Patents

Literature

30results about How to "High single yarn strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

Cotton fiber and jutecell fiber blended yarn and spinning process thereof

The invention discloses a cotton fiber and jutecell fiber blended yarn and a spinning process thereof. The blended yarn comprises jutecell fiber with fiber content blending ratio as 70% and 30% fine staple cotton. The fibers are spun into yarns through the blended spinning process. Raw materials of the yarns are composed of the jutecell fiber and the fine staple cotton. Compared with the prior art where long staple cotton and jutecell fiber are used for blended spinning, the process is low in cost and high in cost performance. The blending mode of one pre-blending and three mixed-blending is adopted, so that the blending spinning ratio is accurate, and components are even. The blended yarns produced in the production process are high in single yarn strength, even in yarn levelness and few in nep and yarn fault. The yarn structure can further improve textile comfortableness, improve textile hand feel and improve lining grade.

Owner:山东超越纺织有限公司

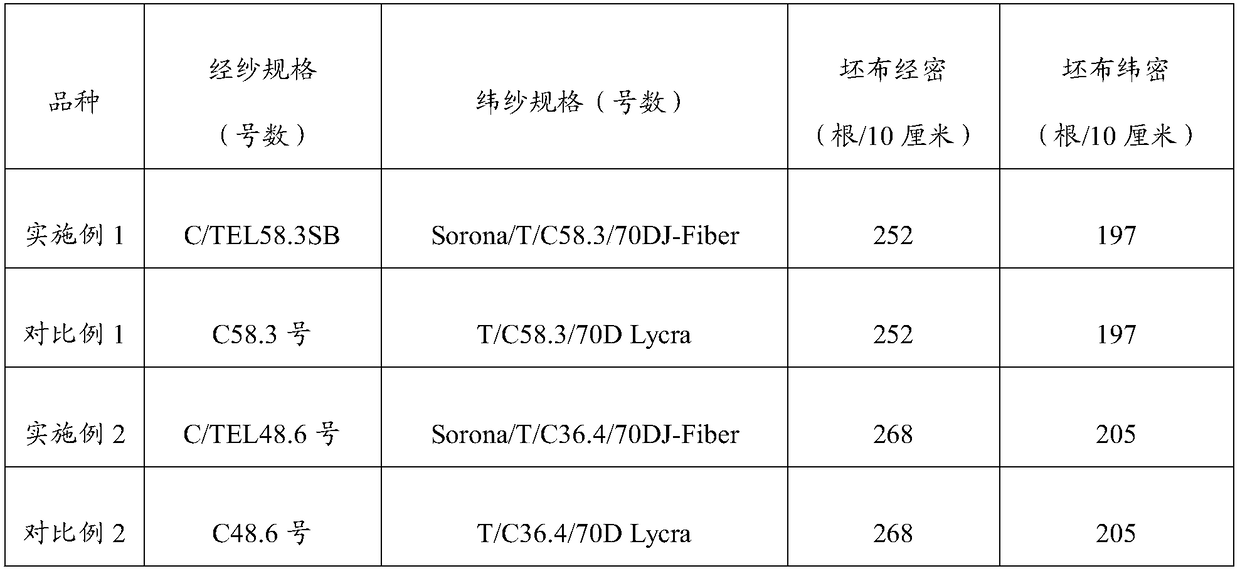

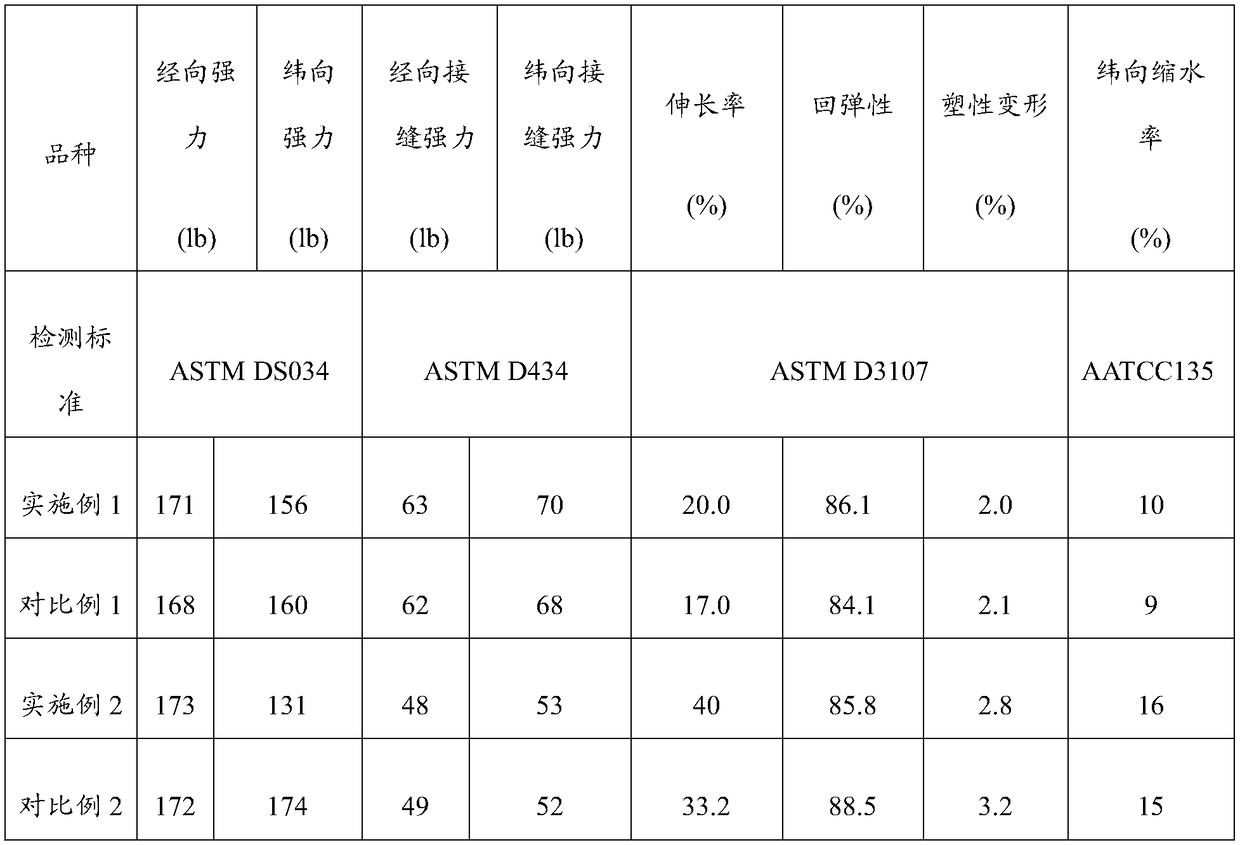

Fabric and preparation method thereof

InactiveCN109183250AHigh single yarn strengthEnhance inner strengthFabric breaking/softeningSingeingYarnFiber

