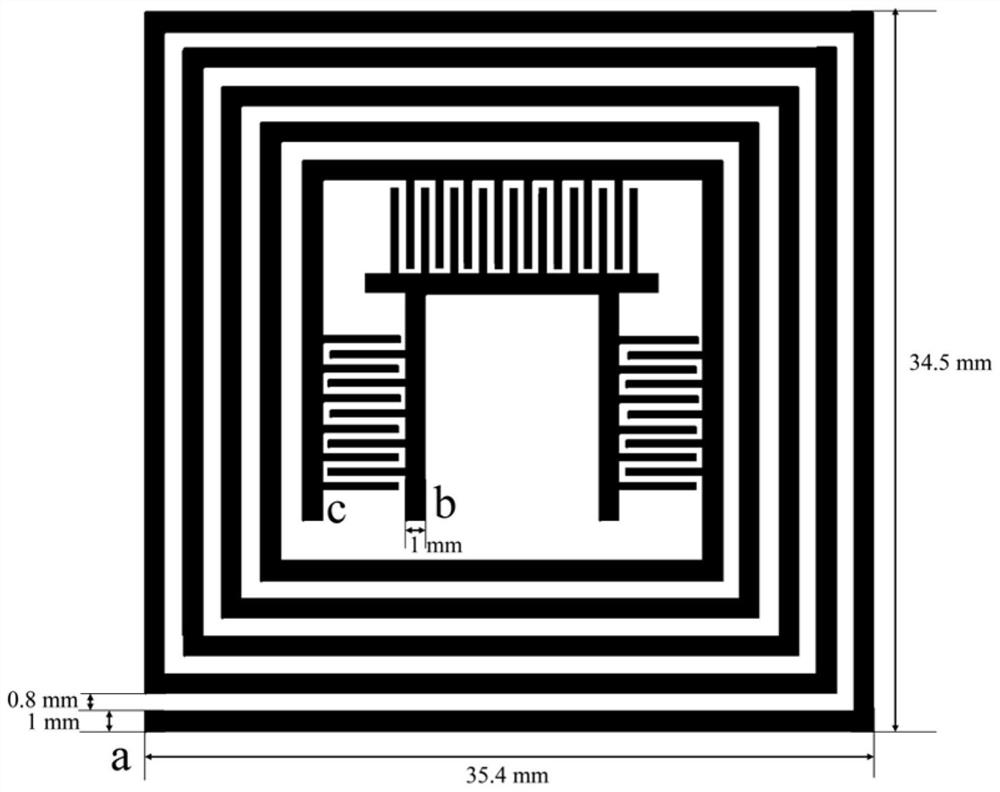

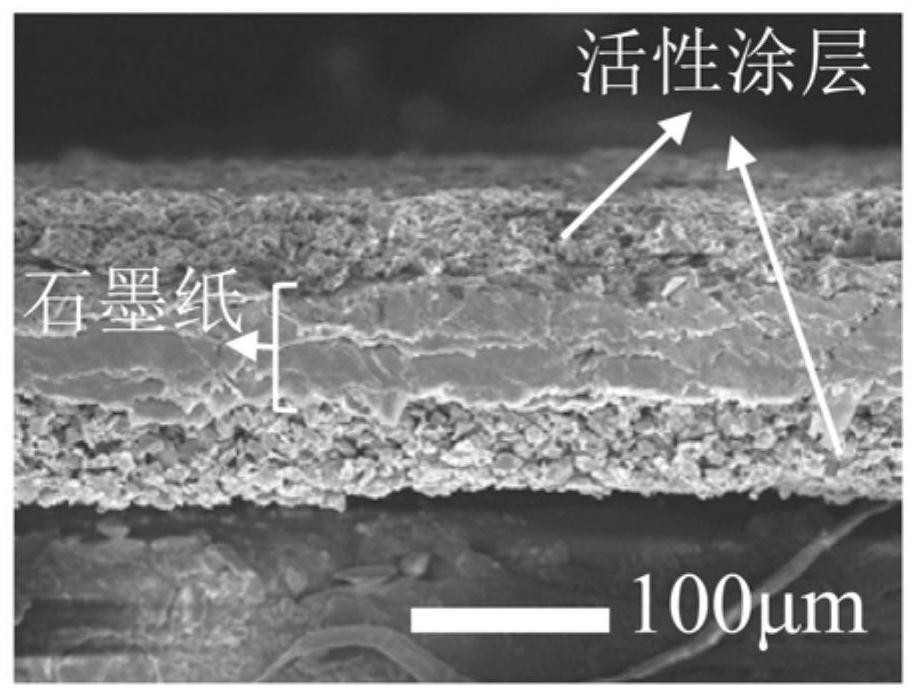

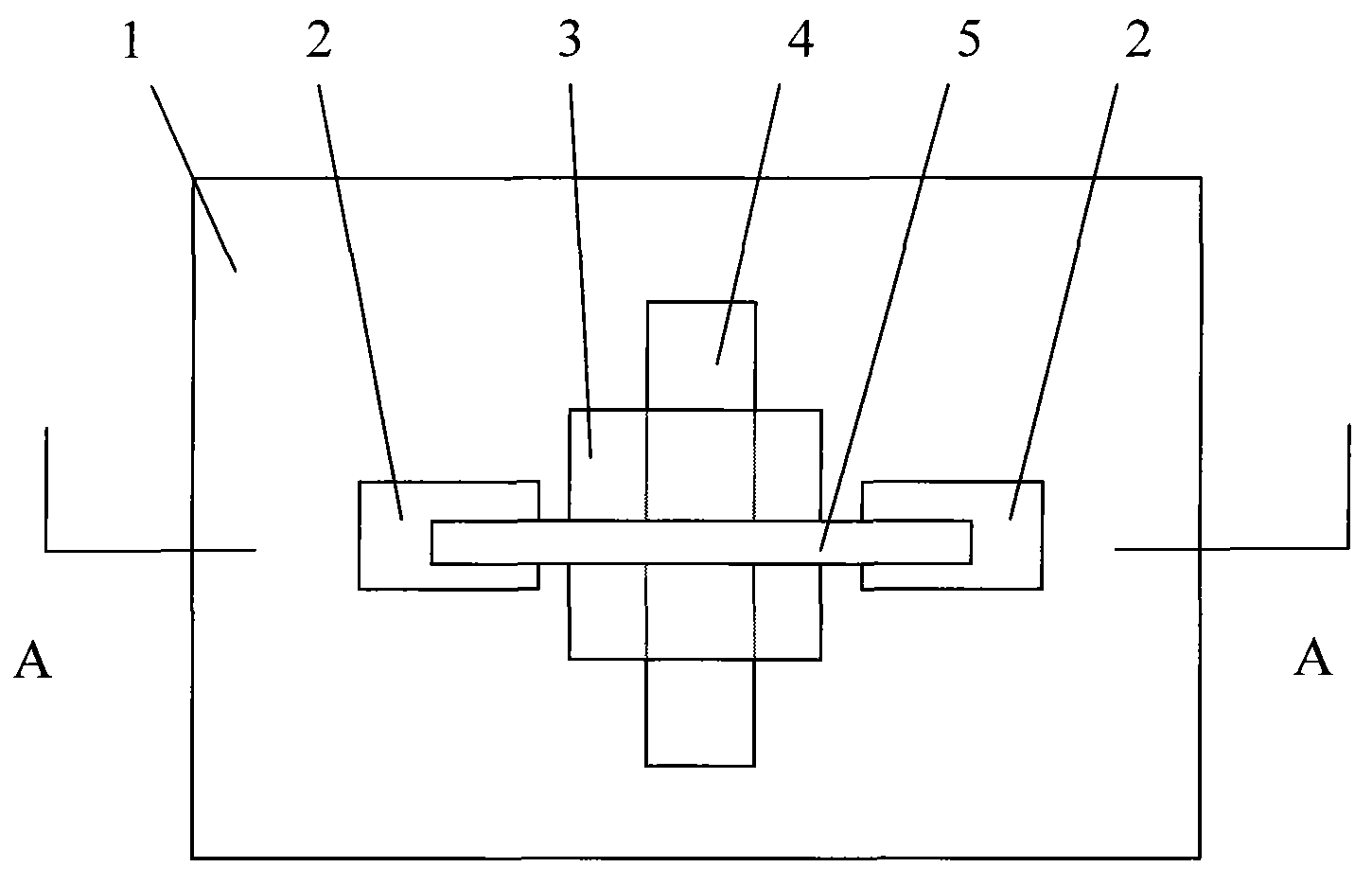

Integrated self-charging micro supercapacitor device and preparation thereof

ActiveCN111968860AIncrease capacityIncrease energy densityHybrid capacitor electrodesDouble layer capacitorsElectrolytic agentHigh energy

The invention relates to an integrated self-charging miniature supercapacitor device and preparation thereof, and belongs to the technical field of energy storage devices. The device comprises an electrode, an electrolytic solution, a packaging material, an outer coil, an inner coil and a rectifier diode, wherein the outer coil, the inner coil and the electrode are of an integrated structure prepared through laser etching. According to the invention, the preparation process is simple, operability is high, and through the integrated design of the wireless charging coil and the miniature supercapacitor, the integrality and connectivity of the device are guaranteed, and internal resistance and heat loss of the device are reduced; graphite paper with the surface coated with an active coating is selected as an electrode, and the high capacitance, high energy density and excellent high-current charging and discharging performance of the device are achieved through the adaptability of activated carbon and conductive carbon black in the active coating to the graphite paper and an electrolyte; and the device has high bendability and toughness and has a good application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

