Patents

Literature

35results about How to "Clear mouth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

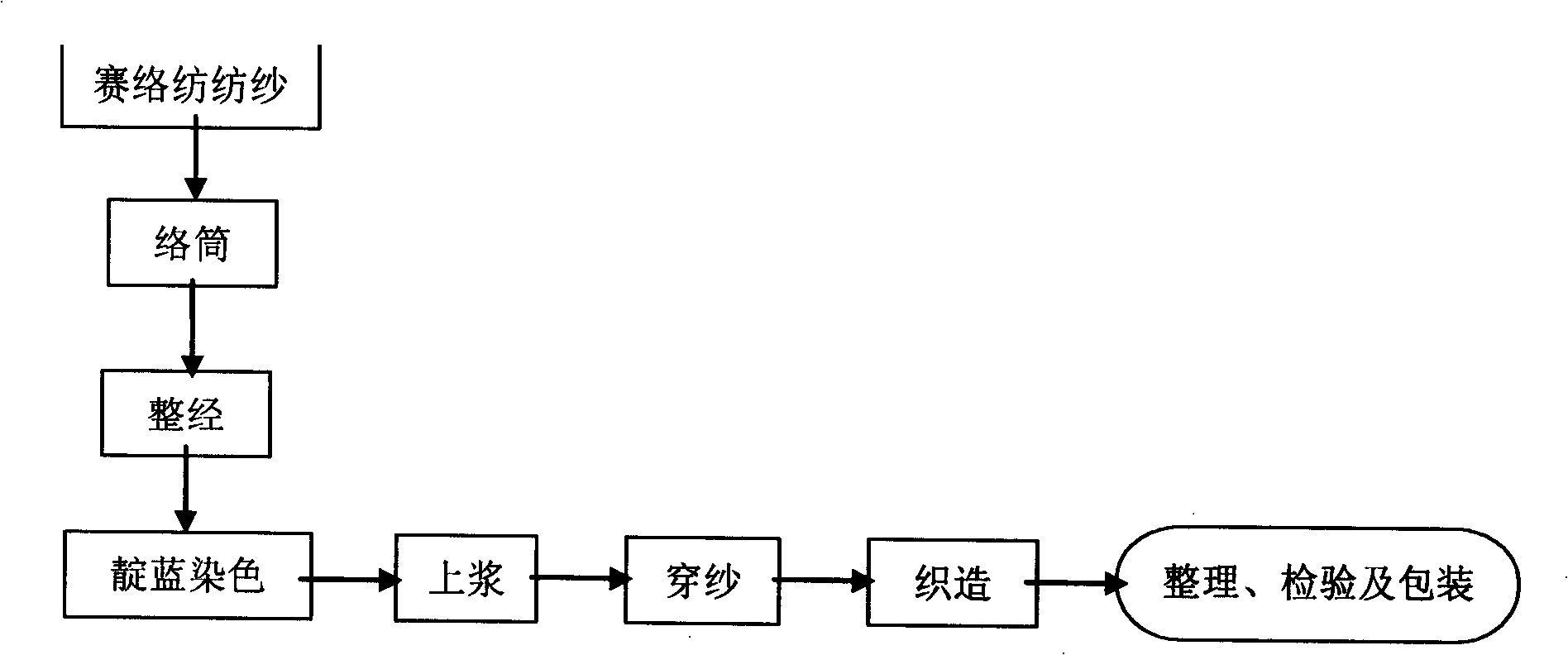

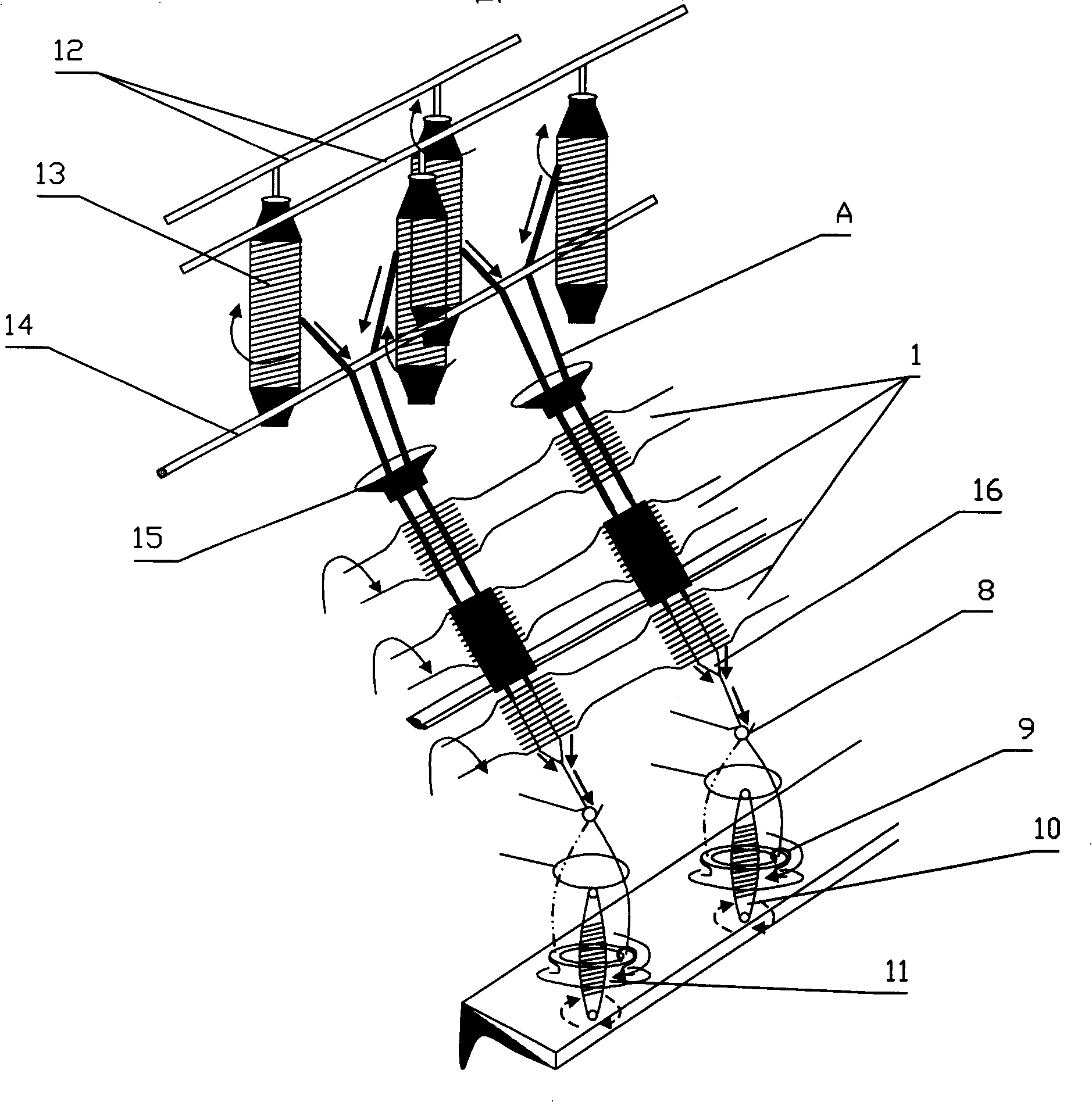

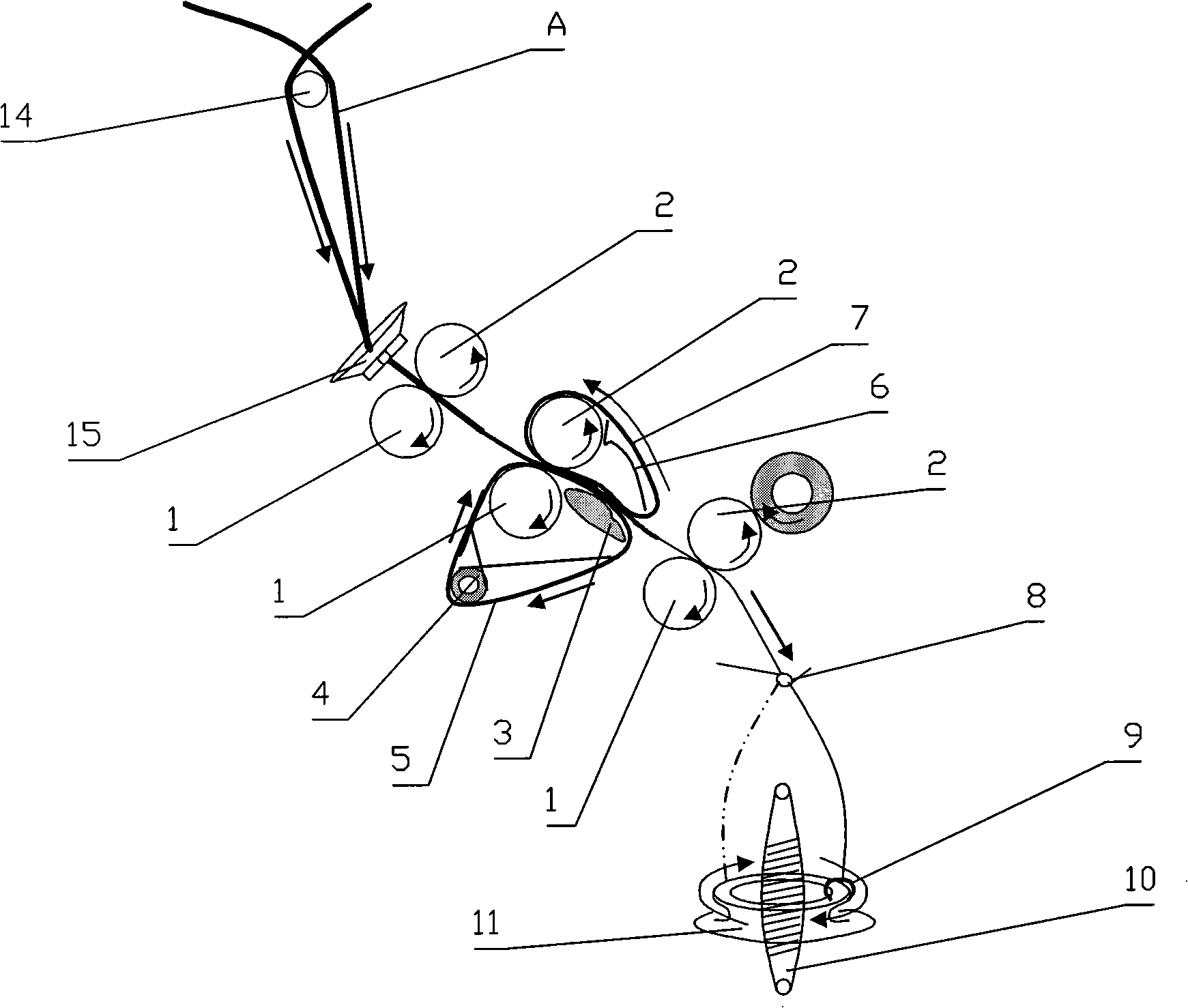

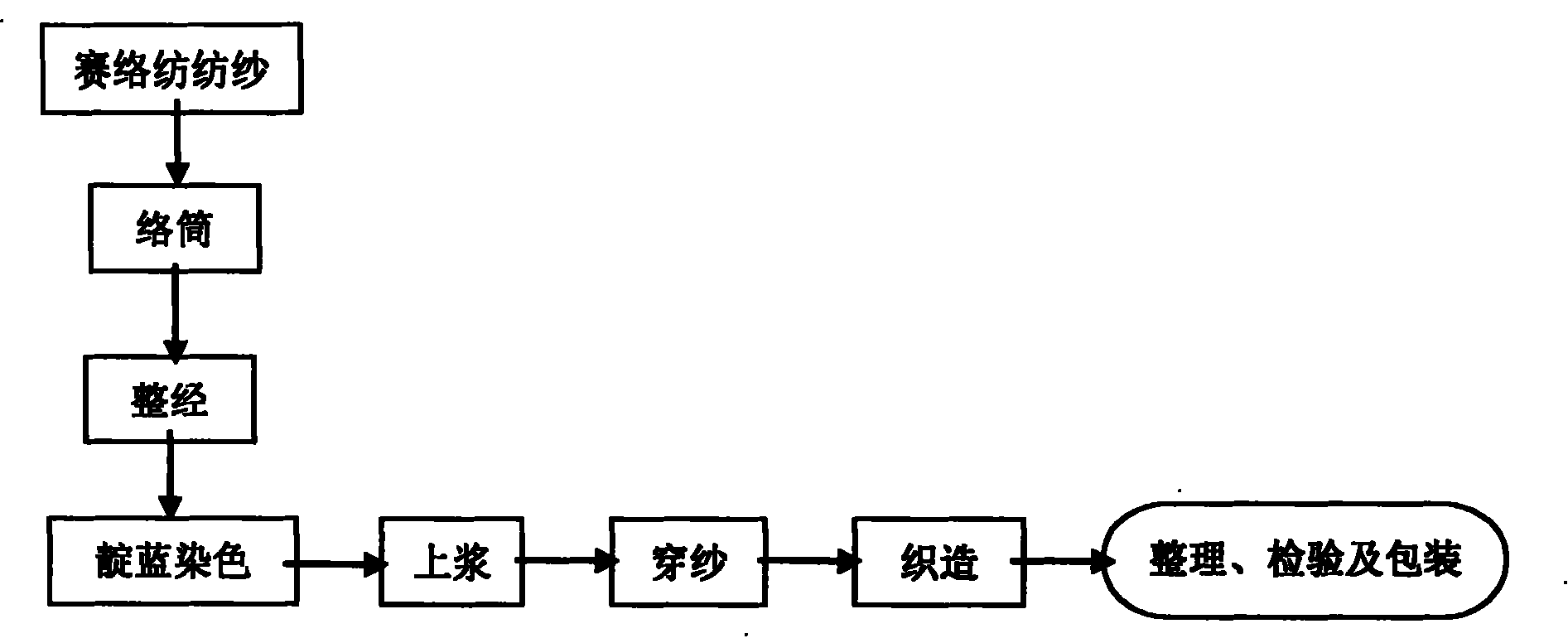

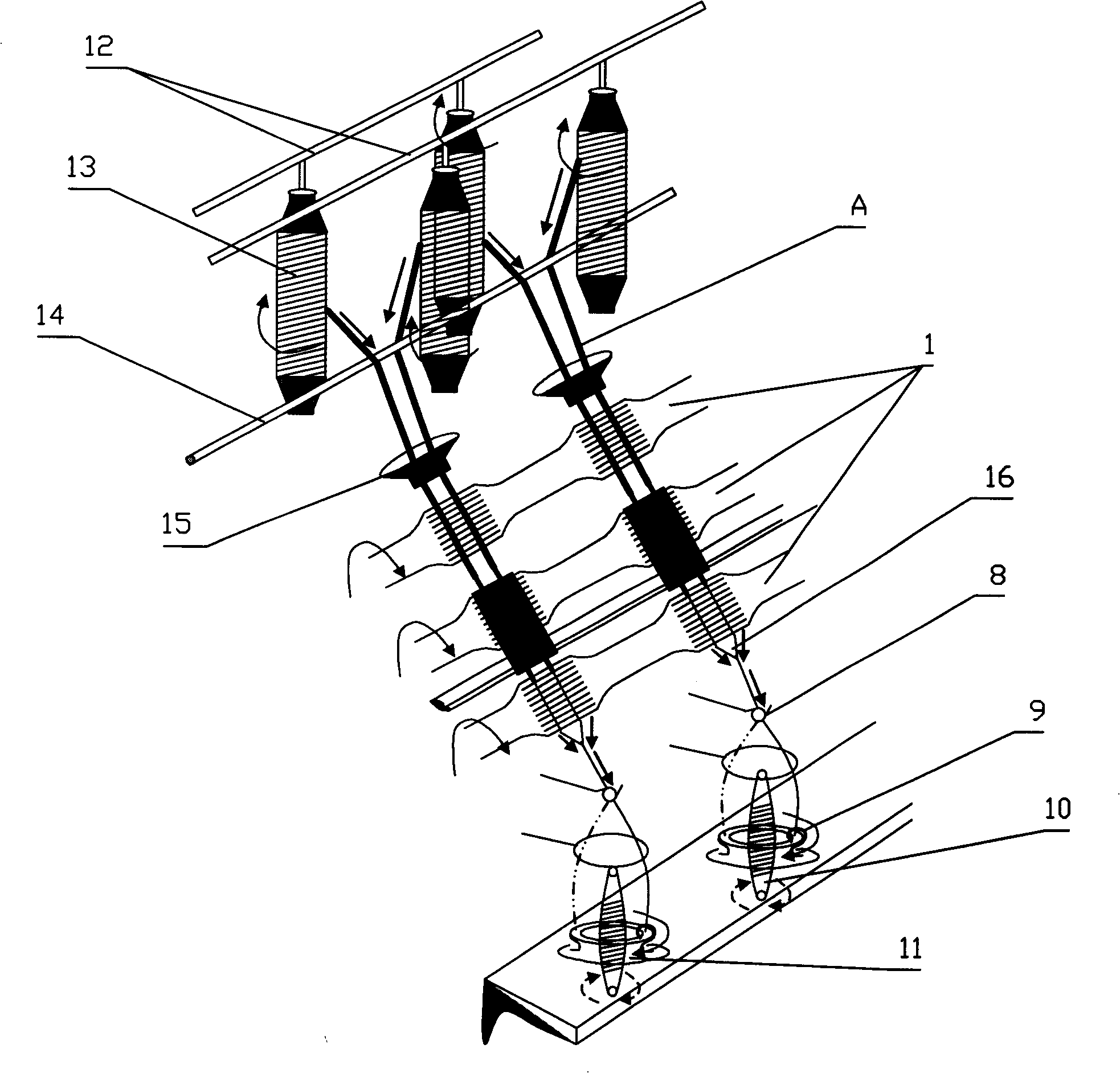

Process for manufacturing sirospun yarn jean facing material

The invention discloses a manufacture technique of a siro yarn jean fabric, in which, firstly an advanced siro yarn spinning technology is adopted to manufacture the siro yarn; the spun siro yarn is wound; then the wound siro yarn which is used as a warp is warped, dyed and starched be manufactured into a beam; then the siro yarn is used as the warp and the siro yarn, a rotor spun yarn or a ring yarn are used as an abb to be woven on a loom according to the fabric weave and the weaving technique of the jean to manufacture a grey fabric and finally the grey fabric is made into a finished product through subsequent finishing. As the siro yarn with better quality is adopted as the warp, the method has the advantages of easy yarn splitting, few broken ends, uniform colorizing, reducible sizing quality requirement as well as high heddle draft and reeding efficiency during the dyeing process, clear cut, uniform tension, few broken ends and stopping, few fly wastes in a workshop and on a machine station as well as being beneficial to the cleanness of the workshop and the maintenance of the machine station when weaving.

