Patents

Literature

31results about How to "Address Dimensional Stability Issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

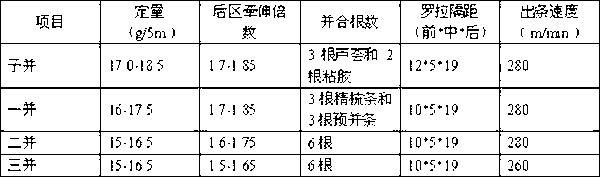

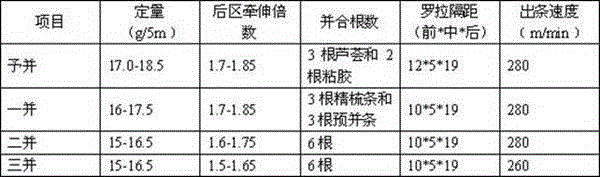

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

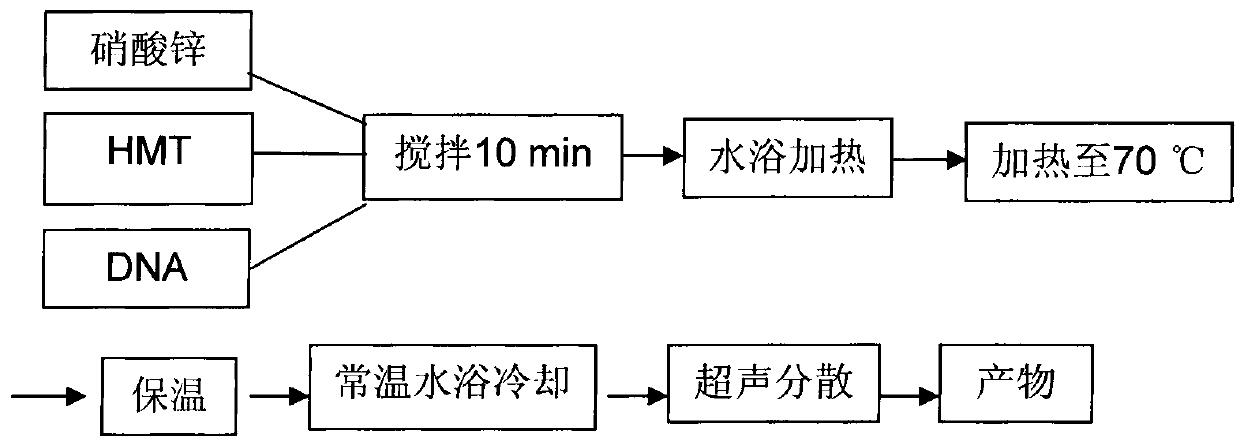

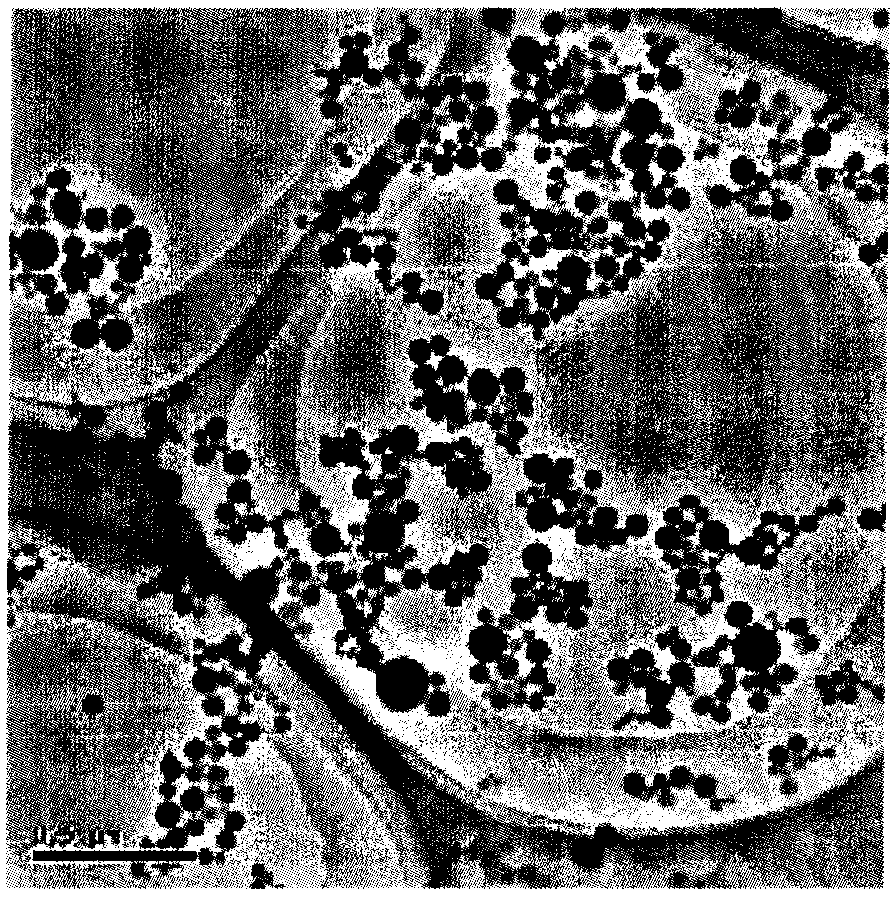

Method for assembling zinc oxide nano-chain by using DNA as template

InactiveCN101717112ASimple ingredientsLow energy consumptionNanostructure manufactureZinc oxides/hydroxidesBiological macromoleculeBatch production

The invention discloses a method for assembling a zinc oxide nano-chain by using DNA as a template, comprising the following steps of: (1) mixing and stirring an aqueous solution of DNA, an aqueous solution of zinc nitrate and an aqueous solution of hexamethylenetetramine; (2) heating to 60 DEG C-80 DEG C and keeping the temperature for 0.5-4h; and (3) reducing the temperature to room temperature of 20 DEG C-25 DEG C and carrying out ultrasound treatment in an ultrasound wave dispersion instrument for 10-20 minutes and sampling to obtain the zinc oxide nano-chain by using the DNA as the template. The method is simple, easily obtains raw materials, consumes less energy and reduces the pollution to the environment; the equipment is less and the cost is low, so the method is suitable for batch production; the reaction time is short, the yield is high and no toxicity and harm exist, so that the method provides the possibility for preparing the zinc oxide nano-chain on a large scale; and zinc oxide nano-chains with different shapes can be constructed by operating the space structure of biological macromolecule DNA. The invention can simultaneously solve the problems of the control of the size and the shape of nanometer materials and the dispersion stability.

Owner:TIANJIN UNIV

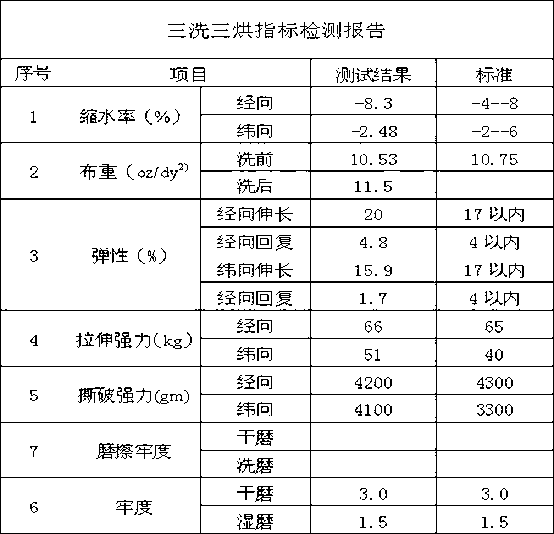

Method for producing warp and weft dual-elastic denim fabric by bundled lines

ActiveCN102936811ABright and uniform colorHigh color fastnessFibre treatmentHeating/cooling textile fabricsEngineeringPre treatment

The invention discloses a method for producing a warp and weft dual-elastic denim fabric by bundled lines. The warp and weft dual-elastic denim fabric is produced by a long technological process through dyeing of a plurality of dyeing cylinders for the bundled lines. The method comprises the following steps of: (1) making warp yarns by cotton-wrapped spandex bamboo joints, and making weft yarns by triple wrapped yarns formed by wrapping cotton on terylene and then wrapping the cotton-wrapped terylene on spandex; (2) always keeping stable temperature and humidity in a ball warp working procedure; (3) performing pressurization by a heavy hammer, before dyeing is executed, performing pretreatment until tension of each part is stable, then implementing an elastic ball shaft connection method, wherein the dyeing process is a multi-dyeing-cylinder low-content dyeing process, so that the penetration and the dyeing rate of a dye can be improved; (4) performing a weft division process by low tension; (5) slashing by a sizing process with low viscosity and low concentration; (6) weaving by a feeding process with a high rear beam, high tension and a small opening; (7) arranging by a desizing pre-contraction arrangement process; and (8) treating by adopting a sizing method. The warp and weft dual-elastic denim fabric produced by the method is bright and uniform in color, relatively high in color fastness and similarly stable in elasticity.

Owner:ZAOZHUANG HIYOUNG DYNASTY TEXTILE

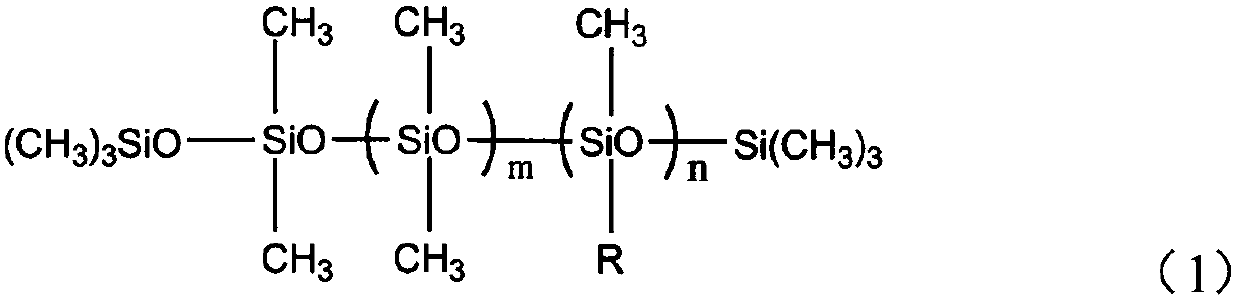

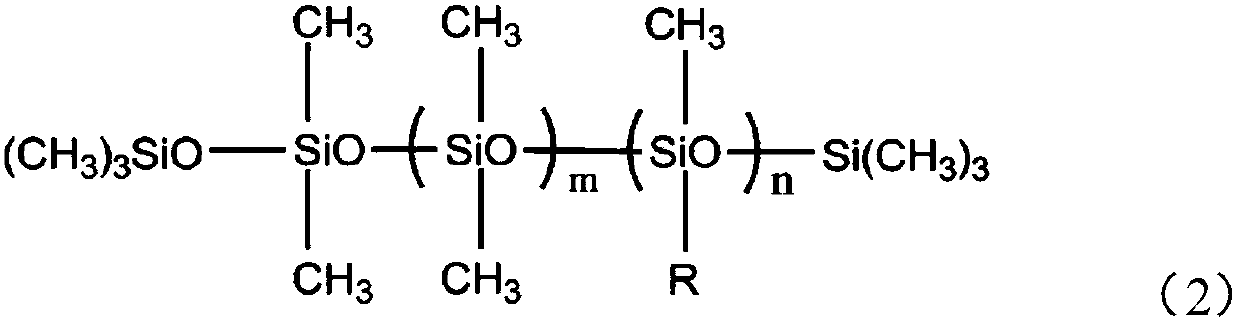

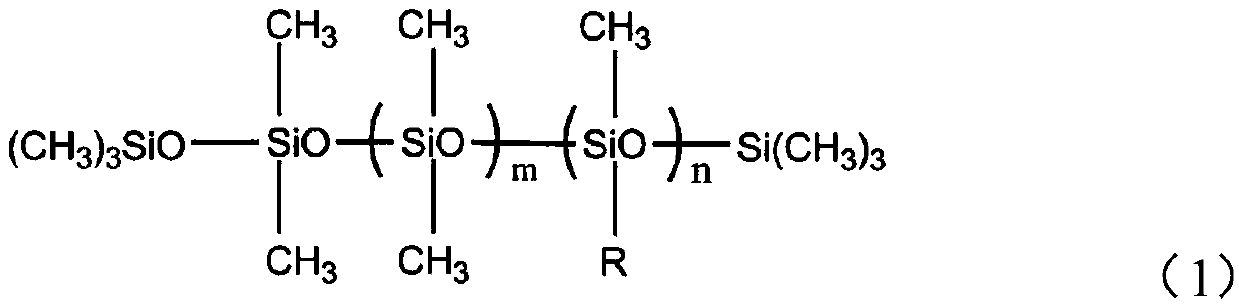

Organosilicon surfactant used for high-resilience foam and preparation method of organosilicon surfactant

The invention discloses an organosilicon surfactant used for high-resilience foam and a preparation method of the organosilicon surfactant, belongs to the technical field of surfactants, and solves the problem of compatibility of a polyurethane high-resilience foam system and surface and dimensional stability of polyurethane foam in the prior art. According to the method provided by the invention,two hydrogen-containing silicone oil having different structures is designed, the hydrogen-containing silicone oil and allyl polyether having different molecular weights are separately subjected to areaction to obtain two polyether-modified silicone surfactants with different structures, a ratio of different components is regulated and controlled to realize balance of openness and stability of the high-resilience foam, so that special requirements of a volume, aeration, shear and surface and dimensional stability of the high-resilience polyurethane foam are met, and the problems of system compatibility and surface and dimensional stability of the polyurethane foam are effectively solved.