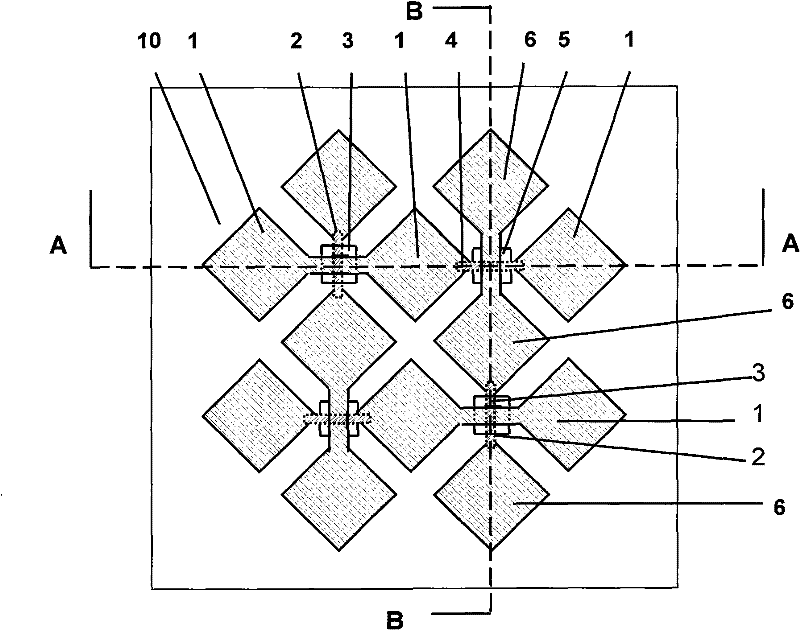

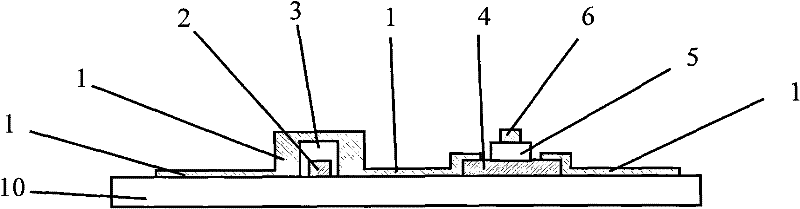

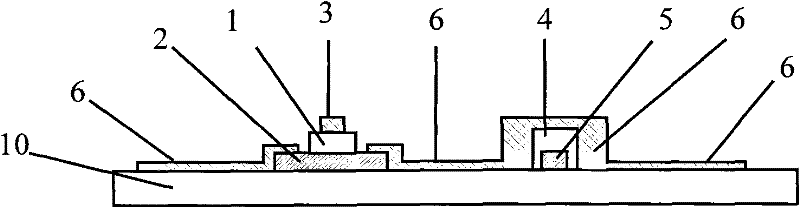

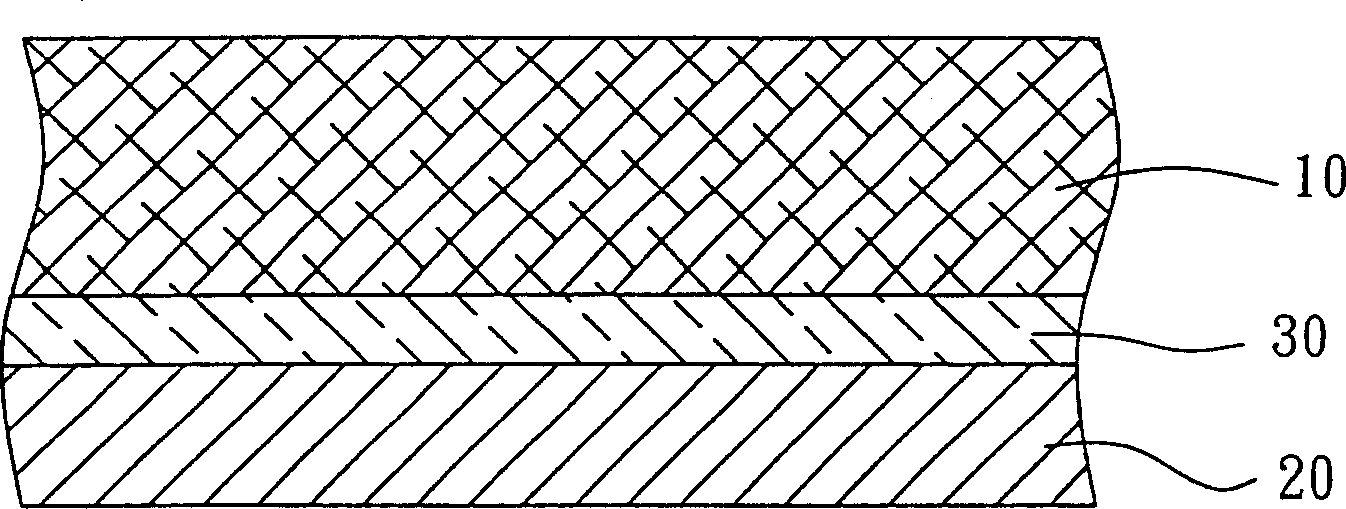

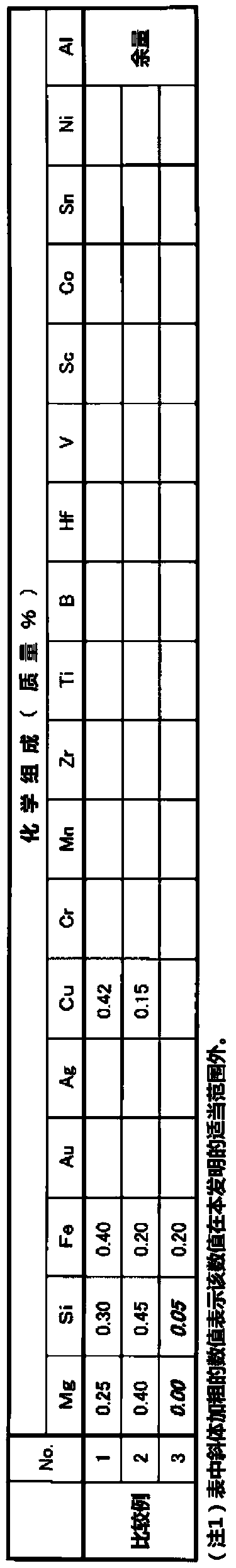

Capacitive touch screen and manufacturing method thereof

ActiveCN101576794BImprove product qualityAvoid chromatic aberrationInput/output processes for data processingTransparent conducting filmTouchscreen

The invention discloses a capacitive touch screen and a manufacturing method thereof. A bridging jumper wire comprises two groups of line conductor transparent conductive films, an insulating film and a metallic bridging film layer which are arranged on a base plate; the first group of line conductor transparent conductive films are arranged continuously, and the second group of line conductor transparent conductive films are arranged sectionally by taking the first group of line conductor transparent conductive films as spacers; the insulating film covers the first group of line conductor transparent conductive films and the adjacent base plate surface at the intersection of two groups of line conductors; the metallic bridging film crosses over the insulating film to connect the second group of line conductor transparent conductive films arranged at intervals as a continuous body and covers the surface of the base plate. The method comprises the steps of: manufacturing two groups of line conductor conductive files, and manufacturing the insulating film and manufacturing the metallic bridging film. In the invention, the transparent conductive films of two groups of line conductors can be manufactured at the same time, thereby avoiding chromatic aberration and improving the quality of the touch screen; the margin of the insulating film is located on the base plate, and the metallic bridging film layer can not be broken, thereby improving the yield of the product; the metallic bridging film layer is thick and not easy to be broken; and the metallic bridging film layer has small wire resistance, thereby improving the performance of the touch screen.

Owner:SHENZHEN LAIBAO HI TECH

A braided wire with elasticity and a processing technology thereof

PendingCN109243681ASimple structureGood lookingInsulated cablesCable/conductor manufactureYarnEngineering

The invention discloses a braided wire with elasticity, which comprises a woven layer and an elastic wire body, the elastic wire body is composed of an elastic inner core and a protective layer, the protective layer is arranged on the outer side of the elastic inner core, A braiding layer is wrapped on that outside of the elastic wire body, the braiding layer is weave by braiding yarn and conductive core wire through a braiding machine, an insulating layer is wrapped on the outside of the conductive core, the diameter of the conductive core wire is the same as the diameter of the braiding yarn. The invention also provides a processing technology of braiding electric wire with elasticity. By adopting the processing technology of the elastic braided electric wire provided by the invention, the production process is fewer, the broken wire phenomenon is not easy to occur in the production process, the braided electric wire is symmetrical, has no burr, and the production cost is low; meanwhile, the braided electric wire produced by the invention has simple structure, simple and beautiful appearance, and has certain elasticity and market popularization value.

Owner:东莞市科圆电子有限公司

Diamond wire saw and preparation method thereof

ActiveCN109352544AEasy to processImprove efficiencyGrinding devicesFine working devicesWire rodPull force

The invention discloses a diamond wire saw. The diamond wire saw comprises a wire base body made of basalt fiber, wherein the wire rod base body is fixedly provided with a diamond grinding material. The diamond wire saw has the advantages of high strength, high temperature resistance and corrosion resistance, still has enough strength after the diameter of the wire rod base body is reduced to bearthe pulling force in the cutting process, the maintenance and replacement frequency and cost of the wire saw are reduced, the production is ensured to be stable and normal, the production efficiencyis guaranteed, the diameter of the wire rod base body is small, the width of the cutting seam can be effectively reduced, the waste of the cut material is reduced, and the sheet discharging rate is improved.