Owner:佛山市致兴纺织服装有限公司

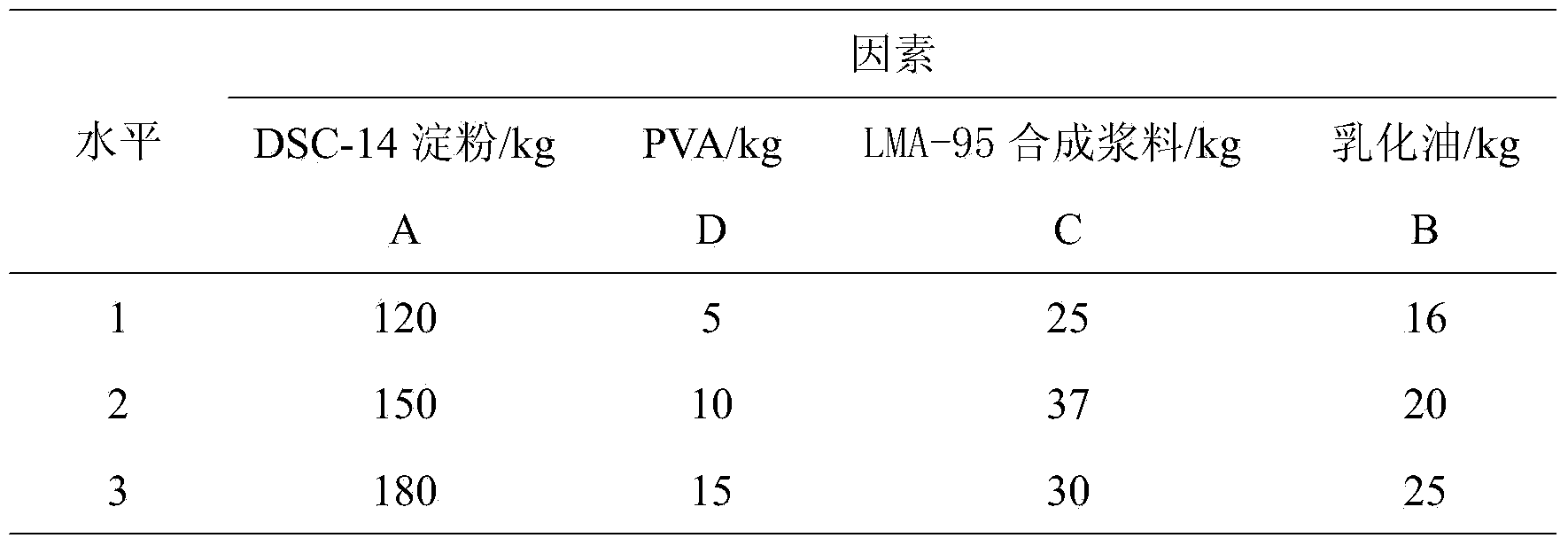

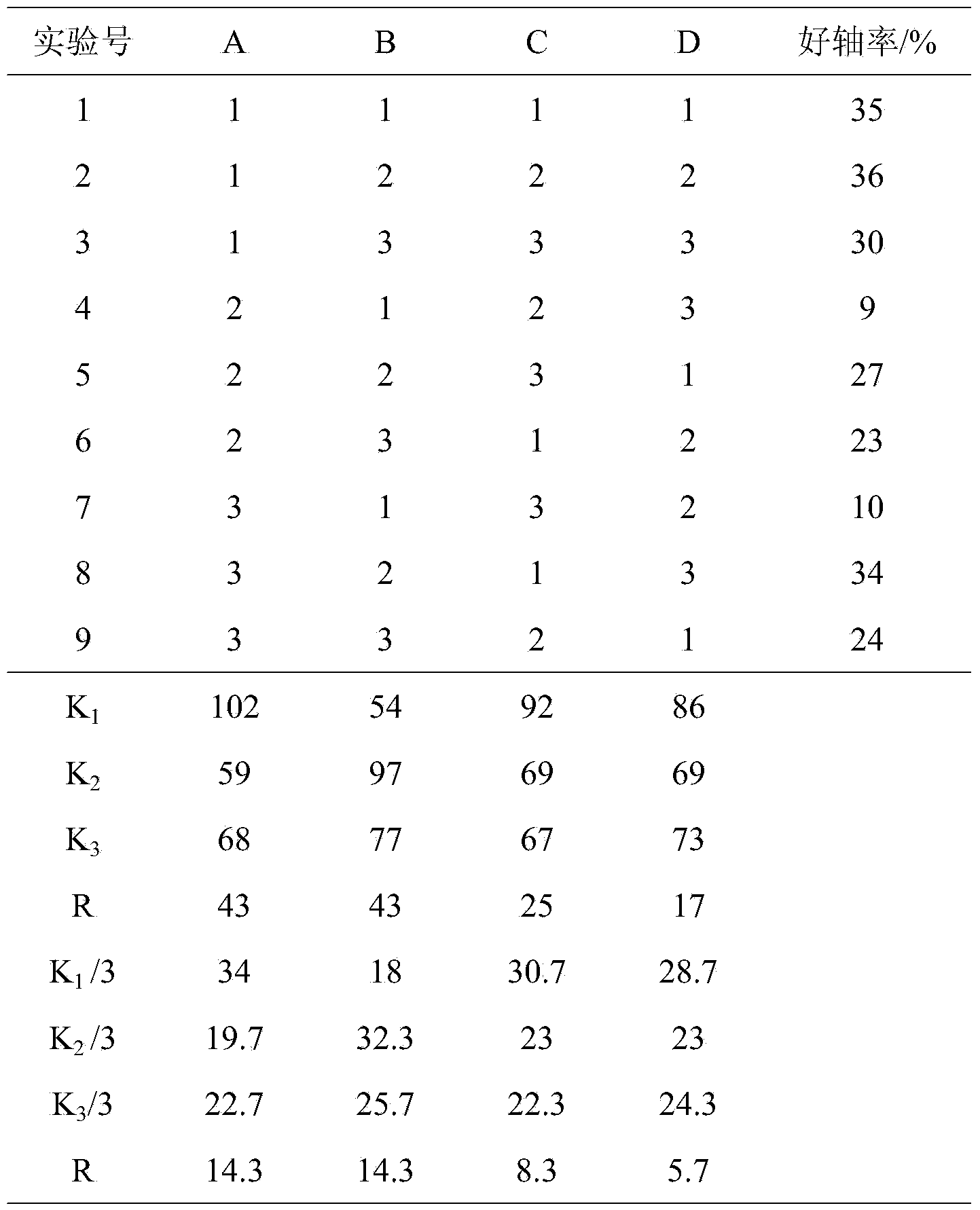

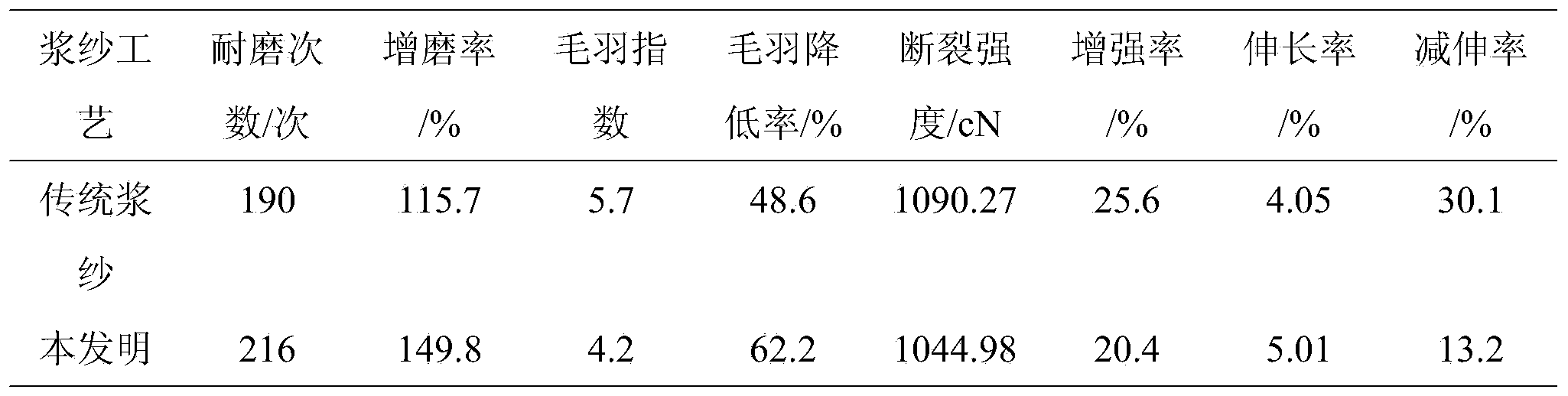

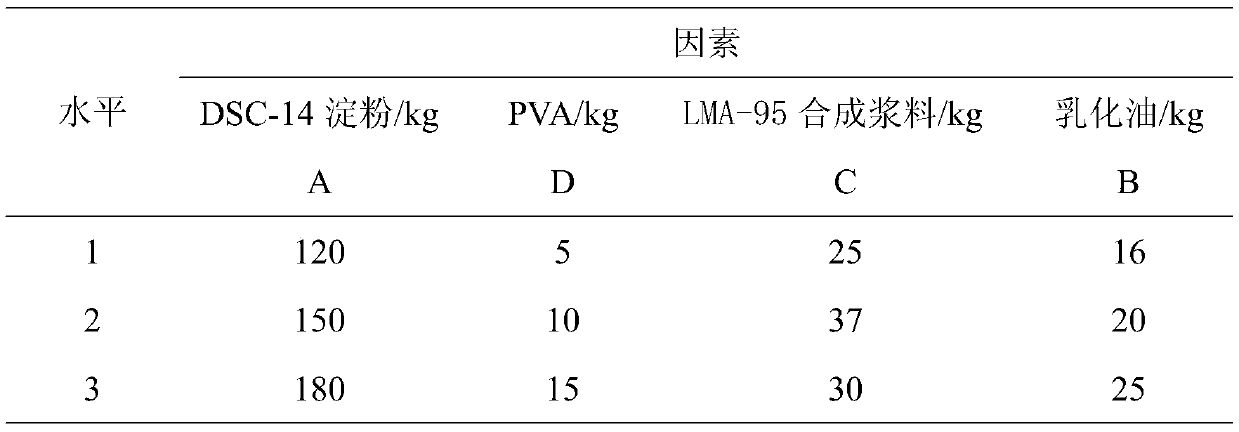

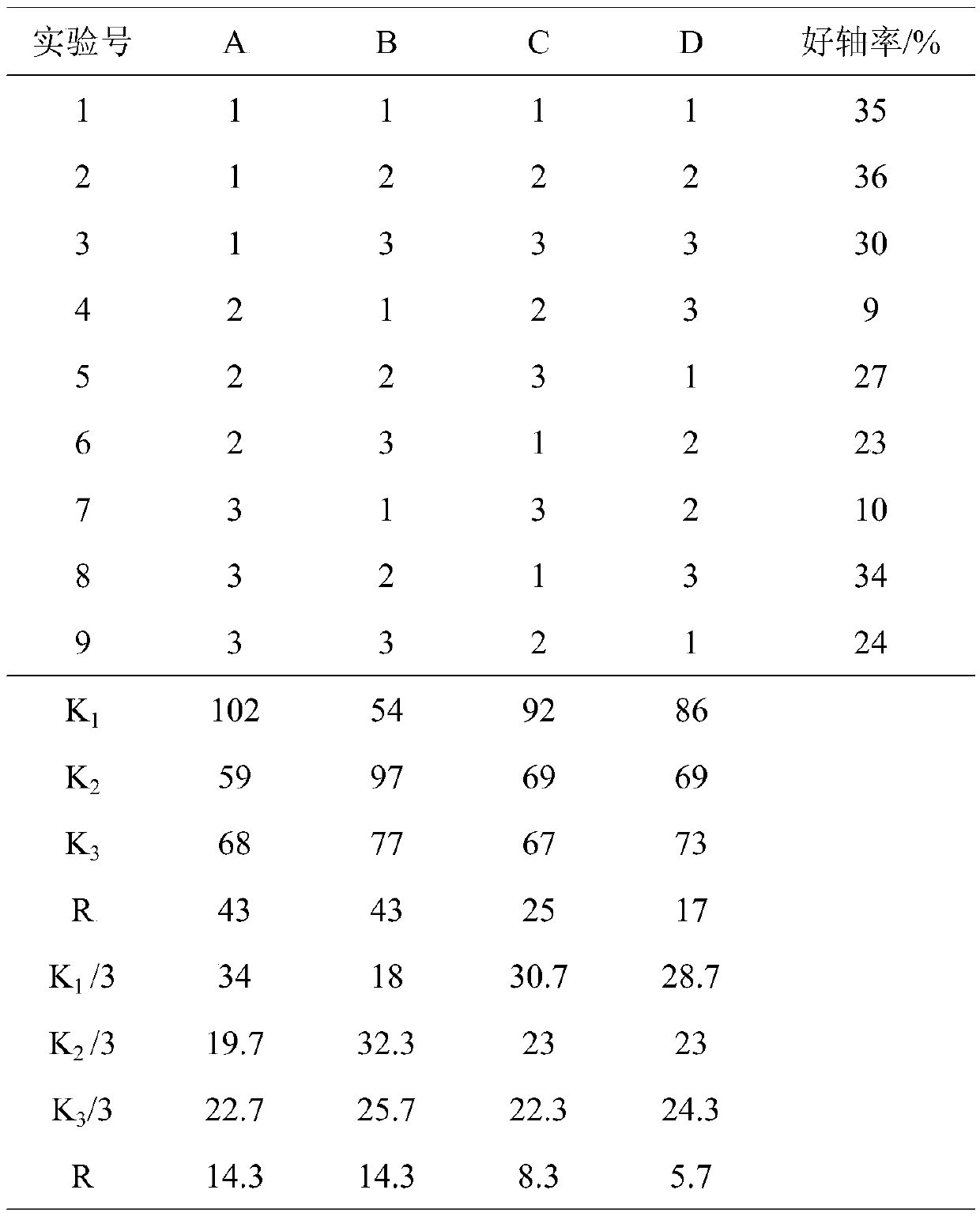

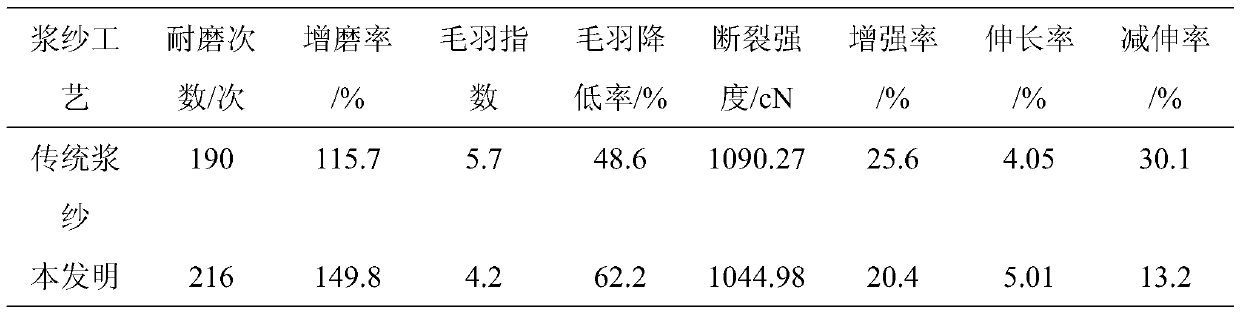

Jean warp sizing slurry and sizing process

ActiveCN103966849AImprove wear resistanceImprove surface propertiesFibre treatmentDenimProcess engineering

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

Textile size and preparation method thereof

The invention relates to a textile size. The textile size comprises a monomer mixed solution, small materials and process water, wherein monomers comprise 25 kg of acrylic acid, 85 kg of methacrylic acid, 80 kg of butyl acrylate, 70 kg of ethyl acrylate, 540 kg of methyl acrylate and 235 kg of methyl methacrylate; the small materials comprise 4.5 kg of an emulsifier, 8.5 kg of an initiator, 15 kg of a foam killer, 3 kg of a static inhibitor, 10 kg of a penetrant, 95 kg of ammonia water and 450 kg of alcohol. The invention further discloses a preparation method of the textile size. The textile size belongs to (pure acrylate and) co-polymerized anionic compounds, has favorable mechanical stability, is suitable for weaving high-grade fabrics, particularly (superfine polyester and polyamide fabric silks) water spraying and air-jet loom dressing, has good water solubility, permeability and antistatic property and strong cohesive force, enhances the silk traction force after silk dressing, is resistant to friction, clear in opening, free from size shedding, convenient to use and less in environmental pollution, and meanwhile, can reduce the desizing cost and the environmental impact of an afterfinish factory.

