Semi-worsted multi-base color satin and color yarn yarn-forming structure

A semi-worsted and color segment technology, applied to spinning machines, yarns, textiles and papermaking, etc., can solve the problems affecting the average strength of the yarn and the failure of the breaking strength of the yarn, so as to achieve the reduction of yarn hairiness and easy High maintenance and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

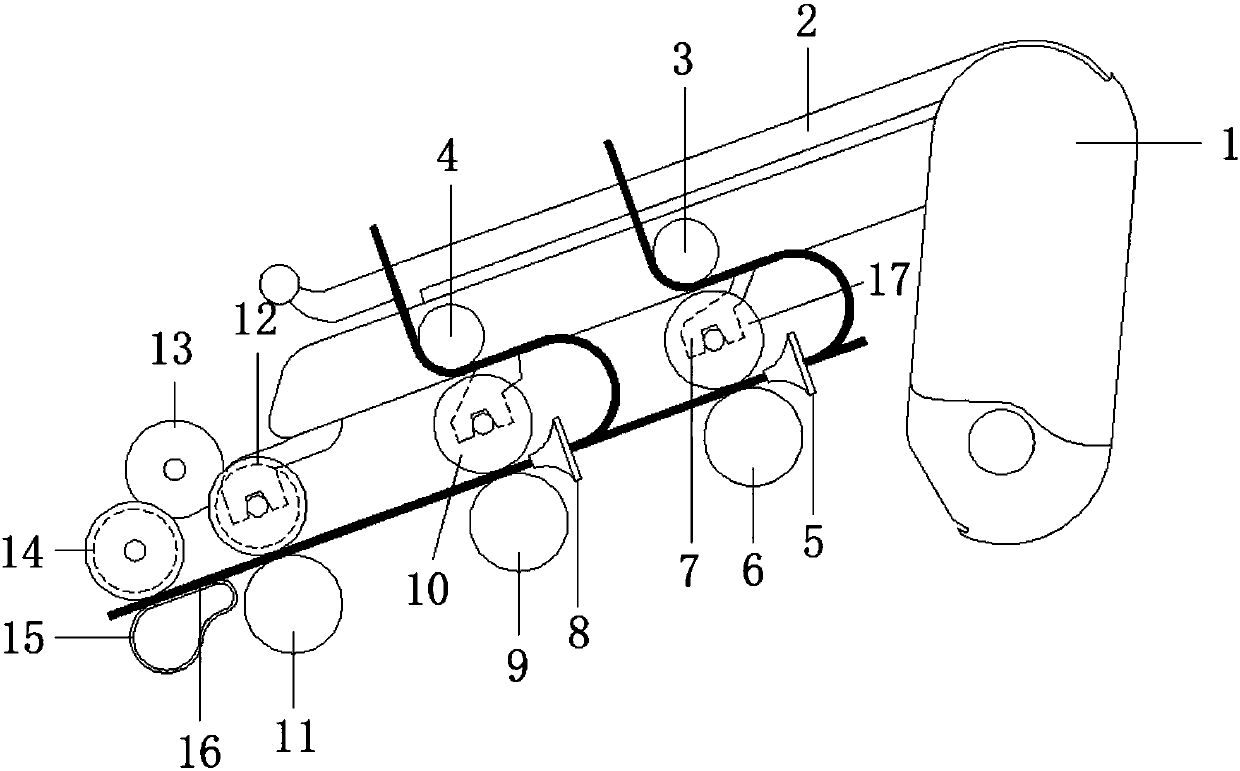

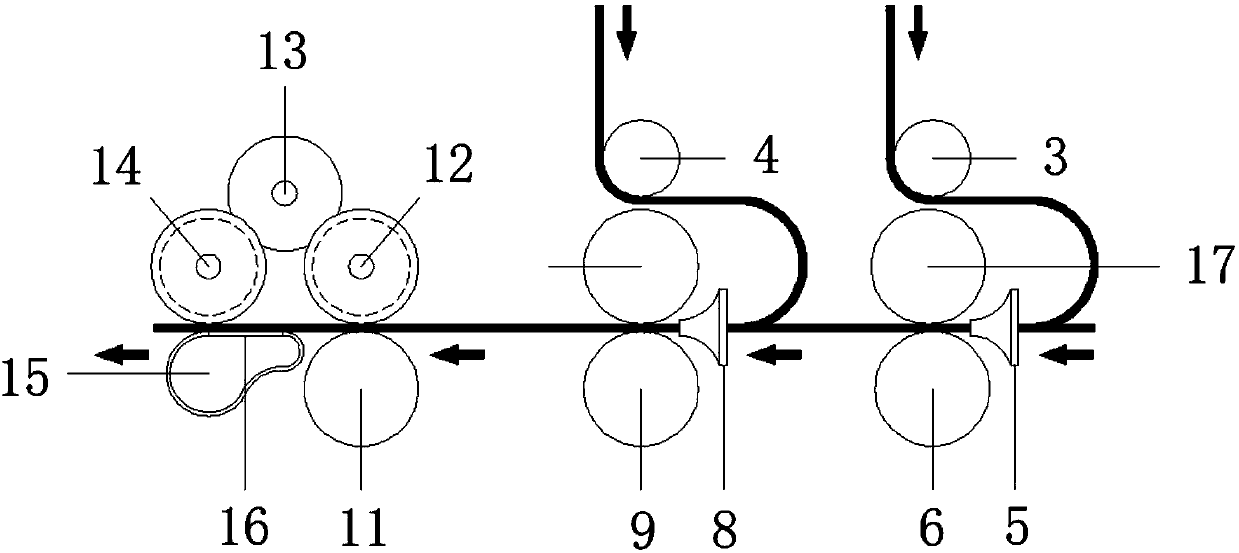

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

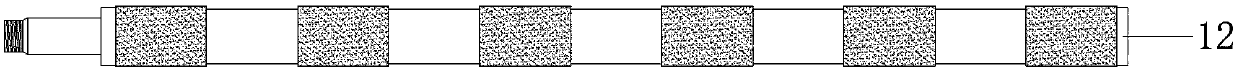

[0022] as attached Figure 1 to Figure 5 The shown yarn forming structure of a semi-worsted multi-base color segment colored yarn of the present invention includes: cradle main body 1, cradle handle 2, first yarn guide wheel 3, second yarn guide wheel 4, first guide wheel Port 5, rear roller 6, top roller seat 7, second inlet 8, middle roller 9, middle top roller 10, front roller 11, front top roller 12, bridge gear 13, export top roller 14, grid ferrule 15. Special-shaped straw 16, rear roller 17; cradle handle 2 is located on the upper part of the cradle body 1, and the cradle handle 2 is connected to the cradle body 1 by embedding; the roller seat 7 is located at the lower part of the cradle body 1 , and the top roller seat 7 is connected with the cradle main body 1 by embedding; the rear roller 6, the middle roller 9, and the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com