Owner:成都惠锋智造科技有限公司

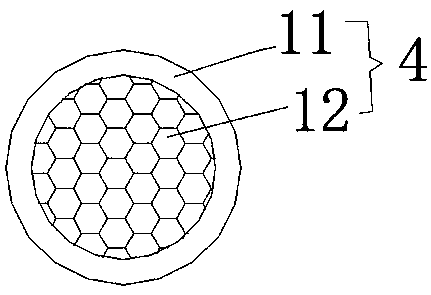

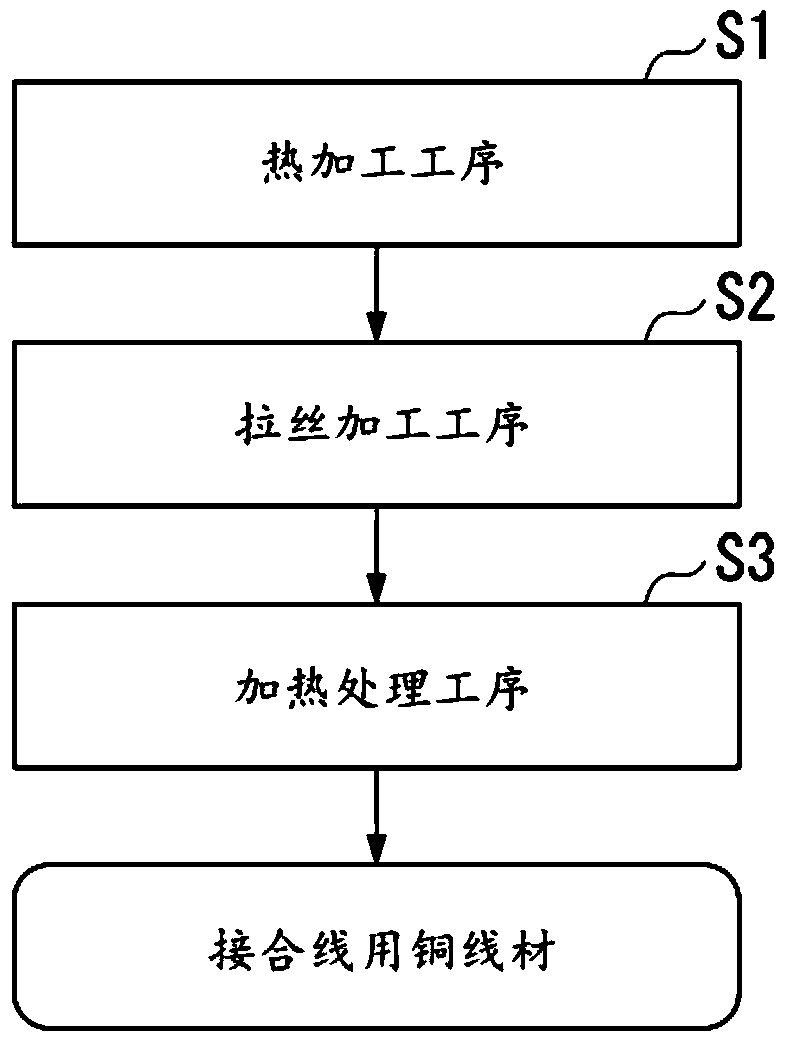

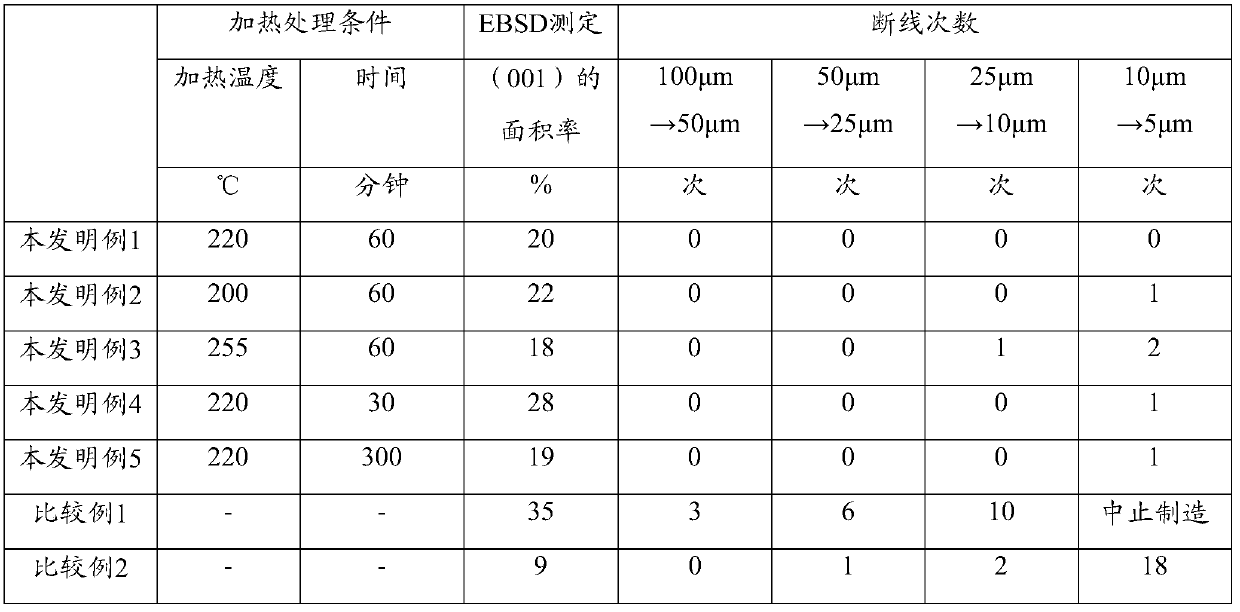

Copper wire material for bonding wire and method for producing copper wire material for bonding wire

ActiveCN104904000BEasy to processLess prone to disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingCopper wire

The copper wire material for bonding wires of the present invention is a copper wire material for bonding wires for forming bonding wires, which is composed of high-purity copper with a purity of 99.9999% by mass or more, has a wire diameter of 0.5 mm to 3.5 mm, and is perpendicular to the wire drawing direction. The area ratio of the (001) plane in the cross section is not less than 15% and not more than 30%.

Owner:MITSUBISHI MATERIALS CORP

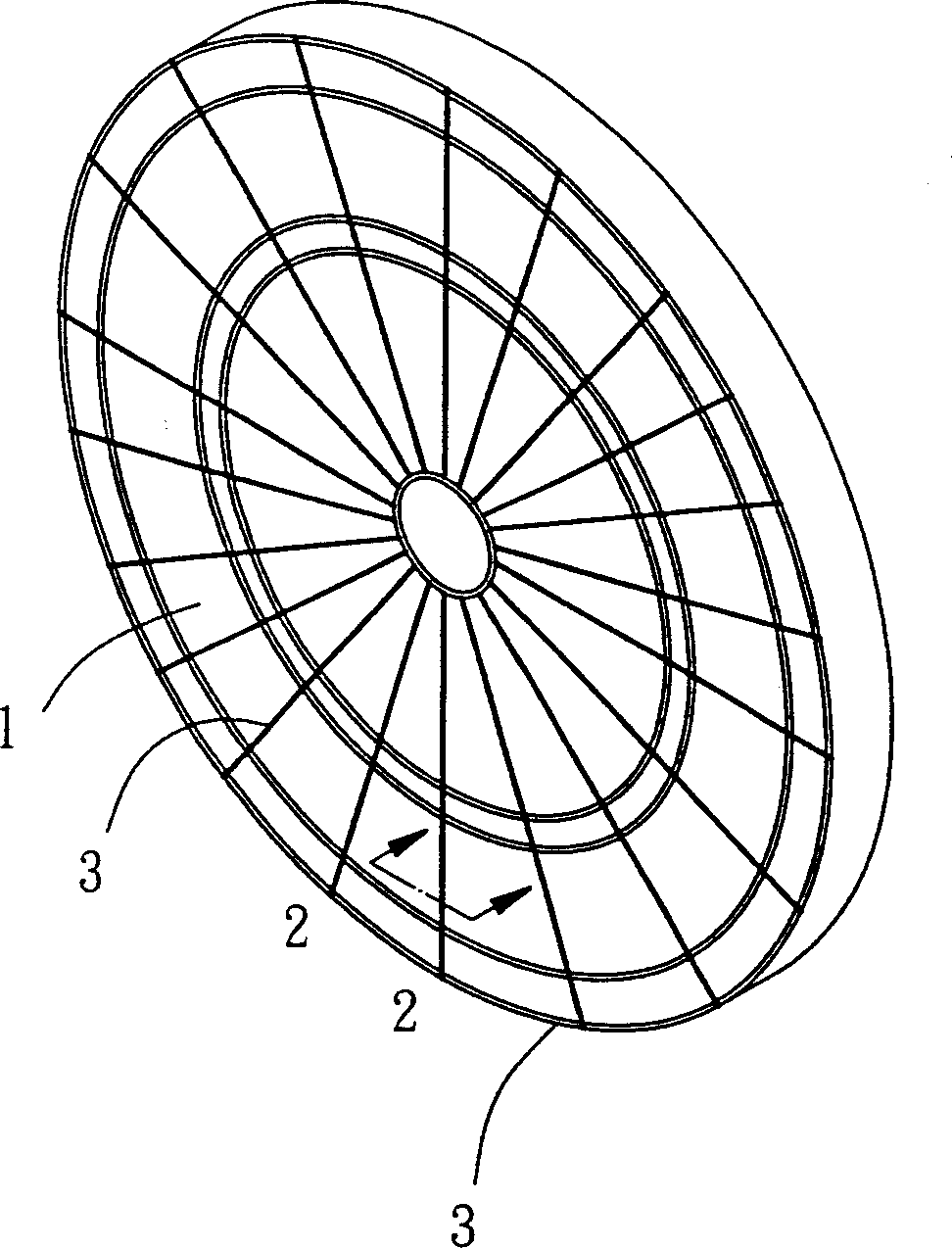

Printing-type magnetic boomerang target

InactiveCN1908571AEasy to useIncrease freedomTarget detectorsDartboardsEngineeringConductive materials

The present invention relates to a printing-type magnetic boomerang target, including a target body, which is divided into several target parts according to the scoring requirement; a magnetic force area, disposed on the back of the target body to form into a fixed magnetic field thereon; an induction layer, arranged between the target body and the magnetic force area, wherein the induction layer is printed on one carrier as the conducting material and the conducting materials are formed into the conducting line. The invention can make the products with more market competitive power, greatly advance the production efficiency, improve the stability of the products, which is more convenient to use.