Owner:桐乡市星邦科技发展股份有限公司

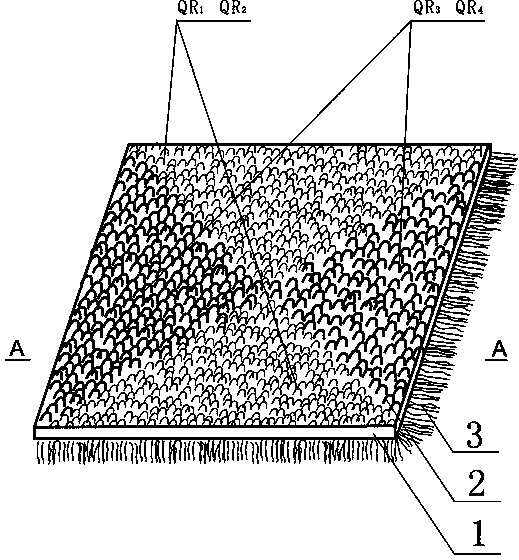

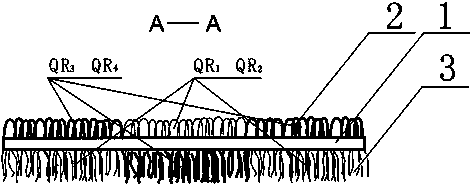

Two-color jacquard fabric with looped piles on one side and velvet on other side and weaving method of two-color jacquard fabric

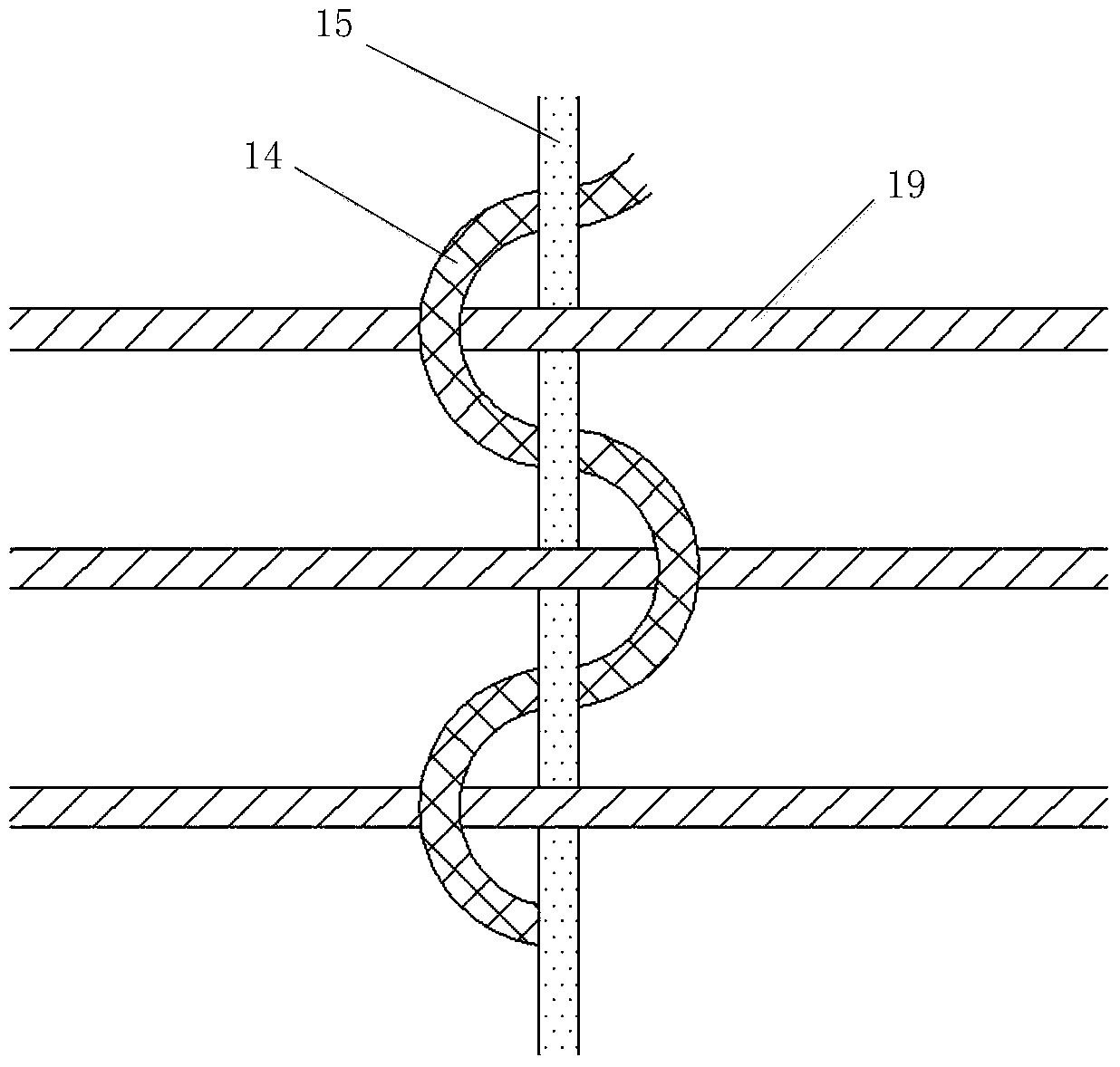

InactiveCN103911747ANormal Mutual Displacement WeavingClear mouthWoven fabricsEngineeringMechanical engineering

The invention discloses two-color jacquard fabric with looped piles on one side and velvet on the other side and a weaving method of the two-color jacquard fabric. The two-color jacquard fabric with the looped piles on one side and the velvet on the other side is formed by connecting a plurality of loop-velvet units end to end in sequence. Each loop-velvet unit comprises base cloth, the looped piles are woven on one side of the base cloth, velvet is woven on the other side, corresponding to the looped piles, of the base cloth, both the looped piles and the velvet can be woven through loop-velvet warps conversed and changed in two colors according to patterns, the loop-velvet of the fabric are jointly arranged on one layer of the base cloth, fineness of the velvet, roughness of the looped piles and softness in hand feeling can be achieved, and the two-color jacquard patterns which are unique in style can be realized; the two-color jacquard fabric produced in the method is unique in style, simple in weaving method, low in production cost and good in product quality.

