Patents

Literature

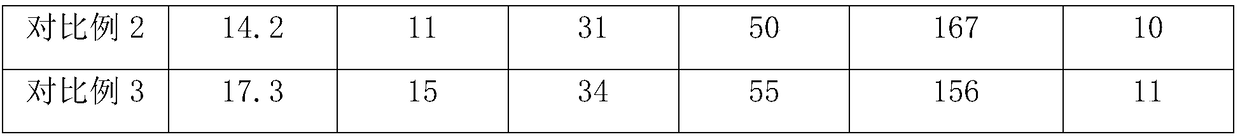

69results about How to "Few yarn defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

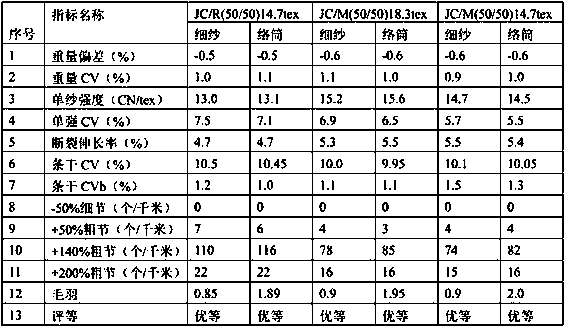

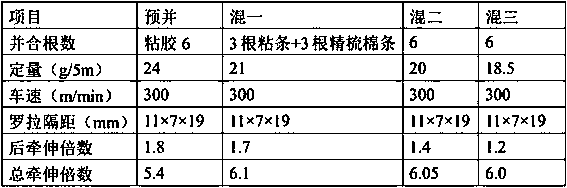

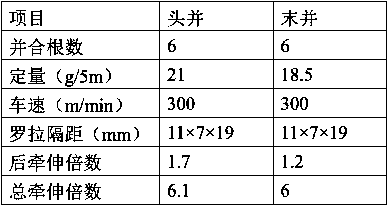

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

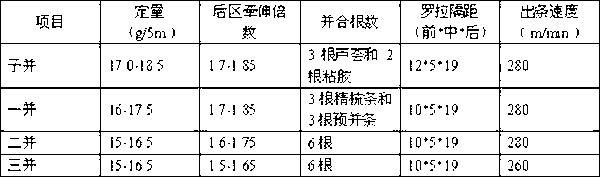

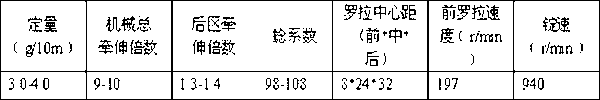

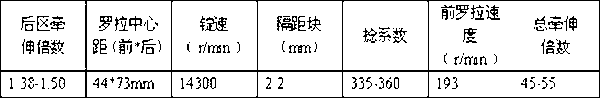

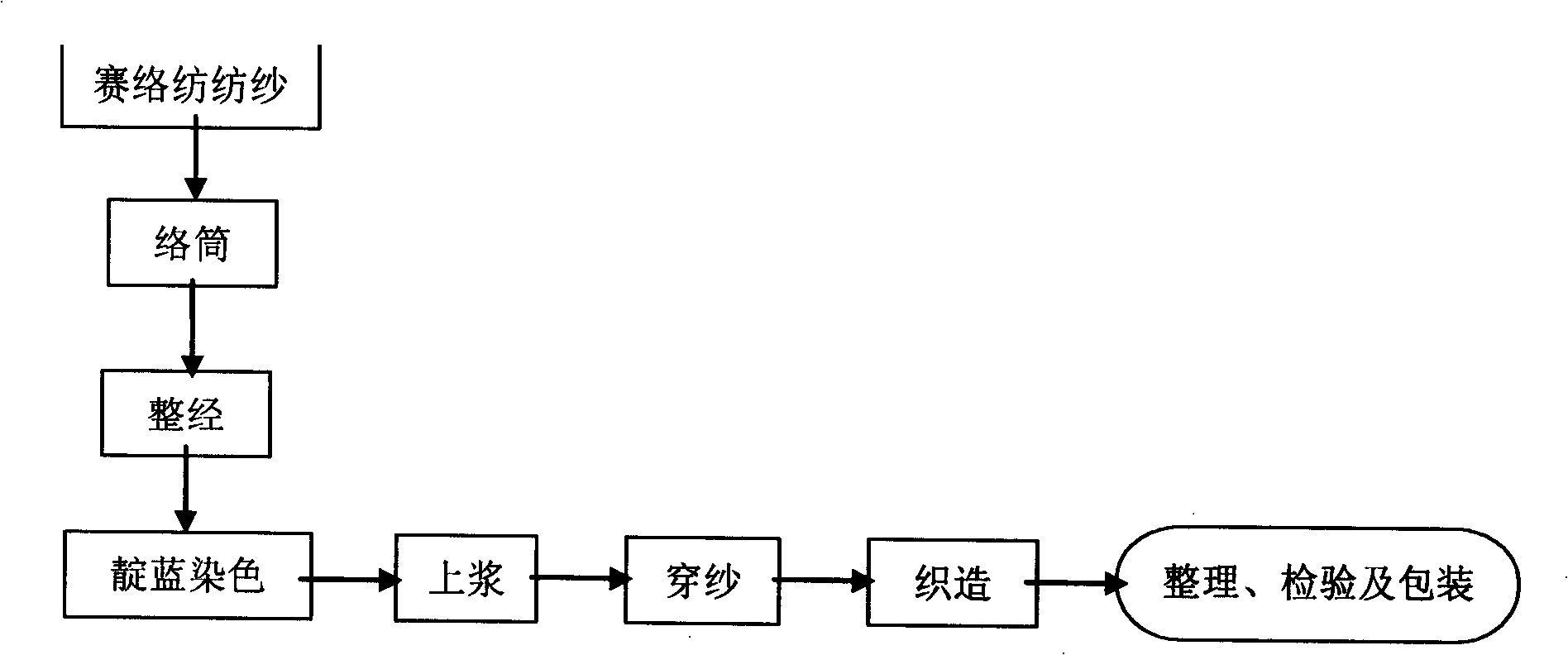

Process for manufacturing sirospun yarn jean facing material

The invention discloses a manufacture technique of a siro yarn jean fabric, in which, firstly an advanced siro yarn spinning technology is adopted to manufacture the siro yarn; the spun siro yarn is wound; then the wound siro yarn which is used as a warp is warped, dyed and starched be manufactured into a beam; then the siro yarn is used as the warp and the siro yarn, a rotor spun yarn or a ring yarn are used as an abb to be woven on a loom according to the fabric weave and the weaving technique of the jean to manufacture a grey fabric and finally the grey fabric is made into a finished product through subsequent finishing. As the siro yarn with better quality is adopted as the warp, the method has the advantages of easy yarn splitting, few broken ends, uniform colorizing, reducible sizing quality requirement as well as high heddle draft and reeding efficiency during the dyeing process, clear cut, uniform tension, few broken ends and stopping, few fly wastes in a workshop and on a machine station as well as being beneficial to the cleanness of the workshop and the maintenance of the machine station when weaving.

Owner:佛山市致兴纺织服装有限公司

Cotton fiber and jutecell fiber blended yarn and spinning process thereof

The invention discloses a cotton fiber and jutecell fiber blended yarn and a spinning process thereof. The blended yarn comprises jutecell fiber with fiber content blending ratio as 70% and 30% fine staple cotton. The fibers are spun into yarns through the blended spinning process. Raw materials of the yarns are composed of the jutecell fiber and the fine staple cotton. Compared with the prior art where long staple cotton and jutecell fiber are used for blended spinning, the process is low in cost and high in cost performance. The blending mode of one pre-blending and three mixed-blending is adopted, so that the blending spinning ratio is accurate, and components are even. The blended yarns produced in the production process are high in single yarn strength, even in yarn levelness and few in nep and yarn fault. The yarn structure can further improve textile comfortableness, improve textile hand feel and improve lining grade.

Owner:山东超越纺织有限公司

Kuralon fiber finely woven fabric and preparation method thereof

A kuralon fiber finely woven fabric is characterized by comprising the following components by weight percent: 70-80% of wool or wool and other fibers and 20-30% of kuralon fiber; and the preparation method comprises the following steps: 1) selecting raw materials; 2) recombing; 3) spinning; 4) weaving; and 5) dyeing and finishing. The kuralon fiber finely woven fabric produced by the method of the invention has bulky and soft hand feeling and the hollowness is up to 20-30%. The selection of kuralon is reasonable, the mixing method ensures that the kuralon fiber finely woven fabric can be smoothly spun, the spinnability is good, the fiber is easy to draw, the evenness is good, the fault is less, the weaving efficiency is high, and the characteristics that the fabric is hollow and the hand feeling is bulky and soft, of the kuralon fiber finely woven fabric can be better embodied after finishing.

