Production process for flame-retardant sewing threads

A production process and sewing thread technology, applied in the field of flame retardant sewing thread production process, can solve the problems of low strength, poor color fastness, and high glass transition temperature, and achieve improved production efficiency, reduced end breakage, and yarn defects. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

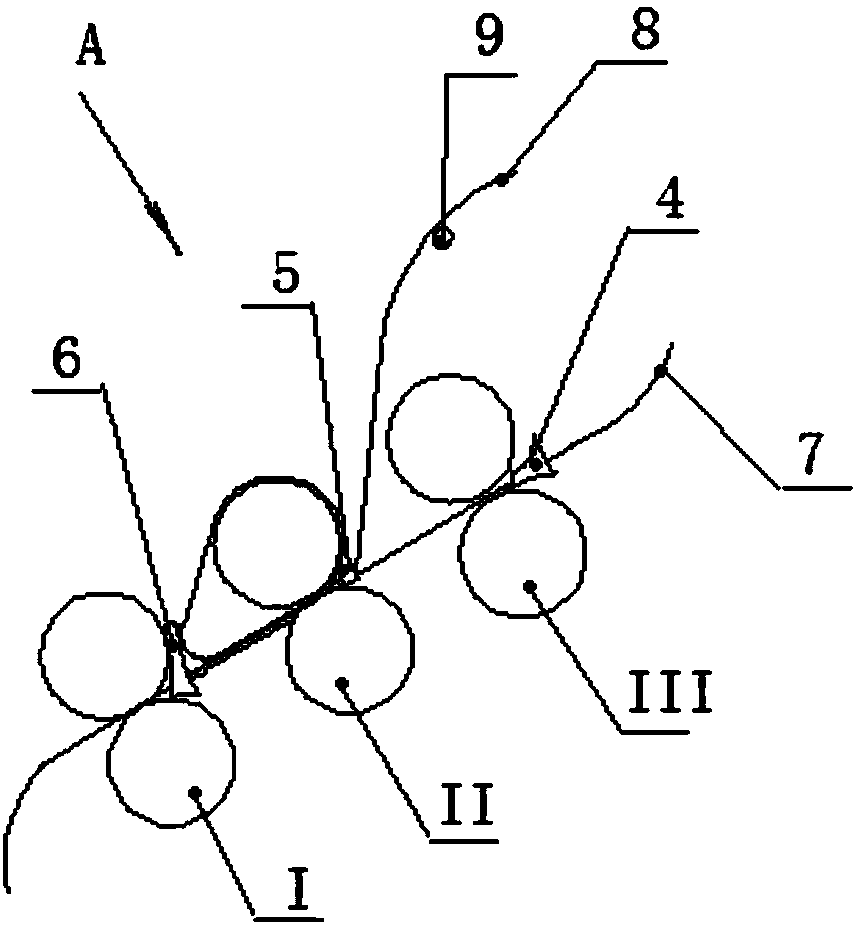

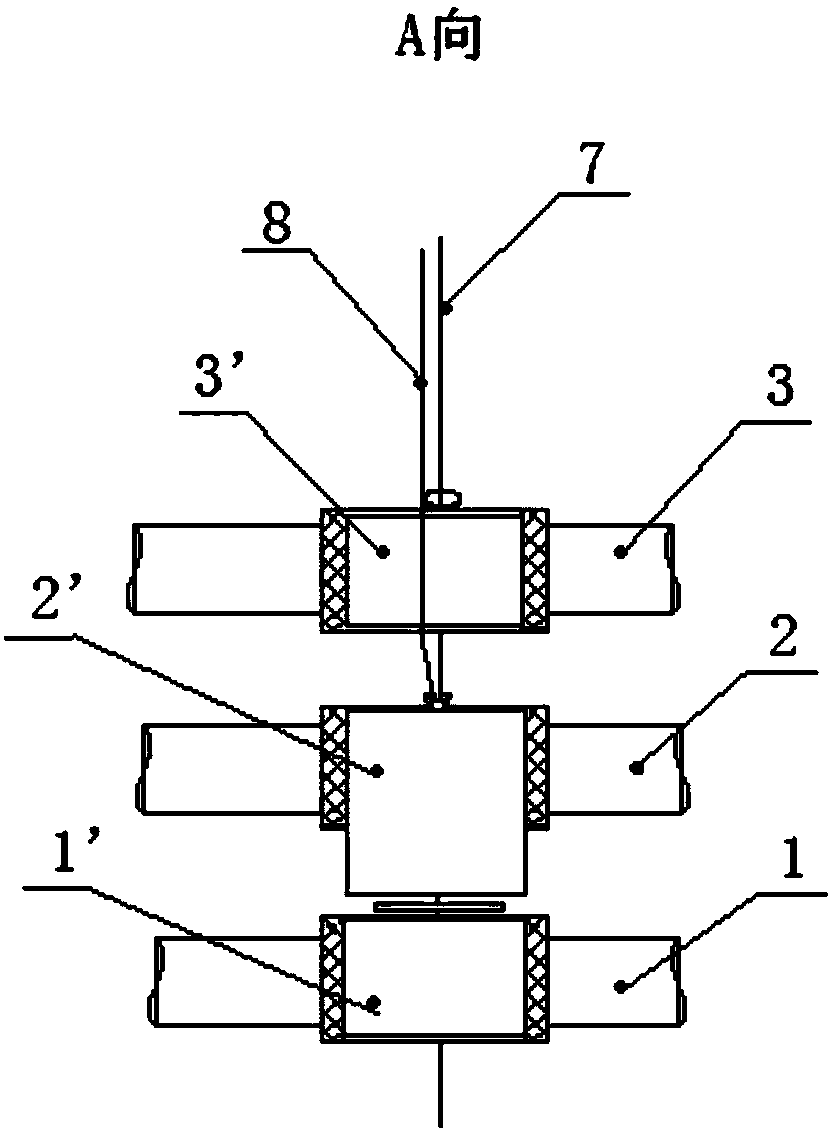

Image

Examples

Embodiment

[0034] Example: 100% of 1.5D╳51mm aramid fiber 1313 is processed, and the yarn count is 40 s The process parameters of each process described in / 3 are:

[0035] ---Cleaning: Lap length 30.6m, basis weight 400g / m, lap roller speed 10r / min, combined beater speed 800r / min 480r / min;

[0036] ---Carding: raw sliver quantitative grams / 5m 18.5 cylinder speed 360 rpm / min licker-in roller speed 760 rpm / min cover plate speed 81 mm / min doffer speed 25 rpm / min four points between cylinder and cover plate Gauge / mm0.25, 0.20, 0.20, 0.25;

[0037] ---Drawing frame: merging method with 8 wires in both lanes, fixed weight (g / 5m), combined number, drafting multiple, roller gauge (mm), speed (m / min) 20.0 8 8.13 11×8×18 206;

[0038] --- Roving: Quantitative (g / 10m), twist coefficient, drafting multiple, roller gauge (mm), front roller speed (rev / min) 5.066 8.1 9.5×24.5×35.5 210; the twist coefficient is too small to master, and the roving tension should be biased small control;

[0039] --...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com