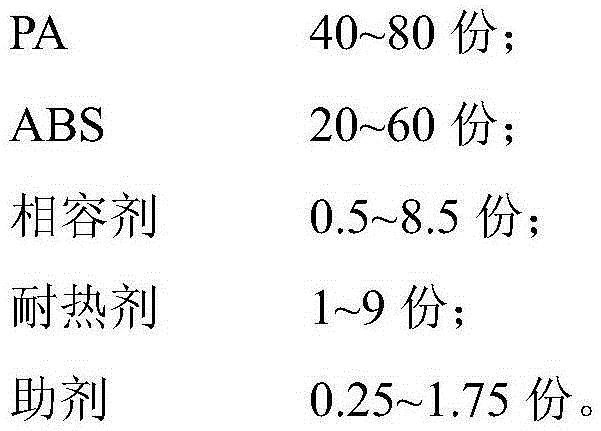

High-size-stability PA/ABS alloy and preparation method

An alloy, styrene technology, applied in the field of high dimensional stability PA/ABS alloy and preparation, can solve the problems of dimensional stability affecting the appearance of products, can not meet the requirements of dimensional accuracy, etc., to solve the problem of dimensional stability, product dimensional stability Good performance and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

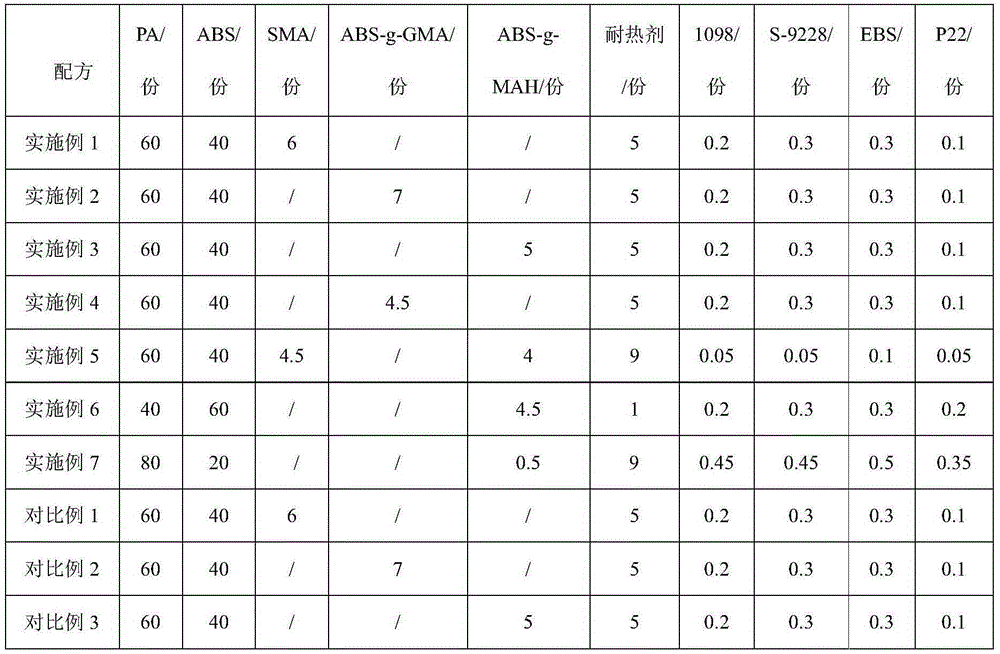

Embodiment 1-7

[0023] The preparation method of embodiment 1-7 and comparative example 1-3 comprises the following steps:

