Camera body structure for temperature adaptive space remote-sensing camera

A remote-sensing camera and self-adaptive technology, which is applied to the camera body, camera, optics, etc., can solve the problems such as the position change of optical components is out of tolerance, and achieve the effect of improving reliability, wide temperature adaptation range, and reducing related requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

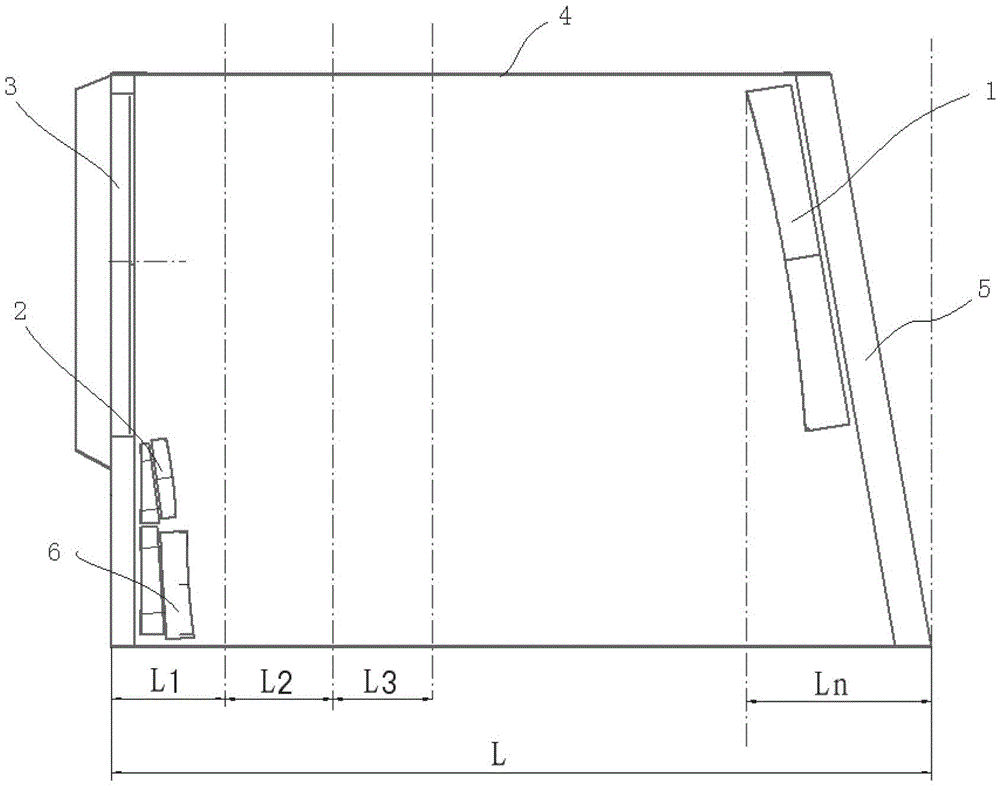

[0023] Such as figure 1 As shown, the aerospace remote sensing camera body is mainly composed of a front frame 3, a bearing tube 4, a rear frame 5, a primary mirror 1, a secondary mirror 2, and a third mirror 6. The materials of the primary mirror 1, the secondary mirror 2 and the third mirror 6 can be flexibly selected according to actual needs, and silicon carbide materials or other materials with better thermal stability are used; the front frame 3, the bearing tube 4 and the rear frame 5 are all made of M40J Carbon fiber composite material or other types of carbon fiber composite material. The front frame 3 and the rear frame 5 are respectively connected with the bearing cylinder 4 by glue screws to form an integral carbon fiber fuselage structure. The front frame 3 and the rear frame 5 can also adopt other materials according to actual needs. The load-bearing cylinder 4 is composed of n sections of carbon fiber composite materials with different thermal linear expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com