Owner:FORHOUSE CORPORATION

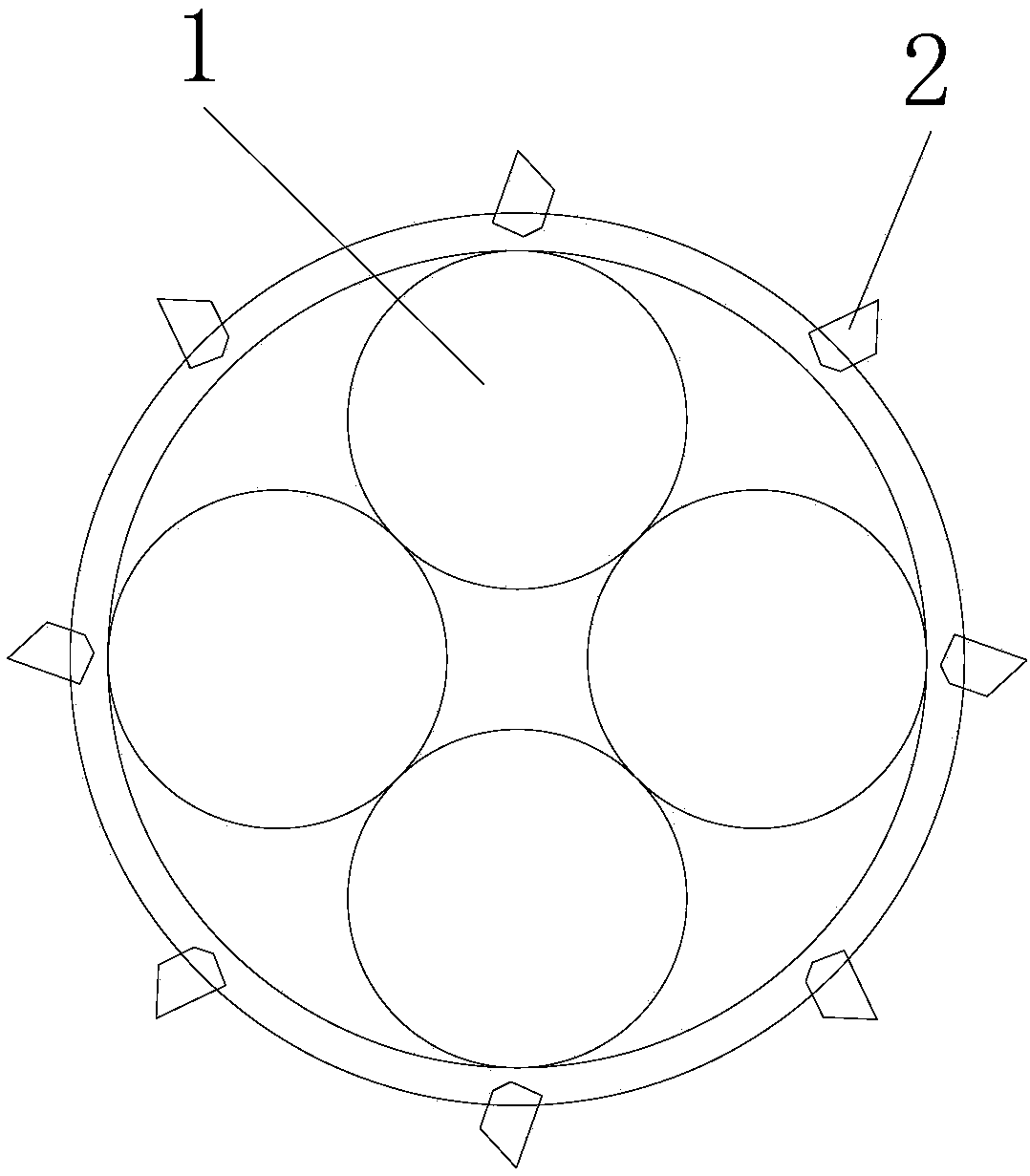

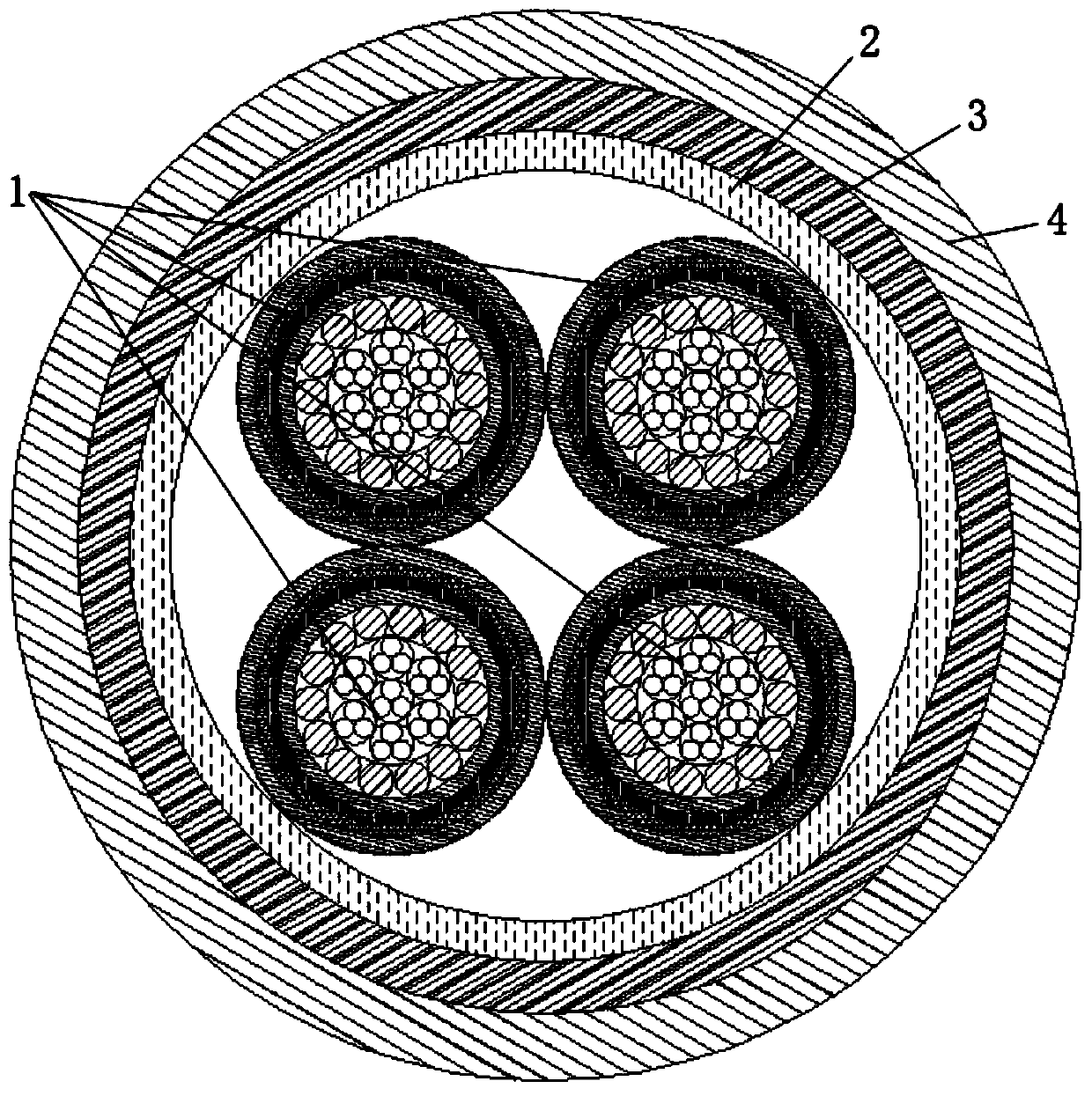

Tensile high-frequency multi-core cable and preparation method thereof

PendingCN111462936AHigh tensile strengthGood flexibilityCable conductor constructionCable insulation constructionTinningElectrical conductor