Owner:LIAONING CAIYI WILD SILK PROD

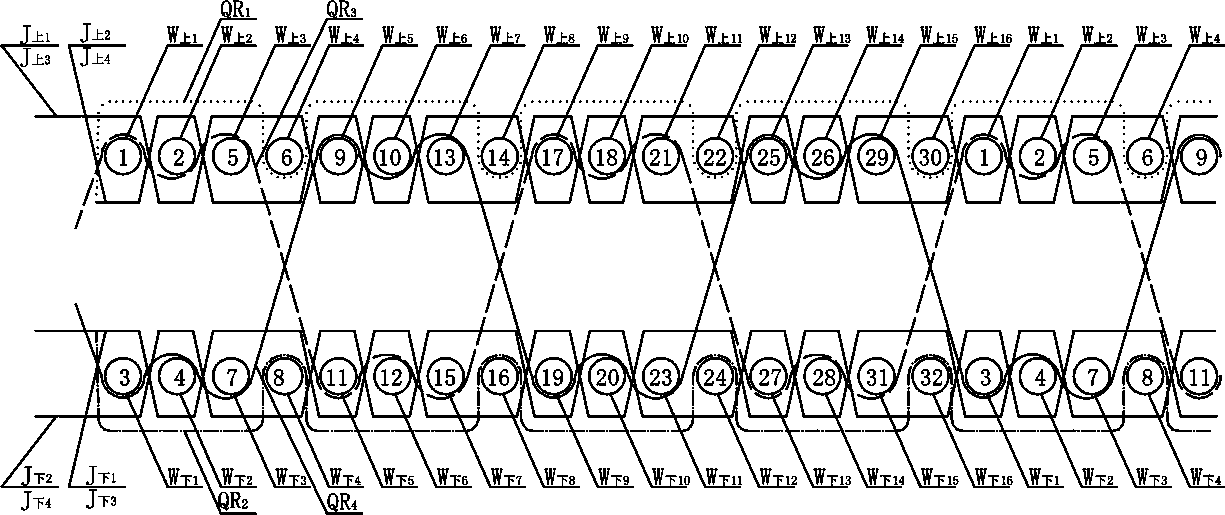

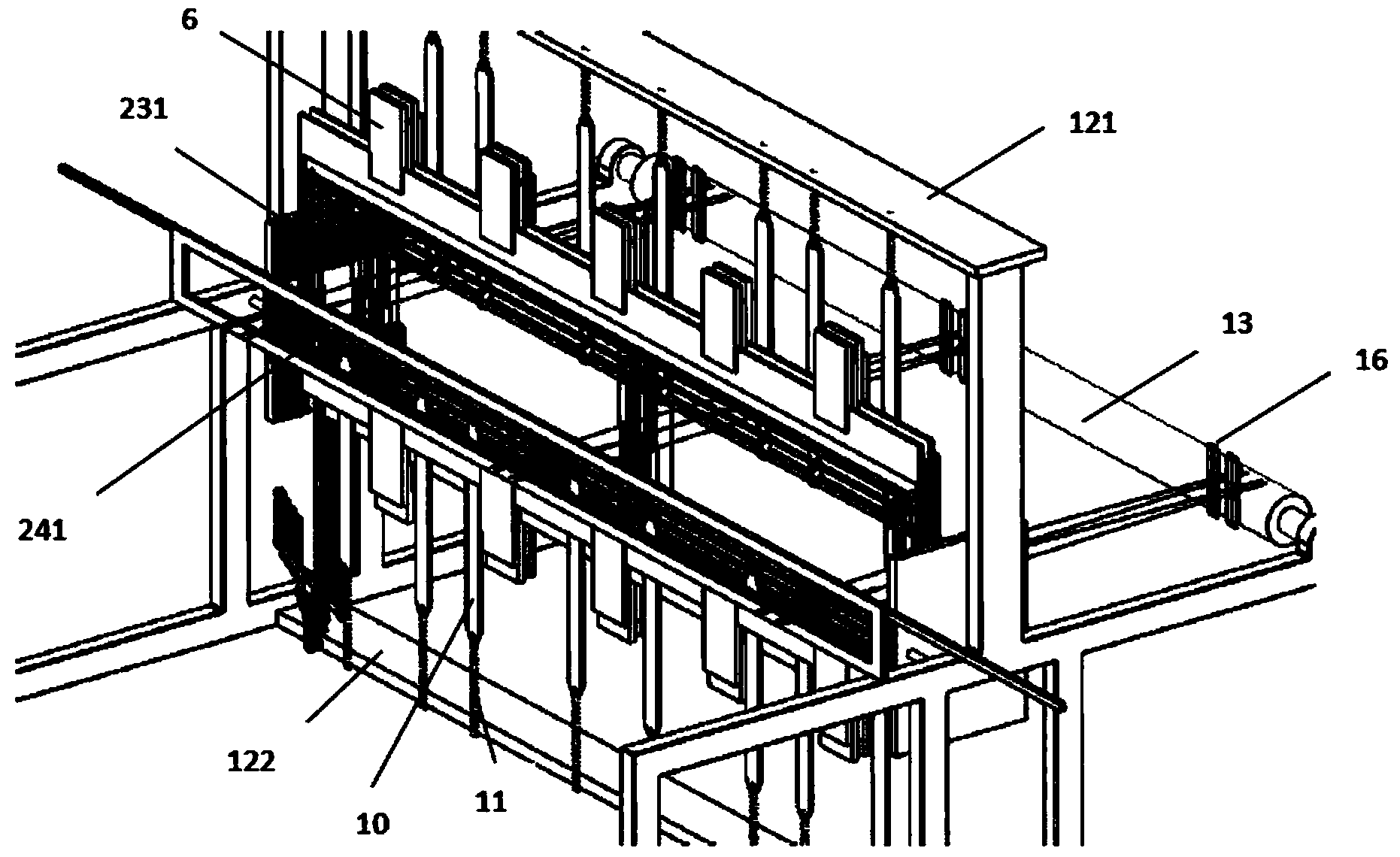

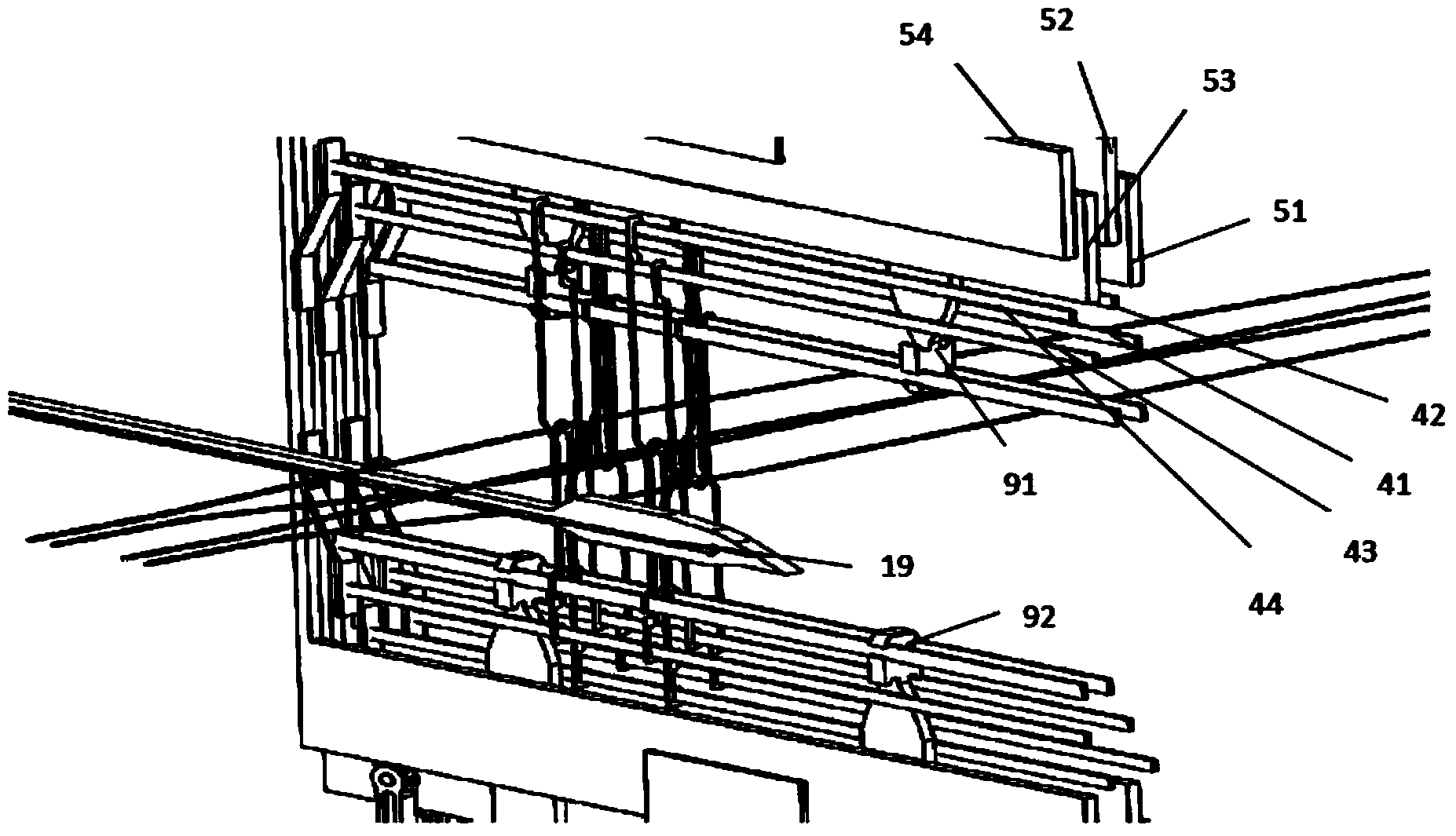

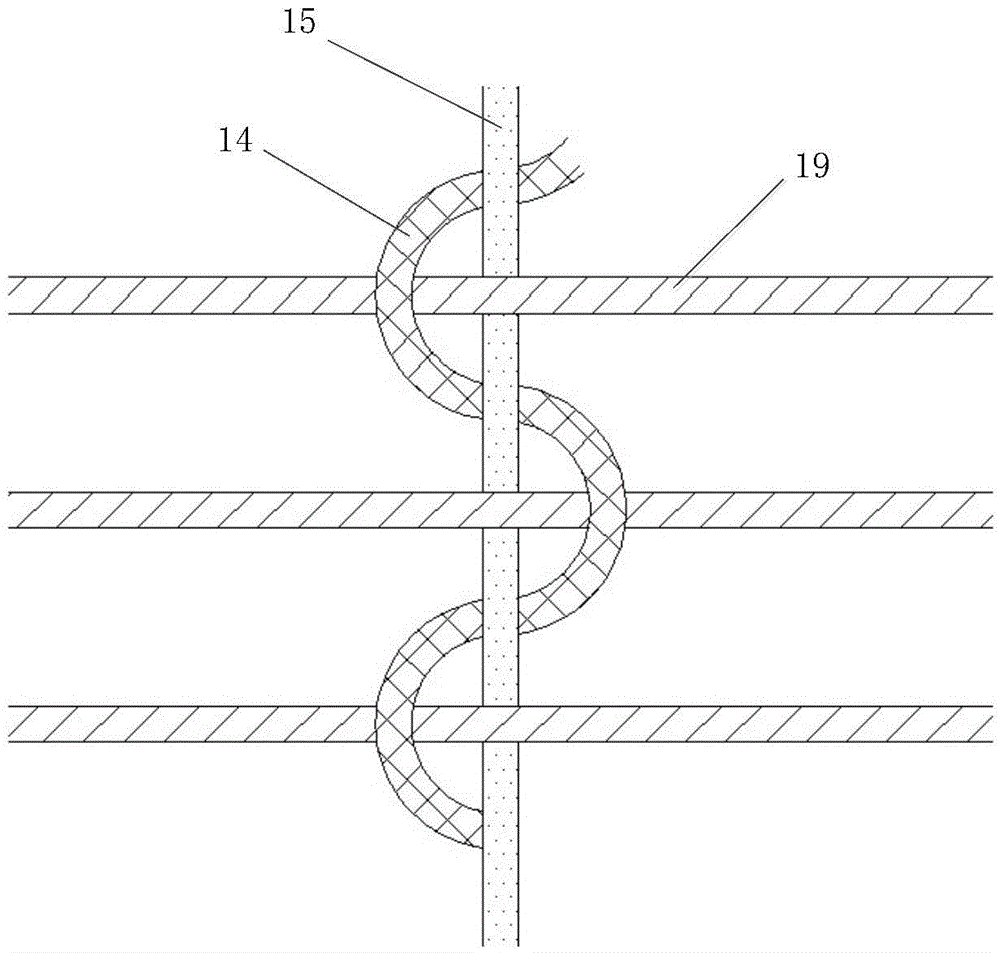

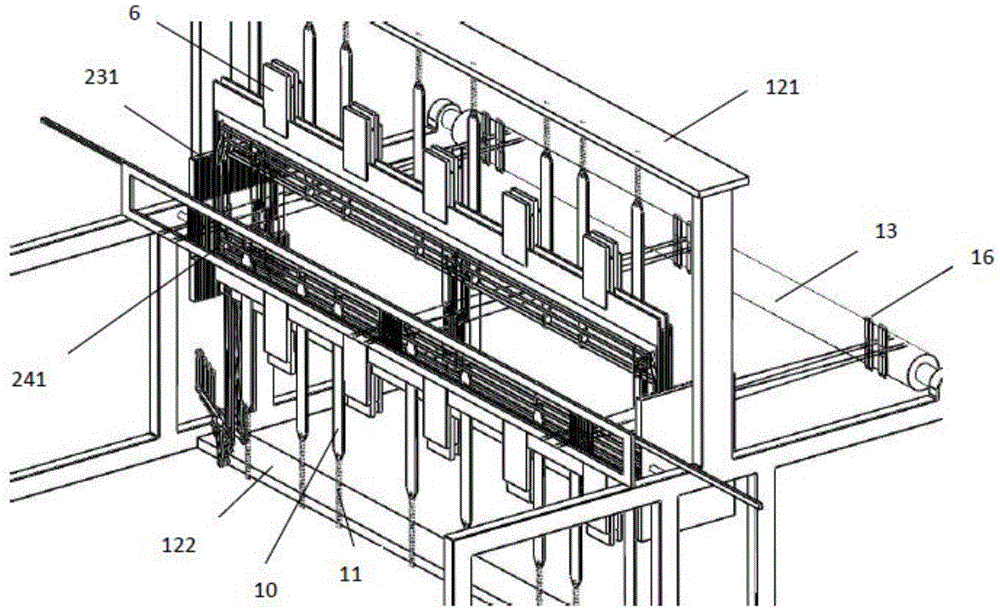

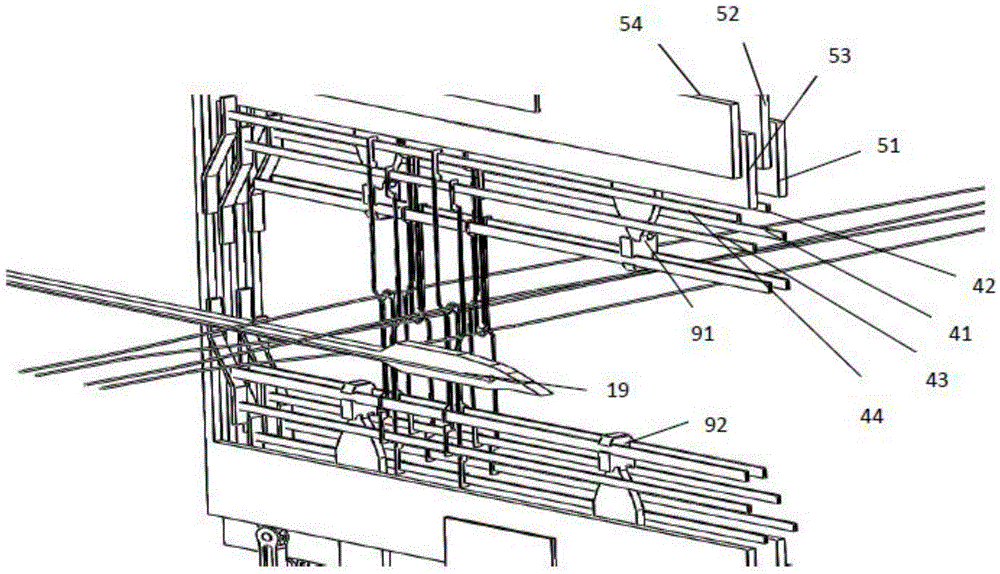

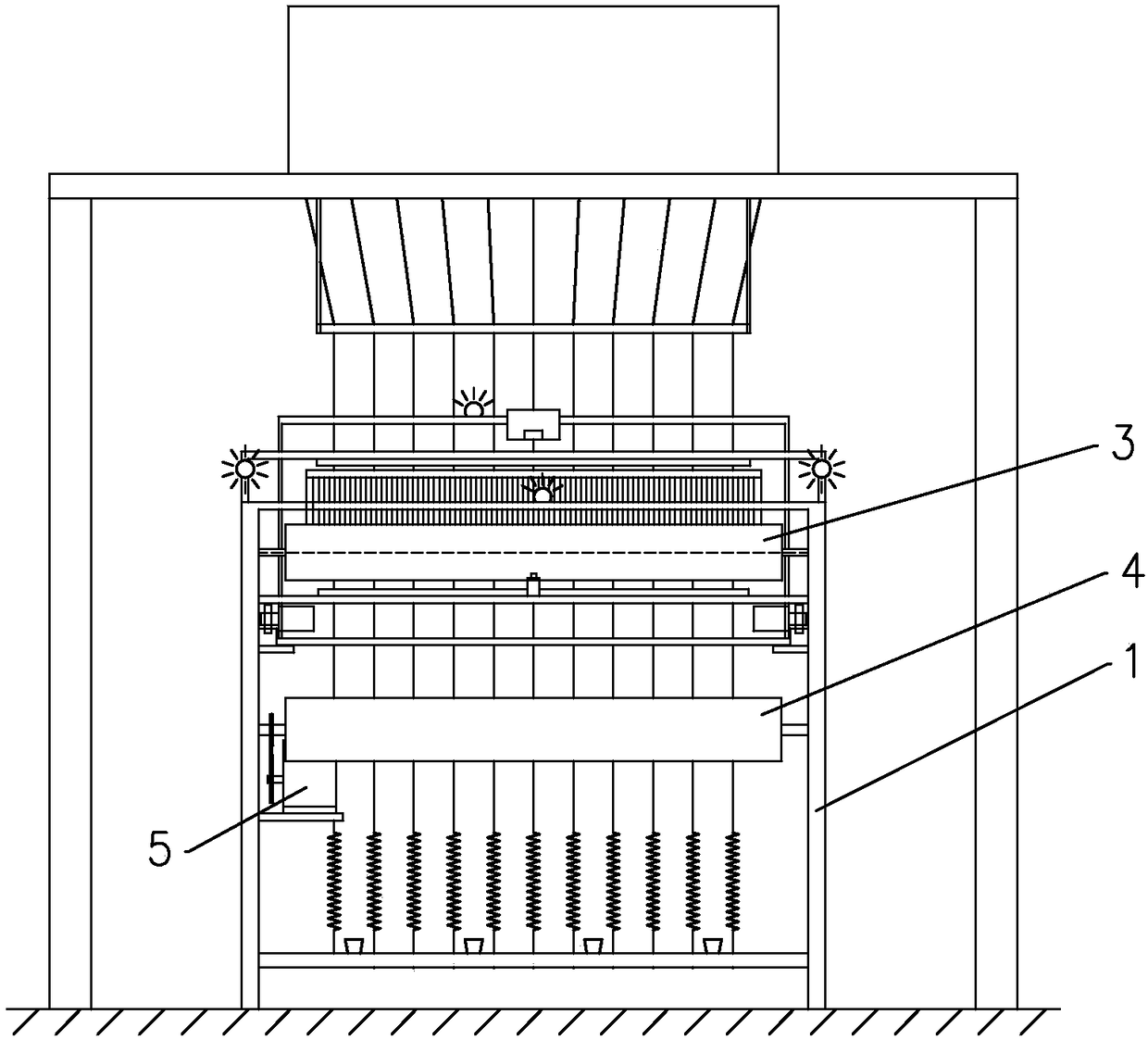

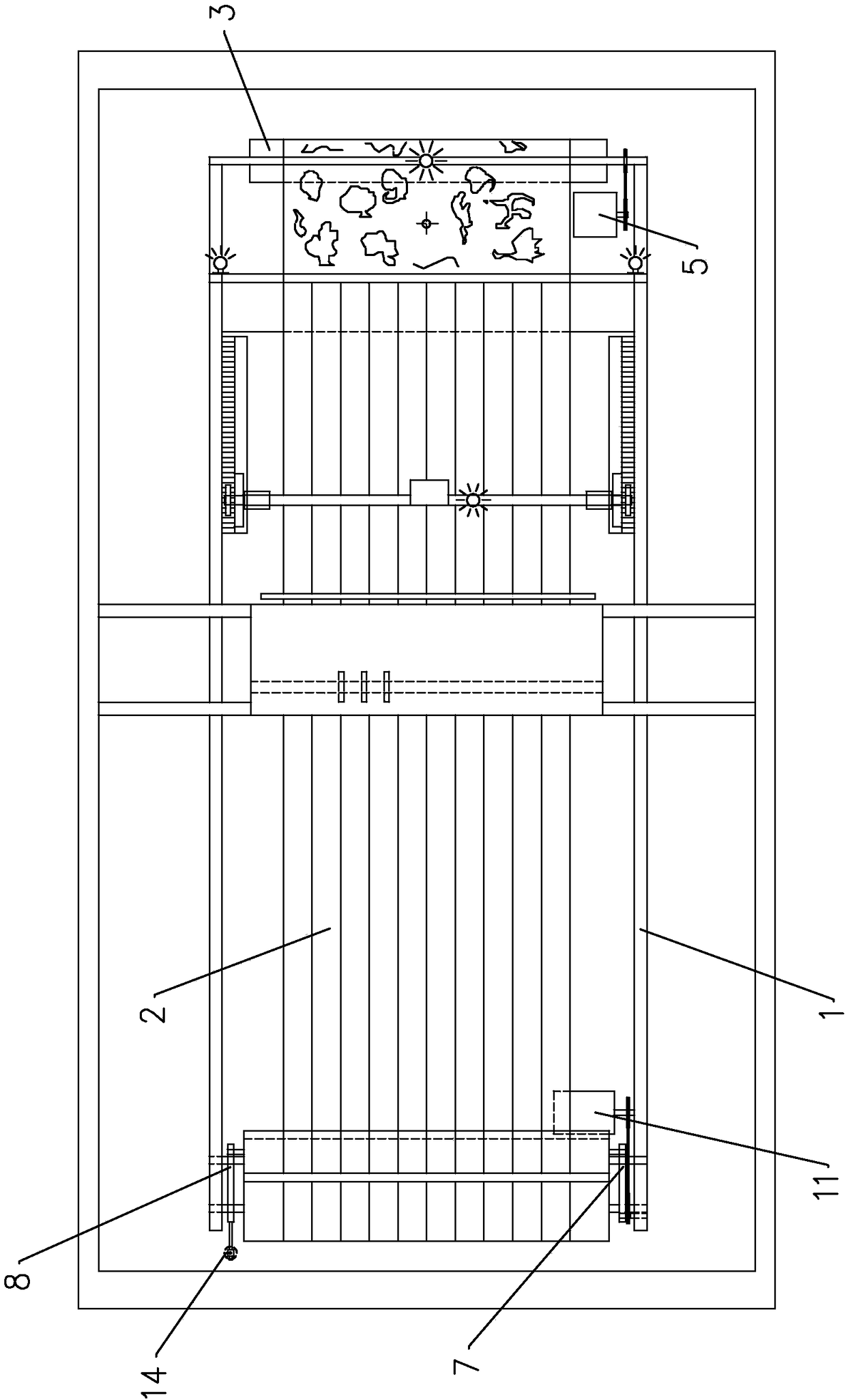

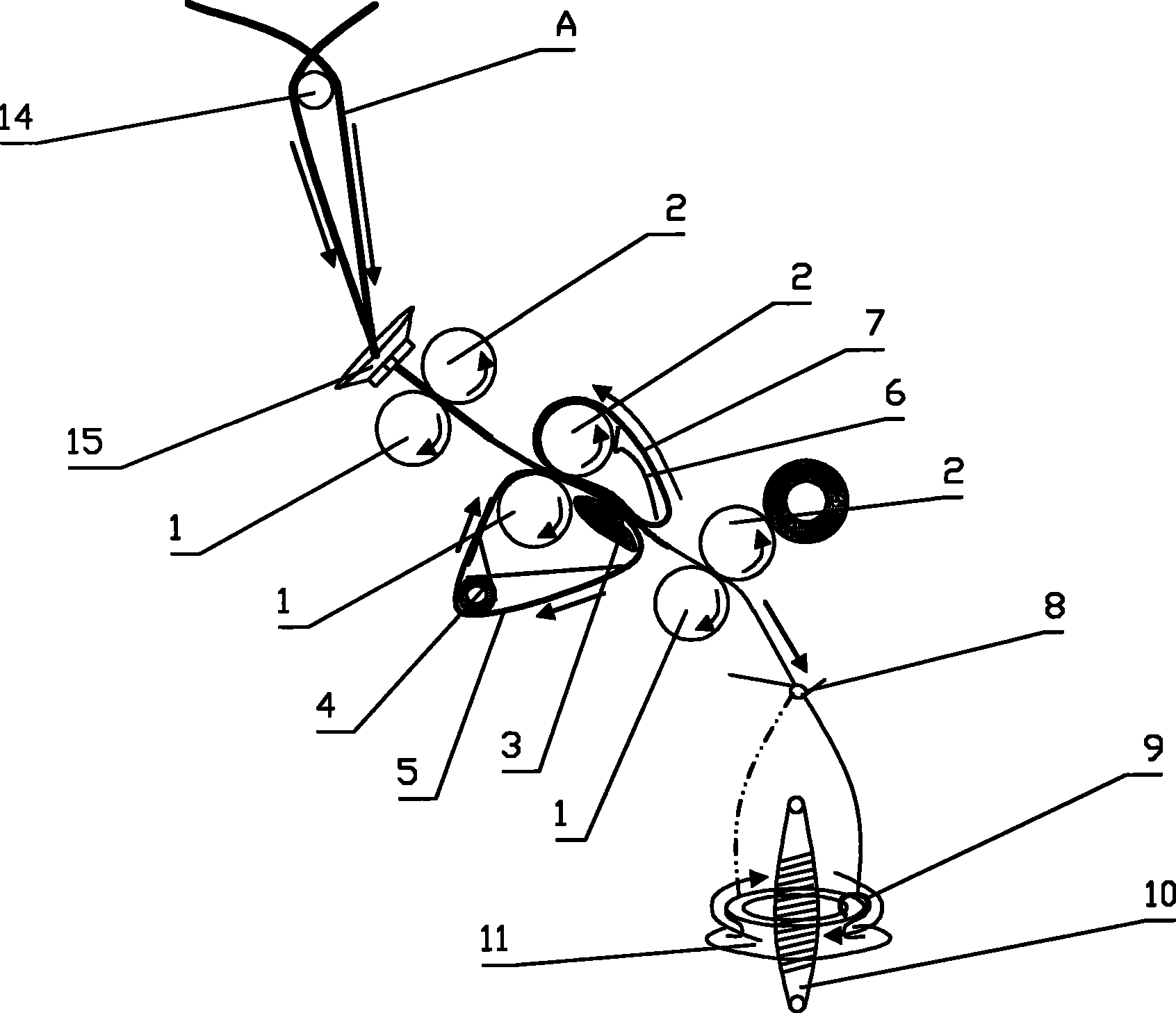

Device and method for controlling warp yarns of gauze cloth on loom

The invention discloses a device and a method for controlling warp yarns of gauze cloth on a loom, and belongs to the technical field of braiding equipments in the textile industry. The device comprises a plurality of heald frames, brackets, first healds, second healds, two-way brackets, linkages and multi-arm mechanisms, wherein the first healds and the second healds are mounted on the brackets front and back in pairs; the brackets are arranged in parallel side by side, and are connected with the heald frames; upper cross beams and lower cross beams of the brackets are respectively connected with a plurality of wooden frames; the heald frames are mounted in baffles on the two sides of the loom; the heald frames are connected with the linkages; the linkages are connected with the multi-arm mechanisms; the two-way brackets are arranged between the adjacent heald frames; the first healds and the second healds respectively pass through the two-way brackets; the two-way brackets are respectively connected with the upper cross beam and the lower cross beam of the loom through nylon pieces and springs. The invention further provides the method for controlling the warp yarns of the gauze cloth. The device and the method have the advantages that the device is suitable for the high-speed weaving of thick yarns, the opening is clear, the friction of yarns is avoided, and the structural design is simple and reasonable.

Owner:北京燕阳新材料技术发展有限公司

Anti-pilling textile water-based size and preparation method thereof

InactiveCN107794759ASoluble in waterImprove anti-pilling performanceAbrasion resistant fibresSolubilityWater based

The invention provides anti-pilling textile water-based size which is good in pilling resistance and mechanical stability, suitable for water spray and air injection weaving machine sizing of variousfiber, has water solubility, permeability, good antistatic property and pilling resistance, enhances the tractive force of silk after sizing of silk, is friction resistant and clear in opening, does not have the phenomenon of size shedding, is convenient to use and low in environmental pollution, and can reduce the sizing cost of an after-finishing factory and environmental implication, and a preparation method of the anti-pilling textile water-based size. The anti-pilling textile water-based size comprises monomer mixed liquor, small materials and process water, wherein the monomer mixed liquor comprises 16kg of crylic acid, 160kg of dyhydroxyl ethyl ester acrylate, 290kg of butyl acrylate, 149kg of methyl acrylate, 134kg of methyl methacrylate, and 30kg of lauryl acrylate; the small materials comprise 3kg of an emulgator, 6kg of an initiator, 8kg of a defoamer, 3kg of an antistatic agent, 16kg of a penetrating agent, 50kg of ammonium hydroxide, and 300kg of alcohol.

Owner:桐乡市星邦科技发展股份有限公司

A kind of denim warp yarn sizing size and sizing process

ActiveCN103966849BImprove wear resistanceImprove surface propertiesFibre treatmentSlurryPulp and paper industry

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

Modified polyester slurry and preparation method thereof

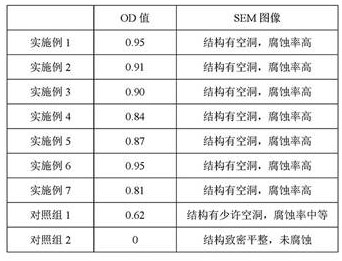

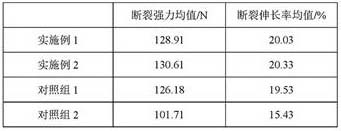

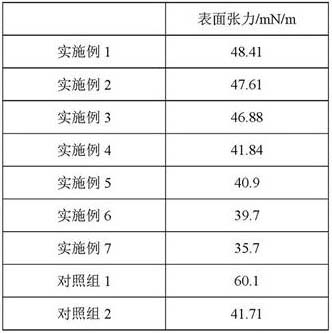

The invention belongs to the technical field of novel chemical fiber materials, and specifically relates to modified polyester slurry and a preparation method thereof. The modified polyester slurry comprises 5 to 100 parts of modifier, 1 to 20 parts of polyester, 0.05 to 0.1 part of modified montmorillonite and 50 to 200 parts of water by weight. The modifier is prepared from hydrated silica and silicone oil, and the polyester is prepared from 30 to 55 parts by weight of citric acid, 15 to 26 parts by weight of PEG-200, 15 to 40 parts by weight of 2,2-bis (hydroxymethyl) propionic acid, 5 to 10 parts by weight of glycerin, and 1 to 10 parts by weight of pure water; and the modified montmorillonite is prepared from 50 to 100 parts by weight of montmorillonite and 30 to 50 parts by weight ofsilicone oil. According to the modified polyester slurry prepared by the invention, the viscosity and the surface tension of the slurry can be reduced by adding the modifier, so that the slurry permeability is improved; and by adding the modified montmorillonite, the tensile property of a yarn is improved, the end breakage rate is reduced, the cost is reduced, the degradation is easy, the operation is convenient, the pollution is avoided, no catalyst is needed in the preparation of the polyester, and the modified polyester slurry has higher economic benefits and social benefits.