Owner:南京美思德新材料有限公司

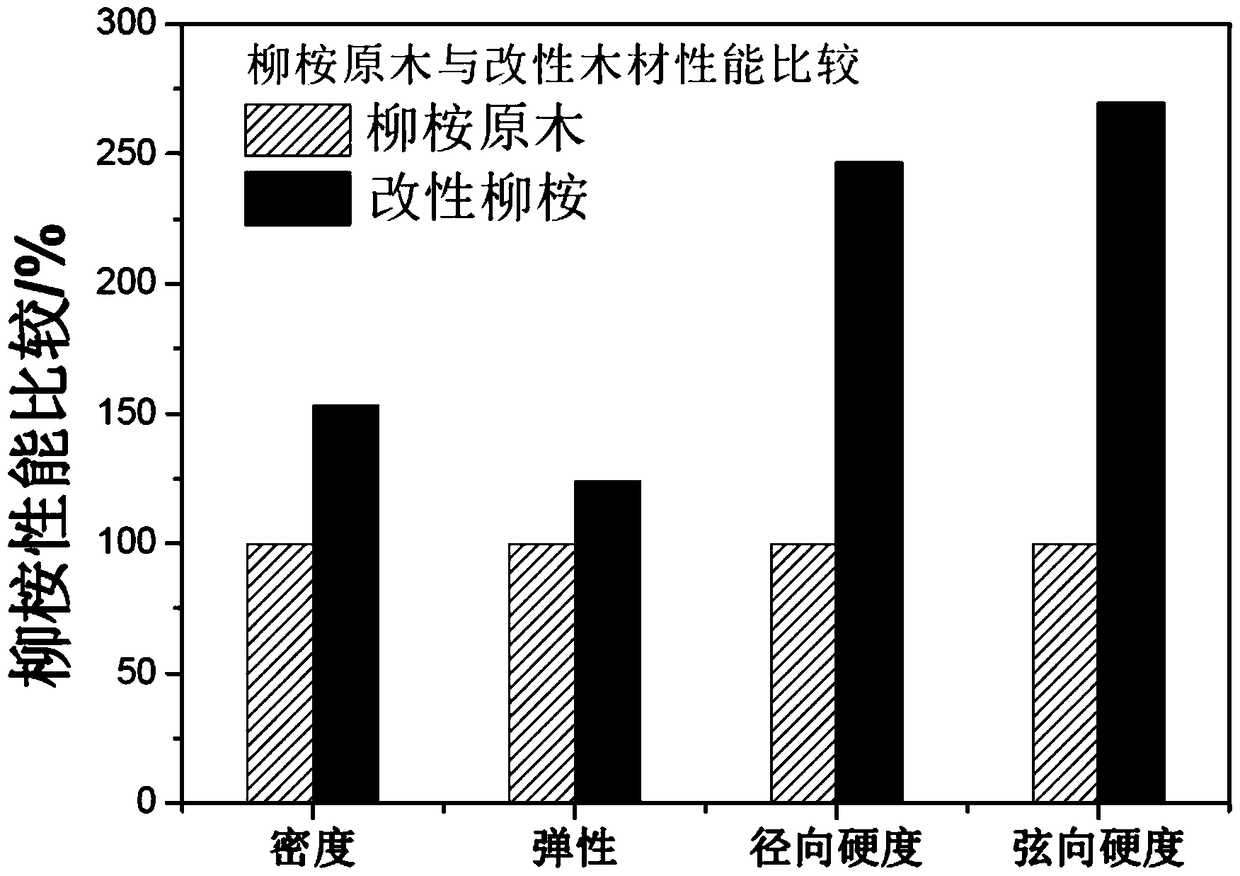

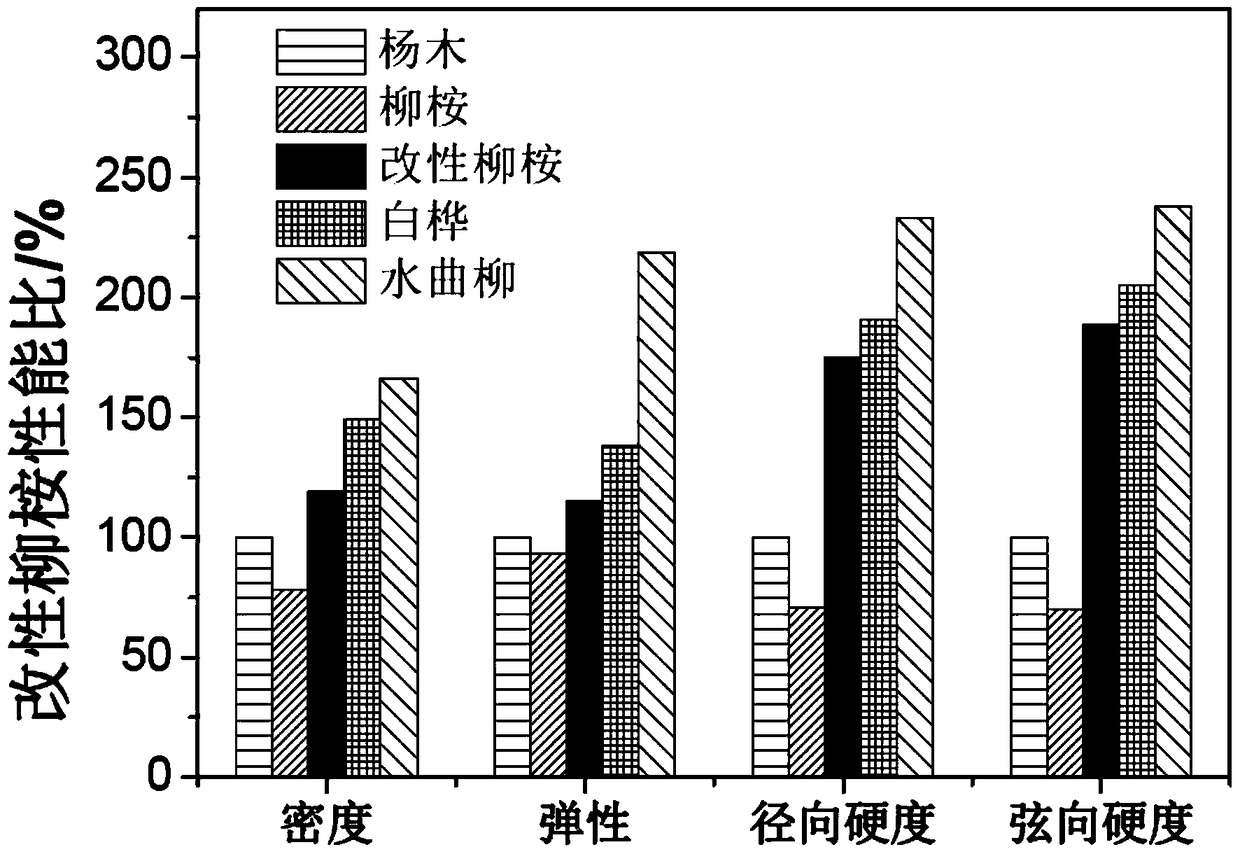

Natural wood dyeing method and natural wood dyeing dye

InactiveCN107699053AImprove permeabilitySolve the colorability of dyeingWood treatment detailsPulp and paper industryTannin

The invention discloses a natural wood dyeing method and a natural wood dyeing dye. According to the present invention, the dyeing solution of the present invention and tannin contained in wood are subjected to a chemical reaction, such that the dyed color is natural, the texture are clear, and the penetration depth of the color is 1.0-2.0 mm; the oxidation color of the dyed wood has advantages ofdelayed fading, beautiful outlook and applicability; and with the method and the dye, the technical problems of poor physical properties such as coloring, dyeing uniformity, dimensional stability, hardness and the like of the wood dyeing in the prior art can be solved, and the upgrading of the low-grade wood is promoted.

Owner:张萱

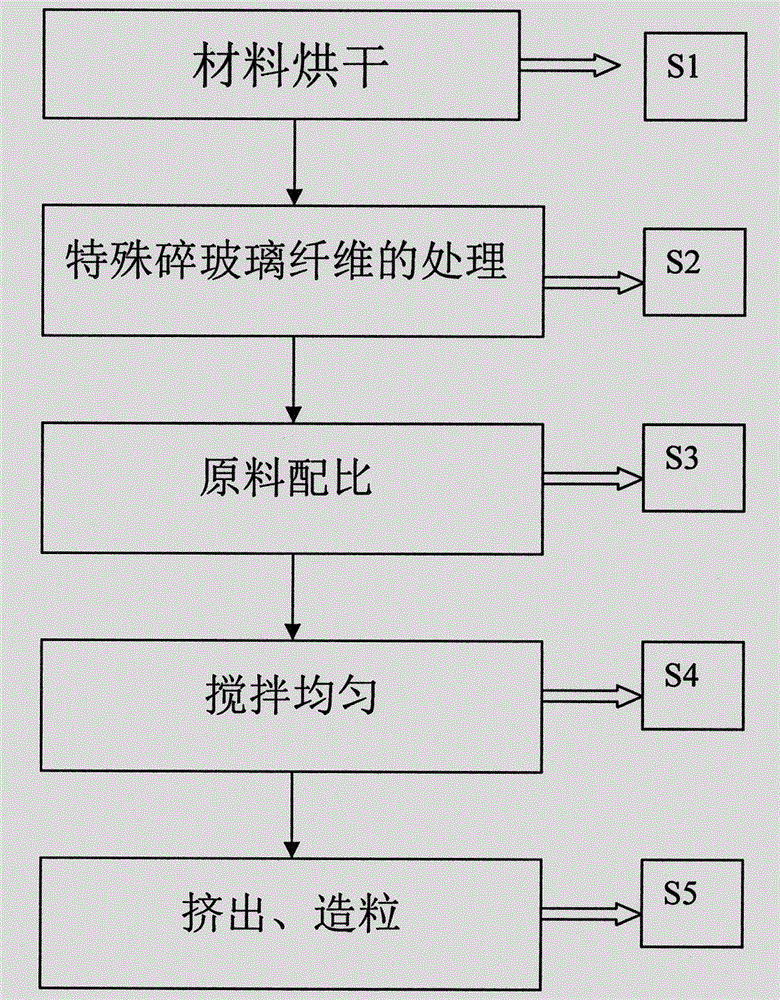

Glass fiber reinforced nylon 66 composite material for panel of dish-washing machine and preparation method thereof

The invention relates to a nylon 66 composite material, especially to a glass fiber reinforced nylon 66 composite material for a panel of a dish-washing machine and a preparation method thereof. The material is composed of, by weight, 66.8 to 76.9% of nylon 66 resin, 10 to 15% of flat short cut glass fiber, 10 to 15% of cullet fiber, 0.5 to 0.8% of a nylon anti-hydrolysis agent, 0.3 to 0.6% of an anti-oxidant, 0.2 to 1.5% of a lubricant and 0.1 to 0.2% of a nucleating agent. According to the invention, through combined action of a variety of functional auxiliary agents, the special cullet fiber and the flat short cut glass fiber and adoption of special twin-screw extrusion technology, the problems of surface warping and surface floating fibers of the glass fiber reinforced nylon 66 composite material and problems in adhesion between a product and glass cement are overcome, and dimensional stability and mechanical property stability of the glass fiber reinforced nylon 66 composite material in a high-temperature humid environment are guaranteed.

Owner:NINGBO EAGLE NEW MATERIAL

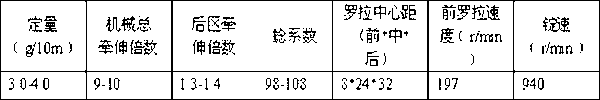

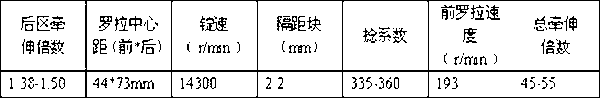

Blending method of alginate fibers, combed fine-fleece cotton and long stapled cotton for production of top-grade knitting yarns

The invention relates to a blending method of alginate fibers, combed fine-fleece cotton and long stapled cotton for production of top-grade knitting yarns. The method comprises following steps: selecting alginate fibers and cotton fibers; carrying out blowing, combing and pre-drawing operation on alginate fibers and combining them with combed fine-fleece cotton and long stapled cotton on a drawing machine; and producing cone yarns through roving, spun-yarn and spooling procedures with the blending proportion of alginate, combed long stapled cotton and combed fine-fleece cotton being 50 / 30 / 20. The blending method of alginate fibers, combed fine-fleece cotton and long stapled cotton for production of top-grade knitting yarns has following beneficial effects: cone yarns have cotton texture due to addition of combed cotton and fine staple cotton so that woven fabric has few hair and shows great piling resistance and high strength and is fluffy, soft and elastic; cotton fabric is not easily wrinkled and has fixed size so that comfort and warm-keeping ability are further enhanced; the cotton fabric can be made into underwear, vests, T-shirts, shorts, and pajamas and shows great warm-keeping ability; and functions of protecting and moistening skin and health-care are fulfilled.