The invention discloses a tensile high-frequency multi-core cable and a preparation method thereof. The cable comprises a cable core formed by twisting a plurality of coaxial cable cores, a fluororesin wrapping tape layer, a copper-plastic composite tape wrapping shielding layer and an outer sheath, wherein the coaxial cable core comprises an inner conductor and a cable core body formed by concentrically twisting a plurality of PFA resin filling wires, an inner insulating layer, a metal winding shielding layer, a metal weaving shielding layer and an outer insulating layer sequentially coat theouter portion of the wire core body, the inner conductor is formed by twisting plural strands of wires, the stranded wire is formed by crossly and spirally twisting a plurality of tinned copper monofilaments with a diameter of 0.02-0.03 mm, the metal winding shielding layer is formed by spirally winding copper alloy wires in one direction, the metal weaving shielding layer is formed by spirally winding and weaving double-layer tinned copper wires in opposite directions, and the double-layer tinned copper wires are coated with lubricating oil. The cable has good tensile strength, flexibility,bending resistance and torsion resistance, and is not easy to break, small in high-frequency signal attenuation and durable in use.

Owner:浙江物产中大线缆有限公司 +1

Wiring structure and manufacturing method of capacitive touch screen

ActiveCN101634922BImprove product qualityAvoid chromatic aberrationInput/output processes for data processingElectrical resistance and conductanceEngineering

The invention relates to a wiring structure of a capacitive touch screen and a manufacturing method thereof, wherein the wiring structure comprises the step of arranging two groups of wire transparent conducting films in X and Y directions, an insulating film and a bridging film on a basal plate, wherein the surface resistance of the bridging film is lower than the surface resistance of the transparent conducting films, an intersection structure of the transparent conducting films in the two directions comprises continuous connection or bridging connection, wherein the continuous connection structure is a continuation of transparent conducting film material at two sides of the intersection point, and the bridging connection structure has the structures that the transparent conducting film in X or Y direction is continuously connected and positioned on the basal plate at the intersection point, the transparent conducting film in the other direction is disconnected at the intersection point, the insulating film is covered on the transparent conducting films that are continuously connected at the intersection part, and the bridging film stretches over the transparent conducting films that are continuously connected at the intersection point and is covered on the insulating film and connected with the transparent conducting film disconnected at the intersection point; and the method comprises the step of manufacturing two groups of wire conducing film, the insulating film and the bridging film. The invention can avoid color difference and improve the sensitivity, the standard ratio and the quality of the touch screen.

Owner:SHENZHEN LAIBAO HI TECH

Aluminum alloy wire, aluminum alloy stranded wire, covered electric wire, wire harness and manufacturing method of aluminum alloy wire

ActiveCN106605003BHigh strengthHigh tensile strengthSingle bars/rods/wires/strips conductorsApparatus for heat treatmentCrystallizationAluminium alloy

The present invention provides an aluminum alloy wire material that has high strength and flexibility and is less prone to breakage when subjected to severe bending such as 180°. The aluminum alloy wire rod of the present invention has the following composition: Mg: 0.1-1.0 mass%, Si: 0.1-1.0 mass%, Fe: 0.01-1.40 mass%, Ti: 0.000-0.100 mass%, B: 0.000-0.030 mass%, Cu: 0.00-1.00 mass%, Ag: 0.00-0.50 mass%, Au: 0.00-0.50 mass%, Mn: 0.00-1.00 mass%, Cr: 0.00-1.00 mass%, Zr: 0.00-0.50 mass%, Hf: 0.00-0.50 mass%, V: 0.00-0.50 mass%, Sc: 0.00-0.50 mass%, Sn: 0.00-0.50 mass%, Co: 0.00-0.50 mass%, Ni: 0.00-0.50 mass%, the balance is Al and unavoidable impurities, the area ratio of the region where the angle formed by the longitudinal direction of the aluminum alloy wire rod and the <111> direction of the crystal is within 20° is 20% to 65%.