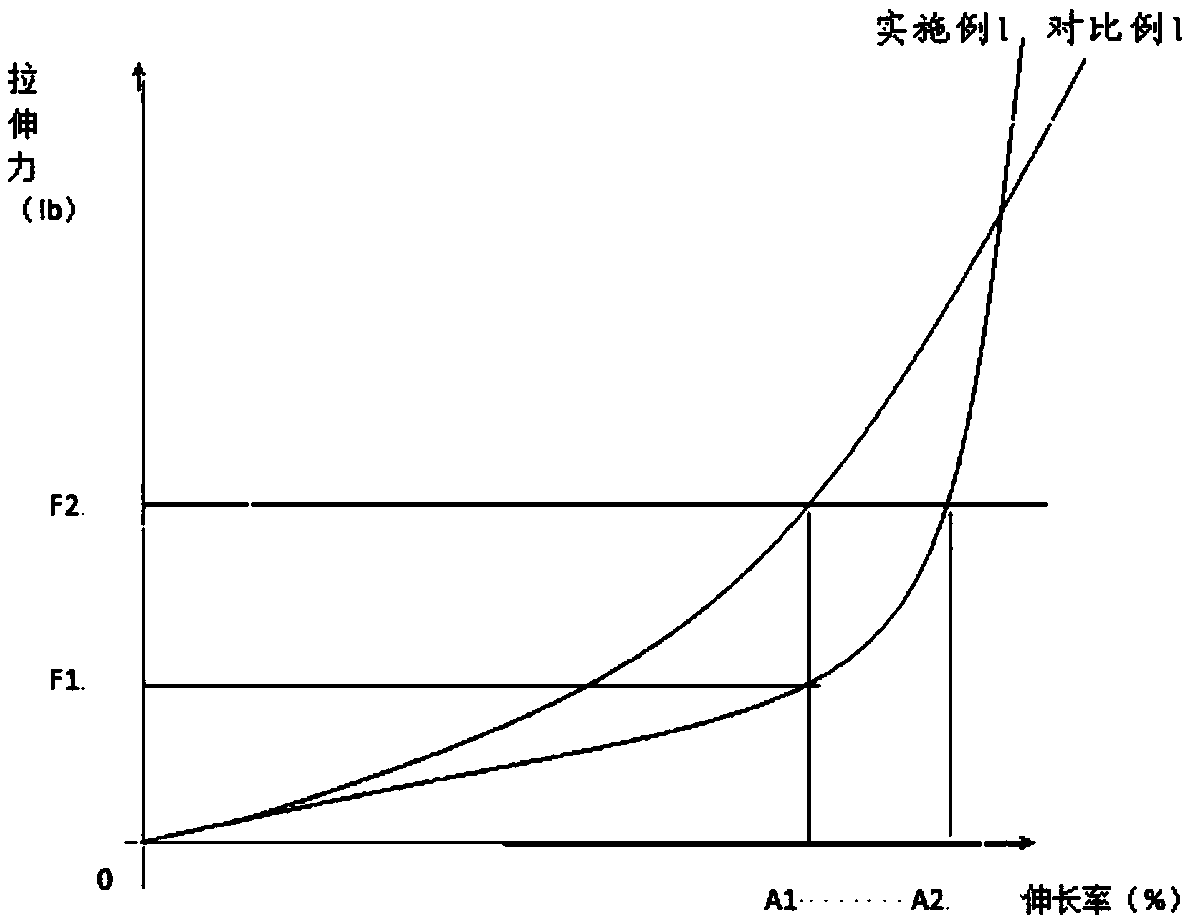

The invention provides a fabric, and belongs to the technical field of textile fabric preparation. The fabric takes a Sorona staple fiber with certain elasticity as an outer wrapping fiber, the innercore adopts an X4zol<TM>-J single-hole spandex filament, both the inner and outer materials of the core-spun yarn have certain elasticity, the Sorona staple fiber has tensile elasticity and recovery with soft and comfortable hand feeling and lasting shape-preserving property, the X4zol<TM>-J single-hole spandex filament has the characteristics of unique tension and recovery, easy tension and easyrecovery compared with other elastic spandex, the combination of the Sorona staple fiber and the X4zol<TM>-J single-hole spandex filament complement each other and achieves an unexpected elasticity effect, thereby being an exceptional combined elastic new product. According to the invention, five fibers (cotton, tencel, Sorona staple fiber, terylene and X4zol<TM>-J single-hole spandex filament) with different performance and different attributes are applied to the same denim fabric, thereby achieving exceptional hand feeling, elastic comfort and difficult arch deformation.

Owner:韶关市北纺智造科技有限公司

Blended yarn of Shu elastic silk fibers and cotton fibers and spinning process thereof

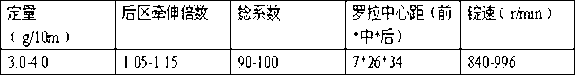

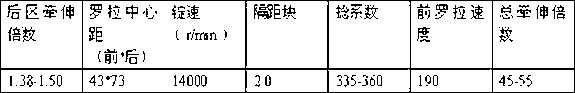

The invention relates to a blended yarn of Shu elastic silk fibers and cotton fibers and a spinning process thereof. The blended yarn has the advantages of the Shu elastic silk fibers and cotton, is transcendental in size stability, natural, soft, high in air permeability and abrasive resistance, capable of being widely applied in the fields of cowboy costume, formal clothes, sport suit, knitted underwear and home textile, and broad in market prospect. According to the preparation process, the difficulties that the Shu elastic silk which serves as raw material fibers is high in elasticity and uneasy to reel separately and has too much crimps are overcome, the Shu elastic silk fibers and the cotton fibers are blended according to a blending proportion, and a cotton carding process, a roving process and a spun yarn process in the later period are completed. According to the process, the spun yarn process is adjusted, and the problem is solved that since the rebound resilience of the Shu elastic silk is high, coiling strips serving as raw materials are difficult to shape; a big-ration high-drafting process is achieved, the supply in the early period and the supply in the later period can be ensured, and the prepared blended yarns are high in single yarn intensity, small in variable coefficient and high in stability of fiber strength, show excellent rebound resilience, and meet demands of downstream manufacturing.

Owner:威海魏桥科技工业园有限公司

Yarn blended with silver fiber and cotton fiber and preparation technology

The invention relates to a yarn blended with silver fiber and cotton fiber and preparation technology, and the yarn is blended with silver fiber and combed cotton fiber through blending, wherein, the content of the silver fiber is 1-50%, and the balance is cotton fiber. The preparation technology comprises the steps of flower removing, cotton combing, preparation, fine combing, blending of silver fiber and combed cotton strip of combed cotton fiber, mixing, roving, spinning and automatic winding. The advantages are that the characteristics of both the silver fiber and the cotton fiber are provided; the yarn has high intensity, good wear resistance, moisture absorption, ventilation, strong antibacterial performance, and radiation hardening. The technology has the advantages that the blending ratio is accurate; the components are uniform; the blended yarn manufactured thereby has a strong force of a single thread, little hairiness, uniform strips, little cotton knobs and little yarn defects.