Owner:湖南万家工贸实业有限公司 +1

Textile slurry and preparation method thereof

The invention relates to a textile slurry, which comprises a monomer mixing liquid, a small material, and process water, wherein the monomer comprises 410 kg of an ethylene-ethyl acrylate copolymer, 44 kg of butyl acrylate, 206 kg of styrene, 40 kg of acrylic acid, 50 kg of methyl methacrylate, and 84-50 kg of methacrylic acid, and the small material comprises 4 kg of an emulsifier, 5 kg of an initiator, 12 kg of a defoamer, 2 kg of an antistatic agent, 15 kg of a penetrant, 70 kg of ammonia water, and 320 kg of alcohol. The invention further discloses a preparation method of the textile slurry. According to the present invention, the slurry belongs to the pure acrylate and copolymerization anionic compound, has good mechanical stability, is suitable for weaving of a variety of high-grade fabrics, especially for water spraying of ultra-fine polyester and nylon fiber silks and sizing with an air-jet loom, and has characteristics of good water-solubility, good permeability, good antistatic property, strong cohesion, silk traction enhancing after silk sizing, abrasion resistance, clear opening, no slurry dropping, easy use, low environmental pollution, and post-finishing plant desizing cost and environmental impact reducing.

Owner:桐乡市星邦科技发展股份有限公司

Method for weaving high-density jute cloth from high-count jute single yarn

InactiveCN107090641AReduced sliver hairinessReduce friction shedding hairiness entanglementWoven fabricsPolyesterYarn

The invention discloses a method for weaving high-density jute cloth from high-count jute single yarn. When the weaving warp is pure jute single yarn, the twist of the single yarn is 26-28 twist / 10 cm; when the weaving warp is jute and ramie or jute and polyester or jute and tencel blend yarn, the twist of the single yarn is 28-29 twist / 10 cm; when a warp beam performs weaving, the warp sequentially and alternately winds around front and back yarn-separating twisting rollers between the warp beam and a dropper; the weaving speed is 180-190 r / min.