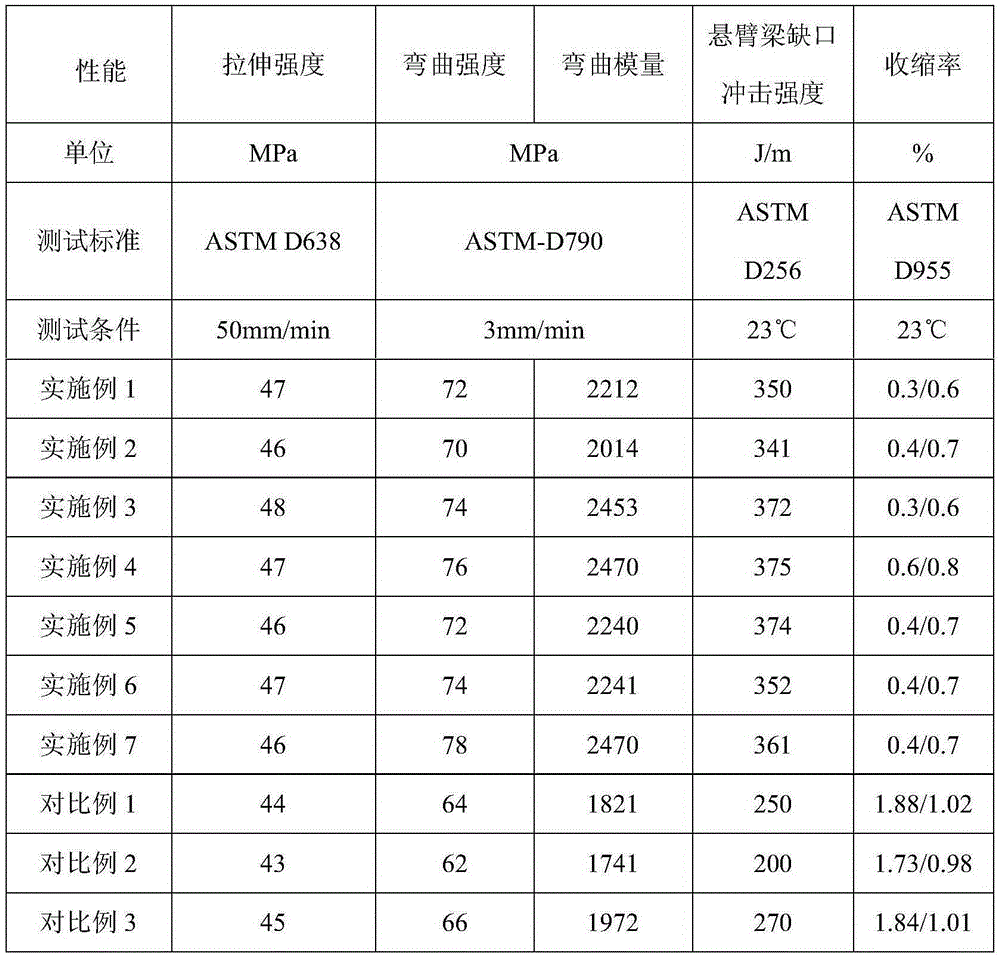

[0024] First, add fully dried PA, ABS, compatibilizer, heat-resistant agent and additives (the specific parts are subject to Table 1) into a high-speed mixer and mix well. After mixing completely, pass through a precision metering feeding device. The material is sent into the twin-screw extruder, and the material is fully fused under the shearing, mixing and conveying of the screw, and finally extruded, drawn, and cooled to make pellets. The temperature of the twin-screw extruder is Set to 215-245°C. The performance test results are shown in Table 2.

[0025] Table 1

[0026]

[0027] In Table 1: the PA used in Examples 1-7 is polyhexamethylene terephthalamide-co-hexamethylene sebacamide copolymer, with a melting point of 230° C.; ABS is acrylonitrile-butadiene-styrene branch copolymer, the rubber content is 60%; the rubber particle size is 350nm. Heat-resistant ...

Embodiment 8

[0032] A preparation method of high dimensional stability PA / ABS alloy, comprising the following steps,

[0033] Fully dry 50 parts of PA, 50 parts of ABS, 3 parts of compatibilizer SMA, 8 parts of heat-resistant agent styrene-N-phenylmaleimide-acrylonitrile copolymer and 1 part of auxiliary agent, and mix well. , the material is fed into the twin-screw extruder through a precision metering feeding device, and the material is fully fused under the shearing, mixing and conveying of the screw, and finally extruded, drawn, and cooled to make pellets To obtain the PA / ABS alloy, the temperature of the twin-screw extruder is set at 215-245°C.

[0034] PA is polyhexamethylene terephthalamide-co-hexamethylene sebacamide copolymer, with a melting point of 230°C.

[0035] ABS is an acrylonitrile-butadiene-styrene graft copolymer with a rubber content of 60% and a rubber particle size of 350nm.

[0036] The additives include 0.2 parts of antioxidant 1098 and 0.3 parts of antioxidant S-...

Embodiment 9

[0038] A preparation method of high dimensional stability PA / ABS alloy, comprising the following steps,

[0039] Fully dry 70 parts of PA, 30 parts of ABS, 8 parts of compatibilizer ABS-g-GMA, 6 parts of heat-resistant agent styrene-N-m-tolylmaleimide copolymer and 1.15 parts of additives and mix well, mix After completion, the material is fed into the twin-screw extruder through the precision metering feeding device, and the material is fully fused under the shearing, mixing and conveying of the screw, and finally extruded, drawn, and cooled to make The pellets were obtained from PA / ABS alloy, and the temperature of the twin-screw extruder was set at 215-245°C.

[0040] PA is polyhexamethylene terephthalamide-co-hexamethylene sebacamide copolymer, with a melting point of 230°C.

[0041] ABS is an acrylonitrile-butadiene-styrene graft copolymer with a rubber content of 60% and a rubber particle size of 350nm.

[0042] The additives include 0.2 parts of antioxidant 1098 and 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com