Owner:山东宏儒纺织科技有限公司

Blended yarn of tussah silk and cotton fiber and spinning method of yarn

The invention discloses a blended yarn of tussah silk and cotton fiber and a spinning method of the yarn and belongs to the field of spinning. The blended yarn is formed by blending the tussah silk with the cotton fiber, wherein the content of the tussah silk in the blended yarn is not higher than 60 wt%, and the balance is the cotton fiber; the fineness of the blended yarn is 20-120 S; single-yarn breaking strength of the blended yarn is 430-120 CN, and the size of neps is 5 / 50-150 / 480. The high-quality blended yarn fills up the market blank, is uniformed in component and evenness, high in single-yarn strength and low in hairiness and has few neps and yarn defects. According to the spinning method, combed cotton strips and tussah silk strips are directly subjected to mixed blending, the spinning flow is short, damage caused to the tussah silk is small, the utilization rate is high, the spinning cost is low, and the controlled blending ratio is accurate.

Owner:WEIQIAO TEXTILE

Novel blended yarn and production process thereof

InactiveCN104862842ALess hairyImprove the defect of poor wrinkle resistanceYarnPolymer scienceCotton fibre

The invention discloses novel blended yarn and a production process thereof. The novel blended yarn is formed by blending cotton fibers with the blending ratio being 50%, bamboo pulp fibers with the blending ratio being 40% and soybean protein fibers with the blending ratio being 10%. The novel blended yarn has the advantages that a compact Siro spinning technology is adopted, raw materials are reasonably mixed, the defect of poor crease resistance of the soybean protein fibers is overcome, the soybean protein fibers are prevented from pilling to a large extent, and the size stability of fabric is improved. The problems that the bamboo pulp fibers are poor in hand feel, skin friendliness and cohesive force are solved. The produced yarn is good in strength, high in evenness, good in breathability, fluffy and soft, and has good skin friendliness and health care functions. The three-blending mode is adopted, the blending ratio can be more accurate, ingredients are even, produced single yarn is high in evenness, the strength of the single yarn is high, the number of cotton neps is small, and the number of yarn faults is small. The yarn variety enables fabric to have good breathability, to be fluffy and soft and to have good skin friendliness and a health care function.