Owner:JIHUA 3509 TEXTILE

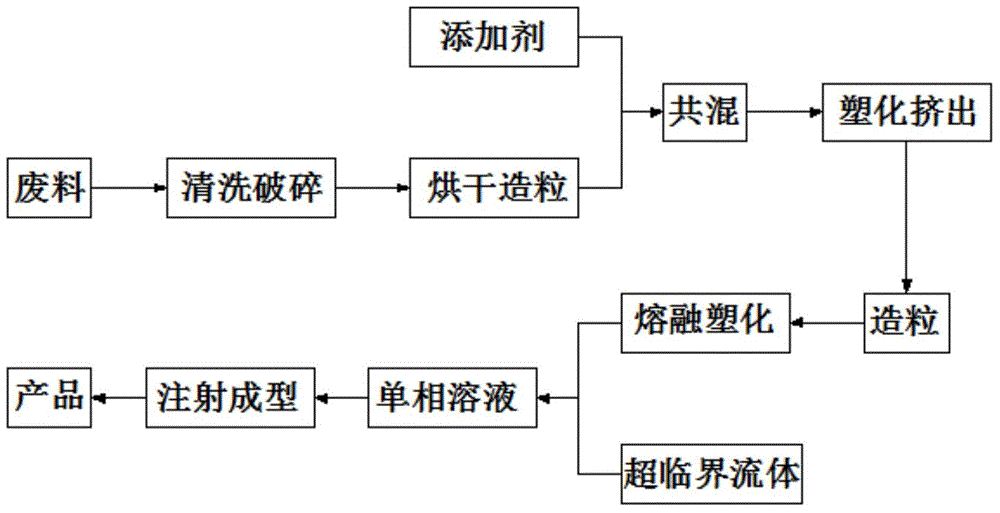

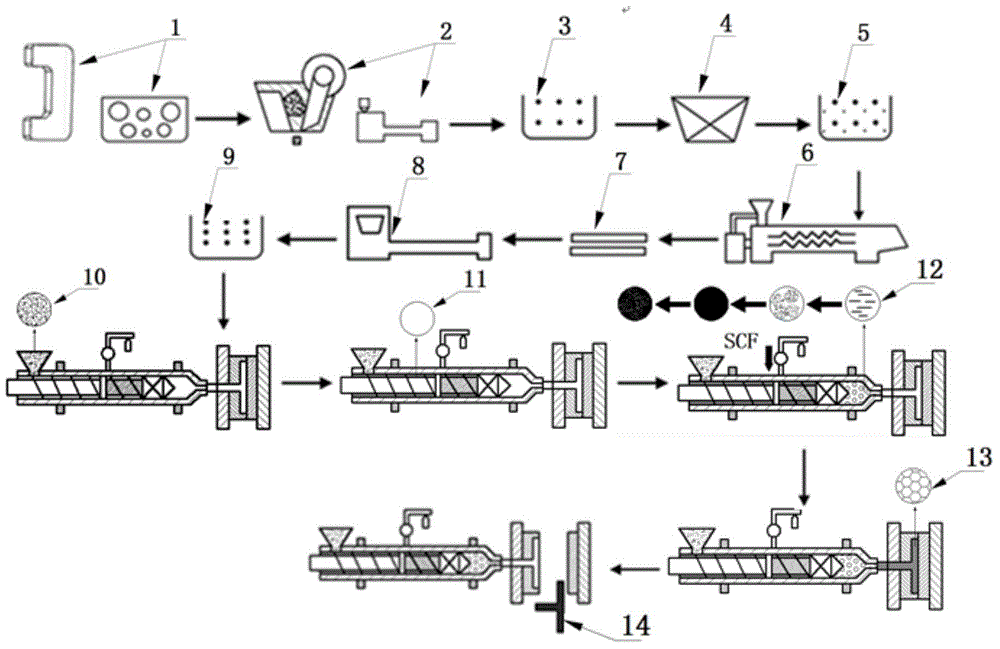

Microcellular foaming recycling method of waste car plastics

InactiveCN104476698AGeneral decline in mechanical propertiesImprove stress distributionPlastic recyclingProduct gasEngineering

The invention discloses a microcellular foaming recycling method of waste car plastics. The method comprises the following steps: preparing the recovery of wastes, modifying the plastics, preparing the recovered material and gas mixed melt, and carrying out the injection molding. By controlling the consumption of additives and key process parameters in the microcellular injection molding, the forming performance and mechanical properties of the recycled plastics can be improved, and especially the mobility and flexibility of the recycled plastics can be improved. According to the method, the waste plastics can be molded into products with a complicated structure and various shapes, such as household appliance shells, car bumpers, and interior and exterior ornaments of cars; the consumption of materials can be reduced, the injection molding thermodynamics can be improved, and the forming period can be shortened.

Owner:WUHAN UNIV OF TECH

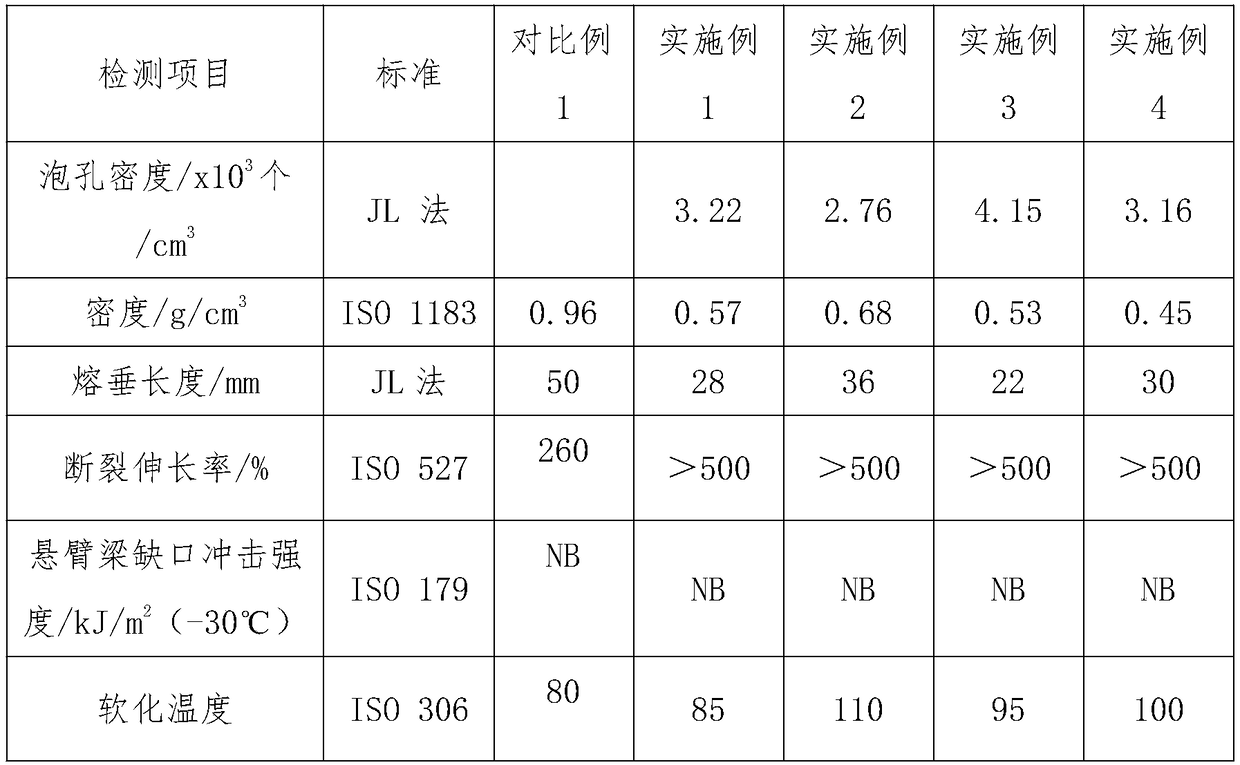

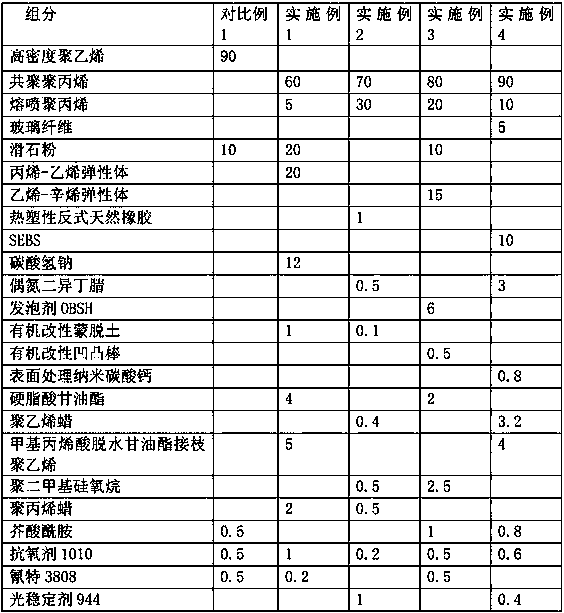

Material for hollow blow-molded micro-foamed tool box and preparation method thereof

The invention relates to a tool box and a preparation method thereof, and particularly relates to a hollow blow-molded micro-foamed tool box and a preparation method of the tool box. The material related to the invention comprises the following components in parts by weight: 60-90 parts of co-polypropylene, 5-30 parts of melt-blown polypropylene, 0-20 parts of a filler, 1-20 parts of a modifier, 0.5-12 parts of a foaming agent, 1-10 parts of a foaming auxiliary agent, 0.5-2 parts of a lubricant, 0.2-1 part of an antioxidant and 0.2-1 part of a light stabilizer. The invention discloses the preparation method of the hollow blow-molded micro-foamed tool box. According to the invention, the tool box with a fine micropore structure is obtained. The anti-sagging property and the transverse stretching performance of the polypropylene melt in a blow-molding and micro-foaming process are effectively improved, the requirements of free regulation of wall thickness distribution of the product is met, the smooth operation of the polypropylene hollow blow-molding micro-foaming process is ensured, and the product has a significant characteristic of light weight. The tool box provided by the invention also has excellent dimensional stability, anti-dropping performance and anti-shocking performance. The preparation method provided by the invention has the advantages of shorter forming period, low manufacturing cost, high product qualification rate and easy realization of industrialization.

Owner:NANJING JULONG SCI&TECH CO LTD

Method for producing aloe cotton blended fabric

InactiveCN106544773AGood fluffySuitable softnessDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsComfort levelsUndershirt

The invention discloses a method for producing an aloe cotton blended fabric. The method includes the following steps: a spooling process, a beam-warping process, a slashing process, a drafting process, a weaving process, and a finishing process. The aloe cotton blended fabric has excellent fluffy and soft performance and suitable elasticity; the problem of crease and size stability of pure cotton fabrics can be solved; the wearing comfort level and the warming performance can be improved further; underclothes such as underwear, vests, undershirts, shorts, T-shirts and pajamas which are made of the aloe cotton blended fabric can protect skins and heath. The warp tensile failure strength of the aloe cotton blended fabric is 267.4N, the weft tensile failure strength of the aloe cotton blended fabric is 225.6N, the warp tearing strength of the aloe cotton blended fabric is 13.3N, and the weft tearing strength of the aloe cotton blended fabric is 10.5N.

Owner:IANGSU COLLEGE OF ENG & TECH

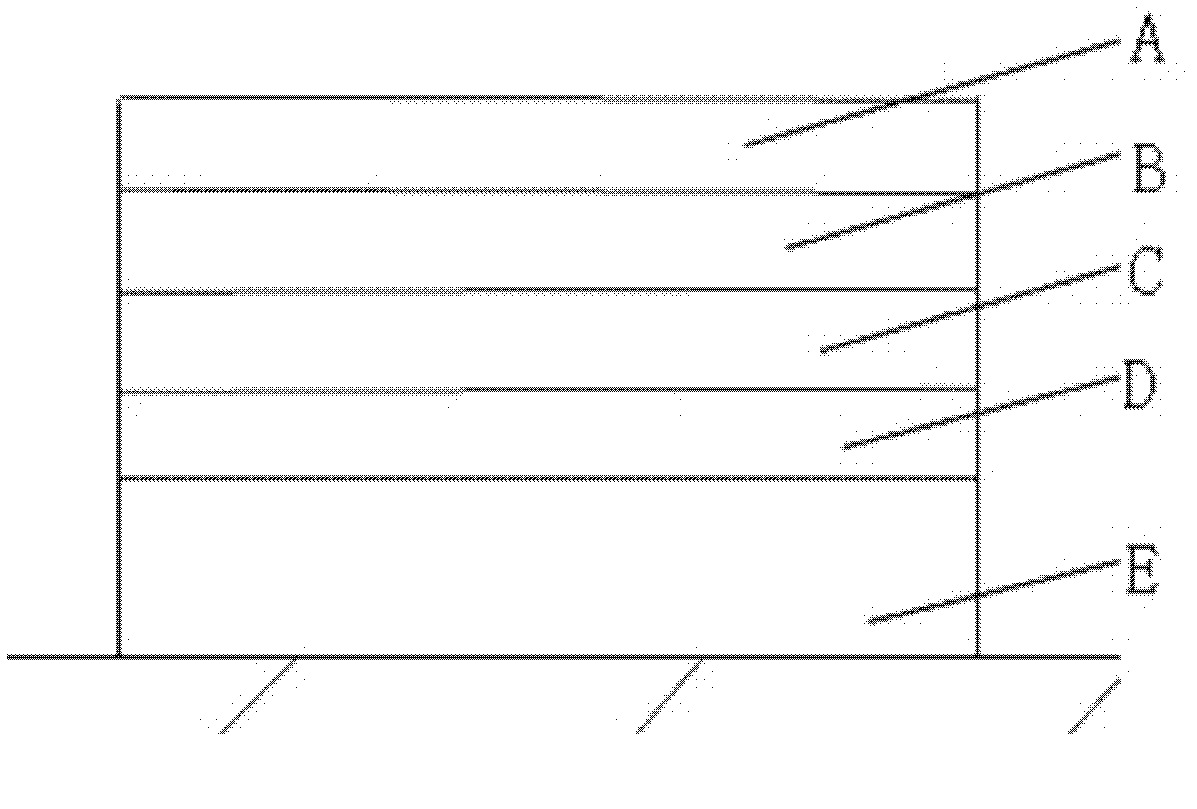

Rotary hearth furnace hearth structure

InactiveCN102586540AAddress Dimensional Stability IssuesAnti-slag erosion performanceManufacturing convertersCarbon compositesThermal insulation

