Photo-induced reversible self-repair polyurethane film and repair method

A polyurethane film and self-healing technology, applied in the field of photoreversible self-healing polyurethane film and its preparation and repair, achieves the effects of easy construction, simple process conditions and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

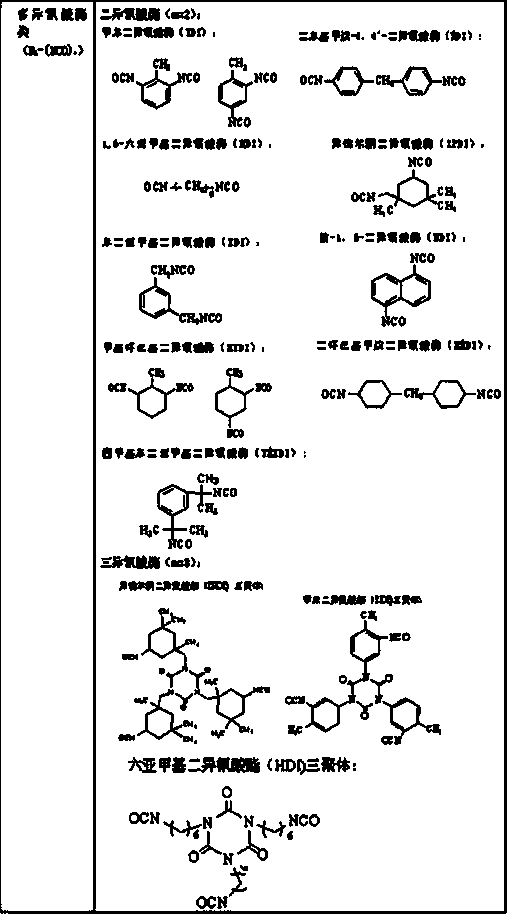

Method used

Image

Examples

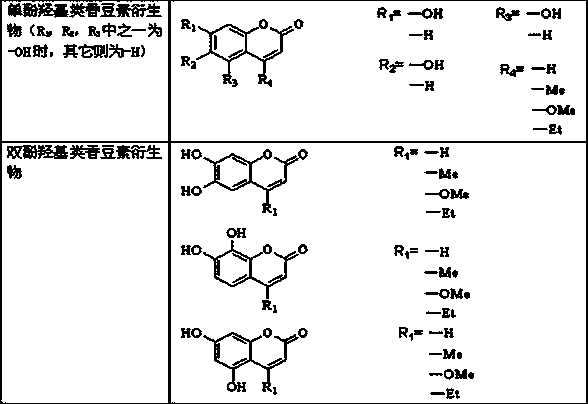

Embodiment 1

[0032] At room temperature and under the protection of argon, 20g of 7-hydroxy-4-methylcoumarin was added to a 250ml two-necked flask, 100g of N,N-dimethylformamide was added and electromagnetic stirring was started to make 7-hydroxy-4- Dissolve methyl coumarin, then add 20g of 2-bromoethanol dropwise at a constant speed, add 32g of catalyst anhydrous potassium carbonate at one time after 5min, raise the temperature of the reaction system to 88°C and react for 18h to end the reaction; when the temperature of the reaction system drops to After room temperature, pour it into 400g of ice water and stir for 30min, filter the precipitate, wash with 500g of distilled water, dry at 50°C for 48h, and recrystallize twice with ethyl acetate to obtain alcoholic hydroxyl-containing 7-hydroxyethoxy-4-methanol base coumarin.

Embodiment 2

[0034] Add 2g of hexamethylene diisocyanate trimer to a 50ml three-necked flask, degas it under vacuum at 120°C for 2h, cool down to 50°C, add 3g of N,N-dimethylformamide to dissolve and dilute, start electromagnetic stirring and pass Argon protection, then the 7-hydroxyethoxy-4-methylcoumarin of 0.81g prepared in Example 1 and 1 drop of 10% dibutyltin dilaurate ethyl acetate solution were dissolved in 7gN,N- Dimethylformamide was transferred to a constant pressure dropping funnel, and added dropwise to the reaction system at a constant speed, and the drop was completed within 1 hour; after raising the temperature of the system to 70°C and reacting for 3 hours, 1.26 g of polyethylene glycol (average molecular weight 400 g / mol), and continue to react at 70°C for 12 hours to obtain a polyurethane solution containing coumarin side groups. Apply this solution directly on a polytetrafluoroethylene plate and dry it under vacuum at 80°C for 48 hours (vacuum pressure 3 Pa), and fina...

Embodiment 3

[0036] Add 28g of 5,7-dihydroxy-4-methylcoumarin into a 250ml two-necked flask, add 100g of N,N-dimethylformamide to dissolve and start electromagnetic stirring, then add 56g of 2-bromoethanol dropwise at a constant speed, After 5 minutes, add 56g of catalyst anhydrous potassium carbonate at one time, raise the temperature to 88°C and react for 18h under the protection of argon, and then end the reaction. When the reaction system drops to room temperature, add 400g of anhydrous ether to extract the organic layer and filter out the inorganic salt K 2 CO 3 , the organic layer was washed with a large amount of water until the pH of the aqueous phase = 7, and the solvent diethyl ether was removed using a vacuum rotary evaporator (vacuum pressure3 Pa), to obtain a brown oily mixture, which was separated by column chromatography (eluent: ethyl acetate:petroleum ether=2:1) to obtain the pure substance 5,7-dihydroxyethoxy-4-methylcoumarin .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com