Owner:NANTONG YUEDA KNITTING GARMENT

Semi-worsted multi-base color satin and color yarn yarn-forming structure

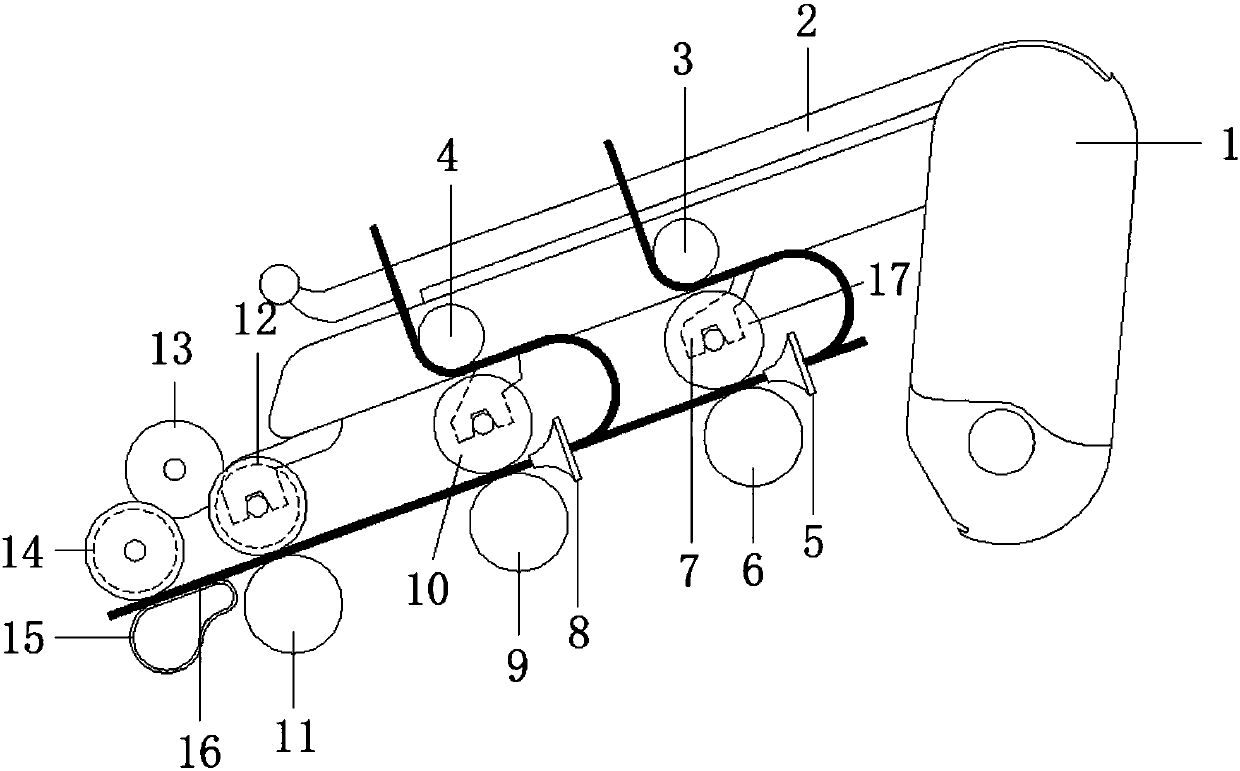

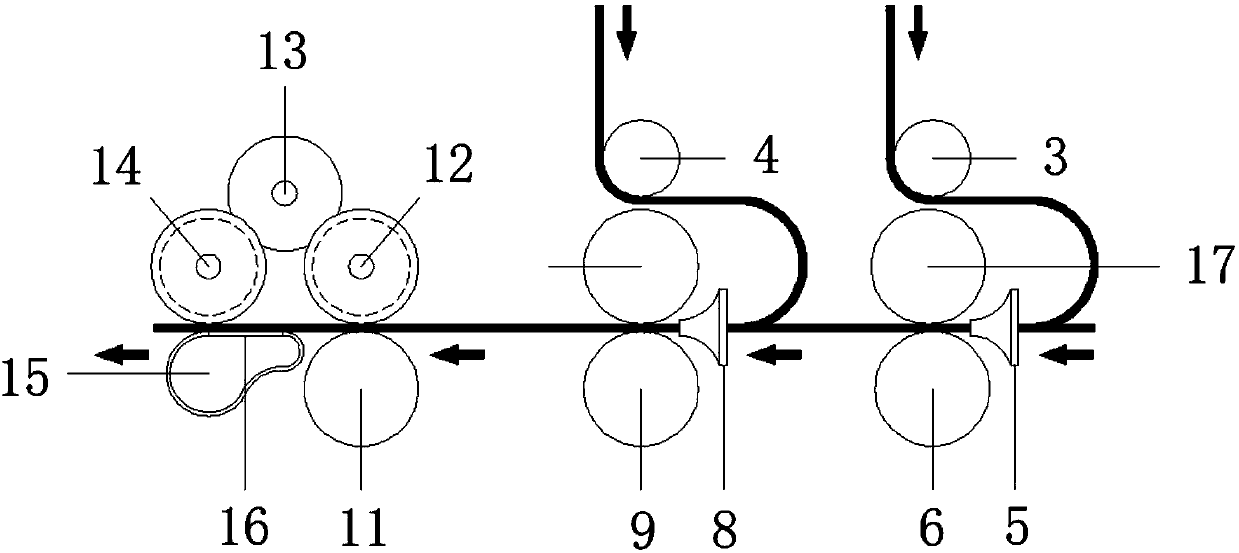

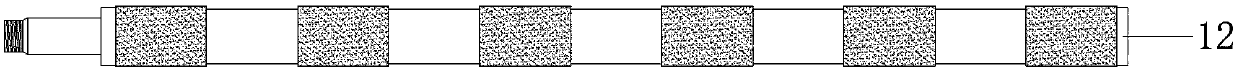

PendingCN107794618AHigh single yarn strengthReduced yarn hairinessDrafting machinesYarnYarnEngineering

The invention relates to the technical field of spinning processing, in particular to a semi-worsted multi-base color satin and color yarn yarn-forming structure. The semi-worsted multi-base color satin and color yarn yarn-forming structure comprises a cradle main body, a cradle handle, and a first yarn guiding wheel, wherein the cradle handle is located at the upper portion of the cradle main body, and is embedded into the cradle main body; a leather roller base is located at the lower portion of the cradle main body, and is embedded into the cradle main body; a rear roller, a middle roller and a front roller are fixedly connected with the leather roller base, and a rear leather roller, a middle leather roller and a front leather roller are located below the rear roller, the middle rollerand the front roller; a grid ferrule is located below an exporting roller, and a special-shaped suction pipe is arranged at the upper portion of the grid ferrule. The semi-worsted multi-base color satin and color yarn yarn-forming structure has the advantages that the single thread strength is high, the yarn hairiness is reduced, and compared with other prior arts, the applicability is high, anda production device is easy to install and maintain and high in cost performance.

Owner:JIANGSU XINFANG TEXTILE GROUP

Tussah silk yarn and spinning process thereof

The invention provides tussah silk blended yarn. The tussah silk blended yarn comprises, by weight, 20% to 30% of mulberry silk, 20% to 30% of modal long fibers and 40% to 50% of tussah silk. The invention further provides a spinning process of the tussah silk blended yarn. The spinning process comprises the steps of blow carding, drawing, roving, spinning and spooling. A compact siro spinning mode is adopted, the advantages of siro spinning and compact spinning are combined in compact siro spinning, the evenness CV value and nub and snick indexes are very good, the single thread strength is high, the structure is compact, wear resistance is good, less hair is generated, the amount of harmful hair of 3 mm or above is extremely small, the yarn is smooth and clean, and the fabric quality ishigh. The yarn made through the process can be used for making common underwear, bath towels and other comfortable, soft and high-moisture absorption textile raw materials next to the skin.

Owner:上海纺织(集团)大丰纺织有限公司

Kapok fiber processing technology

ActiveCN104404762AIncrease temperatureReduce unevennessVegetable materialVegetal fibresBreaking strengthYarn

The invention relates to a kapok fiber processing technology. The technology comprises the following steps: at first, loosening the kapok fibers, removing impurities from the kapok fibers, then sealing the kapok fibers in a cotton warehouse to stew the kapok fibers in the presence of a first aid, then wetting the kapok fibers in the cotton warehouse, spraying a second aid onto the kapok fibers in the cotton warehouse after the humidity of the kapok fibers has met the certain requirements under a heating condition; and then keeping on stewing the kapok fibers. The provided processing technology uses a unique first aid and second aid. In the assistance of the first aid and the second aid, at the same time, the technology comprises a special procedure, and thus the processed kapok fibers has the characteristics of softness, comfort, smoothness, antistatic property, pilling resistance, dampness absorption, dampness guiding, healthcare function, and antibacterial property. The dry unevenness and break strength of yarns made of the kapok fibers are greatly improved. Moreover, the kapok fibers can be blended with cotton fibers, and the kapok fiber content can reach 80% on the basis that the textile quality is not affected.