The invention discloses a rotary hearth furnace hearth structure. The rotary hearth furnace hearth structure which is a multilayer structure sequentially comprises, top to down, a carbon composite material layer which contains 8-45% of graphite and 92-54% of fused magnesia magnesium oxide, a carbon composite material layer which contains 8-45% of graphite and 92-54% of fused magnesia magnesium oxide, a mullite firebrick layer, a high-alumina brick layer, and a light-weight thermal-insulation brick layer. So the comprehensive hearth has a special slag erosion resistance and a metal and liquid slag adhesion resistance, and the dimension stability problem of expend with heat and contract with cold of the hearth is solved.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

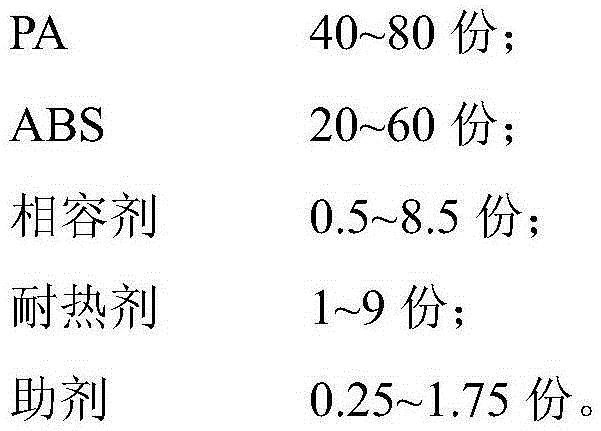

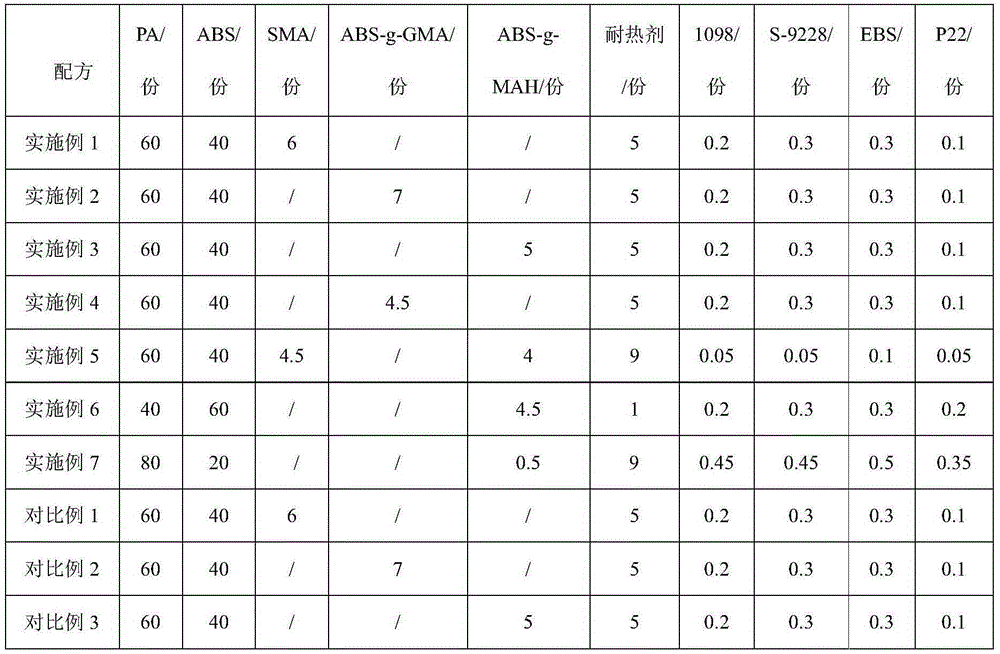

High-size-stability PA/ABS alloy and preparation method

InactiveCN106832909AGood dimensional stabilityAddress Dimensional Stability IssuesAlloyTwin screw extruder

The invention discloses a PA / ABS alloy which is prepared from the following components in parts by weight: 40 to 80 parts of PA, 20 to 60 parts of ABS, 0.5 to 8.5 parts of a compatilizer, 1 to 9 parts of a heat resistant agent and 0.25 to 1.75 parts of an adjuvant. The invention further discloses a preparation method of the PA / ABS alloy. The preparation method comprises the following steps: fully and uniformly mixing 40 to 80 parts of the PA, 20 to 60 parts of the ABS, 0.5 to 8.5 parts of the compatilizer, 1 to 9 parts of the heat resistant agent and 0.25 to 1.75 parts of the adjuvant, conveying the materials into a double-screw extruder through a precision metering material conveying device after the mixing is completed, fully fusing the materials under the shearing, mixing and conveying action of screws, and finally carrying out extrusion, drawing and cooling to obtain particles, and obtaining the PA / ABS alloy. According to the PA / ABS alloy disclosed by the invention, the problem on the size stability of the PA / ABS alloy is fundamentally solved, and the PA / ABS alloy can be widely applied to automobile parts with requirements for high size precision.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

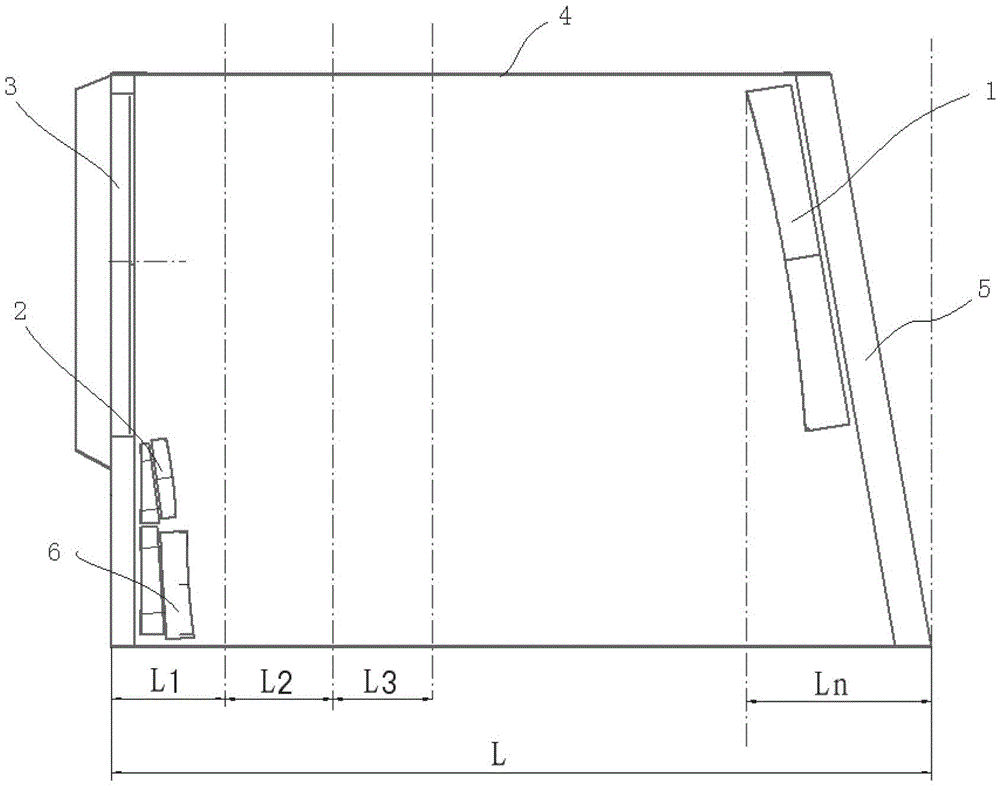

Camera body structure for temperature adaptive space remote-sensing camera

ActiveCN102879980AWide range of temperature adaptationAddress Dimensional Stability IssuesCamera body detailsEngineeringAirframe

The invention relates to a camera body structure for a temperature adaptive space remote-sensing camera. The structure comprises a primary mirror, a secondary mirror, three mirrors, a front frame, a bearing cylinder and a rear frame, wherein the bearing cylinder consists of n sections of carbon fiber composite materials with different hot line expansion coefficients. The overall equivalent hot line expansion coefficients of the bearing cylinder are changed, and the hot line expansion coefficients of the primary mirror, the secondary mirror, the front frame, the bearing cylinder and the rear frame are reasonably designed, so that the position variation between the primary mirror and the secondary mirror is always 0 regardless of the temperature change. By the camera body structure, the problem that the temperature adaptive space remote-sensing camera is low in dimensional stability in the spatial thermal environment is effectively solved, so that the camera has a wide temperature adaptation range, the related requirements on thermal control are reduced, and the reliability of a remote-sensing camera system is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

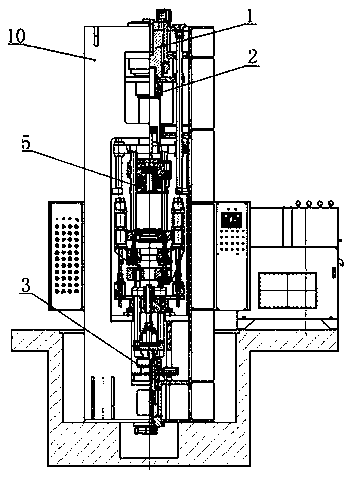

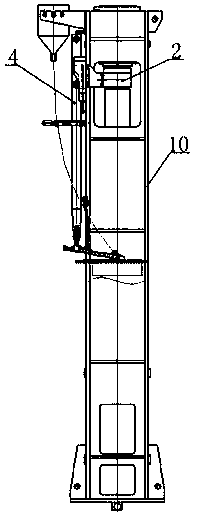

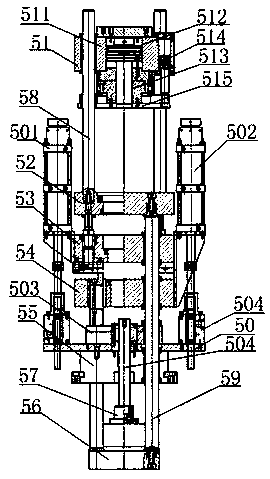

Hydraulically driven mechanical powder molding machine

PendingCN109353060ASolve the problem of molding efficiencyAddress Dimensional Stability IssuesPress ramShaping pressMolding machineEngineering

The invention relates to a hydraulically driven mechanical power molding machine. The hydraulically driven mechanical power molding machine comprises a machine body, an upper limiting oil cylinder, alead screw adjusting structure, a lower oil cylinder structure, a feed mechanism and a formwork assembly. The machine body is a frame machine body. The upper limiting oil cylinder, the lead screw adjusting structure, the formwork assembly and the lower oil cylinder structure are sequentially arranged on the middle of the machine body from top to bottom. The feed mechanism is arranged on one side of the machine body. The upper limiting oil cylinder is connected to the lead screw adjusting structure. The lower end of the lead screw adjusting structure is connected to the formwork assembly. The lower end of the formwork assembly is connected to the lower oil cylinder structure. The hydraulically driven mechanical power molding machine has the characteristics of simple structure, reliable operation, high automation, and convenient mould installation. The hydraulically driven mechanical power molding machine further has advantages of high efficiency, high powder loading, stable product compression and the like. Quickly pressing powder metallurgy parts at a lower cost in the powder metallurgy industry of China becomes possible.