Owner:JIANGSU DANMAO TEXTILE

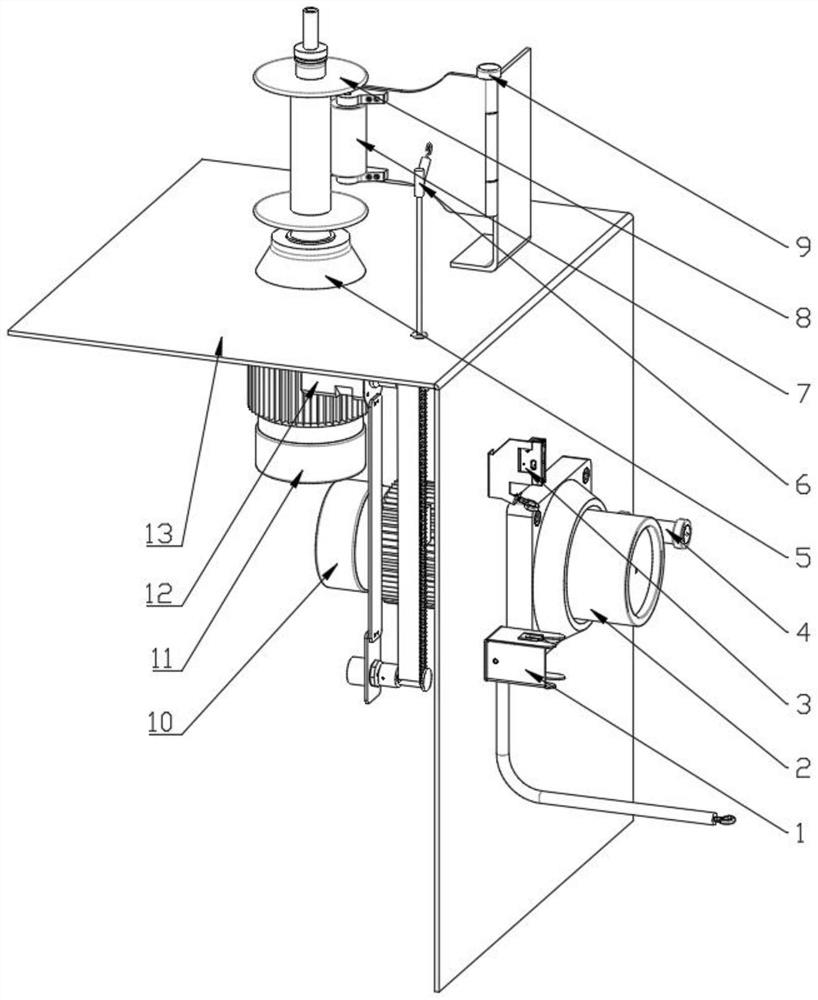

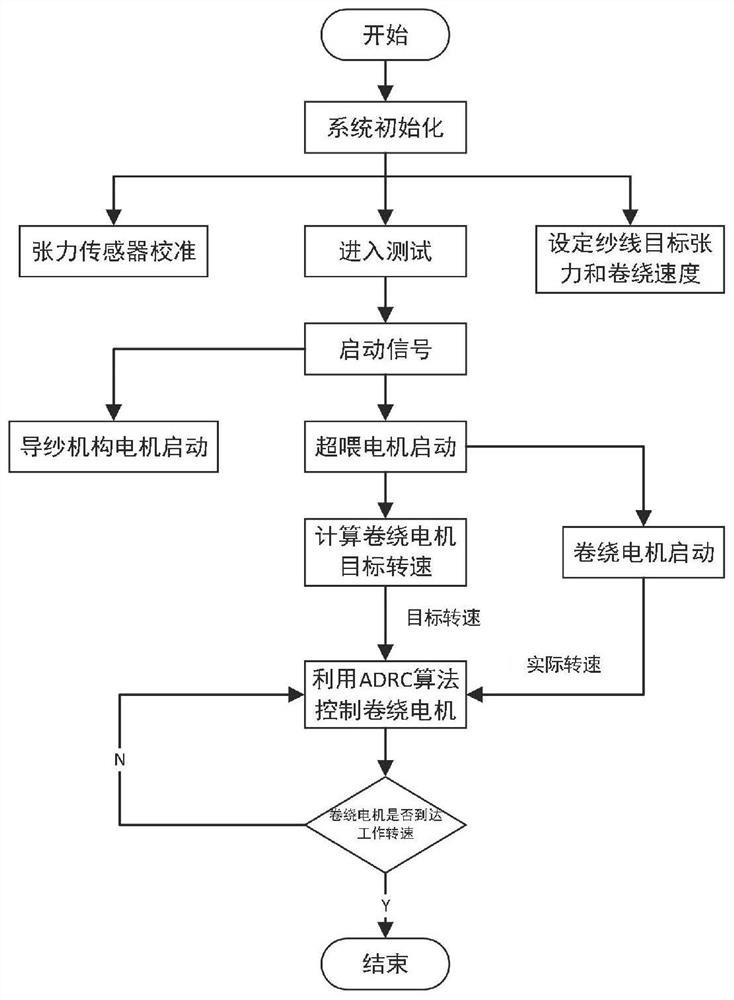

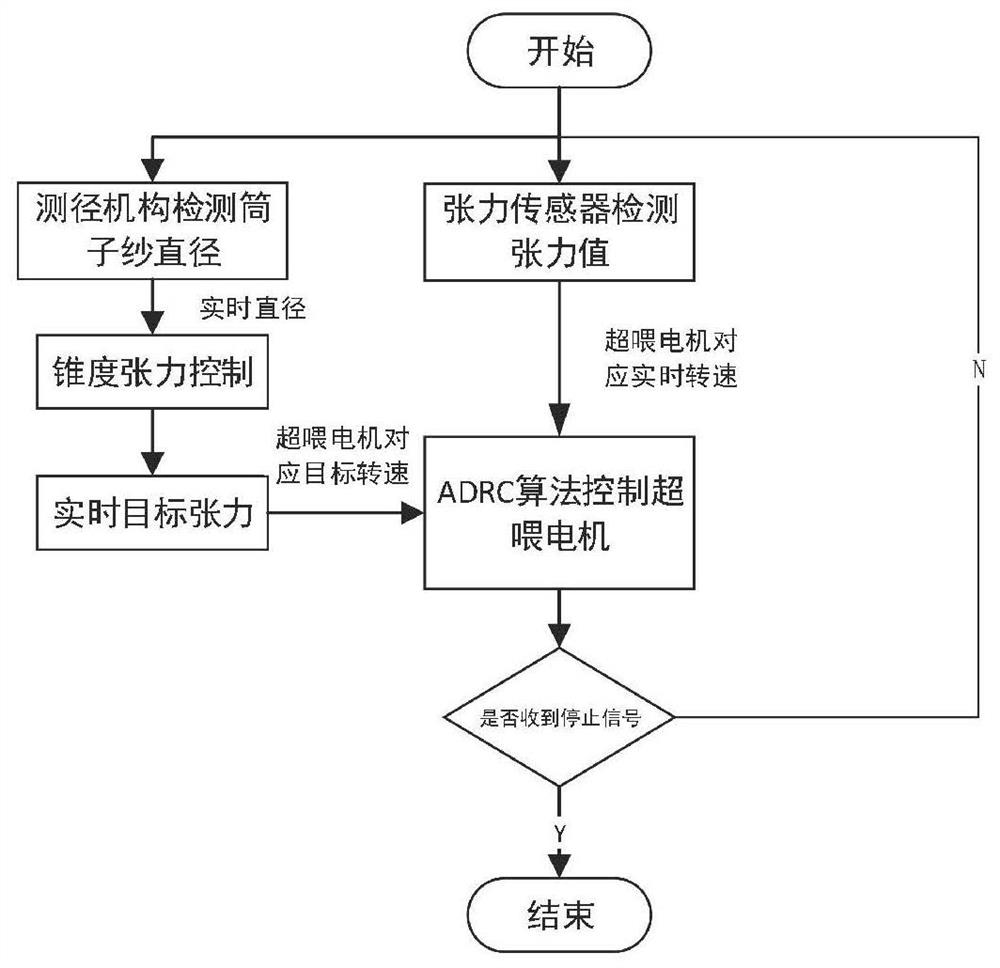

Winding forming control method capable of detecting and dynamically adjusting tension in real time

ActiveCN112960477AReduce tension fluctuationsImprove stabilityFilament handlingClassical mechanicsEngineering

The invention discloses a winding forming control method capable of detecting and dynamically adjusting tension in real time. The winding forming control method capable of detecting and dynamically adjusting the tension in real time comprises the following steps: 1, a winding starting stage: an overfeeding wheel begins to rotate, and a yarn core begins to rotate after delay; the overfeeding wheel does uniformly accelerated motion; the target rotating speed of the yarn core is calculated according to the rotating speed of the overfeeding wheel; and the rotating speed of the yarn core is driven to dynamically follow the target rotating speed; 2, a stable operation stage: the target tension of a yarn roll is dynamically adjusted along with winding of a yarn roll; and under the state that the linear speed of the yarn roll is kept constant, the target rotating speed of the overfeeding wheel is dynamically calculated and updated according to the change of the target tension F, and the rotating speed of the overfeeding wheel is driven to dynamically follow the target rotating speed; and 3, a machine stopping stage: the yarn core does uniformly retarded motion, and after delay, the overfeeding wheel starts to retard; the target rotating speed of the overfeeding wheel is calculated and updated according to the rotating speed change of the yarn core; and the rotating speed of the overfeeding wheel is driven to dynamically follow the target rotating speed. According to the winding forming control method capable of detecting and dynamically adjusting the tension in real time provided by the invention, the tension of yarns is accurately adjusted, so that cheeses are uniformly wound, no yarn broken ends exist, and the number of yarn faults is small.

Owner:ZHEJIANG SCI-TECH UNIV +1

Elastic worsted fabric with contact coldness sense and preparation method thereof

InactiveCN102534949AIncrease elasticityFeel coolWoven fabricsYarnWorstedPolytrimethylene terephthalate

The invention relates to an elastic worsted fabric with a contact coldness sense and a preparation method thereof. The fabric comprises polytrimethylene terephthalate (PTT) fibers with a contact coldness sense effect, wherein the PTT fibers are prepared by spinning PTT slices which contain mineral powder with the contact coldness sense and are taken as raw materials, or prepared by taking PTT slices as raw materials and adding mineral powder with the contact coldness sense effect in the spinning process; the PTT fibers have high heat conductivity, can quickly absorb heat on the surface of skin, and are not stuffy when external temperature is high, and the coolness and comfort of the worsted fabric can be kept all the time; and the PTT fibers have high spinnability, evenness and weaving efficiency and a few yarn faults and are easy to draw, and the elasticity of the worsted fabric with the contact coldness sense is better reflected through after finishing.