Owner:赵正兴

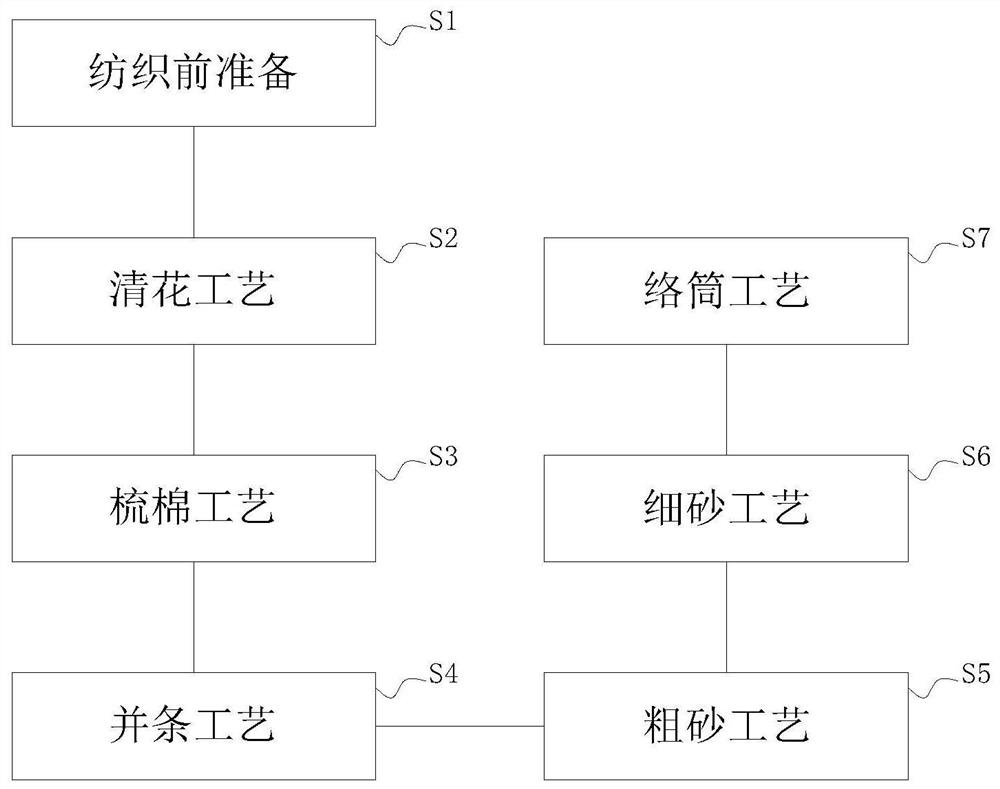

Spinning process of combed cotton yarn

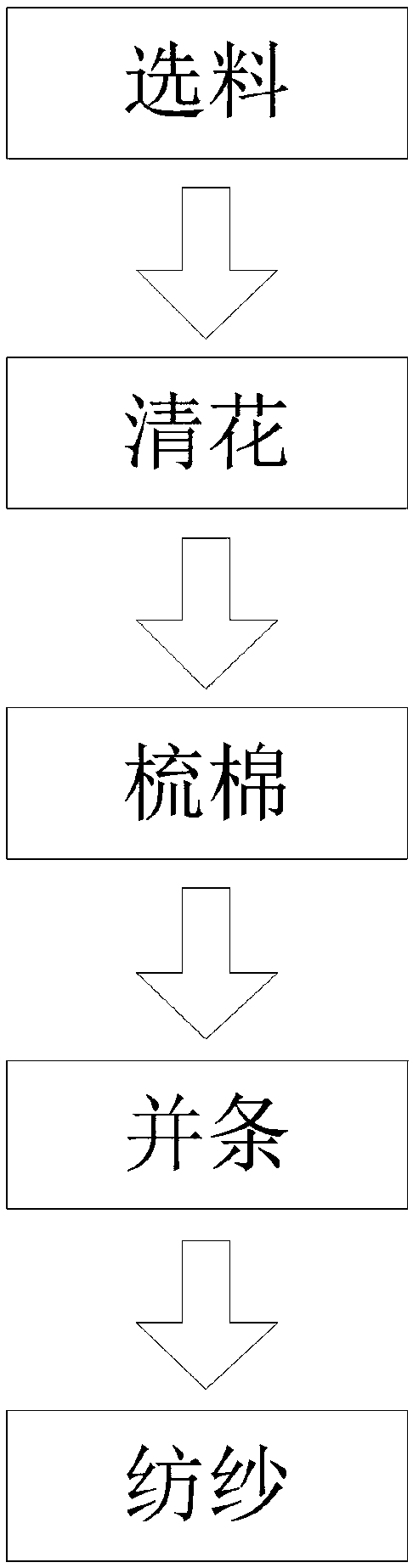

An embodiment of the invention discloses a spinning process of a combed cotton yarn. The process comprises the steps of material selection, wherein the following raw materials in percentage by mass are selected: 20-30% of long stapled cotton, 20-30% of sea island cotton and 40-50% of Egyptian cotton; cotton cleaning; cotton carding, wherein combed noil fiber rolls are treated with a cotton cardingmachine to obtain cotton fiber slivers; drawing, wherein drawing is performed for three times; and spinning, wherein a full-automatic rotor spinning machine is adopted, the cotton slivers obtained bythe drawing process are fed into the rotor spinning machine, and air spinning is performed to obtain a cotton yarn product. An adopted spinning mode is compact siro spinning, the compact siro spinning combines the advantages of siro spinning and compact spinning, the spinning process is simple, the occupied area of a machine is small, the production cost is reduced on the basis of ensuring the product quality, and a theoretical basis is provided for development and research of preparation of an environment-friendly ordinary blended yarn. Furthermore, the rolling step in the cotton cleaning step can be reduced, so that the use of one machine is reduced and the cost is reduced.

Owner:湖北妙虎纺织有限责任公司

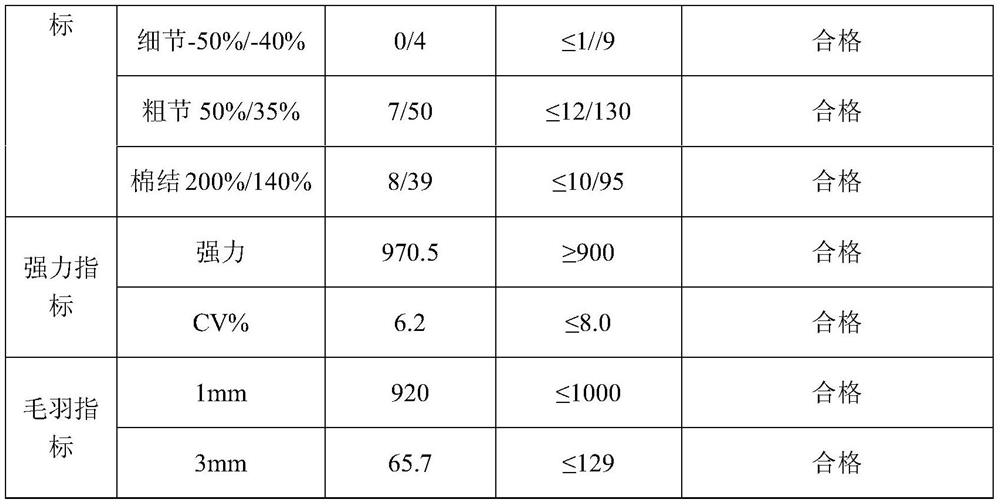

Method for producing purified cotton yarns

The invention provides a method for producing purified cotton yarns, which is characterized by comprising the following steps: (1) a process step of blowing-carding; (2) a process step of drawing; (3) a process step of roving; (4) a process step of fine spinning; (5) a process step of spooling; and (6) a process step of packaging. The method optimizes the production process steps of the purified cotton yarns, the produced purified cotton yarns accord with the national standard, the single yarn strength evenness CV percent value is good, the end breakage rate is low, and the yarn quality is stable.