Owner:南通力友液压机制造有限公司

Geothermal floor base material manufactured in irradiation manner and processing method thereof

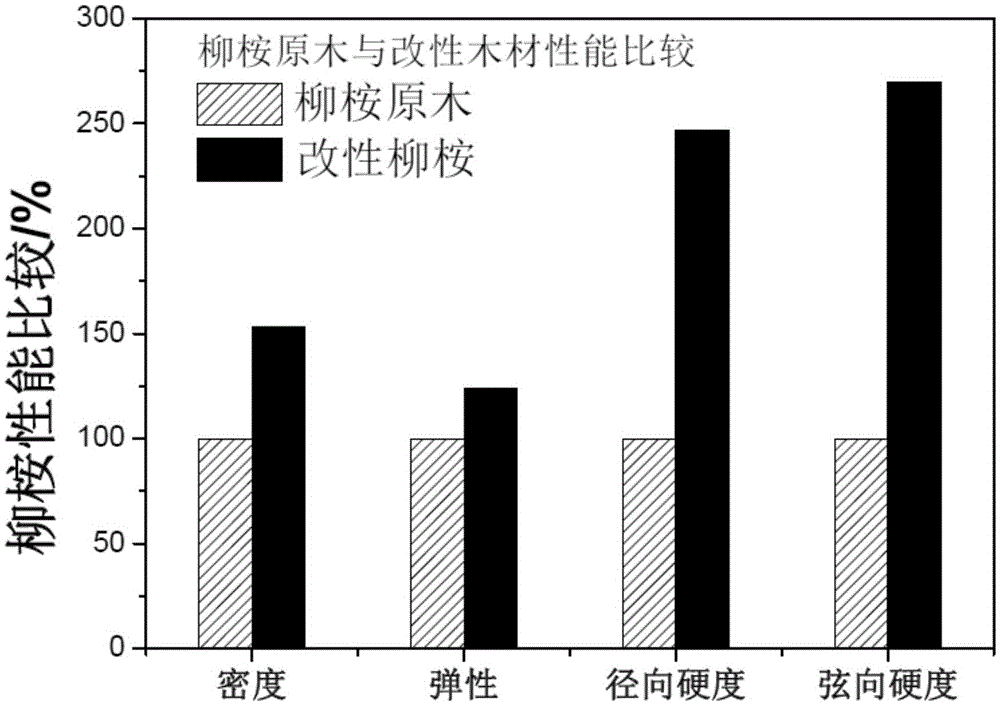

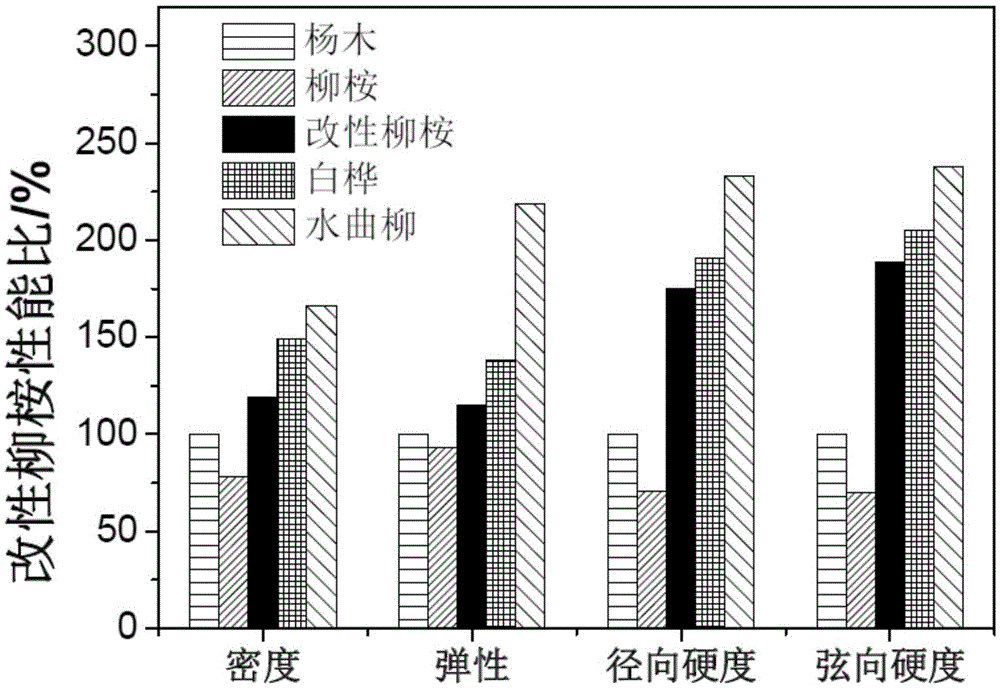

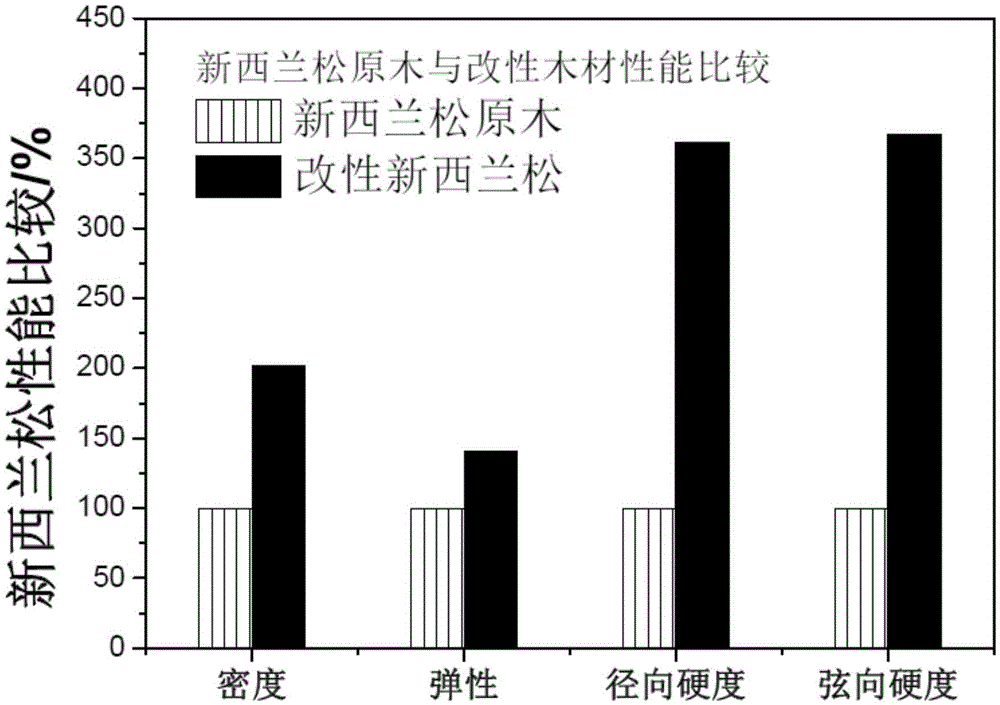

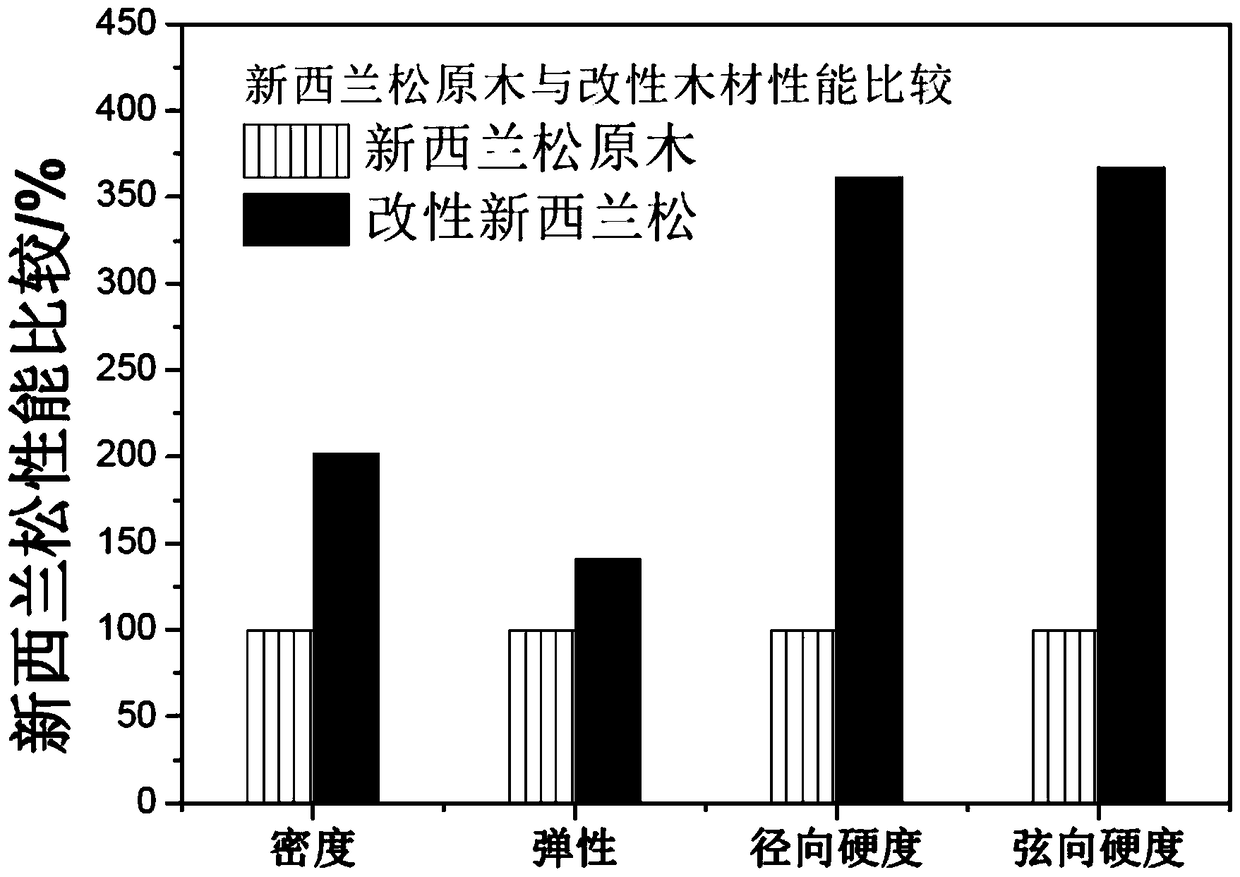

ActiveCN105563597ASimple processLow costRadiation/waves wood treatmentWood treatment detailsToxicityEngineering

The invention discloses a geothermal floor base material manufactured in an irradiation manner and a processing method thereof. The method includes the following steps of baking wood, placing the wood in a closed tank, vacuumizing the closed tank, steeping the wood in a pressurizing manner, reducing pressure to remove surface liquid, taking the wood out, then irradiating the wood with electronic beams and curing the wood to obtain a product. Less time is consumed, cost is low, various properties of the wood can be improved effectively, and the method is a very economical fast-growing wood modifying method. Organic preparation steeping and electronic beam irradiating are utilized to improve the properties of the fast-growing high-yield wood. The method can improve various mechanical properties of the fast-growing wood remarkably. Moreover, price is low, investment is small, operation time is short and additional toxicity is avoided.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Method for processing wool jean plus material

InactiveCN101215745BGuaranteed rendering effectAddress Dimensional Stability IssuesFibre treatmentSingeingPolymer scienceThermal water

The invention discloses a process for preparing wool denim fabric, which solves the problem that the existing wool fiber can not be used in the manufacture of denim fabric. The invention has simple method, convenient operation, and uses wool fiber in the manufacture of denim fabric. The method comprises first, taking shrinkproof top wool as raw material, second, adopting indigo dyes to dye chaine, steps comprise preprocessing under the temperature of 50-70 DEG C, washing in hot water under the temperature of 35-45 DEG C, washing in cold water in normal temperature, dipping for times, oxygenizing, dipping in acid whose PH value is 11.2-11.3, washing in water, carrying out soft process under the temperature of 50-70 DEG C, drying under the temperature of 80-100 DEG C, third, sizing on chaine, steps comprise reeling off through shaft, sizing, the temperature is 50-70 DEG C, wet splitting, drying, the temperature is 80-90 DEG C, dry splitting, and reeling, fourth, weaving denim cloth, fifth, post finishing wool denim cloth: genapping, diagonal tensioning, full-width scouring, full-width crabbing, relaxedly steam preshrinking, full decatizing and doffing cloth, finally obtaining finished product, namely wool denim fabric.