Owner:FURUKAWA ELECTRIC CO LTD +1

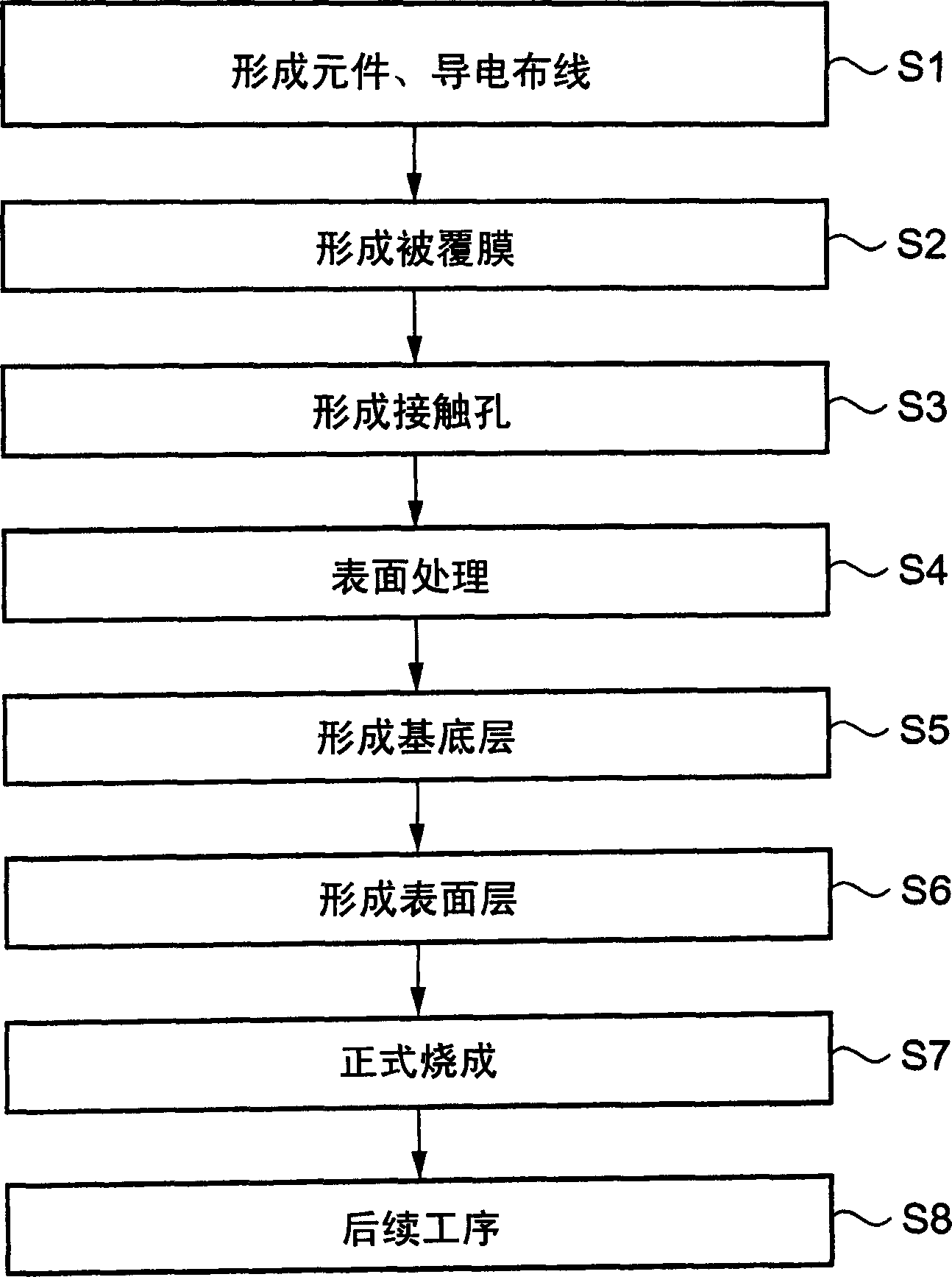

Electronic device and method for manufacturing the electronic device

InactiveCN1905137AEnhanced resistance to peelingImprove productivitySemiconductor/solid-state device detailsSolid-state devicesProduction rateSurface layer

The invention provides a method for manufacturing the electronic device with high productivity to produce much reliable electronic device and the electronic device obtained from such method. An integrated circuit 1 has a bonding pad 8 of a double layer structure connected to a conductive wiring 5 via a contact hole 10. The bonding pad 8 has a surface layer 7 bonded to the bonding wire 9, and a foundation layer 6 which improves adhesion between the surface layer 7 and a coating layer 4. The foundation layer 6 and the surface layer 7 are formed by a droplet delivery method, and Ni and Au are used as materials which can be liquefied under conditions suitable for use in the droplet delivery method.

Owner:SEIKO EPSON CORP

Laser LED electrode connection device

InactiveCN100527532CLess prone to heatGuaranteed safe operationElectric connection structural associationsClamped/spring connectionsMetallic materialsEngineering

The invention is concerned with a kind of laser diode connecting equipment, belonging to whole solid-state laser technology field. This equipment takes insulated material as base plate with inside and outside grooves, and there are metal plates and positive and negative poles inside of the inside and outside grooves in certain order, and the width and thickness of metal plates and poles are same as the width and thickness of grooves. Set laser diodes on the metal plates and positive and negative poles with certain order to connect those laser diodes. This method can connect laser diodes with metal plate and has easy structure for installing and it can bear high output of current to laser diode. This method predigests the structure of whole laser to use for engineering.

Owner:BEIJING UNIV OF TECH

Device and method for controlling leno fabric warp on a loom

The invention discloses a device and method for controlling the warp of leno fabric on a loom, and belongs to the technical field of weaving equipment in the textile industry. The device comprises a plurality of heald frames, a bracket, a first heddle, a second heddle, a two-way bracket, a connecting rod group and a dobby mechanism; the first heddle and the second heddle are installed on the bracket in pairs; the bracket Set side by side in parallel and connected with the heald frame; the upper and lower beams of the heald frame are respectively connected with multiple wooden frames; the heald frame is installed in the baffles on both sides of the loom; the heald frame is connected with the connecting rod group; connected; two-way brackets are arranged between adjacent heald frames, and the first heddle and the second heddle respectively pass through the two-way brackets; the two-way brackets are respectively connected to the upper and lower beams of the loom through nylon sheets and springs. The invention also provides a method for controlling the warp of the leno fabric. The invention has the advantages of being suitable for high-speed weaving of thick yarns, having clear openings and avoiding yarn scratching, etc., and has a simple and reasonable structural design.

Owner:北京燕阳新材料技术发展有限公司

Shielded wire, harness, electrical circuit, fabric, garment and sheet

InactiveCN105097094ALess prone to disconnectionPlastic/resin/waxes insulatorsDetails of conductive coresFiberInsulation layer

A shielded wire includes a center conductor, and an insulation layer and a shield that are sequentially formed on an outer periphery of the center conductor. The center conductor includes a high tensile-strength fiber and a plurality of metal strands wound around the high tensile-strength fiber.

Owner:HITACHI METALS LTD

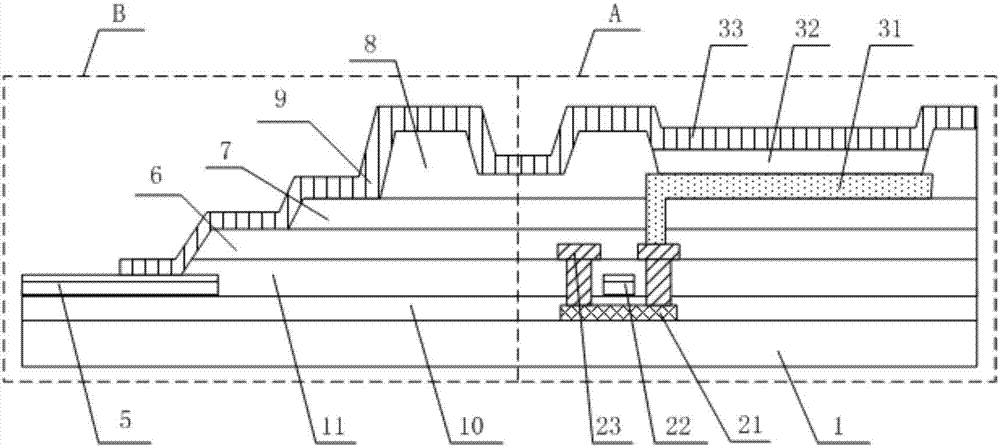

OLED substrate, manufacturing method, and display device

ActiveCN107452780BThe process is simple and reliableLess prone to disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses an OLED substrate, a manufacturing method and a display device, which relate to the field of display technology and are used to solve the problem that electrode leads are easily disconnected, so as to ensure the normal display of the OLED display device. The OLED substrate includes an array substrate having a display area and a peripheral wiring area, and the display area is provided with a plurality of OLEDs arranged in an array, and the OLED includes an upper electrode and a lower electrode arranged oppositely, and a an OLED light-emitting layer between the electrode and the lower electrode, and the lower electrode is formed on the surface of the array substrate; the peripheral wiring area is provided with a functional film layer and a signal line, and the functional film layer partially covers the signal line, The edge surface of the functional film layer is provided with electrode leads, one end of the electrode lead is connected to the part of the signal line not covered by the functional film layer, and the other end is connected to the upper electrode. The OLED substrate provided by the invention is used for OLED display.