Owner:郴州湘南麻业有限公司

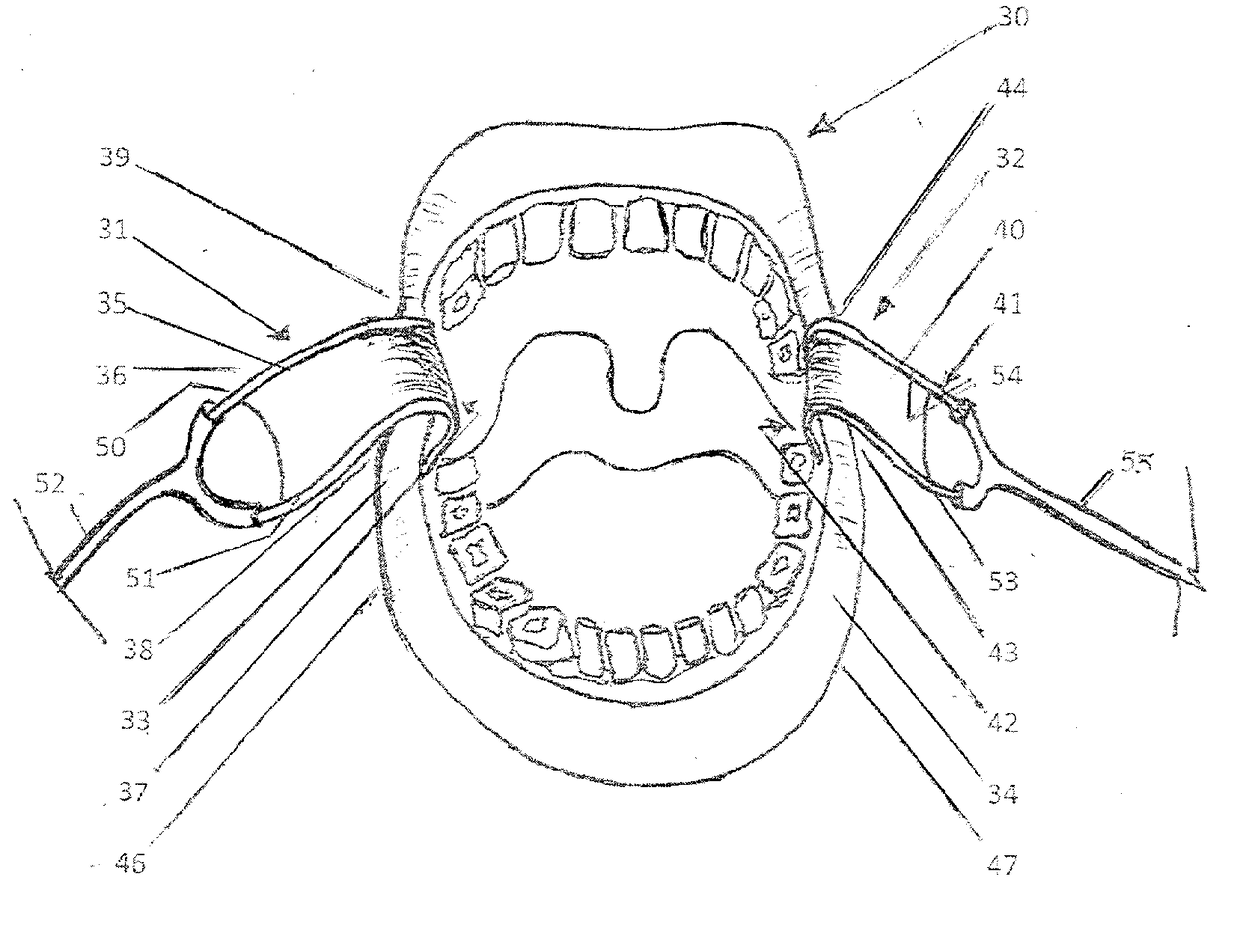

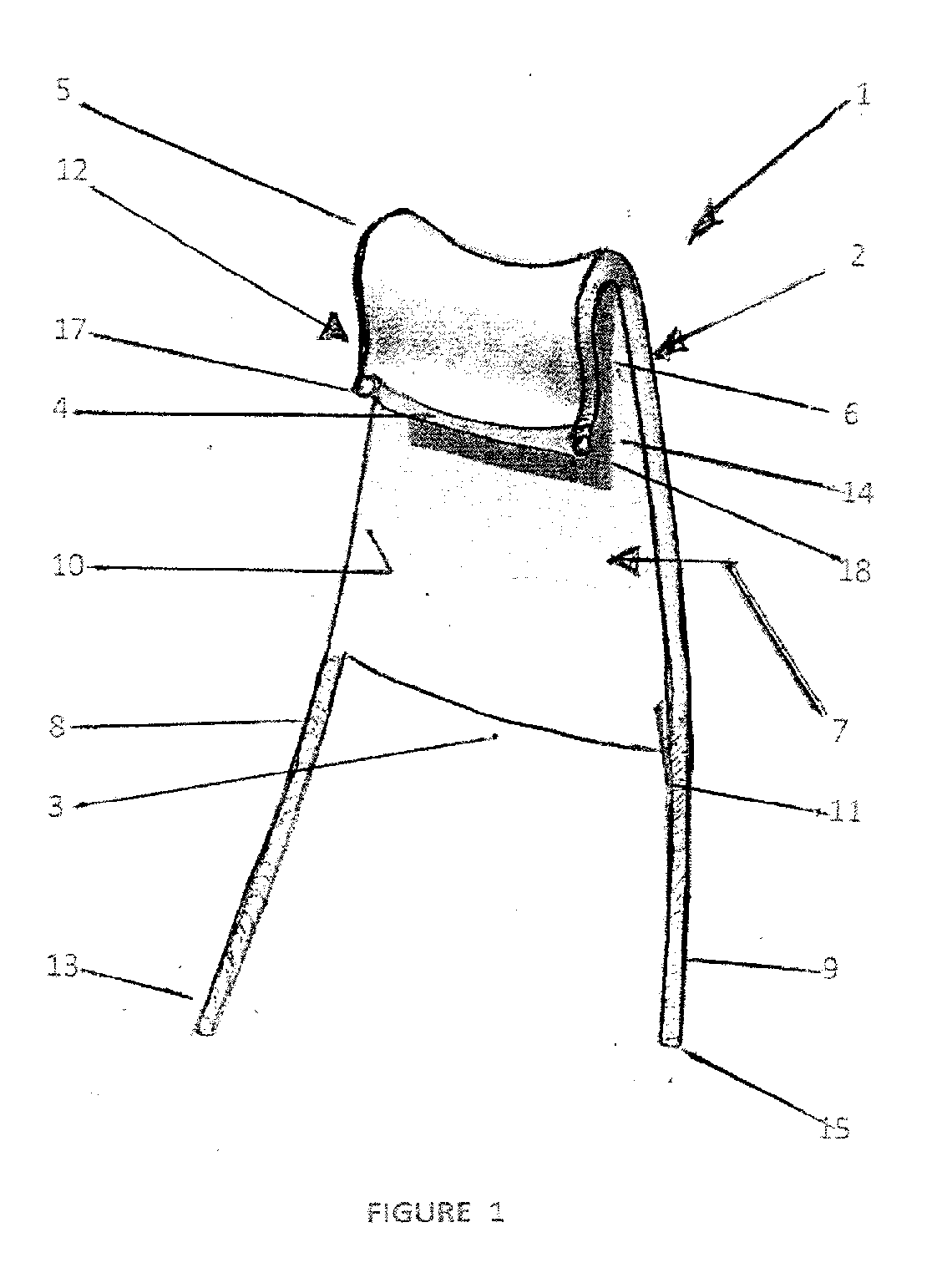

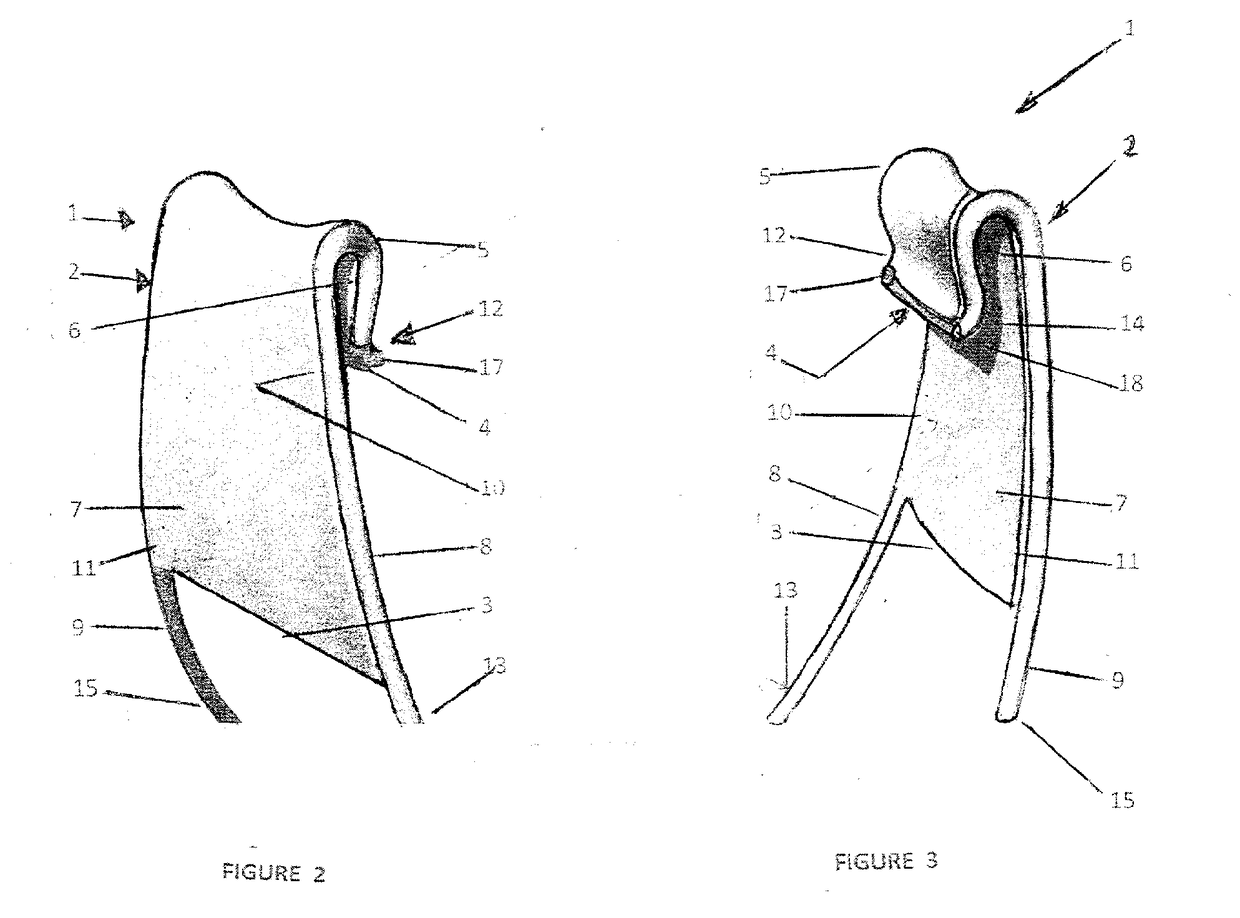

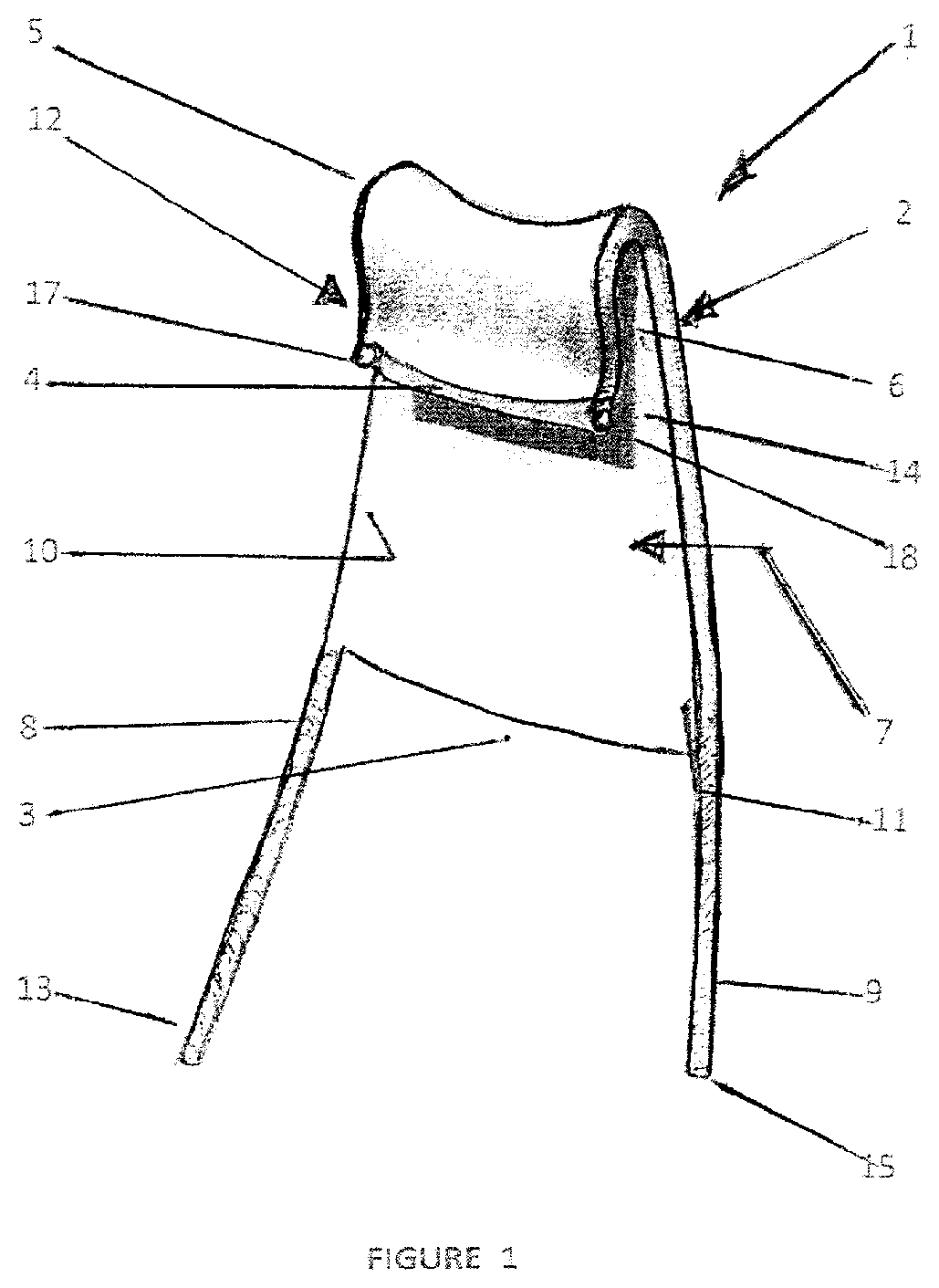

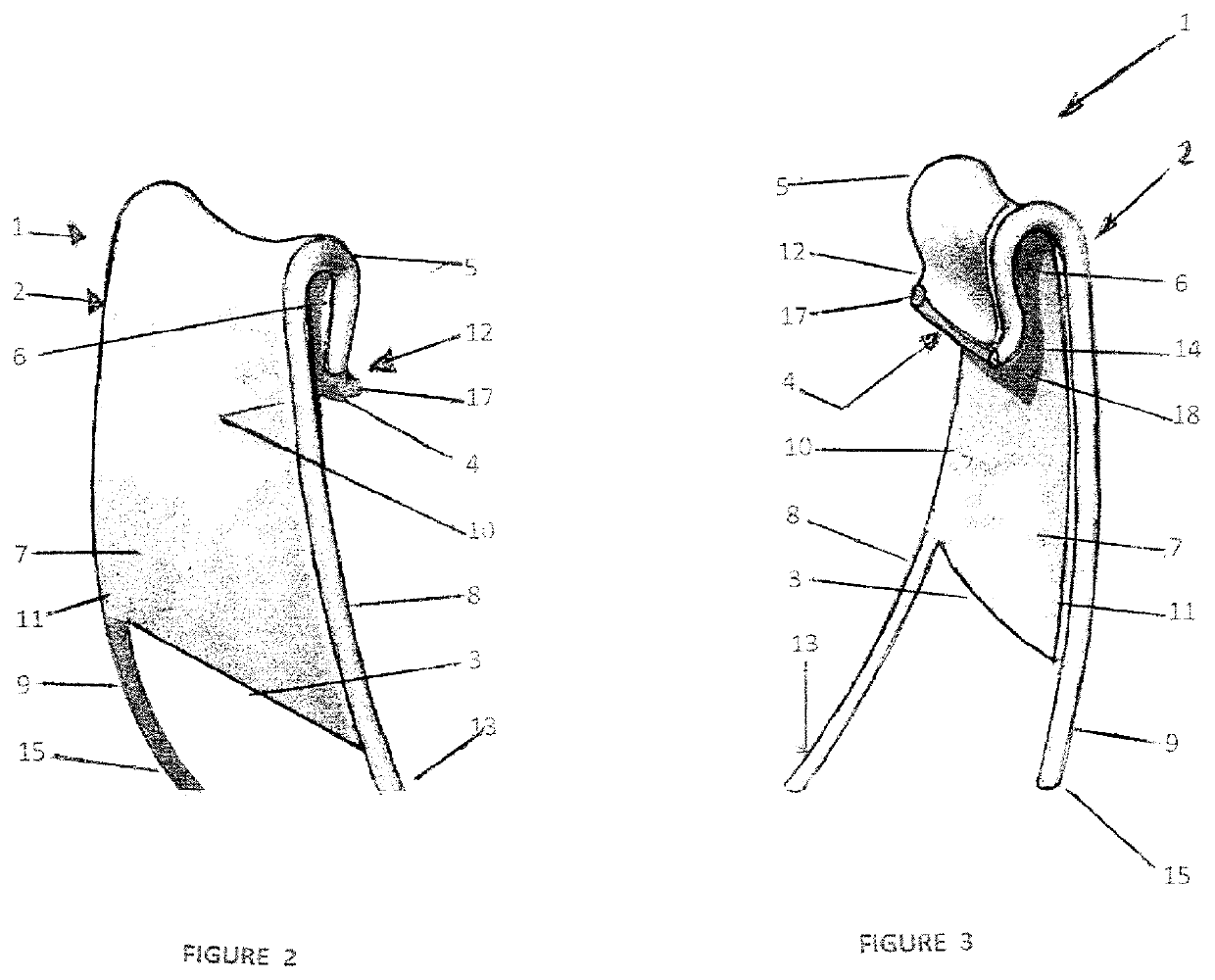

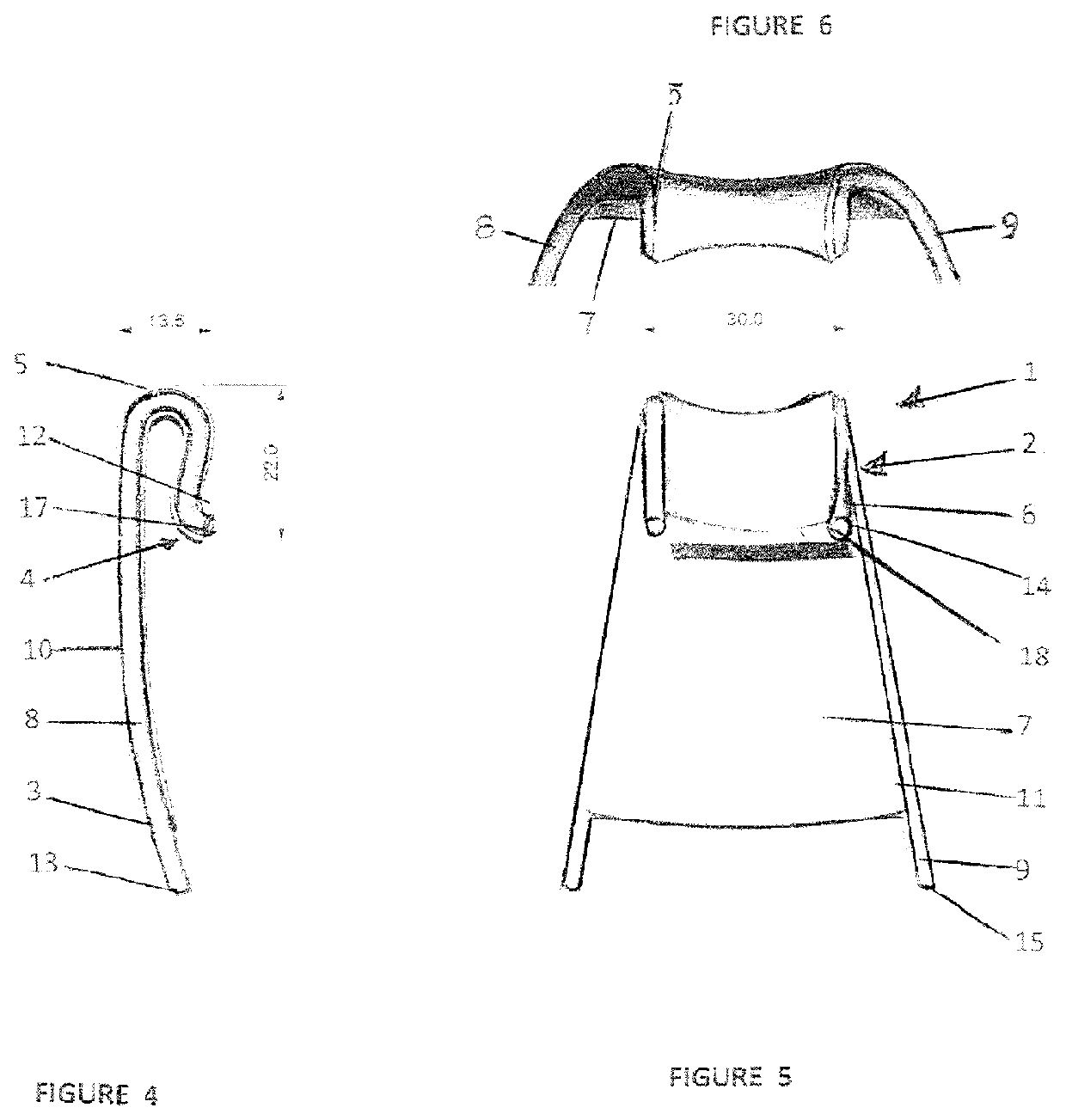

A Protective Device For Use In Oral Surgical Procedure

ActiveUS20180168773A1Minimises risk of tissue burning and gas ingestionEmission minimizationTeeth fillingDiagnosticsSurgical instrumentationPhysical Barrier

A protection device for use in oral surgery. The device comprises; a body having a first part which locates outside a patient's mouth and a second part which, during use, locates inside the mouth. The body is arranged such that at least a part of the body is resiliency deformable to enable manual shaping to accommodate an anatomical shape of at least part of a patient's mouth, thereby providing a physical barrier between surgical instrumentation and a patient's soft tissue.

Owner:ESSENTIAL SURGICAL PTY LTD

Water-based sizing agent for all-cotton spinning and preparation method thereof

The invention relates to a water-based sizing agent for all-cotton spinning and a preparation method thereof. The problems that in the prior art, surface adhesion between water-based sizing agents forall-cotton spinning and cotton fibers is poor, and the tensile property of sizing agents is poor are solved. According to a technical scheme, the water-based sizing agent for all-cotton spinning comprises the following components in parts by weight: 30-40 parts of butyl acrylate, 10-20 parts of methyl acrylate, 10-20 parts of methyl methacrylate, 15-25 parts of acrylonitrile, 10-20 parts of lauryl acrylate, 3-5 parts of a divalent alkaline earth metal compound, 3-4 parts of an emulsifier, 3-5 parts of an initiator, 0.3-0.5 part of an antistatic agent and 1.1-1.9 parts of a penetrant. The acrylonitrile is introduced into a sizing agent monomer, so that the surface adhesive force between the sizing agent and cotton fibers is greatly improved, the sizing rate of the sizing agent is high, andthe antistatic property is good.

Owner:桐乡市星邦科技发展股份有限公司

Special aqueous slurry for nylon spinning and preparation method thereof

The invention provides special aqueous slurry for nylon spinning and a preparation method thereof. The special aqueous slurry is high in water solubility, high in permeability, high in antistatic property, high in cohesive force, capable of improving traction force of nylon silks coated with slurry, resistant to wearing, clear in opening, free from slurry shedding, convenient to use, low in environmental pollution, and capable of decreasing the slurry removing cost of a plant in after-treatment process as well as reducing the environmental influence. The special aqueous slurry for the nylon spinning comprises a monomer mixed liquid, supporting materials and process water, wherein the monomer mixed liquid comprises 16kg of acrylic acid, 29kg of hydroxymethyl acrylamide, 190kg of butyl acrylate, 269kg of methyl acrylate, 254kg of methyl methacrylate, and 10kg of lauryl acrylate; the supporting materials include 3kg of an emulsifying agent, 6kg of an initiator, 8kg of a defoaming agent, 3kg of an antistatic agent, 16kg of a penetrant, 50kg of an ammonia water, and 300kg of ethyl alcohol.

Owner:桐乡市星邦科技发展股份有限公司

Cotton and rayon interwoven micro-flare fabric and processing technology thereof

The invention provides a cotton and rayon interwoven micro-flare fabric and a processing technology thereof. The fabric adopts warp yarns of CJ5.8 tex and weft yarns of CJ5.8tex+(R19.7tex+N30D), the weft arrangement ratio of the CJ5.8tex to the R19.7tex+N30D is 3 to 1, and the phenomenon that nylon yarns wrap spun rayon yarns can be formed; the warp density of the fabric is 354 / 10cm, the weft density is 346 / 10cm, and the breadth is 165 cm; special process conditions are adopted in the yarn adding and spinning technique and weaving technique. The cotton and rayon interwoven micro-flare fabric provided by the invention has the benefits as follows: the cotton and rayon interwoven micro-flare fabric is designed to have a micro-flare effect, adopts the main raw material of natural fiber with excellent hygroscopicity, and is less than 70g / square meter in weight; through preferably selecting yarns, twist texture configuration and weaving process means, the fabric is enabled to be light, thin, comfort and breathable, is suitable for underwear, and is popular for fashion women's wears in summer and spring.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

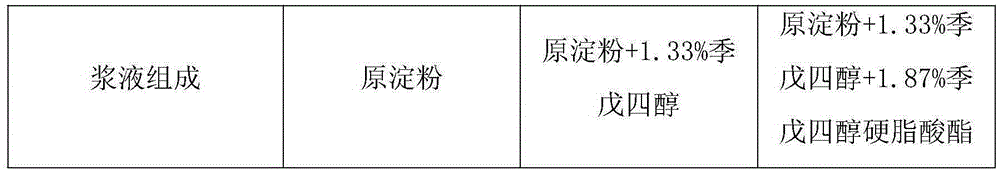

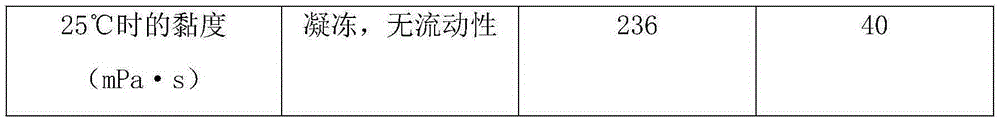

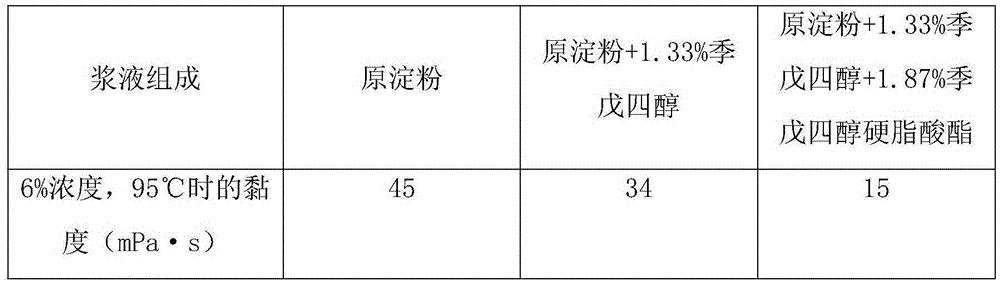

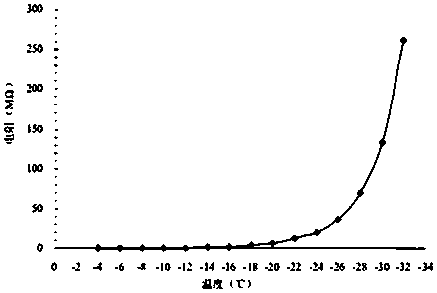

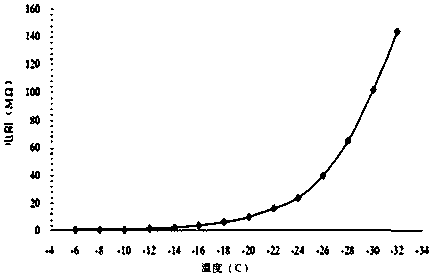

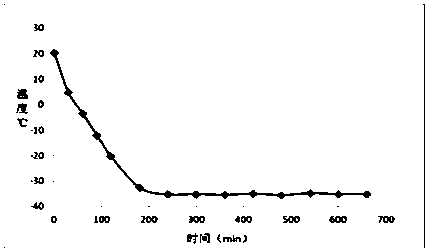

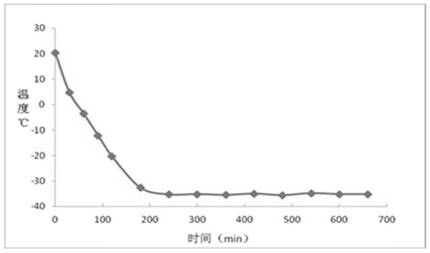

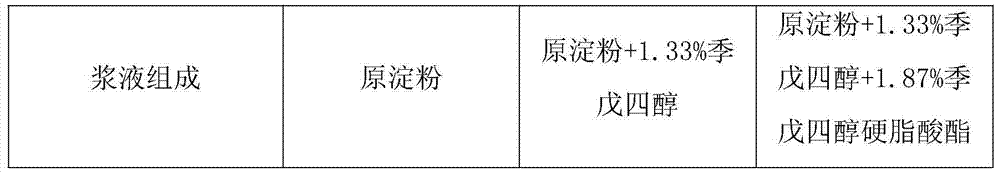

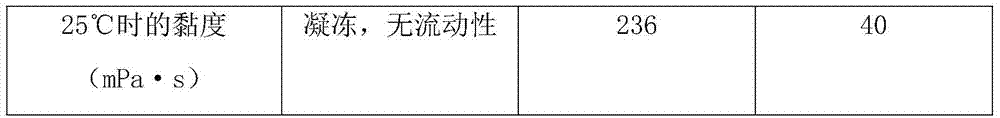

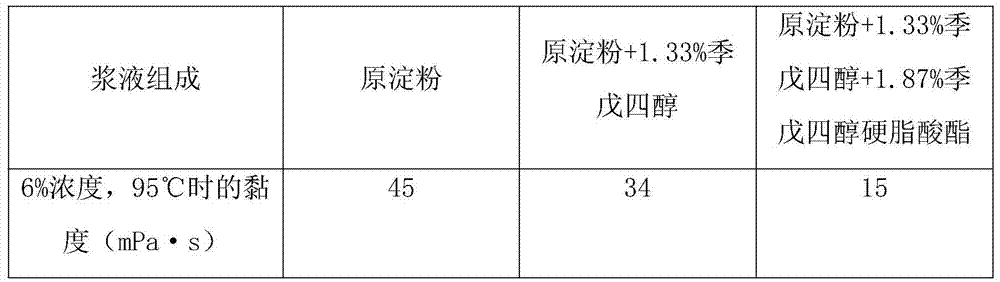

Method for preparing starch size capable of achieving room temperature sizing

ActiveCN105421065AImprove liquidityAchieve room temperature sizingVegetal fibresPentaerythritolRoom temperature

The invention discloses a method for preparing starch size capable of achieving room temperature sizing, and belongs to the field of textile processing. The method is characterized in that in the starch size mixing process, pentaerythritol of which the mass ratio to starch is 0.5%-3.5% and pentaerythritol ester (such as pentaerythritol stearate, pentaerythritol oleate and pentaerythritol tetraacrylate) of which the mass ratio to the starch is 0.3%-3.8%; the adding amount of the pentaerythritol preferably is 1.0%-3.5% and more preferably is 1.0%-2.0%. By adopting the native starch size prepared through the method to perform room temperature sizing on dyed yarn, the phenomenon that dye on the dyed yarn is dissolved in a size vat due to high temperature sizing can be avoided, the color hue and color light of the dyed yarn cannot be influenced, and color staining among the dyed yarn of different colors cannot be caused; when room temperature sizing is performed on wool yarn which does not resist the high temperature, the loss of the wool strength and elasticity can be avoided. The native starch size prepared through the method has the advantages of being low in viscosity and the like, and the adhesion and size film property of the size are similar to those of native starch and are not influenced by the added pentaerythritol and pentaerythritol ester.

Owner:YIXING JUNDA SLURRY TECH +1

Freeze-dried miracle fruit ferment chewing gum and preparation method thereof

ActiveCN108432934APreserve the flavorPreserve nutrientsChewing gumFood ingredient functionsMaltitolGum base

The invention discloses freeze-dried miracle fruit ferment chewing gum and a preparation method thereof. The freeze-dried miracle fruit ferment chewing gum is characterized by comprising the followingraw materials in parts by mass of 150-250 parts of miracle fruit ferment freeze-dried powder, 1000-1300 parts of a gum base, 1200-1600 parts of xylitol, 150-300 parts of maltitol liquid and 20-40 parts of glycerine. The miracle fruit ferment freeze-dried powder can reserve flavor and nutrients of the miracle fruits, and can increase the antioxidant ability. The freeze-dried miracle fruit fermentchewing gum has the functions of sterilizing, diminishing inflammation, relieving a pain, stopping bleeding, strengthening teeth, refreshing an oral cavity, preventing periodonitis, beautifying the features and regulating the stomach and intestine functions.