Owner:江苏省华强纺织有限公司

High-shape-preservation pure cotton yarn of high-density anti-wrinkle fabric and production method thereof

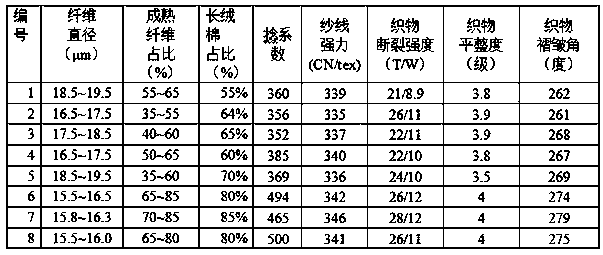

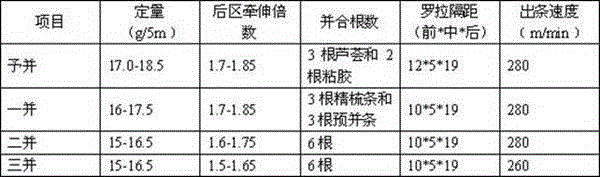

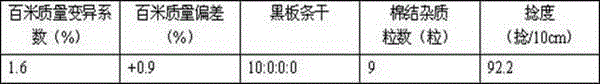

High-shape-preservation pure cotton yarn of high-density anti-wrinkle fabric and a production method thereof belong to the technical field of textile and especially to the production of pure cotton yarn. Pure cotton yarn is obtained by performing cotton picking, carding, combing, pre-mixing, multi-pass mixing, roving, spinning and winding on cotton fiber; the diameter of the cotton fiber is 15.5 to 16.5 [mu]m. The mass percentage of mature cotton fibers in cotton fibers is 65-85%, and the mass percentage of long staple cotton is 75-90%; the obtained pure cotton yarn has a strength of 340CN / texor more. The process of the invention does not need to adjust the equipment and is favorable for production, and the obtained pure cotton yarn meets the requirements of the subsequent weaving, and the obtained fabric has the advantages of strong shape retention, small loss of fabric strength after finishing, and good hand feeling.

Owner:HAIAN LIANFA COTTON SPINNING CO LTD

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

Organic cotton fiber bunchy yarn and manufacturing process thereof

The invention provides an organic cotton fiber bunchy yarn and a manufacturing process thereof. The process includes the procedures of scutching, cotton carding, drawing, roving, spinning and winding.The scutching procedure includes application coordination of an automatic bale plucker, a mixing bale opener and a bale opener after parameter adjustment, a cotton roll enters the cotton carding procedure after the scutching procedure, and is changed into a cotton sliver under the action of a carding machine and then divided into a few parallel slivers, and the parallel slivers enter a drawing frame, are drawn, pass a roving frame and a spinning frame and finally enter a bobbin winder. The yarn made of novel environment-friendly materials is provided for the market by the aid of the manufacturing process, clothes made of the yarn can improve the clothing experience of people, market requirements are met, and economic and social development is promoted.

Owner:上海纺织(集团)大丰纺织有限公司

Compact-spun combed cotton yarn (300S) and spinning process thereof

The invention relates to the technical field of spinning, in particular to a compact-spun combed cotton yarn (300S) and a spinning process thereof. The spinning process includes the steps of blowing,carding, preparing, combing, drawing, roving, spinning and spooling; the 300S cotton yarn refers to the compact-spun combed cotton yarn (300S) prepared by the spinning process. According to spinning process of the compact-spun combed cotton yarn (300S), combing and drawing are adopted so that a production flow is shortened, reduction of lower pile increase is facilitated, and uneven drafting is reduced; the cotton yarn prepared by the process has the advantages of high strength of single yarn, uniform sliver and less yarn defects. By the spinning process, yarn forming process and cloth style stability are both guaranteed, production cost of the spinning factory is reduced greatly, and performance of enterprises is increased.

Owner:WEIQIAO TEXTILE

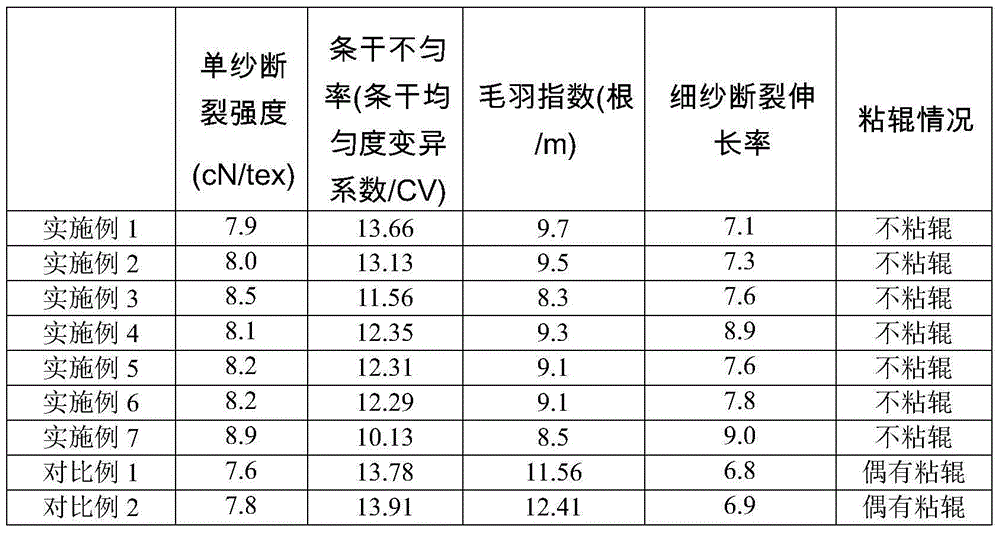

Compact siro spinning process for modal, Deersted acrylic fibers and graphene fibers

ActiveCN114753032AFunctionalWith far infraredDrafting machinesLap-winding devicesPolymer scienceCarding

The invention discloses a compact siro spinning process for modal, Deersted acrylic fiber and graphene fiber, the compact siro spinning process is adopted in a spinning procedure, and the compact siro spinning process is characterized in that the prepared blended yarn comprises the following components in percentage by weight: 48-52% of Lenzing modal, 28-32% of Deersted acrylic fiber and the balance of graphene fiber; the method specifically comprises the steps of raw material preparation, opening picking, cotton carding, drawing, roving, spinning and spooling. The three fibers with different properties are blended through compact siro spinning, so that the different fibers complement each other in characteristics and advantages, and the yarn has the advantages of high single yarn strength, uniform evenness, compact structure, good wear resistance, less hairiness, bright and clean yarn and the like. The yarn not only has the advantages of warmth retention of the Derman acrylic fibers and moisture absorption and comfort of the modal fibers, but also has the unique characteristics of far infrared, bacteria resistance, bacteriostasis, ultraviolet resistance and the like of the graphene functional fibers, and has good functionality.