Owner:JIANGSU DANMAO TEXTILE

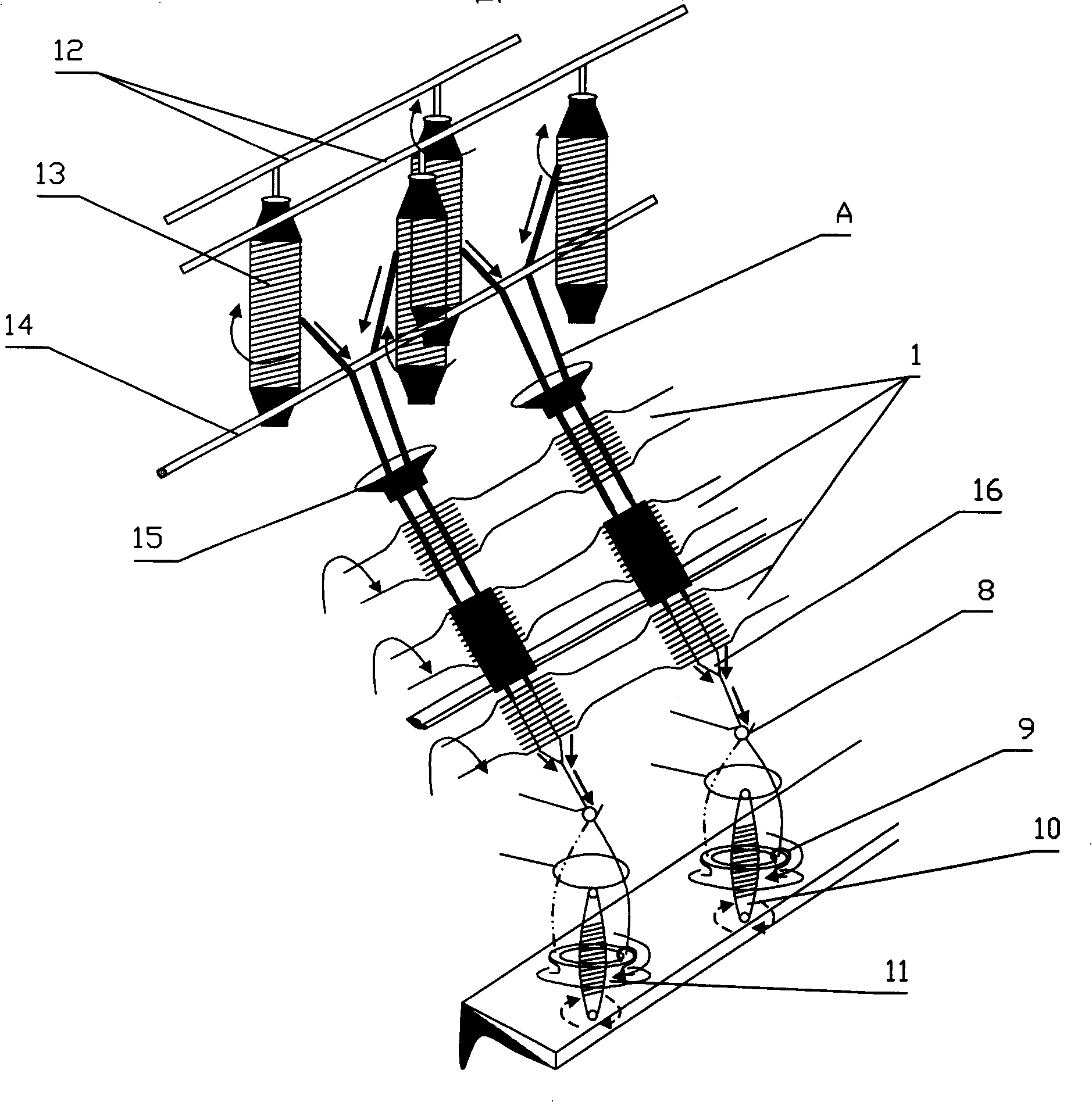

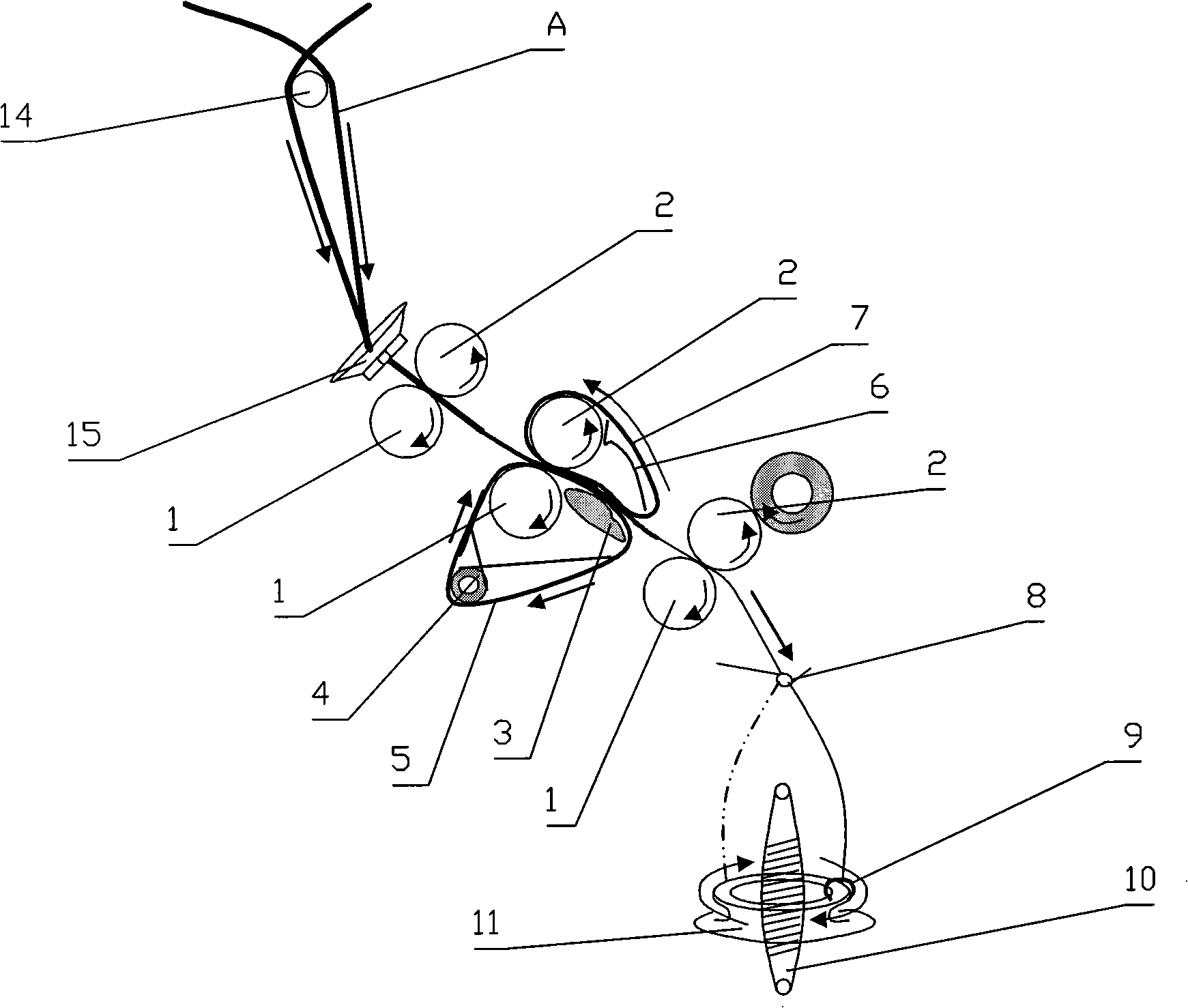

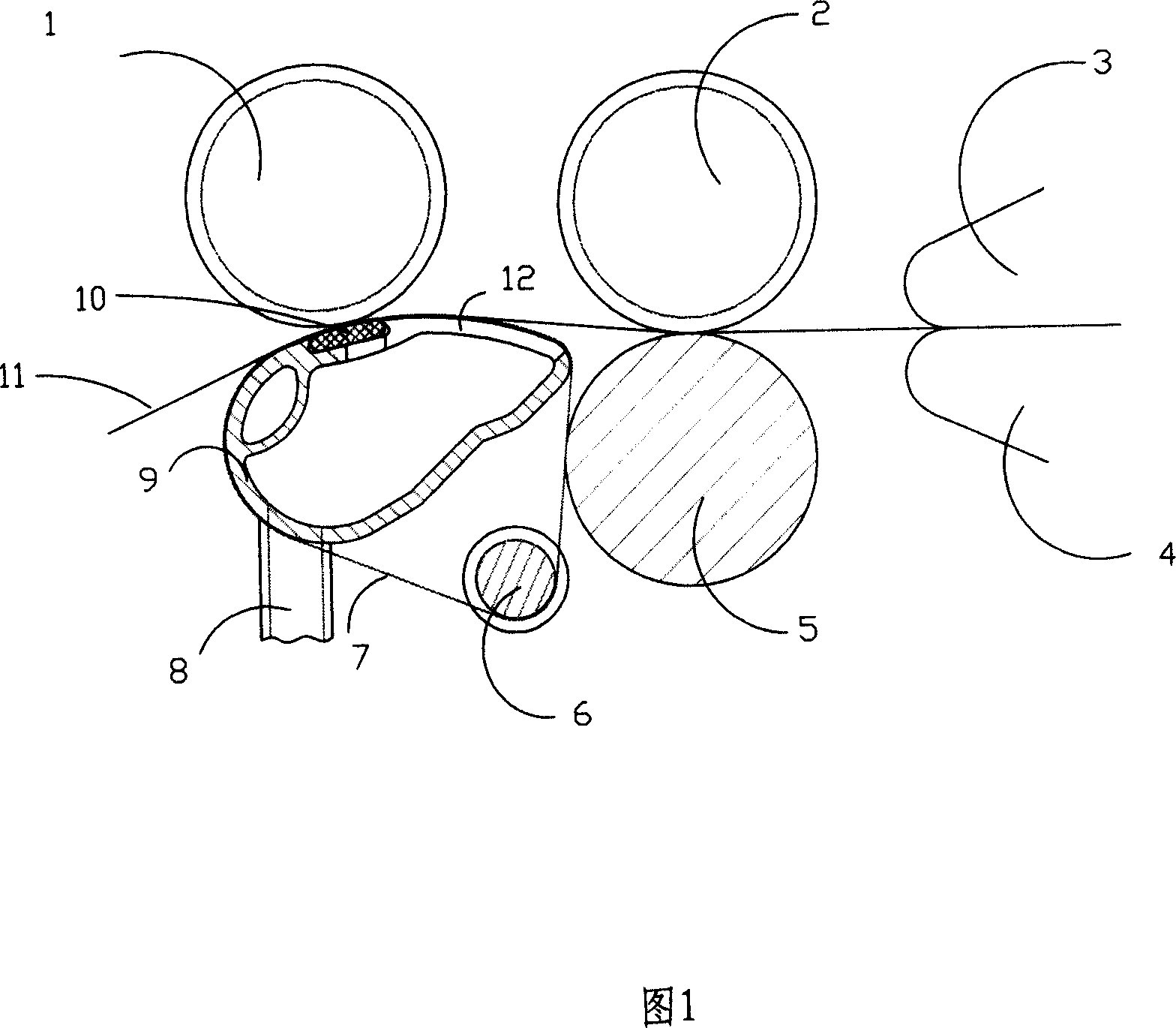

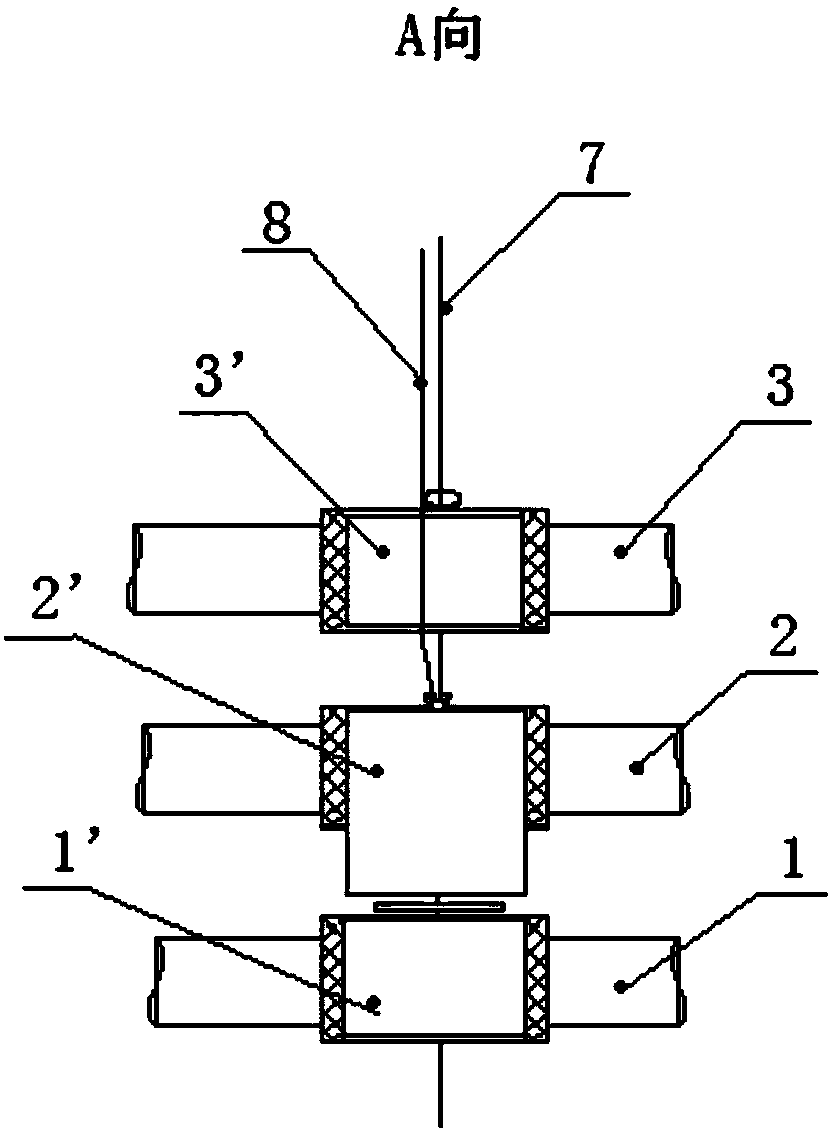

Tightness spinning device of ring spinning frame

InactiveCN1446960AImprove delivery formHigh strengthDrafting machinesContinuous wound-up machinesYarnFiber

A dense spinning unit for ring spinning frame is composed of drawing roller pair, roller seats, cradle pressing unit, air sucking tube with inlet and air oultet, condensing sleeve with condensing slot and sleeving on air sucking tube, stretching unit in the slide slot of condensing sleeve, air-permeable delivering ring sleeving on condensing slot and stretching unit, and drive pressing unit. Its advantages are high spinning power and high yarn quality.

Owner:SHANGHAI TEXTILE MACHINERY CO LTD OF PACIFIC MECHATRONIC GRP

Green multifilament blended fabric

InactiveCN101275328AMeet the requirements of the yarn standardGood moisture absorption and air permeabilityWeft knittingWarp knittingFiberWrinkle skin

The inventive green multifilament blended facing material is formed by blended spinning of zein fibre, bamboo fibre and flaxrichce fibre, wherein, the chaine is same with the weft yarn, and the weight proportion of spinning raw material is 35-45 percent of zein fibre, 35-45 percent of bamboo fibre and 15-25 percent of flaxrichce fibre. The invention adopts a plurality of green fibres for blended spinning and interweaving, which sufficiently exerts the moisture absorption ventilating, peculiar silk like brightness, favorable reversion performance, wrinkle resistance, and pilling resistance of the zein fibre, and the favorable hydroscopicity , dyeability, soft comfortable hand feeling, and good drapability of the wood fiber, thereby the performance of various fibres is ascendency complementary, the spinning perfromance of fibre is increased, the brute force and quality of the yarns is improved; meanwhile the facing material is provided with features of favorable moisture absorption ventilating, comfort of wear, sliding feel well hand feeling, pendant dynamic, non electrostatic puzzle, good reversion perfromance and wrinkle resistance, etc.