Owner:BOE TECH GRP CO LTD

LED lamp

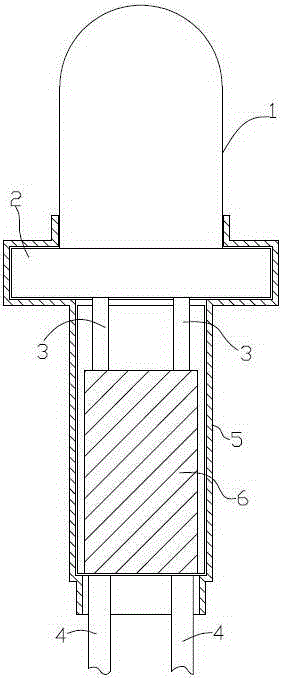

InactiveCN106641743AEasy to fixLess prone to disconnectionElectric circuit arrangementsLight fasteningsEngineeringLamp shell

The invention discloses an LED lamp. The LED lamp comprises a lamp cap; two conductive contacts are arranged at the lower end of the lamp cap; the conductive contacts are welded to wires; the lower end of the lamp cap and the wires are located inside a lamp shell; a lamp holder is arranged at the lower end of the lamp cap; the radius of the lamp holder is larger than the radius of the lower end of the lamp cap; the conductive contacts penetrate through the lamp holder to be welded to the wires inside the lamp shell; the lower end of the lamp cap and the lamp holder are located inside the lamp shell; a fixing sleeve is arranged inside the lamp shell; and grooves are formed in two sides of the fixing sleeve, and the welding positions of the wires and the conductive contacts are located in the grooves. According to the LED lamp, through the improvement of the structure, the fixing effect between the lamp cap and the lamp shell and the fixing effect between the wires and the conductive contacts are greatly improved, and the disjunction phenomenon is not easy to occur.

Owner:周晓东

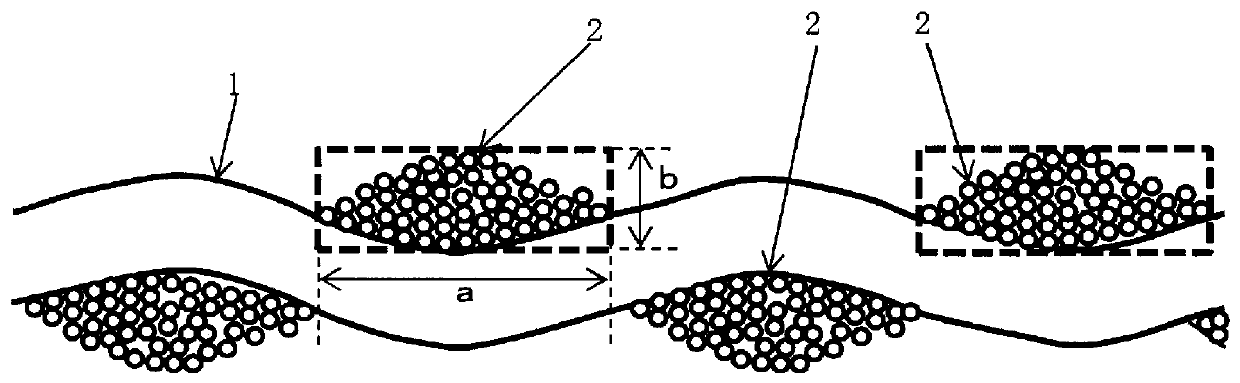

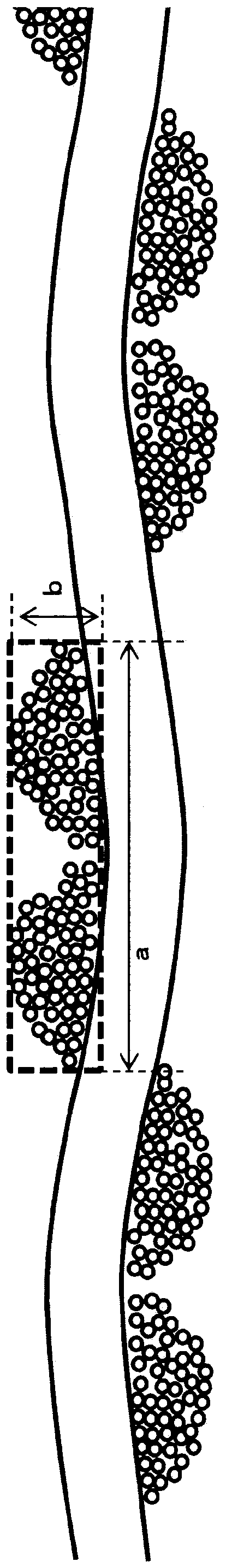

the fabric

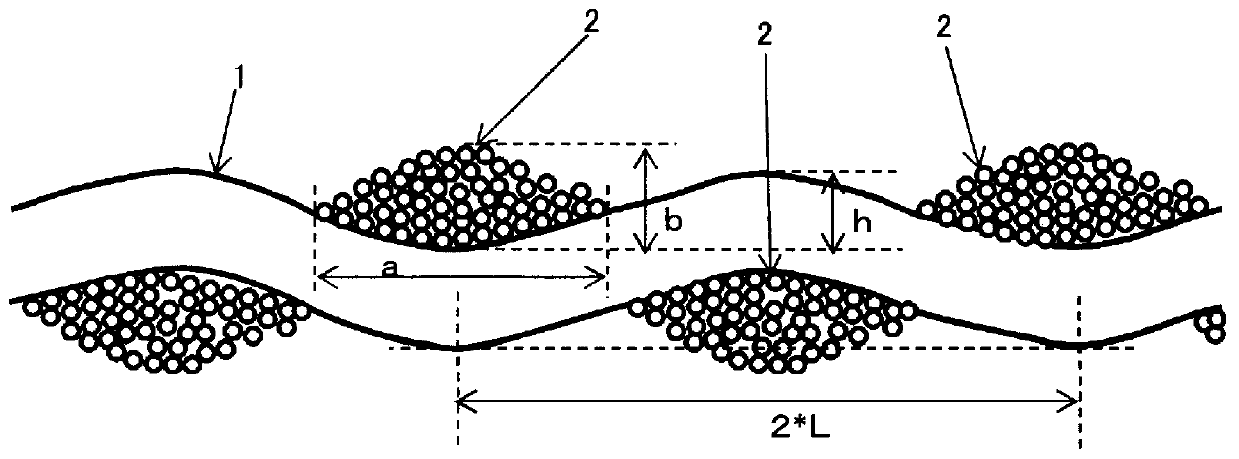

ActiveCN108291335BExcellent abrasion resistanceGood skin feelProtective fabricsPolymer sciencePolymer chemistry

The object of the present invention is to provide a woven fabric which is less prone to mesh dislocation due to friction, has excellent abrasion resistance, has a smooth surface, and is excellent in touch. The present invention is that at least a part of any one of the warp or weft is a fiber (M) that is a monofilament (1), and the fiber (N) intersecting with the above-mentioned fiber (M) is at least a part of a multifilament (2). Fiber (N), and satisfy the following (1) or (2) of the fabric. (1) The above-mentioned monofilament (1) is fused with the above-mentioned multifilament (2), and the following (A) and (B) are satisfied at the same time. 1.0≤a / L≤1.5(A)0.5≤h / b≤1.0(B)(2) The above-mentioned monofilament (1) is not fused with the above-mentioned multifilament (2), and simultaneously satisfy the following (C), (D ). 1.0≤a / L≤1.5(C)0.7≤h / b≤1.0(D)a: the length of the fabric in the cross-section of the multifilament (2) b: the fabric in the cross-section of the multifilament (2) Length L in the thickness direction: distance h between the centers of adjacent multifilaments (2) with fibers (M) interposed therebetween: crimp height of monofilaments (1).

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com