Owner:山东超越纺织有限公司

Mildew-proof yarn and spinning process

InactiveCN113737336AWith anti-mildew functionPrevent mildewBiochemical fibre treatmentGrip property fibresYarnSpinning

The invention discloses mildew-proof yarn and a spinning process. The mildew-proof yarn comprises first yarn and second yarn. The process comprises the following steps of S1, preparing corn fiber raw materials and cotton fiber raw materials, and performing a corn fiber balance treatment process: storing the corn fiber raw materials in a 58% storage environment at 30 DEG C in advance for balance treatment; and S2, performing a cotton cleaning process: loosening the cotton fiber raw materials into small cotton blocks or cotton bundles through a cotton slitter so as to facilitate mixing and impurity removal, then, removing most impurities, defects and short fibers which are not suitable for spinning in the cotton fiber raw materials after cotton opening through a cotton cleaning machine, fully and uniformly mixing the cleaned cotton fiber raw materials with different components through a cotton mixing machine, making the mixed cotton fiber raw materials into cotton rolls which can support a certain weight, are uniform in length and thickness and are good in appearance through a lapper; and feeding the corn fiber raw materials into the cotton slitter after the corn fiber raw materials are opened by a bale plucker. The yarn has a mildew-proof function, the mildewing phenomenon of the yarn can be avoided, and therefore the service life of the yarn can be prolonged.

Owner:浙江港伦纺织有限公司

Novel blended yarn and production process thereof

The invention discloses novel blended yarn and a production process thereof. The blended yarn is blended by cotton fibers with the blending ratio being 50%, bamboo pulp fibers with the blending ratio being 40% and soybean protein fibers with the blending ratio being 10%. The novel blended yarn has the advantages that the compact Siro spinning technology is used, the raw materials are reasonably combined in a matched manner, the defect that the soybean protein fibers are poor in wrinkle resistance is overcome, fuzzing and pilling of soybean protein fiber fabric are prevented to a large degree, and fabric size stability is increased; the problem that the bamboo pulp fibers are poor in touch, skin friendliness and cohesive force is solved; the produced yarn is good in strength, good in evenness, good in breathability, fluffy, soft, and extremely good in skin friendliness and healthcare function; the three raw materials are blended, blending ratio accuracy and component evenness are achieved favorably, and the produced single yarn is good in evenness, high in strength, few in neps and few in yarn faults; the yarn allows fabric to be good in breathability, fluffy, soft, and extremely good in skin friendliness and healthcare function.

Owner:如皋市达瑞织造有限公司

A kind of kapok fiber processing technology

ActiveCN104404762BIncrease temperatureReduce unevennessVegetable materialVegetal fibresYarnBreaking strength

The invention relates to a kapok fiber processing technology. The technology comprises the following steps: at first, loosening the kapok fibers, removing impurities from the kapok fibers, then sealing the kapok fibers in a cotton warehouse to stew the kapok fibers in the presence of a first aid, then wetting the kapok fibers in the cotton warehouse, spraying a second aid onto the kapok fibers in the cotton warehouse after the humidity of the kapok fibers has met the certain requirements under a heating condition; and then keeping on stewing the kapok fibers. The provided processing technology uses a unique first aid and second aid. In the assistance of the first aid and the second aid, at the same time, the technology comprises a special procedure, and thus the processed kapok fibers has the characteristics of softness, comfort, smoothness, antistatic property, pilling resistance, dampness absorption, dampness guiding, healthcare function, and antibacterial property. The dry unevenness and break strength of yarns made of the kapok fibers are greatly improved. Moreover, the kapok fibers can be blended with cotton fibers, and the kapok fiber content can reach 80% on the basis that the textile quality is not affected.

Owner:赵正兴

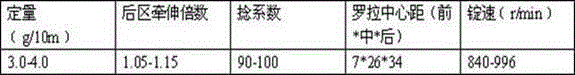

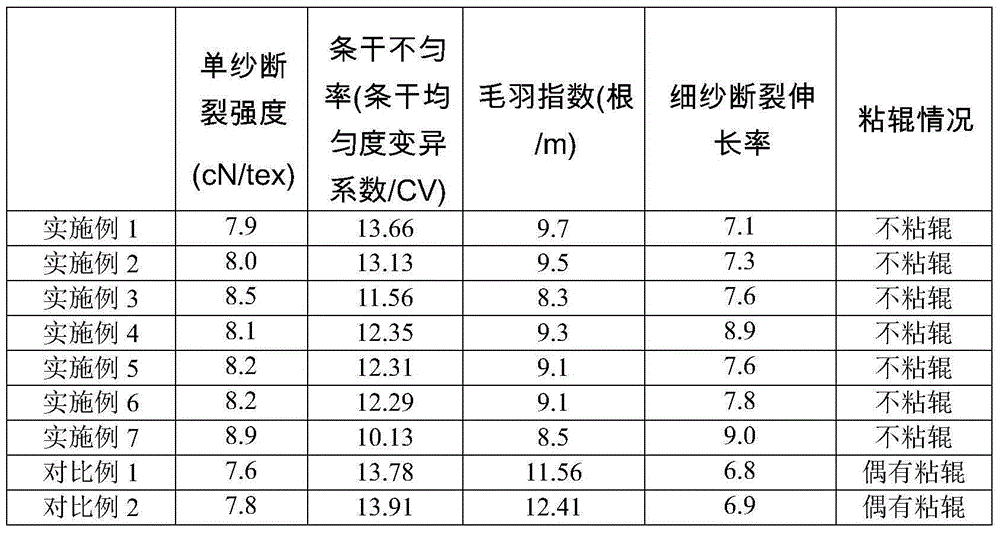

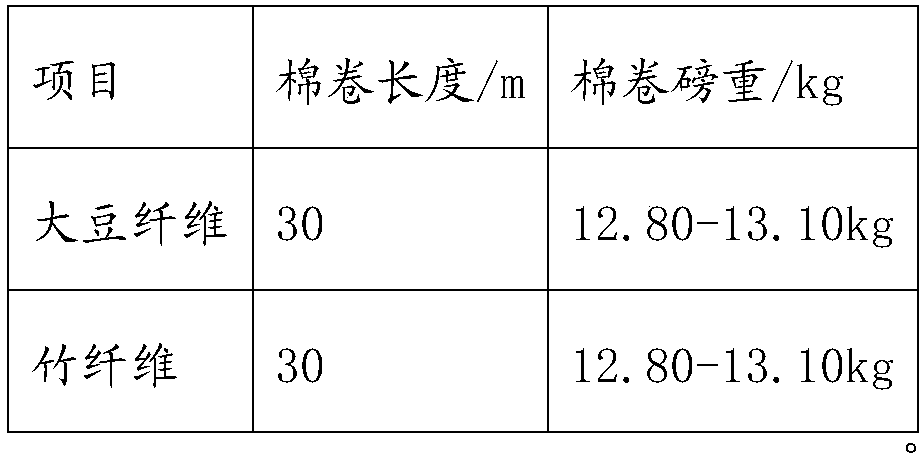

Siro core-spun yarn blended with soybean fiber and bamboo fiber and its spinning process

The invention discloses a Siro-spinning core-spun yarn blended with soybean fiber and bamboo fiber and spinning technology. The blended yarn is produced by blending soybean fiber and bamboo fiber, wherein, the content of the soybean fiber is 1%-9%, and the residual is bamboo fiber. Siro-spinning is adopted; and spandex filament is added to produce Siro-spinning core-spun yarn. The blended yarn has the advantages of the soybean fiber and the bamboo fiber, at the same time, the spandex filament is added, so that the blended yarn has a good elasticity, a good shape-retaining ability, and has no wrinkling.