Owner:SHANDONG QISAI TEXTILE

Method for producing metal fiber blended yarn

The invention discloses a method for producing metal fiber blended yarn. First, drawing of textile fiber rods and metal fiber rods is carried out; the proportion by weight of the metal fiber is 2.9%-3.2% after the drawing; and then the metal fiber blended yarn is formed through the process of tearing up, opening, scutching and coiling, cotton carding, drawing and spinning of the drawn textile fiber rods and metal fiber rods. The method can be completely applied to production, and is convenient in application and easy in operation; metal fibrous raw materials are not liable to fall off during the production, and the content of the metal fiber is easy to control; and the produced metal fiber blended yarn has the advantages of high strength, low yarn unevenness, less hairiness, less yarn faults and good shielding performance, and meets the requirements of garment fabrics.

Owner:丁宏利

Production method of flax blended knitting yarns

The invention discloses a production method of flax blended knitting yarns. In the method, flax and modal fibers are blended according to a ratio of 15:85 to 85:15. The method comprises a spinning process and a rotor spinning process. The modal fibers selected in the invention are the most ideal material for light and thin knitted fabrics for their sweat-absorbing, thermal-insulation and cooling properties and integration of the comfortableness of cotton, the drapability of adhesive, the strength of terylene and the handfeel of real silk. The flax-modal blended knitting yarns exploit development space for high-quality flax light and thin knitted fabrics. Although the flax and modal fibers are susceptible to generating hairiness, the rotor spinning used in the invention is one-step bobbin forming and therefore reduces the hairiness of finished fibers and ensures the knitted fabrics are clear and full in appearance. The rotor spun yarns also have the advantages of few yarn faults, high elasticity, pilling resistance, wear resistance and the like. The method has the advantages that: the process flow is short; the cost is low; high grade flax knitting yarns with high balance of various performance indexes such as high fineness, little hairiness, yarn levelness and soft handfeel; and the application value in textile processing field is high.

Owner:QIQIHAR UNIVERSITY

Silver-element fibre spinning technology

The invention relates in particular to a new sliver-element fibre spinning technology, belonging to the spinning engineering field of textile industry production, comprising the following steps: pre-opening silver-element fibre to 80% by an opening machine; maintaining the blowing integrated beater speed in the blowing process of less than 600r / m and the beater frequency of sliver-element fibre per gram of less than 0.55; blocking the noil airdraft opening when carding cotton; using a flatbed drawing frame and a wool-top-proof conducting bar device with the drawing funnel caliber of 5.2mm; keeping the roving cycles of 33-38 cycle / 10cm, spinning frame guide stroke of 3-6mm; maintaining the groove drum speed in spooling less than or equal to 700 meter / minute and using a photoelectric type flaw-cutting device. Compared with the existing technology, the invention has the advantages of effective control of noil rate of blowing and cotton carding, small fibre damage, little nep, removal of belt roller wound by drawing and roving, smooth passage and winding, less broken ends, higher intrinsic quality of semi-manufactured goods, less flaws and better resultant yarn quality.

Owner:SHANGHAI FEILIAN TEXTILE

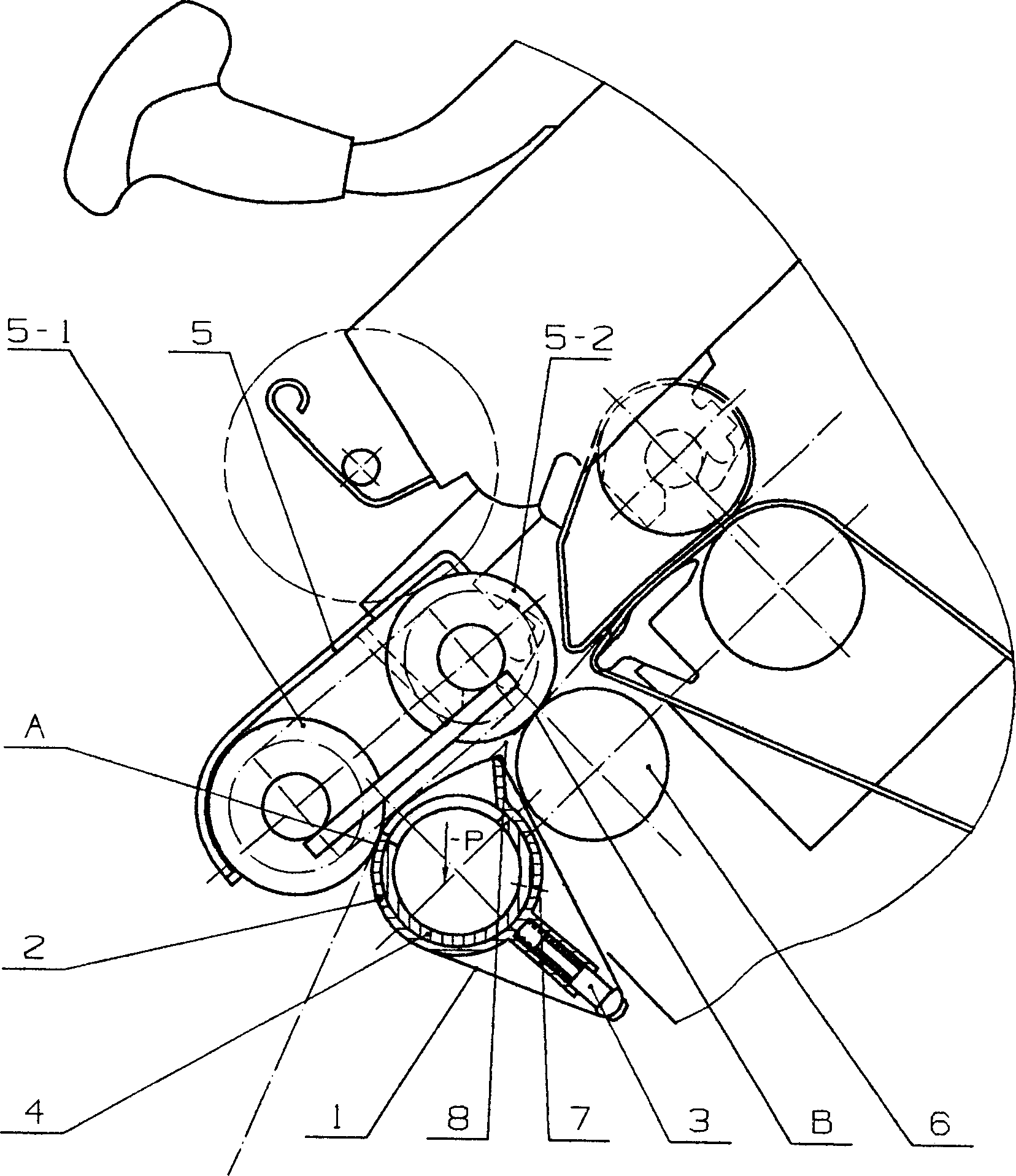

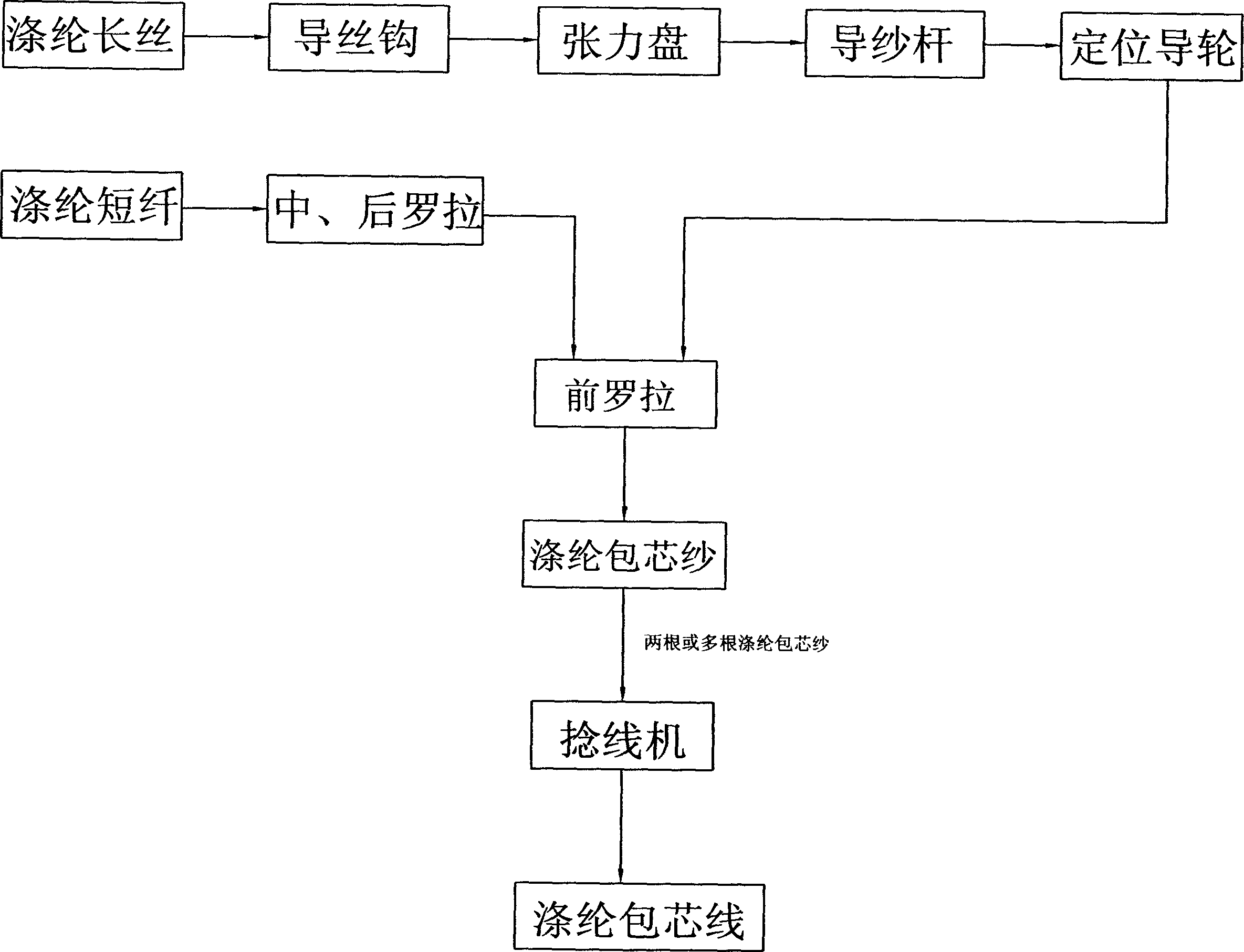

Terylene wrapped core wire and fabrication method

This invention discloses a terylene core-spun thread twisted by two or many terylene core-spun yarns composed of terylene long silk wrapped by terylene short fibers, the process method is as follow: 1) the processed long silks and the short fibers after middle and rear roller drawing are fed into a front roller. 2) the short fibers wrap the long silks in the front roller to become the terylene core-spun yarn to be output from the roller clamp, 3) two or many terylene core-sun yarns are twisted to terylene core-spun threads. The long silk tension is stabilized and controlled by godet hook and a tension disk then to be fed into the front roller after positioning by the carrier rod and the locationing guide wheel.