Owner:LINYI AOTAI TEXTILE

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

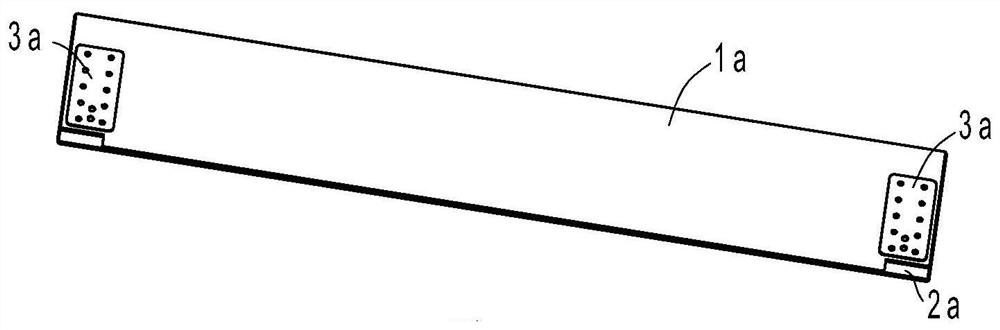

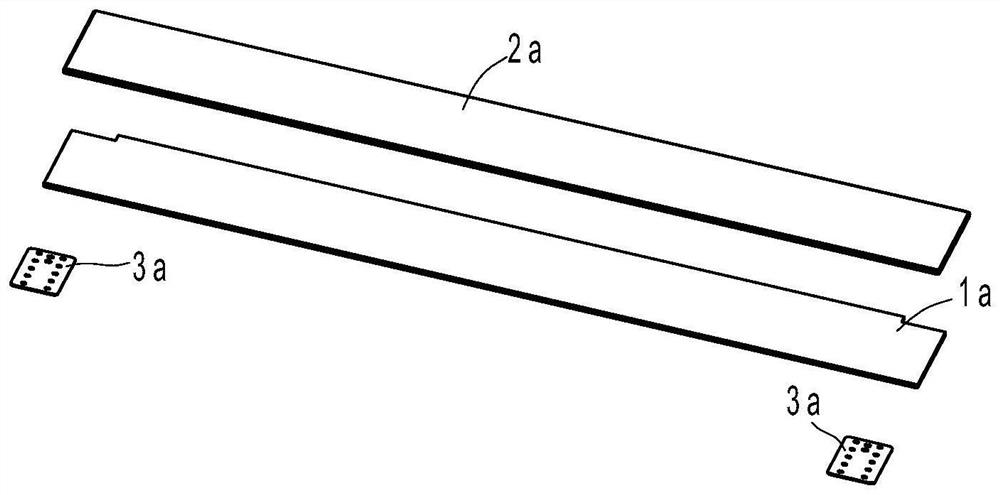

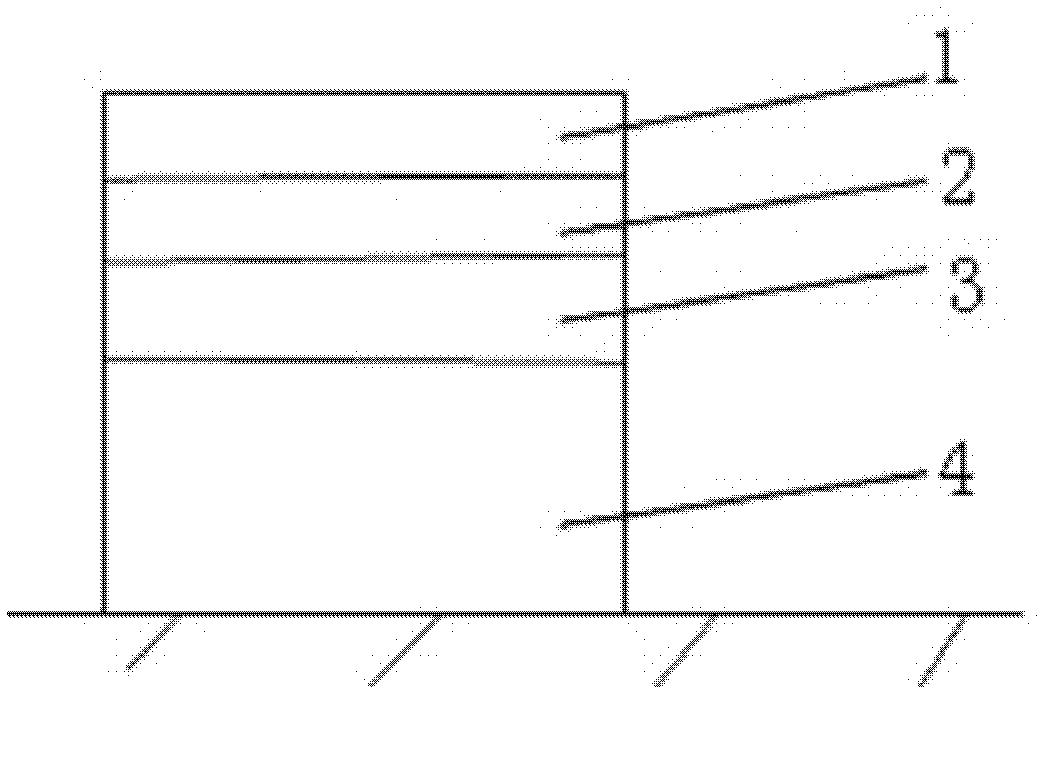

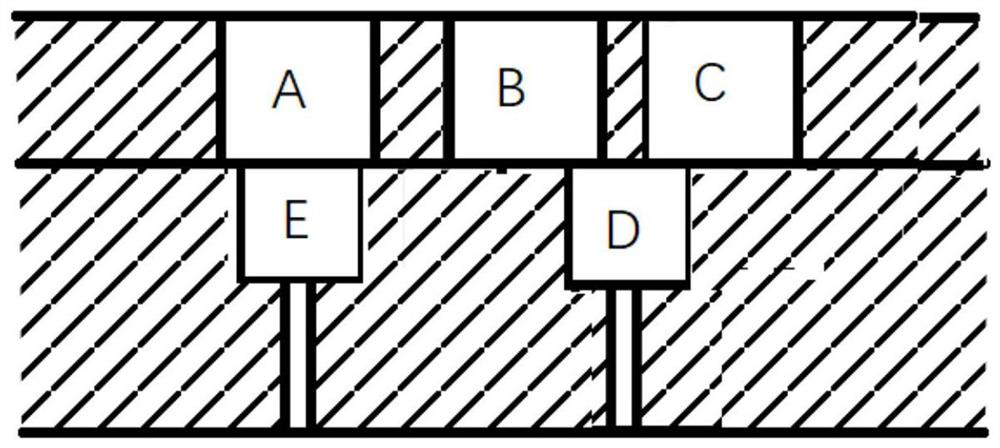

Decorative panel assembly bonding method

ActiveCN108999852BSolve the deformationImprove surface qualityDomestic stoves or rangesLighting and heating apparatusStructural engineeringWorkbench

The invention discloses a decorative board assembly bonding tool. The tool is characterized in that the tool includes a worktable (1), positioning frames (5), first stop blocks (51), second stop blocks (52), down-pressing air cylinders (2) and a down-pressing plate (3); the vertical directions of the positioning frames (5) have elasticity, and the inner rings of the positioning frames (5) fit a glass face plate (1a); the inner sides of the positioning frames (5) have supporting parts (57) used for supporting the glass face plate (1a); the down-pressing air cylinders (2) have vertically downward power output ends; the power output ends are provided with the down-pressing plate (3) whose appearance accords with a decorative plate (2a); and the down-pressing plate (3) is located above the worktable (1). A decorative board assembly bonding method is also disclosed. Compared with the prior art, the advantages of the tool and the method are that accurate positioning can be guaranteed by adopting the elastic positioning frames to combine the first stop blocks and the second stop blocks; and through the bonding of three parts, dimensional stability can be solved, the surface quality of decorative boards can be improved, labor productivity can be enhanced, and production costs can be reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