Owner:山东宏儒纺织科技有限公司

Spinning method of organic cotton modal composite yarn

The invention belongs to the technical field of yarn spinning, and particularly relates to a spinning method of an organic cotton modal composite yarn. The spinning method of the organic cotton modal composite yarn comprises the following steps of S1, preparing before spinning: selecting raw materials, namely organic cotton fibers and modal fibers which respectively account for 50 percent by mass, and performing water bath heat treatment on the organic cotton fibers and the modal fibers; and after drying, putting into a mixed solution prepared from an antistatic agent and an anti-pilling agent according to the volume ratio of 2: 1, soaking for 2 to 3 hours, and pre-humidifying for 20 to 24 hours in a standard atmospheric state with the relative humidity of 25 to 35 percent. According to the spinning method of the organic cotton modal composite yarn provided by the invention, the organic cotton fibers and the modal fibers are subjected to temperature and humidity treatment, antistatic agent treatment and anti-pilling agent treatment, so that the softness and antistatic property of the blended fibers are improved, and the hairiness of the blended yarns is reduced; through the mixing mode of wrapping and mixing the organic cotton fibers and the modal fibers, component uniformity is facilitated, and the spinnability of the organic cotton fibers is improved; and the blended yarn produced by the production process is high in single yarn strength, uniform in yarn evenness, less in neps and less in yarn faults.

Owner:HONGDOU GROUP WUXI YUANDONG CLOTHING

Dope dyeing core-spun yarn and preparation process thereof

InactiveCN112210859AHigh color fastnessAvoid pollutionElectroconductive/antistatic filament manufactureMonocomponent cellulose artificial filamentYarnPolyester

The invention discloses dope dyeing core-spun yarn and a preparation process thereof. The dope dyeing core-spun yarn comprises core yarn and wrap yarn, the wrap yarn is located on the outer layer of the core yarn, the core yarn is spandex fiber, and the wrap yarn is composed of 60-70% of polyester fiber and 30-40% of viscose fiber, wherein the polyester fiber and the viscose fiber are colored fiber, and the fineness of the spandex fiber is 30-60D. The dope dyeing core-spun yarn is high in elastic capacity and strength, resistant to wrinkles and scalding, easy to wash, quick to dry, resistant to ultraviolet rays, smooth, cool, breathable, resistant to static electricity, gorgeous in dyeing, soft, comfortable and capable of meeting the skin physiology science of a human body.

Owner:上海纺织(集团)大丰纺织有限公司

A kind of silver fiber and cotton fiber blended yarn and its preparation process

The invention relates to a yarn blended with silver fiber and cotton fiber and preparation technology, and the yarn is blended with silver fiber and combed cotton fiber through blending, wherein, the content of the silver fiber is 1-50%, and the balance is cotton fiber. The preparation technology comprises the steps of flower removing, cotton combing, preparation, fine combing, blending of silver fiber and combed cotton strip of combed cotton fiber, mixing, roving, spinning and automatic winding. The advantages are that the characteristics of both the silver fiber and the cotton fiber are provided; the yarn has high intensity, good wear resistance, moisture absorption, ventilation, strong antibacterial performance, and radiation hardening. The technology has the advantages that the blending ratio is accurate; the components are uniform; the blended yarn manufactured thereby has a strong force of a single thread, little hairiness, uniform strips, little cotton knobs and little yarn defects.

Owner:山东宏儒纺织科技有限公司

Yacell and regenerated cotton blended yarn as well as preparation method and cloth of Yacell and regenerated cotton blended yarn

Owner:佛山市康亚纺织有限公司

A kind of cotton fiber, viscose fiber blended yarn and its manufacturing method

Owner:ZHEJIANG SHUANGDUN TEXTILE TECH CO LTD

Soft core yarn and preparation method

The invention provides a soft core yarn and a preparation method. The soft core yarn comprises a core yarn and an outer layer fiber, and the outer layer fiber wraps the core yarn; and the twist of thecore yarn is lower than that of the outer layer fiber. Compared with the prior art that long stapled cotton and cotton fiber are blended, the soft core yarn composed of cotton fiber and long stapledcotton is low in cost and high in cost performance; and yarns produced by the spinning process are high in single yarn strength, less in hairiness, uniform in evenness, less in neps and less in yarn faults. The yarn structure can further improve the comfort of the fabric, improve the hand feeling of the fabric and improve the grade of the fabric.

Owner:WEIQIAO TEXTILE

Blended yarn of mulberry silk long fiber and modal fiber and its spinning process

The invention discloses blended yarn of mulberry silk macrofiber and modal fiber and a spinning technology thereof. The blended yarn is formed by blending the mulberry silk macrofiber and the modal fiber through a blending technology, wherein the content of the mulberry silk fiber is 1 to 99%, and the balance of modal fiber. The blended yarn not only has the advantages of the mulberry silk fiber but also has the characteristics of the modal fiber. With different tissue structures adopted, silk fabric can be as light and thin as yarn, and can also be thick and full, the spinning product of the blended yarn is particularly suitable for developing garment materials, T-shirts and the like in summer, and is comfortable and graceful when worn.

Owner:山东宏儒纺织科技有限公司

A kind of elastic silk fiber and cotton fiber blended yarn and its spinning process

The invention relates to a blended yarn of Shu elastic silk fibers and cotton fibers and a spinning process thereof. The blended yarn has the advantages of the Shu elastic silk fibers and cotton, is transcendental in size stability, natural, soft, high in air permeability and abrasive resistance, capable of being widely applied in the fields of cowboy costume, formal clothes, sport suit, knitted underwear and home textile, and broad in market prospect. According to the preparation process, the difficulties that the Shu elastic silk which serves as raw material fibers is high in elasticity and uneasy to reel separately and has too much crimps are overcome, the Shu elastic silk fibers and the cotton fibers are blended according to a blending proportion, and a cotton carding process, a roving process and a spun yarn process in the later period are completed. According to the process, the spun yarn process is adjusted, and the problem is solved that since the rebound resilience of the Shu elastic silk is high, coiling strips serving as raw materials are difficult to shape; a big-ration high-drafting process is achieved, the supply in the early period and the supply in the later period can be ensured, and the prepared blended yarns are high in single yarn intensity, small in variable coefficient and high in stability of fiber strength, show excellent rebound resilience, and meet demands of downstream manufacturing.

Owner:威海魏桥科技工业园有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com