Owner:CHUNYAN TEXTILE GUANGDONG

Production method for spun-silk wool blended worsted fabrics

ActiveCN103774319AGood extensibilityGuaranteed smooth productionWoven fabricsYarnFiberAfter treatment

The invention relates to a production method for spun-silk wool blended worsted fabrics and relates to the technical field of textile manufacture. The method comprises top dyeing and recombing, spinning, weaving and after treatment to manufacture the fabrics successively. The mass percentage of wool in spinning raw materials accounts for 50% to 60%, the mass percent of spun silks ranges from 40% to 50%, the spun silk raw materials are machined and are broken through a breaking machine to be manufactured into spun silk velvet strips with the average length between 40mm and 50mm, the length discretion smaller than 50%, and the gram weight ranging from 5g / m to 8g / m. The spun silk velvet strips with the fiber length smaller than 30mm account for less than 30% of the total spun silk velvet number. According to the production method, the spun silk content is high, the spinnability is good, the yarn levelness quality is guaranteed effectively, and yarn faults are few.

Owner:江苏丹毛时装有限公司

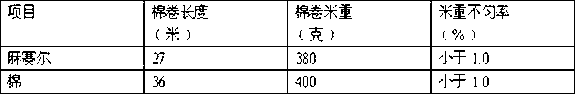

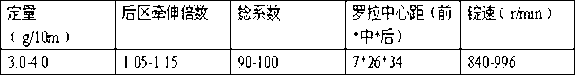

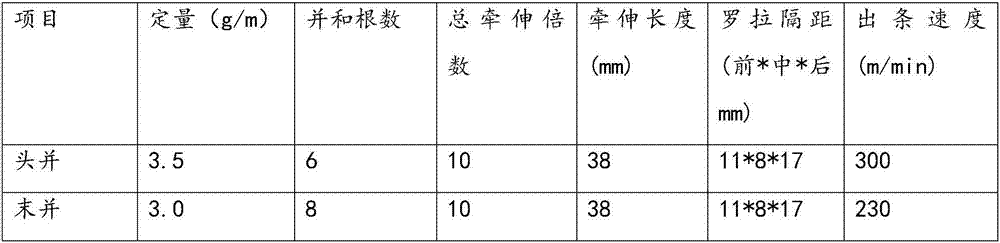

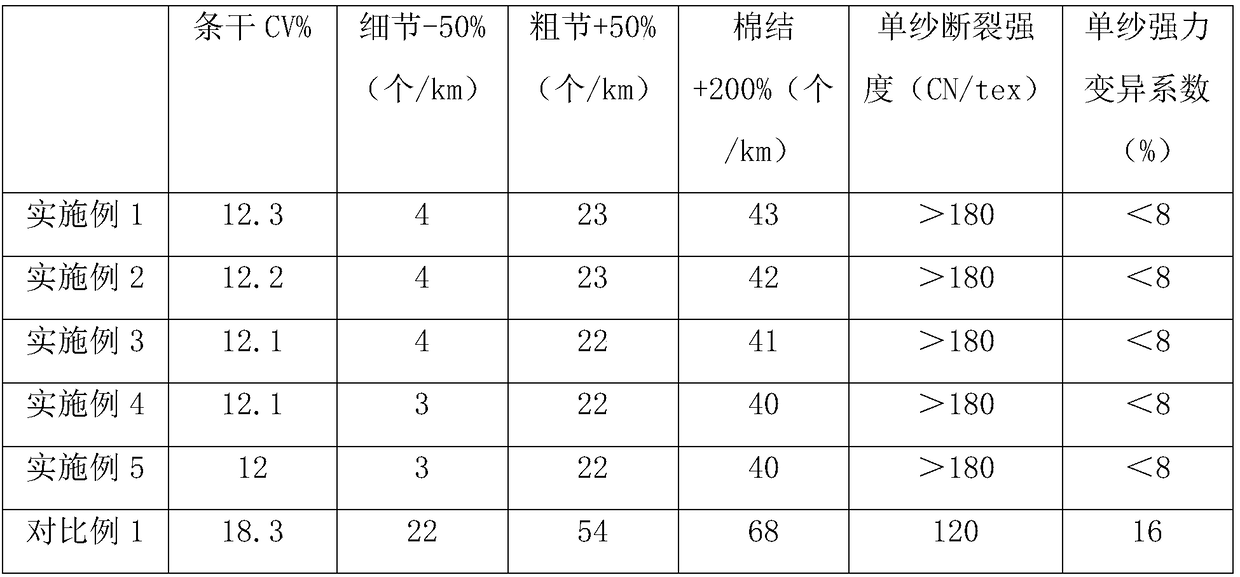

Production technology for siro compact spinning combed cotton and cellulosic fiber blended yarn

The invention discloses a production technology for siro compact spinning combed cotton and cellulosic fiber blended yarn. The technology includes the following steps that 1, fiber ribbons are spun; 2, spinning of the blended yarn includes the processes of drawing, roving, spinning and spooling. Cellulosic fibers in chemical fibers are used for replacing part of cotton fibers, through a siro compact spinning technology, combed cotton and cellulosic fibers are blended to prepare yarn, and combed cotton and cellulosic fibers are blended to prepare yarn with part of differentiated chemical fibers, the advantages of multi-component fibers are exerted, performance complementation of all the fibers is realized, respective defects are overcome, the quality of the yarn is remarkably improved, andthe gloss is improved; after the yarn is processed into a fabric, serviceability and home textile performance are more comprehensive, and the fabric quite accords with the pursue of people for clothing, costumes and home use.

Owner:河南省禹州市神禹纺织有限公司

Fire-prevention and flame-retardant aramid fiber yarn and preparation method thereof

The invention provides a fire-prevention and flame-retardant armid fiber yarn. The armid fiber yarn comprises the following components by weight ratio: 93% of polyisophthaloyl metaphenylene diamine fiber, 5% of poly-p-phenylene terephthamide and 2% of carbon-guiding fiber. The invention also provides a preparation method of the fire-prevention and flame-retardant fiber yarn. The preparation method comprises the steps of a. raw material preparation, b. blowing process, c. cotton carding process, d. drawing and doubling process, e. spinning process and f. post processing process. The fire-prevention and flame-retardant aramid fiber yarn has the beneficial effects that the yarn levelness is uniform, the strength is strong, the yarn hairness and the yarn fault are few, the flame retardant property is good, the aramid fiber yarn has good radiation resisting property, acid resisting property, alkali resisting property and other various chemical properties, cannot be softened and melted under high temperature due to high temperature resistance, and is stable in prolongation due to good mechanical property so as to be completely suitable for fire-prevention and flame-retardant requirements of spaceflight, military use and civil use.