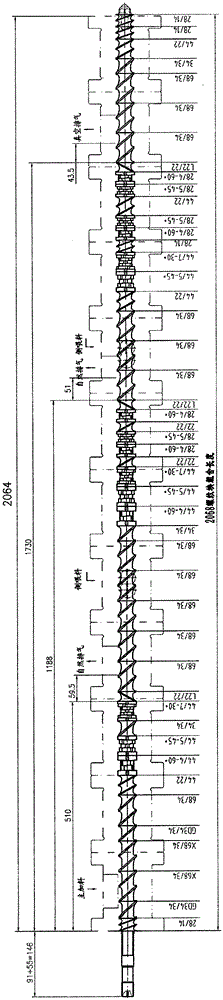

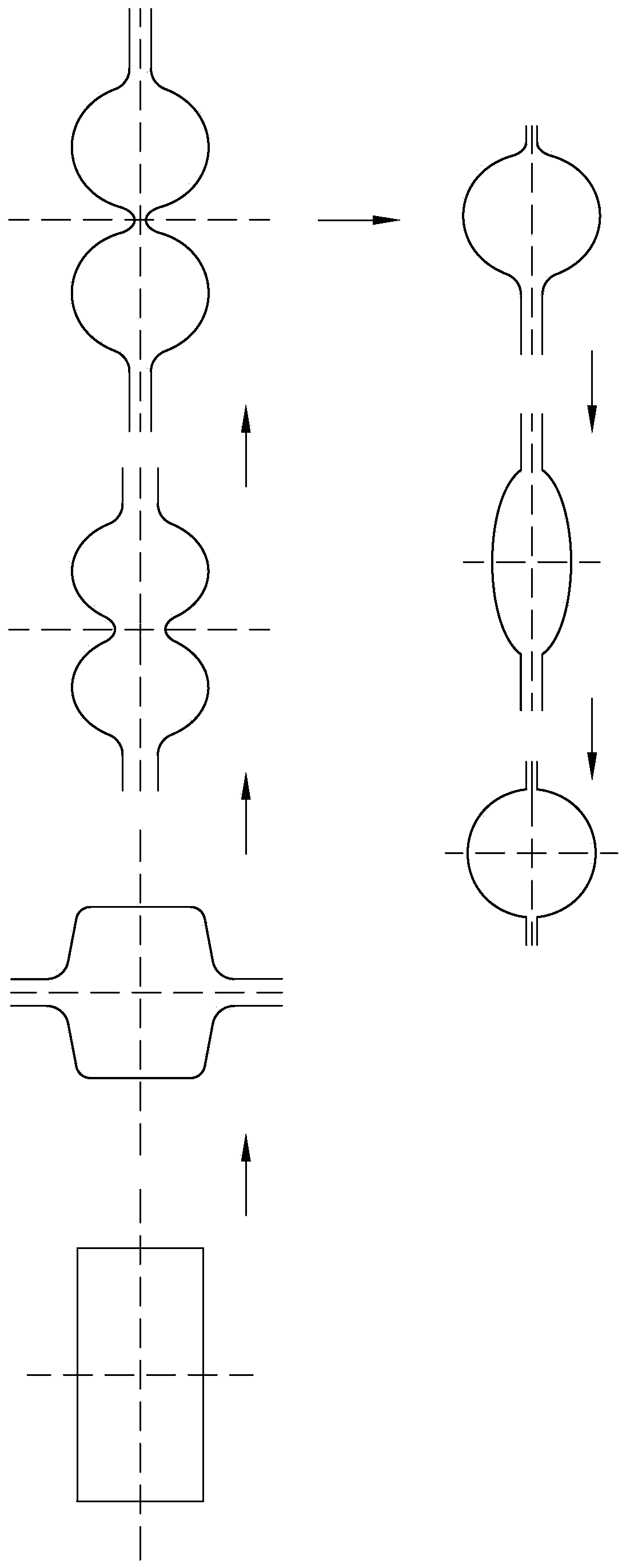

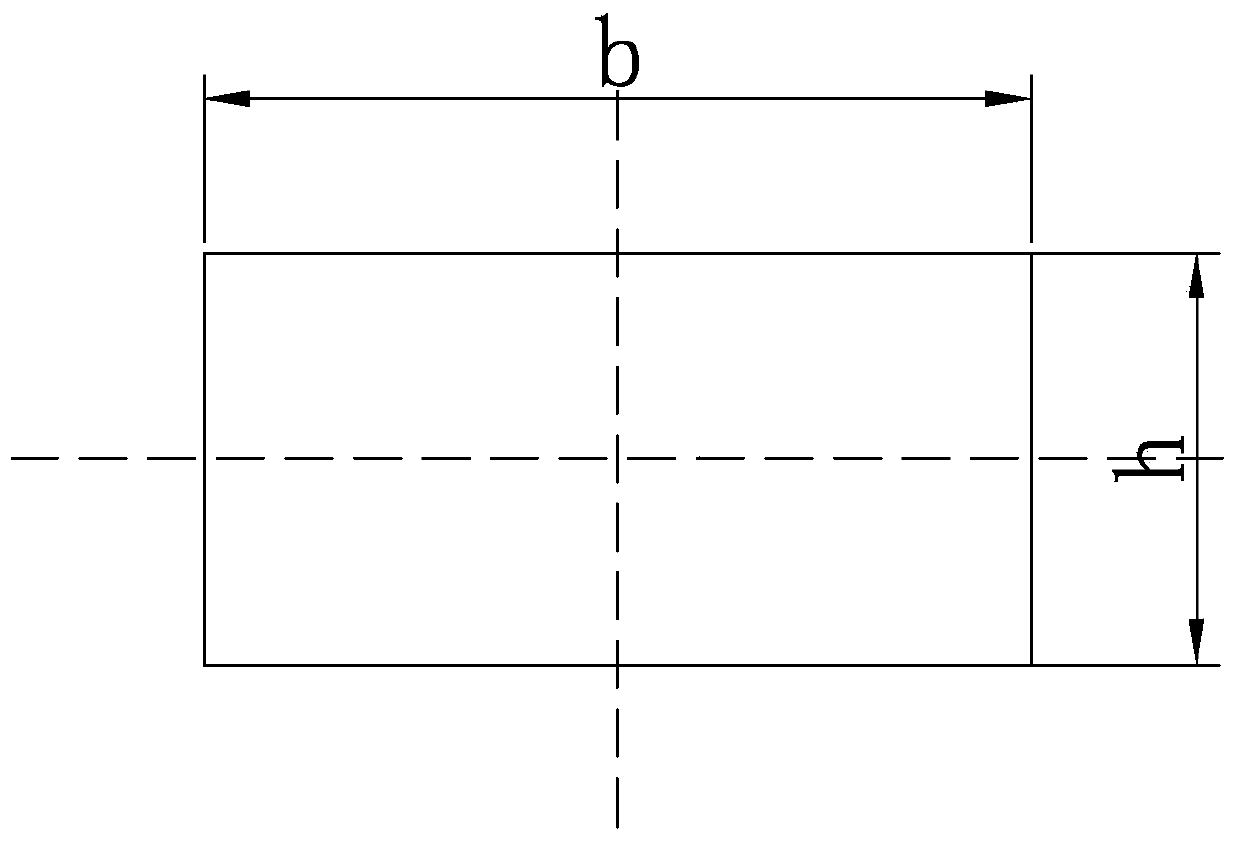

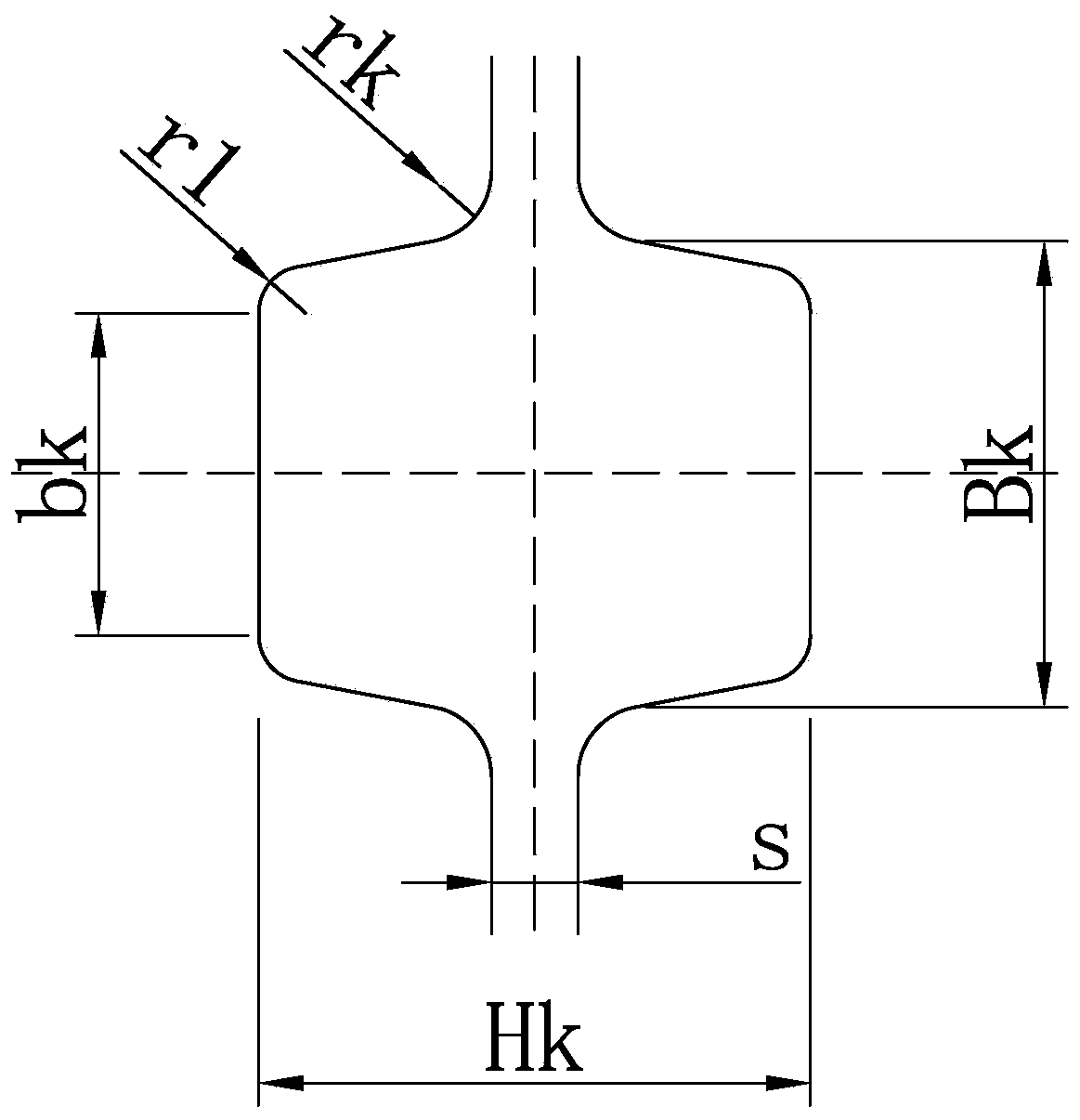

A kind of round steel slitting and rolling process

ActiveCN109127725BTurn to steelImprove out of roundnessRollsMetal rolling arrangementsMetallurgyMechanical engineering

The invention discloses a round steel cutting and rolling process. In this round steel split rolling process, after the round holes are rolled out in the rough and intermediate rolling stage, the roll passes used in the finish rolling stage are: flat rolling pass, vertical box pass, pre-splitting pass, Segmented, oval and round passes. The round steel split rolling process of the present invention solves the problem of surface defects and dimensional stability of the split wedge part of the round steel split rolling, and the surface quality of the finished product is stable, realizing the production of chain circles and standard parts by using round steel splitting And other high-quality round steel.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

Rotary hearth furnace hearth structure

InactiveCN102586540BAddress Dimensional Stability IssuesManufacturing convertersCarbon compositesThermal insulation

The invention discloses a rotary hearth furnace hearth structure. The rotary hearth furnace hearth structure which is a multilayer structure sequentially comprises, top to down, a carbon composite material layer which contains 8-45% of graphite and 92-54% of fused magnesia magnesium oxide, a carbon composite material layer which contains 8-45% of graphite and 92-54% of fused magnesia magnesium oxide, a mullite firebrick layer, a high-alumina brick layer, and a light-weight thermal-insulation brick layer. So the comprehensive hearth has a special slag erosion resistance and a metal and liquid slag adhesion resistance, and the dimension stability problem of expend with heat and contract with cold of the hearth is solved.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

Method for producing high-grade knitting yarn by blending seaweed fiber with combed fine-staple cotton and long-staple cotton

Owner:JIHUA 3509 TEXTILE

Surface modification inorganic nanoparticle modified polyurethane rigid foam and preparation

InactiveCN101475741BImprove physical and chemical propertiesRealize regulationPolymer scienceFoaming agent

The invention discloses a surface-modified inorganic nanoparticle modified polyurethane hard foam and a preparation method. The polyurethane hard foam not only has good flame retardant property, but also has good compressive strength and dimension stability. The surface-modified inorganic nanoparticle modified halogen-free flame retardant polyurethane hard foam is prepared by the following raw materials in portion by weight: 100 portions of polylol, 100 to 150 portions of isocyanate, 0.05 to 0.5 portion of catalyst, 1 to 5 portions of foam homogenizing agent, 0.05 to 0.5 portion of foaming agent, 10 to 30 portions of flame retardant, and 3 to 9 portions of modified nanoparticles.

Owner:黎卓

Preparation method of terylene light-shieding flame-retardant coated fabric

InactiveCN111101380ASolve environmental problemsAddress Dimensional Stability IssuesCurtain accessoriesCoatingsPhysical chemistryPolymer chemistry

The invention discloses a preparation method of a terylene light-shielding flame-retardant coated fabric. The preparation method is carried out according to the following flow of: fabric pre-shrinking, fabric padding pretreatment agent drying, base coating drying, light-shielding layer coating drying and surface color coating drying, wherein in the fabric pre-shrinking process, a pre-shrinking setting speed is reduced to 20m / min from 40m / min, a pre-shrinking temperature is risen to 200 DEG C from 150 DEG C, and an effective width of 150cm of a base fabric before pre-shrinking is reduced to aneffective width of 146cm after pre-shrinking; an assistant water-soluble flame-retardant pretreatment agent is selected to carry out padding on the fabric, coating agents are compositely coated and scraped on the base fabric, the coating agents sequentially comprise three coating agents of a PA emulsion, a flame retardant and silver colloid, and finally, the fabric enters a drying oven in a completely relax state to be set. Proper environmental-friendly glue is selected, so that the problem of environmental protection is solved. The pre-shrinking setting speed and the pre-shrinking temperaturein the fabric pre-shrinking process are controlled, so that problems of size stability and seam slippage are solved, shrinkage control is smaller than 1%, and seam slippage is smaller than 2%.

Owner:WUJIANG FUHUA WEAVING

A kind of anti-shrinkage and non-ironing wool-like fabric and preparation method thereof

ActiveCN111101264BAddress Dimensional Stability IssuesGood dimensional stabilityWeft knittingWarp knittingPolymer scienceSpinning

Owner:JIANGSU HENGLI CHEM FIBER

Poly L lactic acid/zirconium dioxide organic and inorganic hybridization fiber and preparation method thereof

InactiveCN102839445BSolve the uniformity of dispersionAddress Dimensional Stability IssuesMonocomponent polyesters artificial filamentArtifical filament manufactureFiberLaccaic acid

Owner:HEFEI UNIV OF TECH

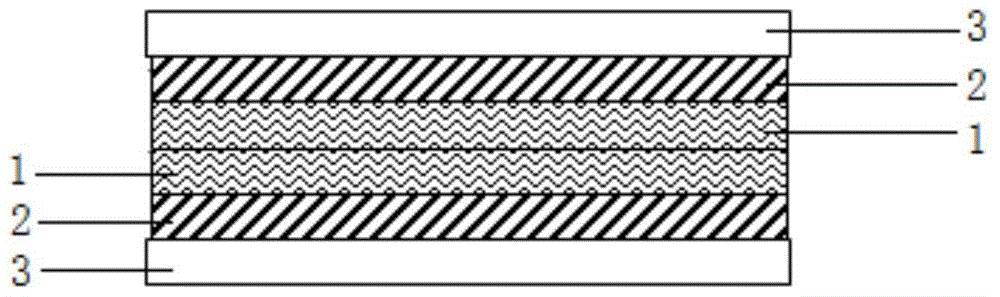

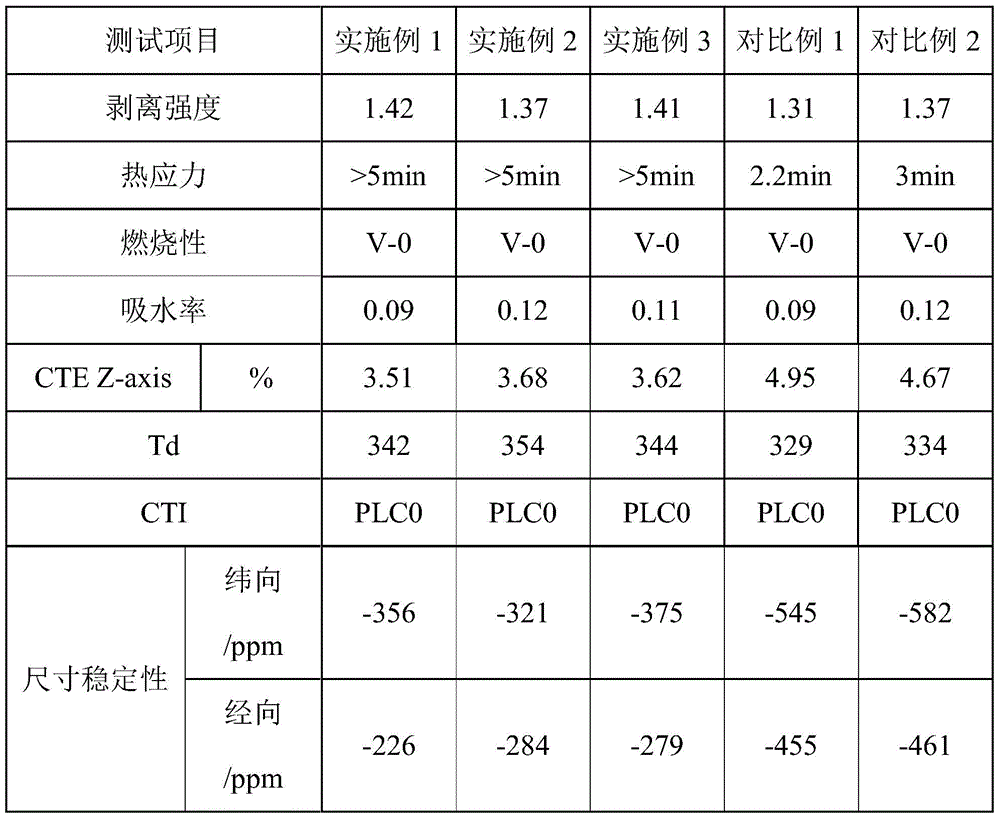

A kind of resin composition and its application

ActiveCN104448718BGood dimensional stabilityImprove heat resistanceSynthetic resin layered productsMetal layered productsEpoxyThermal expansion

The invention discloses a resin composition. The resin composition is prepared from the following components in parts by weight: 10-30 parts of epoxy soybean oil modified epoxy resin, 70-90 parts of phosphorus modified phenolic epoxy resin, 15-20 parts of biphenyl type phenolic resin, 5-20 parts of nonyl phenol modified benzoxazine, 70-103 parts of silicon dioxide, 20-50 parts of boehmite, 0.08-0.85 part of diphenyl imidazole, 30-80 parts of acetone and 30-80 parts of ethylene glycol monomethyl ether. The resin composition is used for preparing a copper-clad plate. According to the resin composition, the problems that a copper-clad plate is poor in dimensional stability and heat resistance after being solidified by an existing adhesive resin system are solved; the heat resistance and dimensional stability of CEM-3 are improved; and the coefficient of thermal expansion of the plate is also improved, so that the production technology of the CEM-3 reaches the advanced level at home.

Owner:SHAANXI SHENGYI TECH

Method for producing warp and weft dual-elastic denim fabric by bundled lines

ActiveCN102936811BBright and uniform colorHigh color fastnessFibre treatmentHeating/cooling textile fabricsDenimHigh color

A method for producing warp and weft double-elastic denim fabric with a beam line. The warp and weft double-elastic denim fabric is produced in a long process by dyeing the beam line in multiple dyeing vats; process steps: (1) use cotton-wrapped spandex slubs as warp yarns, and use cotton as weft yarns Three packs of polyester-coated and spandex-wrapped yarns are used as weft yarns; (2) The ball warping process maintains a stable temperature and humidity throughout; (3) Heavy hammers are used to pressurize, and pretreatment is carried out before dyeing until the tension of each part is stable. , and then connected to the elastic ball shaft; the dyeing process adopts a low-content dyeing process with multiple dye vats to increase the penetration and dyeing rate of the dye; (4) the dividing process adopts small tension; (5) the sizing adopts low viscosity and low Thick sizing process; (6) Weaving adopts high back beam, large tension and small opening machine process; (7) Finishing adopts desizing and pre-shrinking finishing process; (8) Adopts the method of shaping. The latitude and longitude double-elastic denim produced by the invention has bright and uniform color, high color fastness and stable elasticity.