Owner:CHENGDU RUNXINTANG PHARMA

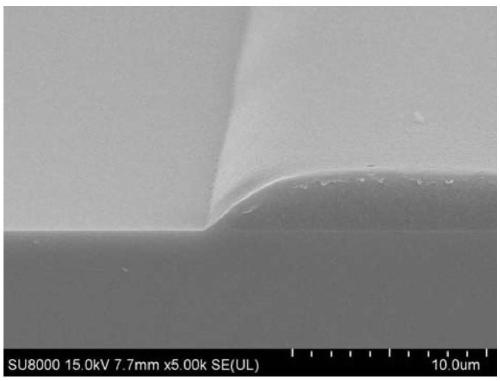

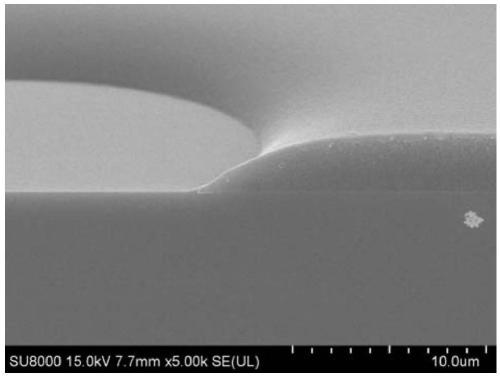

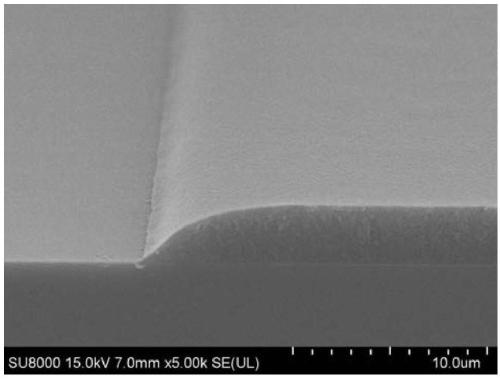

Reactive alkali-soluble resin, photosensitive resin composition containing same and application of photosensitive resin composition

ActiveCN111324011AGood alkali solubilityHigh strengthPhotosensitive materials for photomechanical apparatusNon-linear opticsPolymer scienceImage resolution

The invention provides reactive alkali-soluble resin, a photosensitive resin composition containing the same and application of the photosensitive resin composition. The reactive alkali-soluble resincomprises at least one structural unit (A), at least one structural unit (B) and at least one structural unit (C). The photosensitive resin composition is prepared from the following components in parts by weight: 1 to 30 parts of reactive alkali-soluble resin, 1 to 30 parts of non-reactive alkali-soluble resin and 0.1 to 10 parts of an initiator. The photosensitive resin composition has the characteristics of good development performance, excellent line width, good heat resistance, high resolution, clear opening, tidy pixel edge and the like.

Owner:BEIJING ETERNAL MATERIAL TECH

Protective device for use in oral surgical procedures

ActiveUS11179225B2Minimises risk of tissue burning and gas ingestionEmission minimizationTeeth fillingSomatoscopeSurgical operationSurgical instrumentation

A protection device for use in oral surgery. The device comprises; a body having a first part which locates outside a patient's mouth and a second part which, during use, locates inside the mouth. The body is arranged such that at least a part of the body is resiliency deformable to enable manual shaping to accommodate an anatomical shape of at least part of a patient's mouth, thereby providing a physical barrier between surgical instrumentation and a patient's soft tissue.

Owner:ESSENTIAL SURGICAL PTY LTD

A kind of freeze-dried miracle fruit enzyme chewing gum and preparation method thereof

ActiveCN108432934BPreserve the flavorImprove antioxidant capacityChewing gumFood ingredient functionsBiotechnologyGlycerol

The invention discloses a freeze-dried miracle fruit enzyme chewing gum and its preparation method, which is characterized in that it comprises the following raw materials in parts by mass: 150-250 parts of miracle fruit enzyme freeze-dried powder, 1000-1300 parts of gum base, xylose 1200-1600 parts of alcohol, 150-300 parts of maltitol liquid, 20-40 parts of glycerin. The miracle fruit enzyme freeze-dried powder in the present invention has preserved the local flavor and nutritive substance of the miracle fruit, and has also increased its antioxidant capacity. Freeze-dried miracle fruit enzyme chewing gum has the functions of sterilization, anti-inflammation, pain relief, hemostasis, tooth strengthening, mouth cleaning, periodontitis prevention, beauty treatment, and gastrointestinal function regulation.

Owner:CHENGDU RUNXINTANG PHARMA

A kind of method for preparing starch size that can be sized at room temperature

The invention discloses a method for preparing starch size capable of achieving room temperature sizing, and belongs to the field of textile processing. The method is characterized in that in the starch size mixing process, pentaerythritol of which the mass ratio to starch is 0.5%-3.5% and pentaerythritol ester (such as pentaerythritol stearate, pentaerythritol oleate and pentaerythritol tetraacrylate) of which the mass ratio to the starch is 0.3%-3.8%; the adding amount of the pentaerythritol preferably is 1.0%-3.5% and more preferably is 1.0%-2.0%. By adopting the native starch size prepared through the method to perform room temperature sizing on dyed yarn, the phenomenon that dye on the dyed yarn is dissolved in a size vat due to high temperature sizing can be avoided, the color hue and color light of the dyed yarn cannot be influenced, and color staining among the dyed yarn of different colors cannot be caused; when room temperature sizing is performed on wool yarn which does not resist the high temperature, the loss of the wool strength and elasticity can be avoided. The native starch size prepared through the method has the advantages of being low in viscosity and the like, and the adhesion and size film property of the size are similar to those of native starch and are not influenced by the added pentaerythritol and pentaerythritol ester.

Owner:YIXING JUNDA SLURRY TECH +1

A kind of textile size used for sizing pure cotton fabric warp yarn without pva and low sizing rate

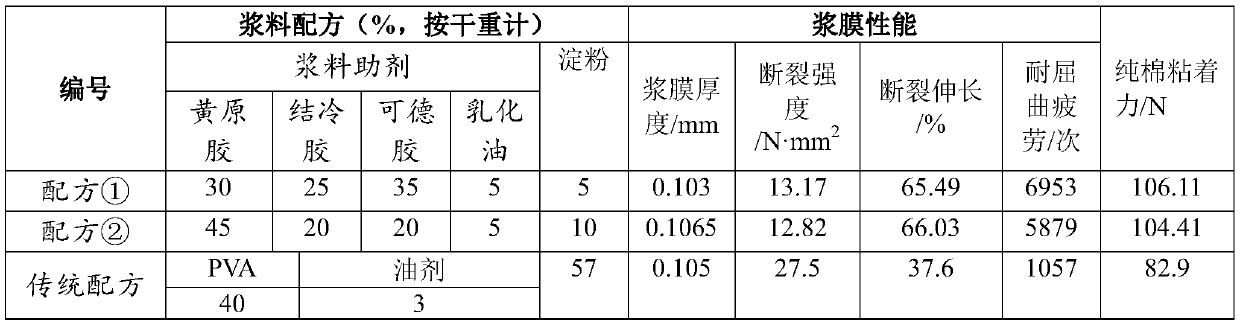

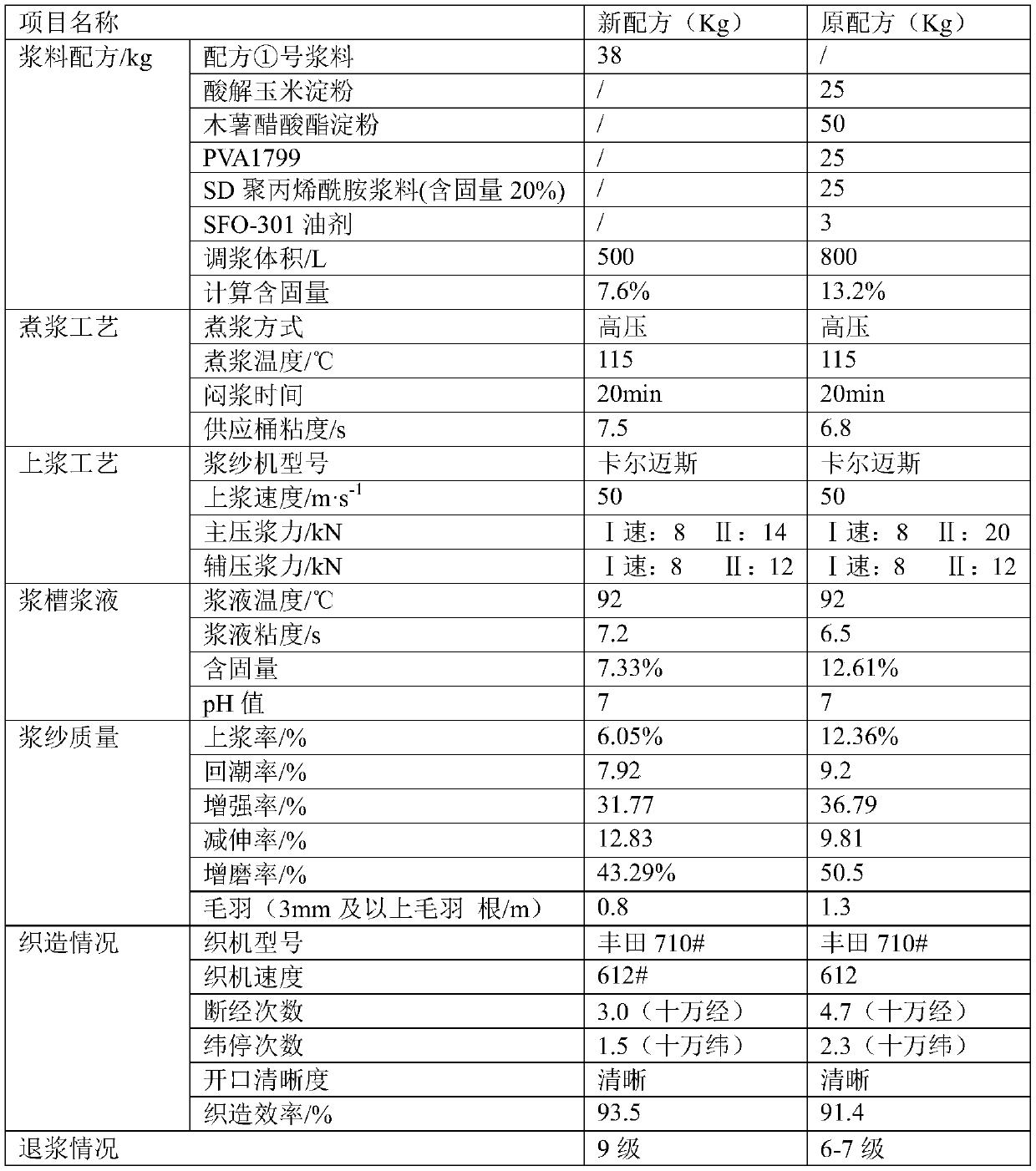

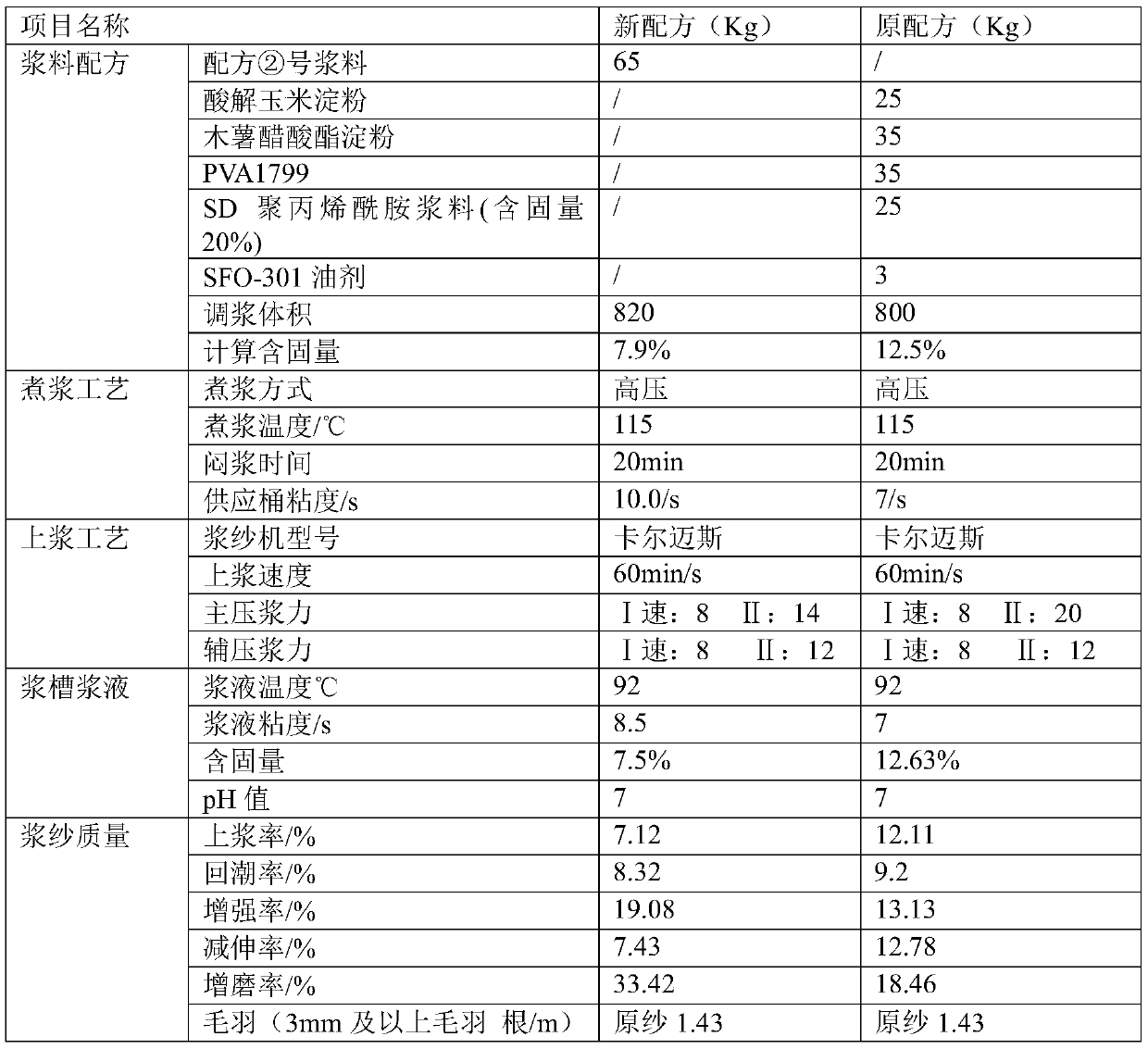

The invention discloses a textile sizing agent for PVA-free and low-sizing rate sizing of pure cotton fabric warps, and belongs to the field of textiles. Through combination of microbial polysaccharide xanthan gum, gellan gum and curdlan which are biotechnologically developed and starch, the pure cotton warps are sized. 5-20wt% of starch and 80-95wt% of an auxiliary agent, comprising 30-50wt% of xanthan gum, 20-30wt% of gellan gum, 20-40wt% of curdlan and 3-10wt% of emulsified oil, are proportionally mixed for sizing 40-60-count pure cotton warps, so that PVA-free and low-sizing rate sizing can be achieved, the sizing rate can be reduced from the conventional 12-14% to 6-7%, and the sizing agent resource can be significantly saved; in addition, when the textile sizing agent is used for sizing, few cotton and few sizing agent drop, opening is clear, the weaving efficiency can reach 91% or above, and the desizing grade is up to 9.

Owner:JIANGNAN UNIV

Device and method for controlling leno fabric warp on a loom

The invention discloses a device and method for controlling the warp of leno fabric on a loom, and belongs to the technical field of weaving equipment in the textile industry. The device comprises a plurality of heald frames, a bracket, a first heddle, a second heddle, a two-way bracket, a connecting rod group and a dobby mechanism; the first heddle and the second heddle are installed on the bracket in pairs; the bracket Set side by side in parallel and connected with the heald frame; the upper and lower beams of the heald frame are respectively connected with multiple wooden frames; the heald frame is installed in the baffles on both sides of the loom; the heald frame is connected with the connecting rod group; connected; two-way brackets are arranged between adjacent heald frames, and the first heddle and the second heddle respectively pass through the two-way brackets; the two-way brackets are respectively connected to the upper and lower beams of the loom through nylon sheets and springs. The invention also provides a method for controlling the warp of the leno fabric. The invention has the advantages of being suitable for high-speed weaving of thick yarns, having clear openings and avoiding yarn scratching, etc., and has a simple and reasonable structural design.

Owner:北京燕阳新材料技术发展有限公司

Device and method for assisting weaving, wrapping and stranding of ceramic fiber fabric

The invention relates to a device and a method for assisting weaving, wrapping and stranding of a ceramic fiber fabric. The device comprises a spool, wherein the spool is used for leading out a ceramic fiber bundle; the hollow spindle is wound with cellulose fibers, a channel for ceramic fiber bundles to pass through is formed in the hollow spindle, and the hollow spindle can rotate around the central axis of the hollow spindle; the yarn guide hook can rotate according to rotation of the hollow spindle, and after the ceramic fiber bundle passes through the channel, the yarn guide hook guides the cellulose fibers on the hollow spindle and wraps the cellulose fibers on the ceramic fiber bundle, so that wrapped and formed ceramic fibers are obtained; and the winding mechanism is used for winding the wrapped and formed ceramic fibers into a barrel. According to the invention, the two fiber bundles can be stranded and wrapped while ceramic fibers are prevented from being broken, so that the frictional wear of yarns is reduced, and the weaving efficiency and mechanical properties of products are remarkably improved.