Owner:PINGHU RISHU TEXTILE

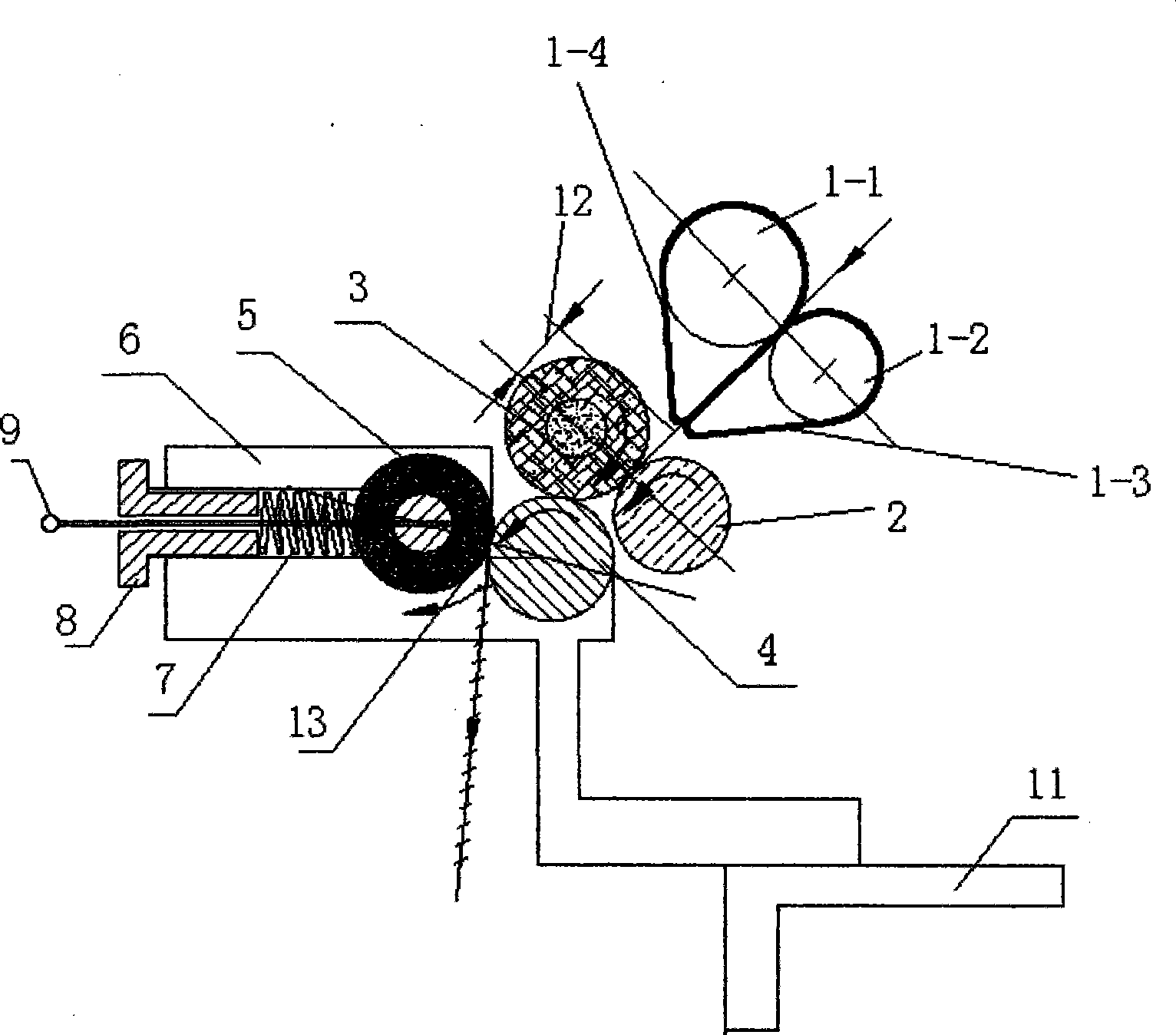

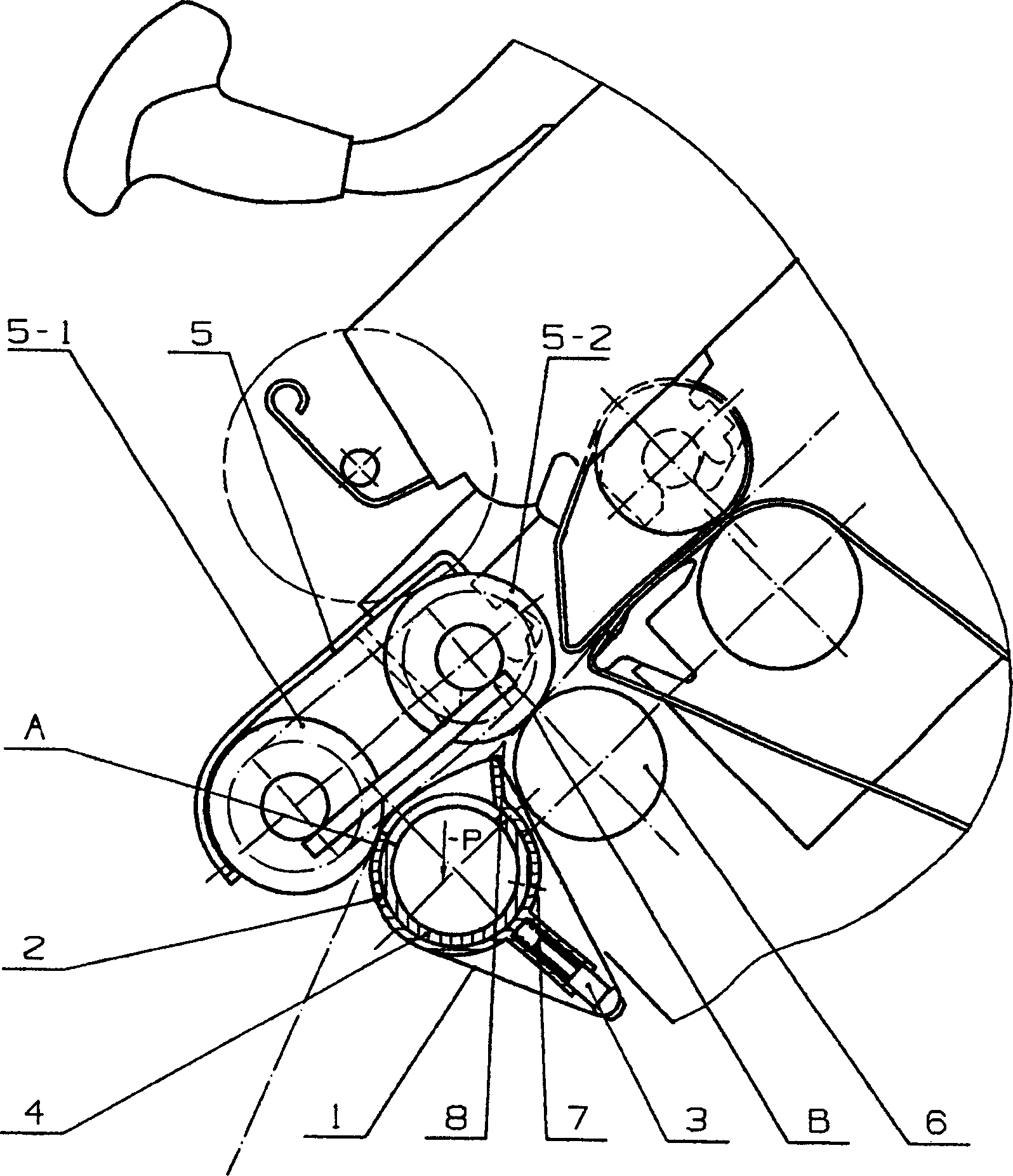

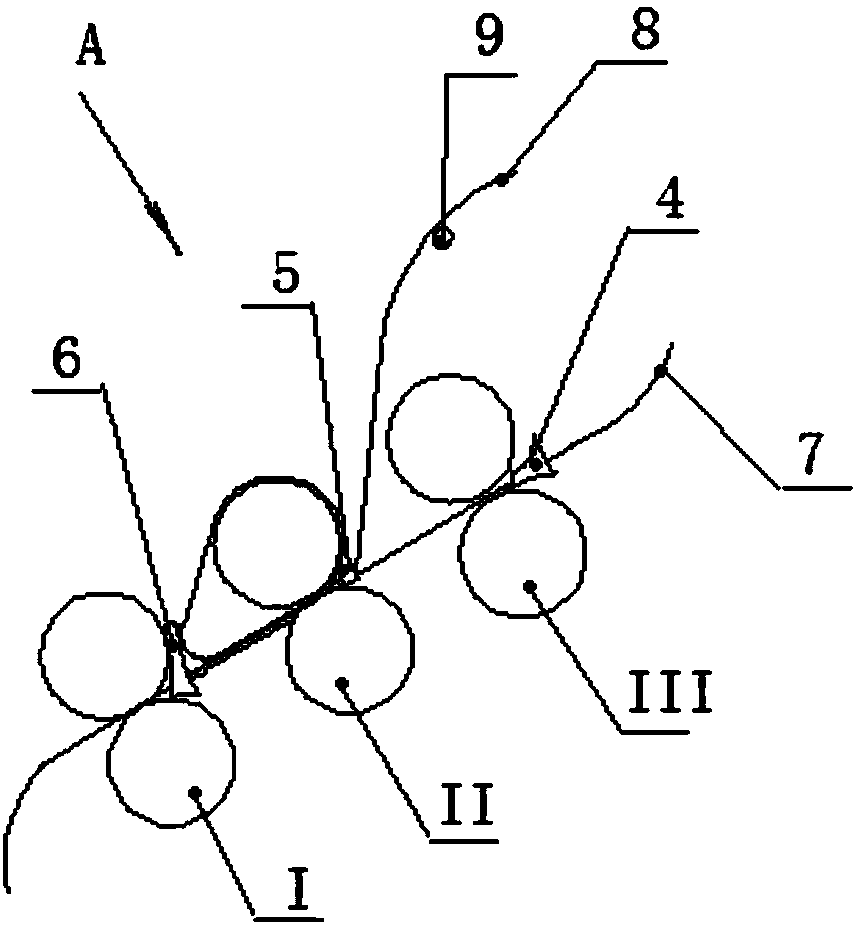

Compact twin-spunyarn spinning device

The invention relates to a compactness strand spinning device that includes a drafting assembly, two fiber sticks, a gathering area, a conveyer belt, air intake sew and twister. Two paralleled air intake sews are not paralleled to the moving direction of conveyer belt. The advantages of the invention are low yarn faults, better bar, and stronger brute force. It could also be used to produce compactness strand spinning composite yarn and worsted spinning strand and chemical fiber. The application value of spinning fiber would be improved.

Owner:NINGBO DECHANG PRECISION TEXTILE MACHINERY

Viscose fiber and leecy fiber blended yarn and spinning technology thereof

The invention discloses a viscose fiber and leecy fiber blended yarn and a spinning technology thereof. The blended yarn comprises viscose fibers with the fiber content blending ratio of 60-70%, and leecy fibers with the fiber content blending ratio of 30-40%. The fibers are woven into the yarn through the spinning technology. Firstly, after the leecy fibers are subjected to opening and picking and cotton carding, the leecy fibers and the viscose fibers are mixed, then opening and picking and cotton carding are carried out, and the leecy fibers and the viscose fibers can be mixed to be uniform; due to the fact that the leecy fibers with the durable physical bacteriostasis function are added, the viscose fiber finished products can be prepared into the yarn with the antibacterial function directly through the following spinning technology, it is not needed to independently carry out antibacterial treatment on the viscose fiber finished products, the technology is simplified while the antibacterial effect is guaranteed, the production cost is reduced, fabric woven from the viscose fiber and leecy fiber blended yarn can be rapidly dyed, the colors are gorgeous, gradually varied and rich in layering sense after the fabric is colored, and multiple colors can be obtained through one time of dyeing.