Owner:ZAOZHUANG HIYOUNG DYNASTY TEXTILE

A kind of cotton fiber, viscose fiber blended yarn and its manufacturing method

Owner:ZHEJIANG SHUANGDUN TEXTILE TECH CO LTD

Irradiation preparation of geothermal floor substrate and its processing method

ActiveCN105563597BSimple processLow costRadiation/waves wood treatmentWood treatment detailsEngineeringIrradiation

The invention discloses a geothermal floor base material manufactured in an irradiation manner and a processing method thereof. The method includes the following steps of baking wood, placing the wood in a closed tank, vacuumizing the closed tank, steeping the wood in a pressurizing manner, reducing pressure to remove surface liquid, taking the wood out, then irradiating the wood with electronic beams and curing the wood to obtain a product. Less time is consumed, cost is low, various properties of the wood can be improved effectively, and the method is a very economical fast-growing wood modifying method. Organic preparation steeping and electronic beam irradiating are utilized to improve the properties of the fast-growing high-yield wood. The method can improve various mechanical properties of the fast-growing wood remarkably. Moreover, price is low, investment is small, operation time is short and additional toxicity is avoided.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

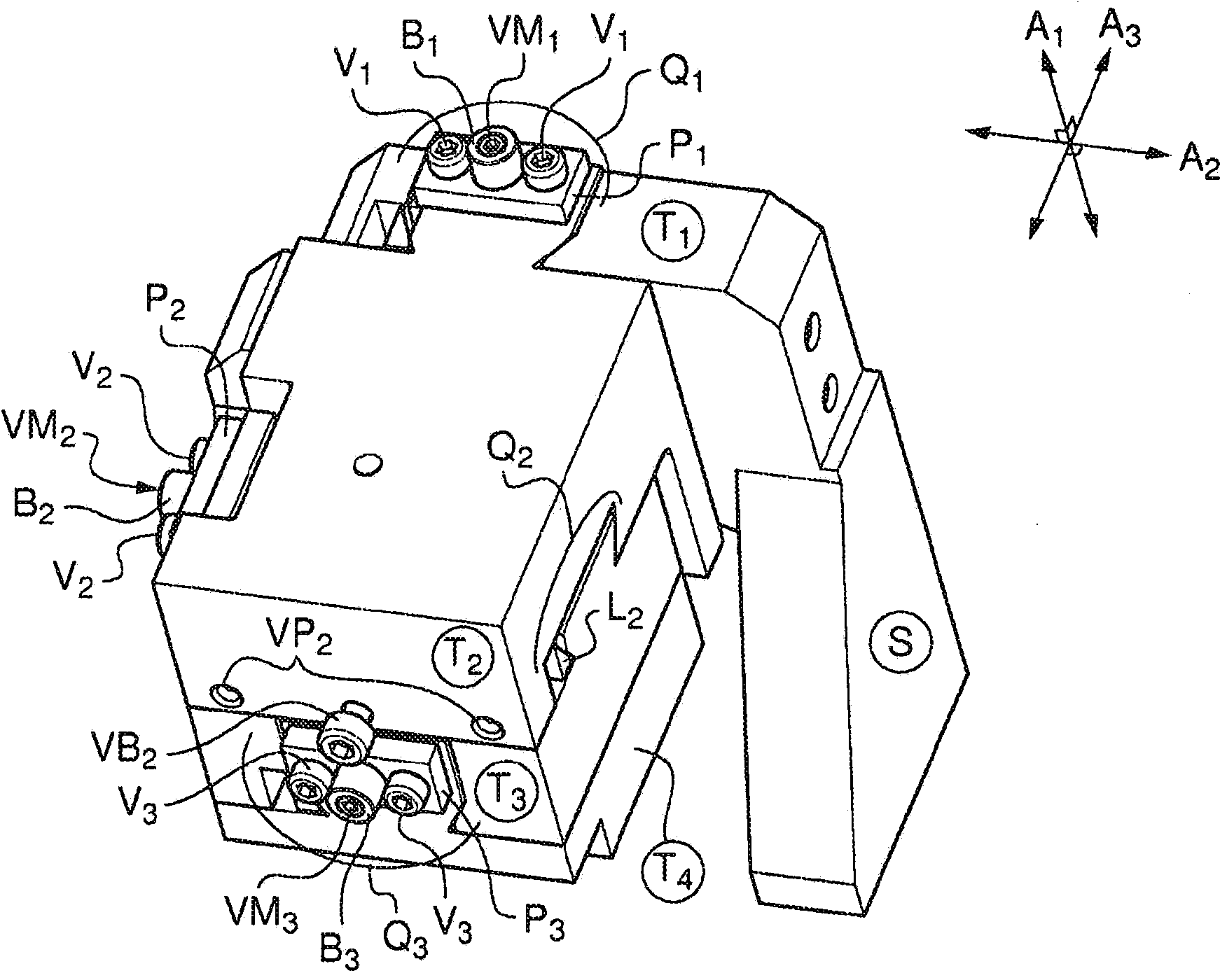

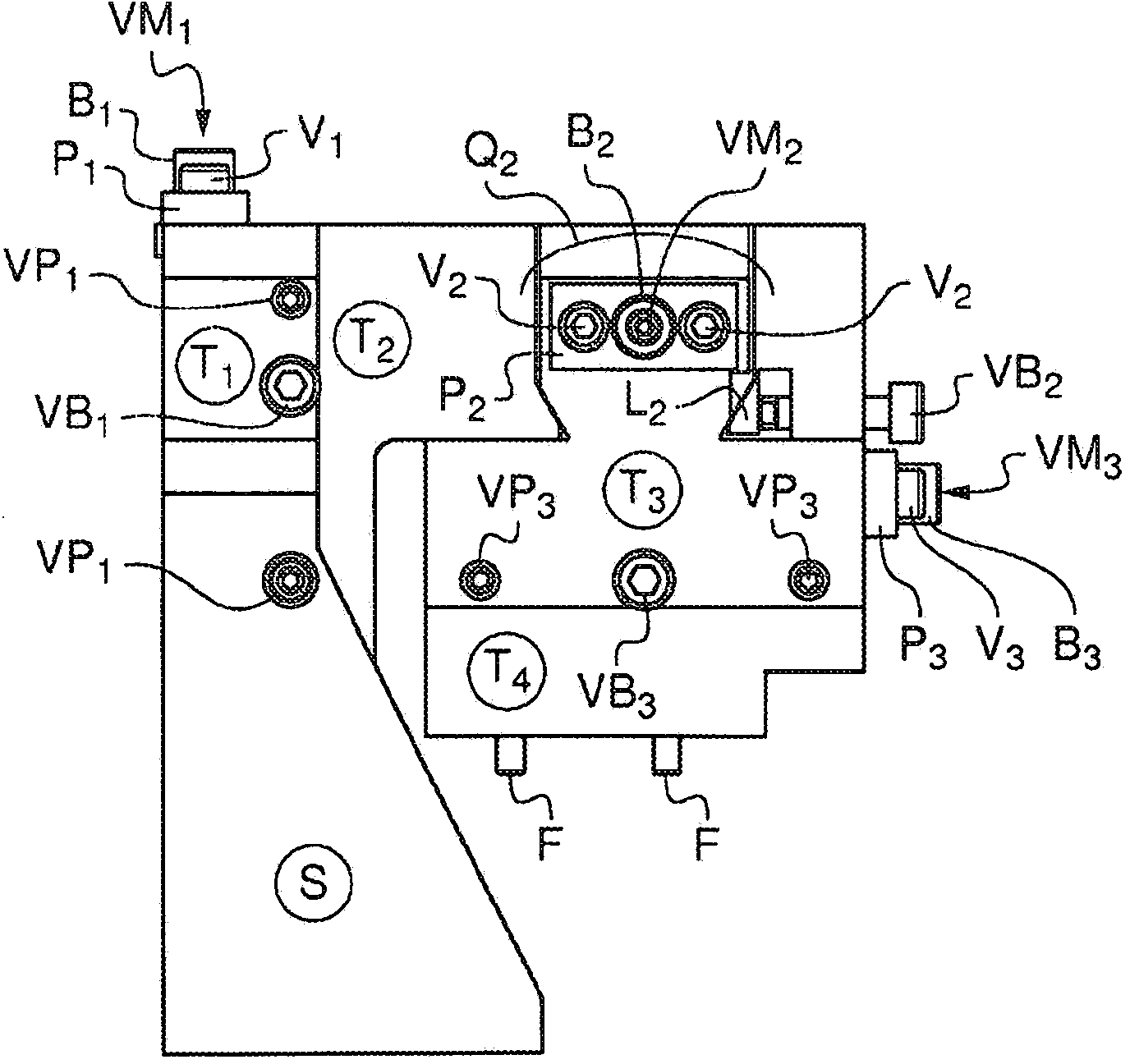

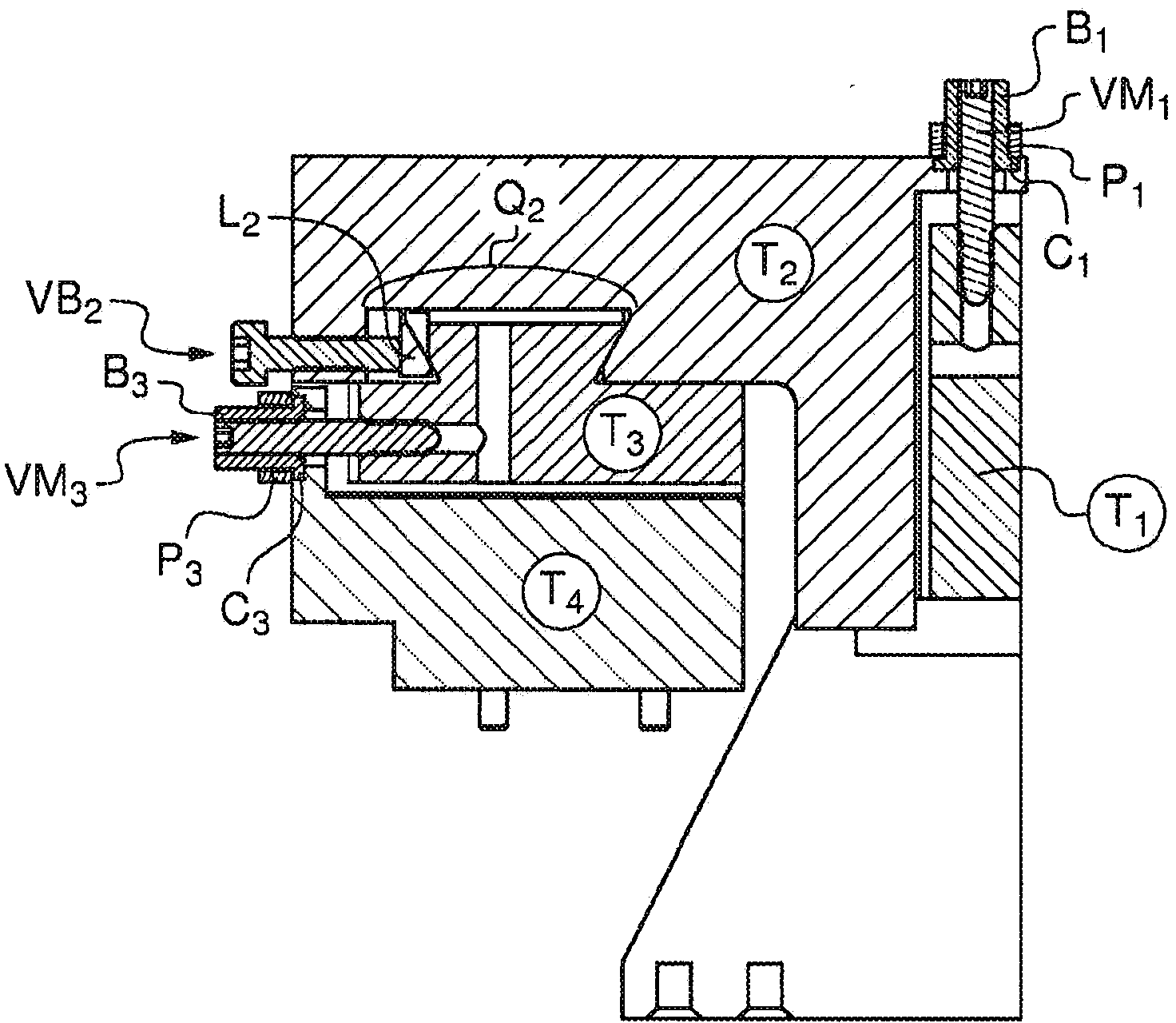

Device for positioning an object in space

ActiveCN104204718AImprove distributionAddress Dimensional Stability IssuesUsing electrical meansStands/trestlesSubject matterEngineering

"Device for positioning an object in space" Abstract The subject matter of the invention is a device for positioning an object in space comprising at least 4 plates (T1, T2, T3, T4), each capable of moving in relation to one of the other said plates with which it is contiguous along one of the 3 axes of space, the movement of a plate in relation to another plate potentially being guided by a mortise / tenon assembly in which said tenon may be rigidly connected with one of said plates and the mortise thereof may be built into the other plate, the orientation in space of each of the mortise / tenon assemblies being different from the other 2 and along one of the 3 axes of space, characterised in that: Said device is free of all return springs; At least one of the mortise / tenon assemblies may be in a dovetailed shape; A pre-tension aimed at limiting the movement of a plate with respect to another is laterally applied to one of the edges of the tenon of the mortise / tenon assembly, said pre-tension limiting but not preventing the movement of said plates with respect to one another; The movement of at least one plate with respect to another plate may be assured by means of at least one micrometric screw that can act on at least one of the 2 plates that must be moved with respect to one another, said micrometric screw potentially being rigidly connected with one of said 2 plates, said micrometric screw potentially being fastened in direct contact with said plate; The immobilisation of one plate with respect to another plate in the desired position may be assured, independently for each of the mortise / tenon assemblies, by at least one means of immobilisation.

Owner:HORIBA ABX SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com