Owner:JIANGNAN UNIV

YDM-J type organic composite slurry for bast fibre spinning industry and its preparation method

ActiveCN101319463BImprove working environmentSensory fullnessVegetal fibresPolymer scienceOrganosolv

The invention relates to YDM-J type organic compound slurry for the flax spinning industry, as well as a preparation method thereof. The slurry is characterized by comprising the following components in percentage by weight: 2-4 percent of oxidative high-carbon alkyl dimethyl amine, 1-2 percent of diethylene triamine, 2-4 percent of alcamines, 1-3 percent of polyoxyethylene ether type emulsifier,2-4 percent of oleic acid, 1-2 percent of organic solvent, 2-4 percent of penetrating agent, 3-5 percent of carboxymethyl cellulose and 72-86 percent of water. The preparation method comprises the following steps that: firstly: the components are added to a reaction kettle according to mixture ratio, wherein the water with the weight half of the mixture weight is added; secondly, the carboxymethyl cellulose, a semi-finished product of a first step and the penetrating agent are injected into the reaction kettle. A usage of the slurry comprises the following: A. a technique of finishing flax warp sizing in a small flume of a sectional warping machine; B. a technique of finishing flax warp sizing in a slurry tank of a sizing machine. The slurry forms a smooth, wear-resistant and flexile thinfilm on the surface of warp, which improves yarn strength, reduces rear-machine broken ends and improves loom efficiency.

Owner:上海新浦特种助剂有限公司

Volcanic blended fabric and production method thereof

InactiveCN111172645ASoft touchClear mouthSwivel-woven fabricsLappet-woven fabricsCotton fibreWeft yarn

The invention discloses a volcanic blended fabric and a production method thereof. Warp yarns and weft yarns are blended yarns; raw yarns comprise the components including 40% of volcanic fibers, 30%of combed cotton fibers and 30% of viscose fibers; the cotton fibers are relatively long and soft in hand feeling; the viscose fibers are soft in hand feeling and good in affinity; and during weaving,opening is clear, fabric defects are few, and the weaving efficiency is high. The fabric has the heat storage heating and moisture absorption heating effects of volcanic, and is soft and relatively good in hand feeling.

Owner:JIANGSU YUEDA HOME TEXTILE

A kind of modified polyester size and preparation method thereof

The invention belongs to the technical field of novel chemical fiber materials, and specifically relates to modified polyester slurry and a preparation method thereof. The modified polyester slurry comprises 5 to 100 parts of modifier, 1 to 20 parts of polyester, 0.05 to 0.1 part of modified montmorillonite and 50 to 200 parts of water by weight. The modifier is prepared from hydrated silica and silicone oil, and the polyester is prepared from 30 to 55 parts by weight of citric acid, 15 to 26 parts by weight of PEG-200, 15 to 40 parts by weight of 2,2-bis (hydroxymethyl) propionic acid, 5 to 10 parts by weight of glycerin, and 1 to 10 parts by weight of pure water; and the modified montmorillonite is prepared from 50 to 100 parts by weight of montmorillonite and 30 to 50 parts by weight ofsilicone oil. According to the modified polyester slurry prepared by the invention, the viscosity and the surface tension of the slurry can be reduced by adding the modifier, so that the slurry permeability is improved; and by adding the modified montmorillonite, the tensile property of a yarn is improved, the end breakage rate is reduced, the cost is reduced, the degradation is easy, the operation is convenient, the pollution is avoided, no catalyst is needed in the preparation of the polyester, and the modified polyester slurry has higher economic benefits and social benefits.

Owner:湖南万家工贸实业有限公司 +1

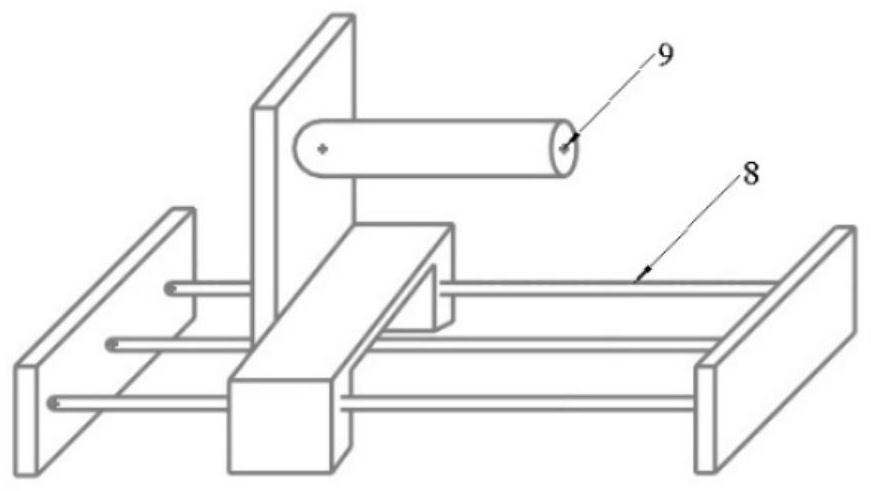

Constant-tension warp and k'o-ssy feeding machine

The invention discloses a constant-tension warp and k'o-ssy feeding machine. The constant-tension warp and k'o-ssy feeding machine comprises a k'o-ssy machine rack, wherein a front chest beam is arranged at one end of the k'o-ssy machine rack; the front chest beam is connected with the k'o-ssy machine rack; a cloth rolling roller is arranged below the front chest beam; the cloth rolling roller isrotatably mounted on the k'o-ssy machine rack; the cloth rolling roller is in transmission connection with a power output shaft of the cloth rolling drive motor; the other end of the k'o-ssy machine rack is equipped with a swing shaft for tightening warp silks; the left end of the swing shaft is rotatably mounted at the outer end of a left swing rod; the right end of the swing shaft is rotatably mounted at the outer end of a right swing rod; the inner end of the right swing rod and the inner end of the left swing rod are mounted on the k'o-ssy machine rack through the swing rod shaft; the axisof the swing rod shaft is parallel to the axis of the swing shaft; a warp silk feeding roller is arranged near the swing shaft; and the warp silk feeding roller is rotatably mounted on the k'o-ssy machine rack. The invention aims to provide the constant-tension warp and k'o-ssy feeding machine which can increase warp penetrating speed, guarantees straightness and uniformity of warp yarns, so thatproduct quality can be guaranteed, and working efficiency of k'o-ssy knitting is improved.

Owner:沈红

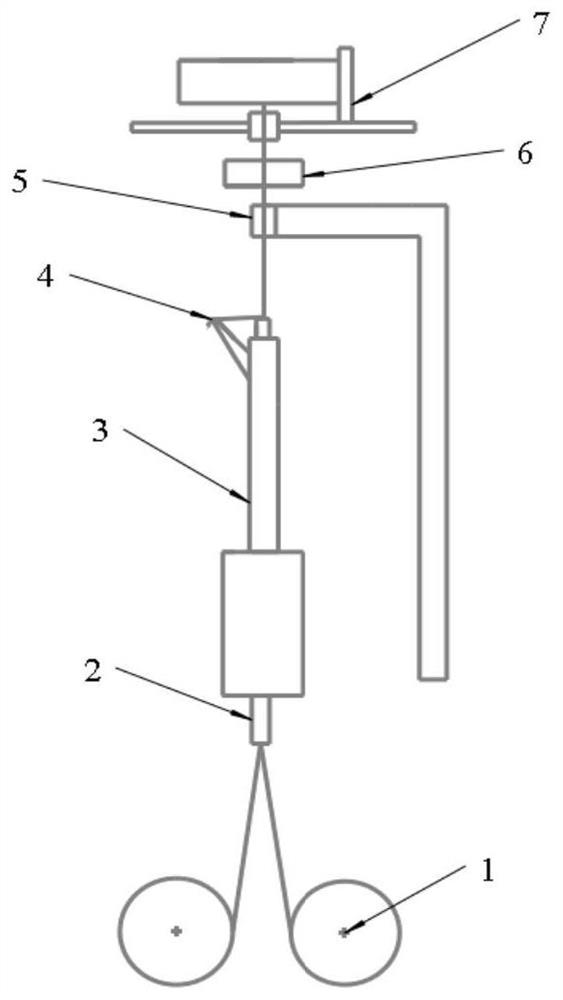

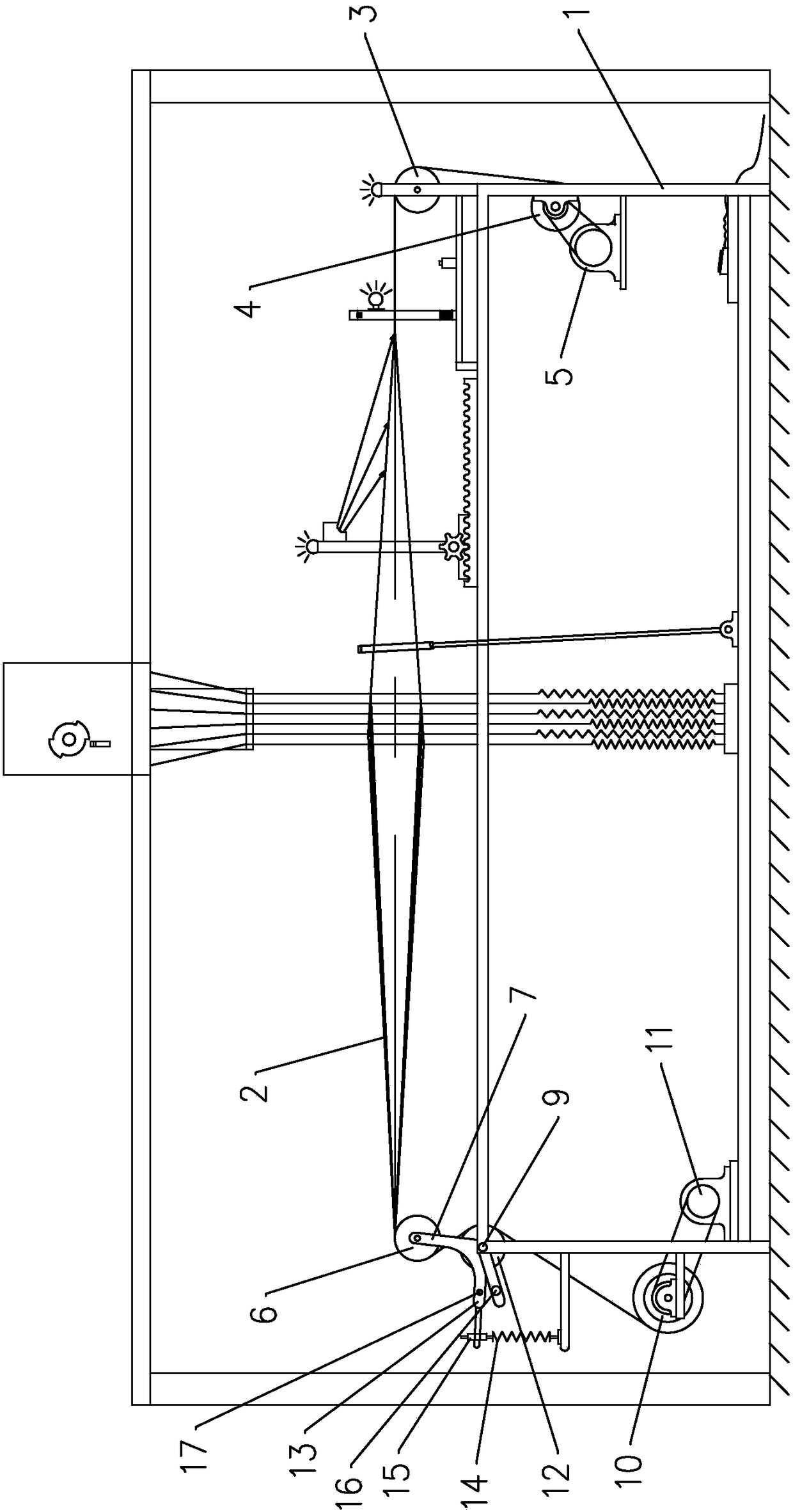

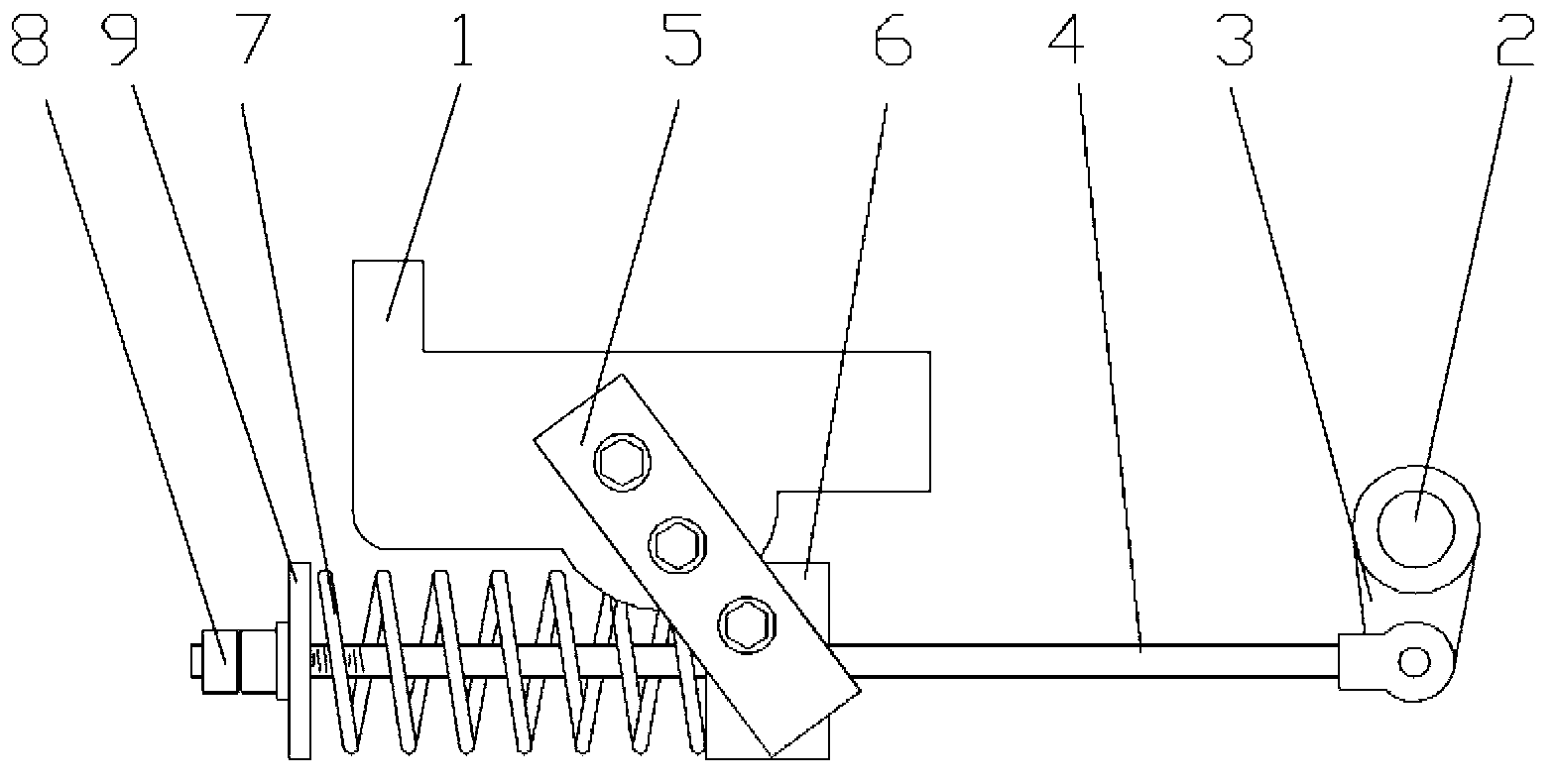

Wrap loosening device for air jet loom

A warp loosening device for an air jet loom comprises an air jet loom frame (1), an air jet loom warp loosing shaft (2), a crank (3) is hinged on the air jet loom warp loosening shaft (2), a warp loosening rod (4) is hinged on the crank (3), the air jet loom frame (1) is fixedly provided with a support (5), the support (5) is fixedly provided with a guide block (6), the warp loosening rod (4) is sleeved outside the guide block (6) through insertion, one end of a pressure spring (7) acts on the warp loosening rod (4), and the other end of the pressure spring (7) acts on the guide block (6). Under the condition that the rotating speed of the loom is not high, the warp loosening device for the air jet loom enables the back rest roller inertia to be in a controllable range, enables the warp to be synchronous with the opening of the loom all the time and keep balanced tension, is clear in opening, and facilitates the weaving of multicolour different fiber yarn on the loom.

Owner:HUZHOU LIHUA YUJIE UNION TEXTILE

A kind of emulsified paraffin for textile

ActiveCN104562648BClear mouthIncrease the rate of first-class productsFibre treatmentFiberMonoglyceride

The invention discloses emulsion paraffin for textile. The emulsion paraffin is prepared by following raw materials in parts by weight: 100 to 120 parts of paraffin, 10 to 15 parts of calcium stearate, 3 to 6 parts of carboxymethylcellulose, 3 to 6 parts of stearic acid monoglycerides, 6 to 12 parts of sorbitol mono-olein, 2 to 5 parts of Vaseline, 3 to 6 parts of crylic acid, 20 to 40 parts of ethanol, 0.5 to 1.5 parts of triethylhexyl phosphate, 12 to 15 parts of an emulsifier and 180 to 200 parts of water, wherein the emulsifier is a mixture of sodium dodecyl sulfate, Arabic gum, sodium caseinate and polyacrylamide. The emulsion paraffin is suitable for various fiber fabrics such as chemical fibers, blended fabric, silk, pure cotton and hemp, the weaving friction coefficient can be effectively reduced, the weaving end broken rate is reduced, the opening of the fabric is clear, the first-grade ratio of the cloth can be increased, and the efficiency of a weaving machine can be greatly improved; moreover, the emulsion paraffin is easy in desizing, suitable for printing and little in consumption, and the cost can be reduced by 10 to 12 Yuan for each bolt of cloth.

Owner:WUJIANG HUAWEI SPECIAL OIL

Process for manufacturing sirospun yarn jean facing material

The invention discloses a manufacture technique of a siro yarn jean fabric, in which, firstly an advanced siro yarn spinning technology is adopted to manufacture the siro yarn; the spun siro yarn is wound; then the wound siro yarn which is used as a warp is warped, dyed and starched be manufactured into a beam; then the siro yarn is used as the warp and the siro yarn, a rotor spun yarn or a ring yarn are used as an abb to be woven on a loom according to the fabric weave and the weaving technique of the jean to manufacture a grey fabric and finally the grey fabric is made into a finished product through subsequent finishing. As the siro yarn with better quality is adopted as the warp, the method has the advantages of easy yarn splitting, few broken ends, uniform colorizing, reducible sizing quality requirement as well as high heddle draft and reeding efficiency during the dyeing process, clear cut, uniform tension, few broken ends and stopping, few fly wastes in a workshop and on a machine station as well as being beneficial to the cleanness of the workshop and the maintenance of the machine station when weaving.

Owner:佛山市致兴纺织服装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com