Owner:宜宾恒丰丽雅纺织科技有限公司

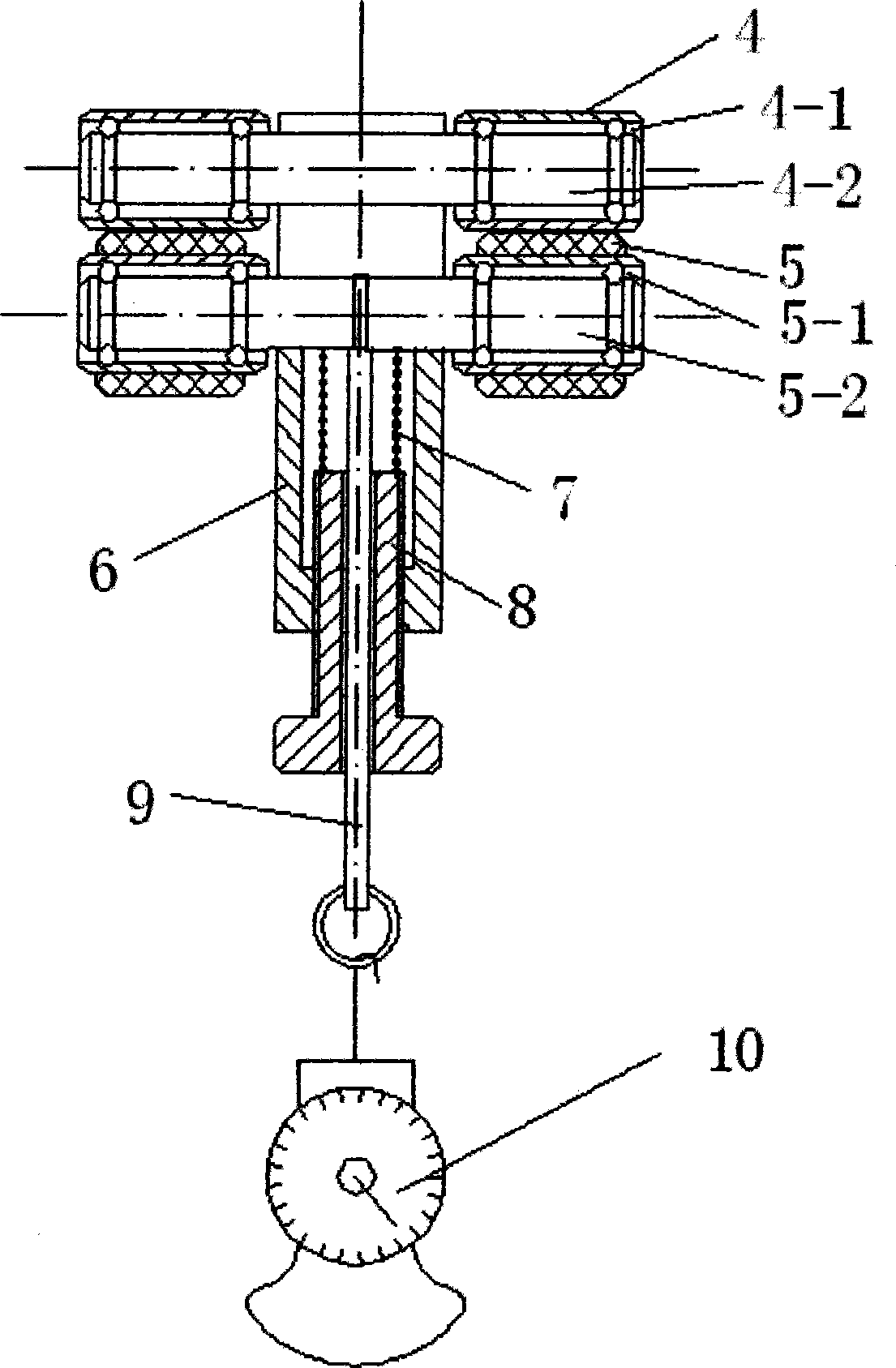

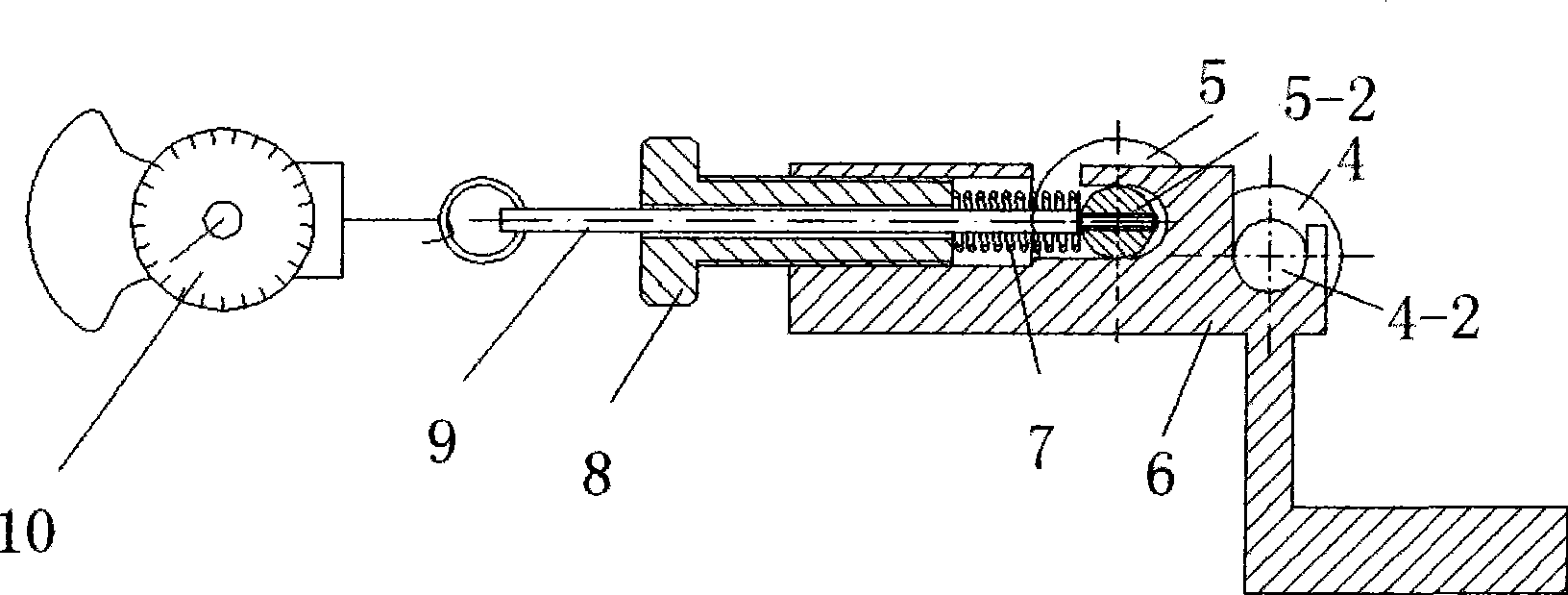

Yarn leading roller apparatus for ring spinner

InactiveCN101451284AImprove uniformityReduce the differenceDrafting machinesContinuous wound-up machinesFiberYarn

The invention discloses a doffing roller device for a ring spinner, in particular a doffing roller device for a cylindrical spring-pressurized rocking frame of the ring spinner. The doffing roller device consists of an original rocking frame, a doffing roller, a roller mandrel, a doffing belt roller, a doffing belt roller mandrel, a device seat, a pressurization spring, a pressurization bolt, a bearing, a force metering lever and a dynamometer. When used, a front belt roller of the original rocking frame drives the doffing roller to rotate; and the doffing roller drives the doffing belt roller to rotate. A drawing fiber strand passes through an original front roller pair, is transferred to between the doffing roller and the doffing belt roller and is twisted to form yarn. The doffing roller device has the advantages that yarn strips are even; the length of a floating region and a weak twisting region can be adjusted respectively and independently; and the pressurizing of the doffing belt roller can be directly measured and is convenient to implement.

Owner:上海依福瑞实业有限公司

Blended yarn of Shu elastic silk fibers and cotton fibers and spinning process thereof

The invention relates to a blended yarn of Shu elastic silk fibers and cotton fibers and a spinning process thereof. The blended yarn has the advantages of the Shu elastic silk fibers and cotton, is transcendental in size stability, natural, soft, high in air permeability and abrasive resistance, capable of being widely applied in the fields of cowboy costume, formal clothes, sport suit, knitted underwear and home textile, and broad in market prospect. According to the preparation process, the difficulties that the Shu elastic silk which serves as raw material fibers is high in elasticity and uneasy to reel separately and has too much crimps are overcome, the Shu elastic silk fibers and the cotton fibers are blended according to a blending proportion, and a cotton carding process, a roving process and a spun yarn process in the later period are completed. According to the process, the spun yarn process is adjusted, and the problem is solved that since the rebound resilience of the Shu elastic silk is high, coiling strips serving as raw materials are difficult to shape; a big-ration high-drafting process is achieved, the supply in the early period and the supply in the later period can be ensured, and the prepared blended yarns are high in single yarn intensity, small in variable coefficient and high in stability of fiber strength, show excellent rebound resilience, and meet demands of downstream manufacturing.

Owner:威海魏桥科技工业园有限公司

Tightness spinning device of ring spinning frame

InactiveCN1279231CImprove delivery formHigh strengthDrafting machinesContinuous wound-up machinesFiber bundleEngineering

The compact spinning device of the ring spinning machine in the textile industry, including the drafting roller pair, the roller seat and the cradle pressurization device, is characterized in that it also has two ends fixed on the adjacent two roller seats and has a suction port and an exhaust port. The suction pipe is set outside the suction pipe and has a condensation sleeve with a condensation groove in the circumferential direction corresponding to the position of the suction port. The tensioning device stuck in the chute of the condensation sleeve is set between the condensation groove and the tensioning device The air-permeable conveying ring and its transmission pressurization device on the top, the pressurization device is installed on the front claw of the cradle body. Using this device can greatly improve the shape of the output fiber bundle before twisting, with high yarn strength, less hairiness, evenness and less yarn defects.

Owner:SHANGHAI TEXTILE MACHINERY CO LTD OF PACIFIC MECHATRONIC GRP

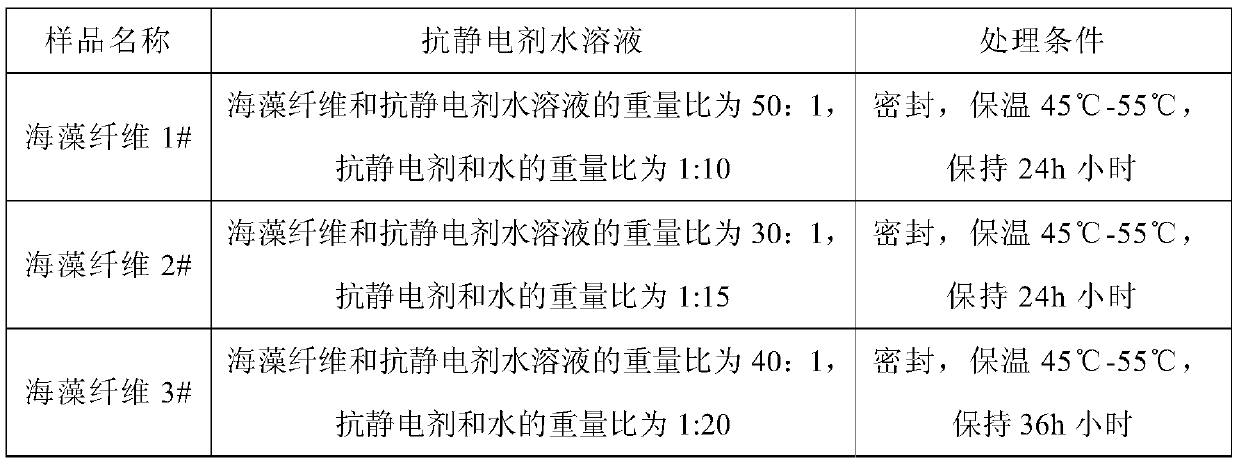

Blended yarn and preparation method and application thereof

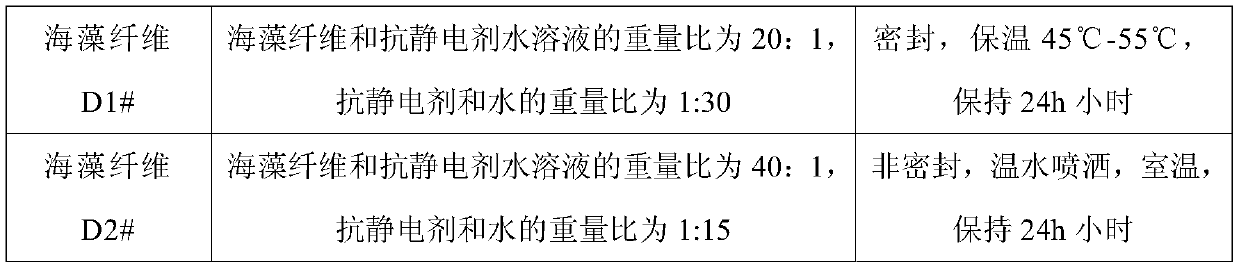

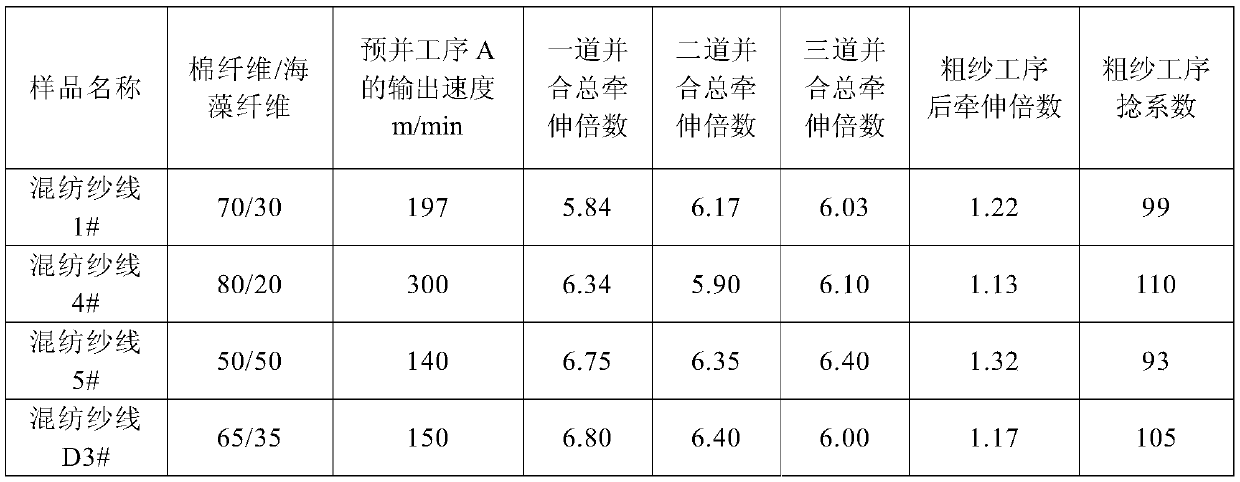

The invention relates to the technical field of textiles, in particular to a blended yarn and a preparation method and application thereof. The method comprises the following steps that pretreated seaweed fibers are subjected to treatment of a blowing process A, a carding process A and a pre-drawing process A to obtain pre-drawn seaweed fiber raw slivers A; cotton fibers are subjected to treatmentof a blowing process B, a carding process B, a pre-drawing process B, a winding process B and a fine combing process B to obtain finely combed cotton slivers B; the prepared pre-drawn seaweed fiber raw slivers A and the finely combed cotton slivers B are subjected to treatment of a mixing process, a roving process and a spinning process to obtain the blended yarn. The blended yarn can be used formanufacture of a knit or a fiber product. The blended yarn is good in single yarn evennes and has few neps and yarn defects, and the comfort of a fabric can be further improved, so that the fabric issmooth in surface, exquisite and delicate in texture and clear in pattern.

Owner:WEIQIAO TEXTILE

Yarn blended with silver fiber and cotton fiber and preparation technology

The invention relates to a yarn blended with silver fiber and cotton fiber and preparation technology, and the yarn is blended with silver fiber and combed cotton fiber through blending, wherein, the content of the silver fiber is 1-50%, and the balance is cotton fiber. The preparation technology comprises the steps of flower removing, cotton combing, preparation, fine combing, blending of silver fiber and combed cotton strip of combed cotton fiber, mixing, roving, spinning and automatic winding. The advantages are that the characteristics of both the silver fiber and the cotton fiber are provided; the yarn has high intensity, good wear resistance, moisture absorption, ventilation, strong antibacterial performance, and radiation hardening. The technology has the advantages that the blending ratio is accurate; the components are uniform; the blended yarn manufactured thereby has a strong force of a single thread, little hairiness, uniform strips, little cotton knobs and little yarn defects.

Owner:山东宏儒纺织科技有限公司

Antibacterial healthcare multi-component fiber integrated blended yarn, production method and application

The invention discloses an antibacterial healthcare multi-component fiber integrated blended yarn and a preparation method thereof. The yarn comprises an aloe viscose fiber, a Viloft fiber and a cashmere fiber, the weight content of the aloe viscose fiber accounts for 30-65%, the weight content of the Viloft fiber accounts for 25-50%, and the weight content of the cashmere fiber accounts for 10-25%. Performance indexes of the blended yarn include single yarn breaking strength 12.0-19.9cN / tex, a single yarn breaking strength variable coefficient Cv value 7.8-17.0% and a yarn evenness variable coefficient Cv value 12.9-21.0%. The blended yarn has the advantage that a fabric made of the blended yarn has healthcare functions such as bacteria resistance, inflammation diminishing, skin care, body building, beauty and skin moistening, is fine in skin friendliness, has fine comfort, high strength, fine moisture absorption breathability, fine dyeing property, soft hand feeling and fine fullness, moisture guiding breathability, warmth retention property and ecological environmental protection property, is noble, elegant and unique in appearance, bright in color, rich in gloss and wide in application, and can be used for manufacturing various knitted or woven healthcare textiles such as various garments, bedding articles, underwear, sportswear and workout clothes.

Owner:ZHONGYUAN ENGINEERING COLLEGE

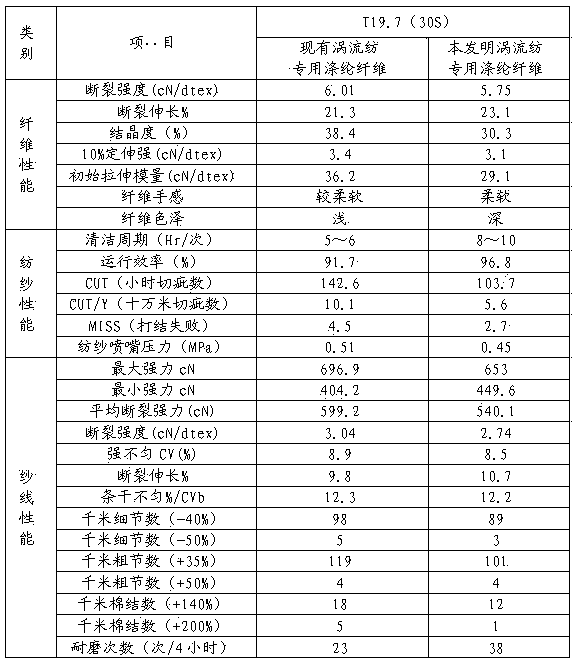

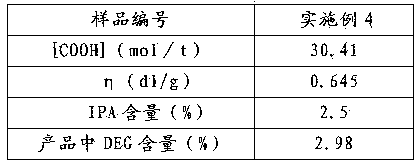

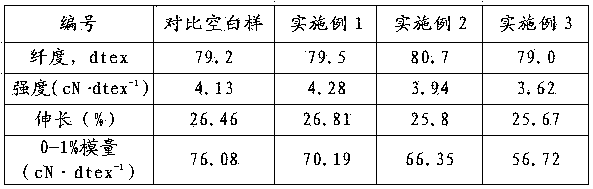

Preparation method of polyester staple fiber used for vortex spinning

ActiveCN104233500ASoft touchDeep colorMonocomponent copolyesters artificial filamentAlcoholCopolyester

The invention provides a preparation method of polyester staple fiber used for vortex spinning, which takes PTA and IPA as diacid, and takes EG as dihydric alcohol for performing an esterification reaction, then DEG is added, and is polycondensated under catalysis of a catalyst to prepare copolyester, and then the copolyester is treated through a polyester staple fiber spinning technology to prepare the polyester staple fiber used for vortex spinning. The IPA and DEG take effect together, the crystallization property of copolyester is decreased, the fiber modulus is reduced by 7-50%, breaking tenacity is reduced by 3-10%, hand feel flexibility can be greatly enhanced, and vortex spinning requirement can be satisfied.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Production process for flame-retardant sewing threads

The invention discloses production process for flame-retardant sewing threads. The flame-retardant sewing threads are prepared by processing of 100% of 1.5D*51mm aramid 1313 fibers with yarn count being 40s / 3. The production method of flame-retardant sewing threads comprises the following steps: pre-processing aramid 1313 fibers; performing opening picking on pre-processed aramid 1313 fibers, performing cotton carding operation on pre-processed aramid 1313 fibers, drawing pre-processed aramid 1313 fibers, performing roving operation in order to form aramid fiber 1313 roving; utilizing siro spinning yarns to spin aramid fiber 1313 roving into aramid 1313 single yarns; making single yarns into aramid 1313 three folded yarns through an automatic winding machine, yarn doubling and piling operation; making three folded yarns into aramid 1313 sewing threads through yarn steaming and setting process; performing humidification and moisture preservation operation on half finished products in all processes such that the moisture regain is kept within 9%-10%. With compact siro-spinning technology, the end breakage rate of spun yarns is decreased at 1 hour of every 1000 spindles. Yarn faults are reduced. Therefore, production efficiency is relatively increased. The flame-retardant sewing threads are higher in quality.

Owner:SHANDONG HONGYE TEXTILE

Cotton yarn production process

The invention provides a cotton yarn production process. Cotton serves as a raw material, and the cotton yarn production process includes the procedures of blowing, cotton carding, drawing, roving, spinning, spooling and baling. The blowing procedure includes the steps of plucking, opening, scutching, cotton blending and lapping. Before plucking, 0.002-0.003 time by weight of antistatic agents and0.006-0.007 time by weight of water are sprayed to the cotton, ultrasonic oscillation is performed, so that the cotton sufficiently absorbs moisture, cotton fiber surfaces are activated, and a reciprocation bale plucker is used for plucking. The roving procedure is characterized in that parts of slivers obtained by drawing are made into roving intermediates by a roving machine through drafting and twisting, residual slivers and the roving intermediate are fed into the roving machine together to prepare rough yarns, and the rough yarns are wound into rolls. The spinning procedure adopts Siro compact spinning. The cotton yarn production process is good in yarn quality.

Owner:辉县市鑫海纺织有限公司

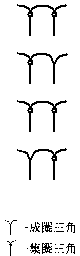

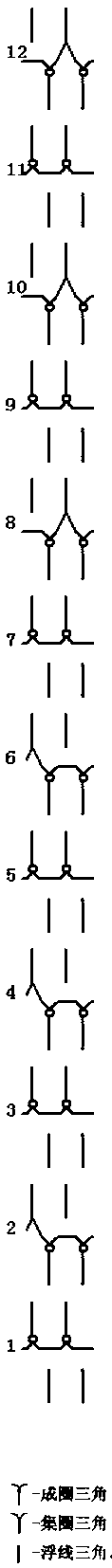

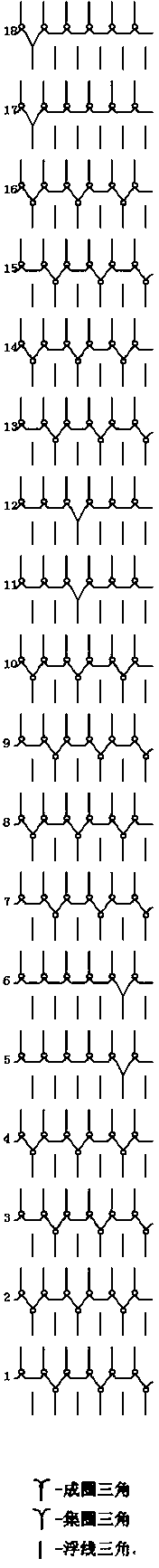

Processing technology of multifunctional photocatalytic knitwear

The invention discloses a processing technology of multifunctional photocatalytic knitwear and belongs to the technical field of textile processing. The processing technology comprises yarn forming, weaving and dyeing and finishing; photocatalytic fibers and one of cotton fibers, bamboo fibers and tencel are subjected to processes of the first drawing, the second drawing, combing, the third drawing, the fourth drawing, roving and spinning respectively after opening and carding to obtain photocatalytic blended yarn; the photocatalytic blended yarn is woven according to different looping triangle, tucking triangle and floating thread triangle tissue modes to obtain original fabric; and the original fabric is dyed and finished sequentially according to the following steps of singeing, desizing, bleaching, primary soaping, cationic dyeing, reactive dyeing, secondary dyeing, softening treatment, heat setting, checking of finished products, rolling and storing. The multifunctional photocatalytic knitwear which is good in serviceability, antibacterial, ultraviolet-resistant, deodorant and anti-static can be produced through the processing technology which can be applied to processing and post-processing processes of textiles.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Blended yarn of tussah silk and cotton fiber and spinning method of yarn

The invention discloses a blended yarn of tussah silk and cotton fiber and a spinning method of the yarn and belongs to the field of spinning. The blended yarn is formed by blending the tussah silk with the cotton fiber, wherein the content of the tussah silk in the blended yarn is not higher than 60 wt%, and the balance is the cotton fiber; the fineness of the blended yarn is 20-120 S; single-yarn breaking strength of the blended yarn is 430-120 CN, and the size of neps is 5 / 50-150 / 480. The high-quality blended yarn fills up the market blank, is uniformed in component and evenness, high in single-yarn strength and low in hairiness and has few neps and yarn defects. According to the spinning method, combed cotton strips and tussah silk strips are directly subjected to mixed blending, the spinning flow is short, damage caused to the tussah silk is small, the utilization rate is high, the spinning cost is low, and the controlled blending ratio is accurate.

Owner:WEIQIAO TEXTILE

Novel blended yarn and production process thereof

InactiveCN104862842ALess hairyImprove the defect of poor wrinkle resistanceYarnPolymer scienceCotton fibre

The invention discloses novel blended yarn and a production process thereof. The novel blended yarn is formed by blending cotton fibers with the blending ratio being 50%, bamboo pulp fibers with the blending ratio being 40% and soybean protein fibers with the blending ratio being 10%. The novel blended yarn has the advantages that a compact Siro spinning technology is adopted, raw materials are reasonably mixed, the defect of poor crease resistance of the soybean protein fibers is overcome, the soybean protein fibers are prevented from pilling to a large extent, and the size stability of fabric is improved. The problems that the bamboo pulp fibers are poor in hand feel, skin friendliness and cohesive force are solved. The produced yarn is good in strength, high in evenness, good in breathability, fluffy and soft, and has good skin friendliness and health care functions. The three-blending mode is adopted, the blending ratio can be more accurate, ingredients are even, produced single yarn is high in evenness, the strength of the single yarn is high, the number of cotton neps is small, and the number of yarn faults is small. The yarn variety enables fabric to have good breathability, to be fluffy and soft and to have good skin friendliness and a health care function.

Owner:NANTONG YUEDA KNITTING GARMENT

Production method capable of fully improving tussah silk wool blended yarns

The invention relates to a production method capable of fully improving tussah silk wool blended yarns. Blended yarn materials are successively dyed, recombed, and spun by wool worsted corollary equipment to obtain yarns; the blended yarn materials include wools and tussah silks, wherein the mass percent of the wools is 50%, the length of the wools is 90 mm, the mass percent of the tussah silks is 50%, and the length of the tussah silks is 105 mm. Through selection of tussah silk materials, technology improvement, and equipment upgrading, the spinnability is improved, the production can go smoothly, and the yarn fault is reduced, so that the production efficiency and the spinning yield are improved, and the product quality is assured.

Owner:JIANGSU DANMAO TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com