Patents

Literature

60 results about "Undershirt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An undershirt is an article of underwear worn underneath a dress shirt intended to protect it from body sweat and odors. Alternatively, it may be worn to protect the body from stiff or otherwise uncomfortable fabric that a person may be required to wear (such as a mandatory work uniform). It can have short sleeves or be sleeveless. The term most commonly refers to upper-body wear worn by males. This article of clothing typically has a low, round neckline that can be worn for athletic purposes.

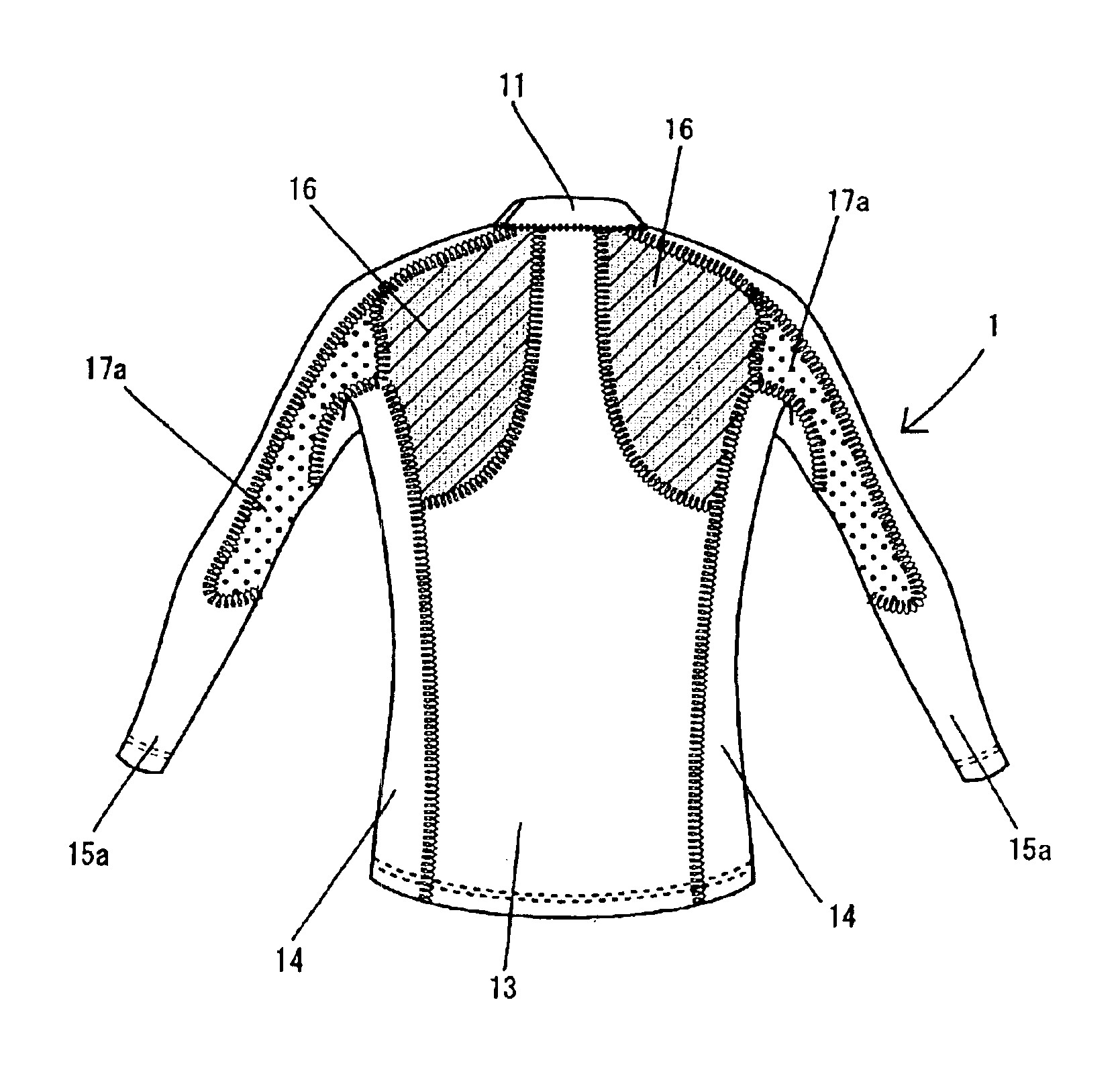

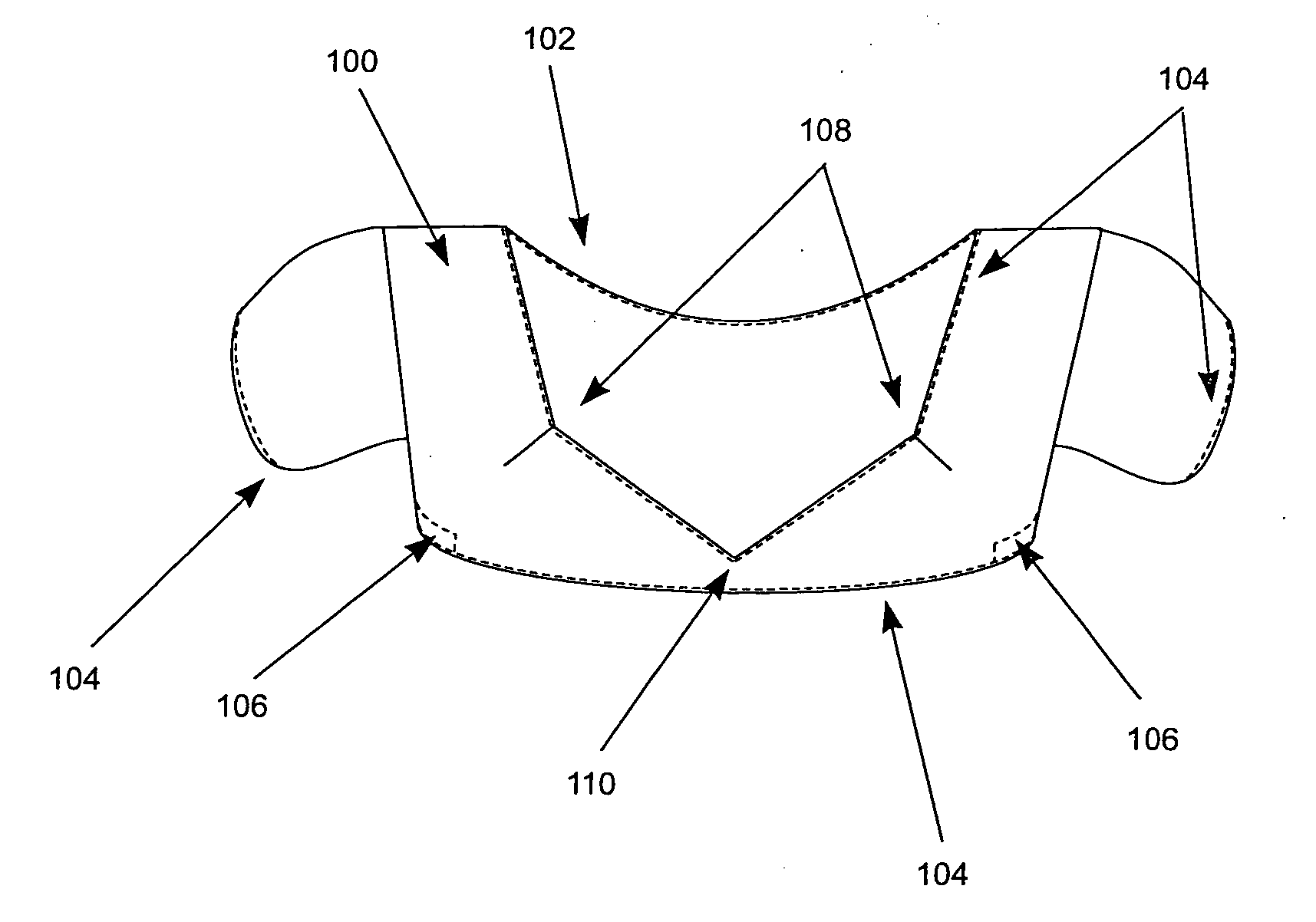

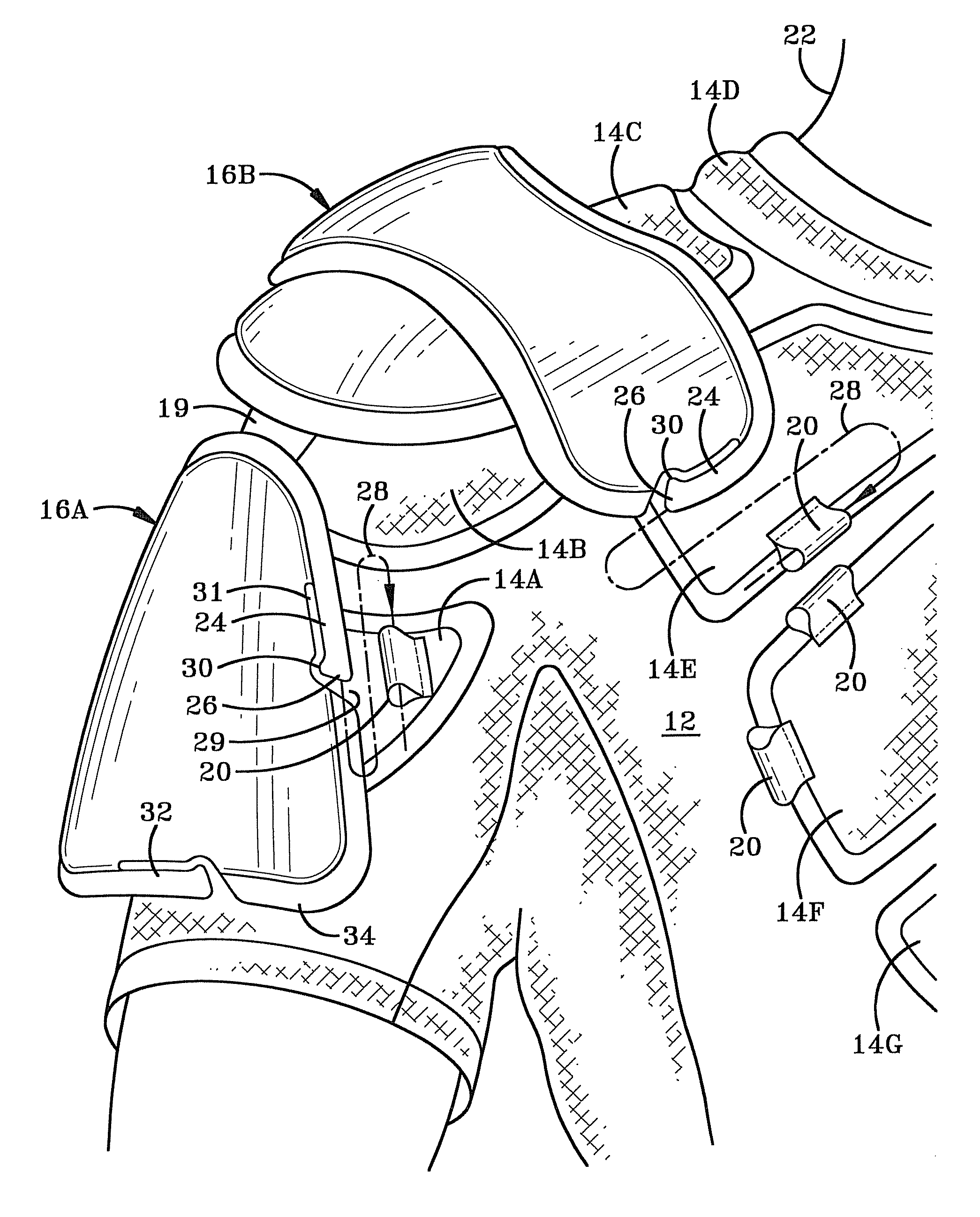

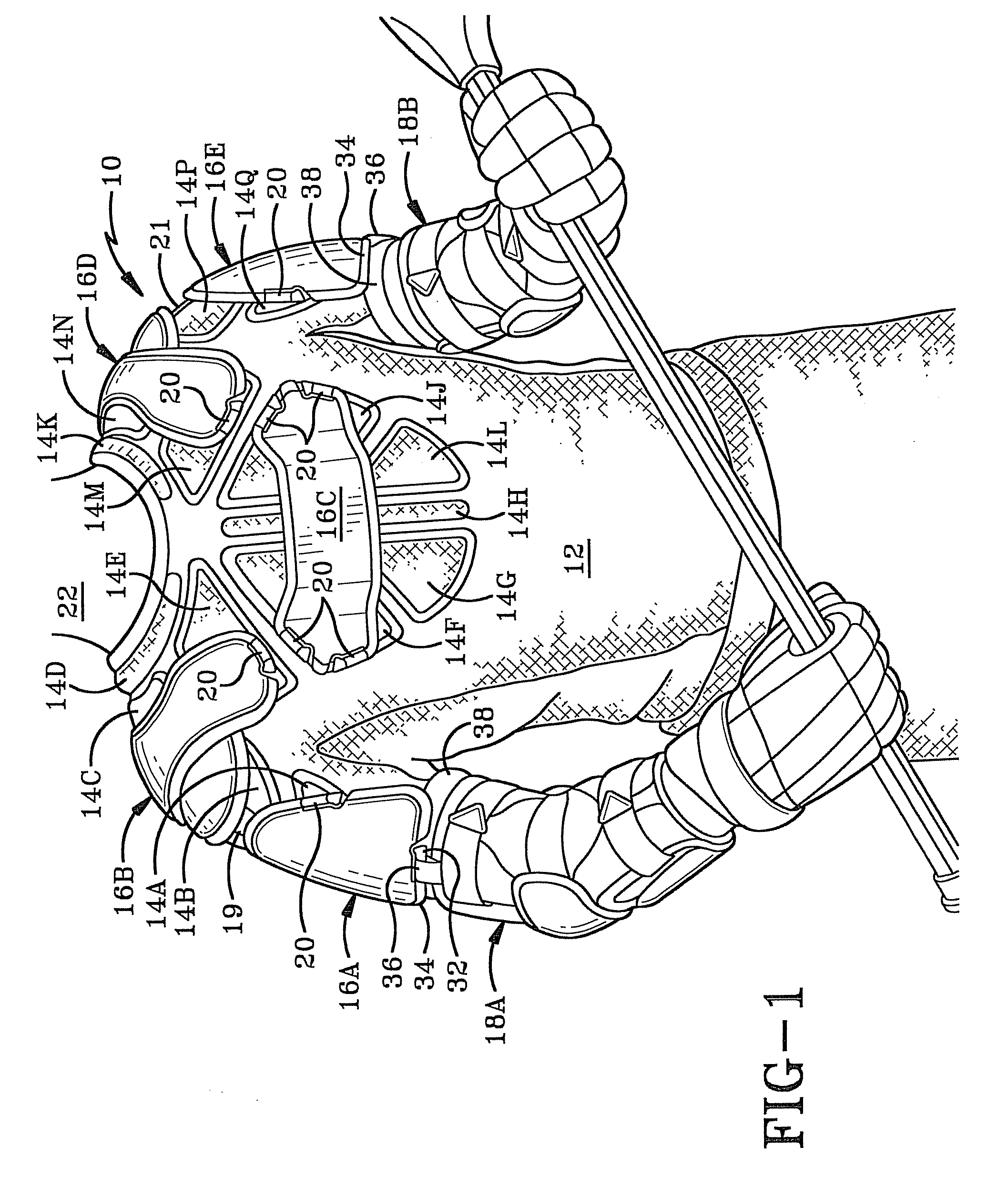

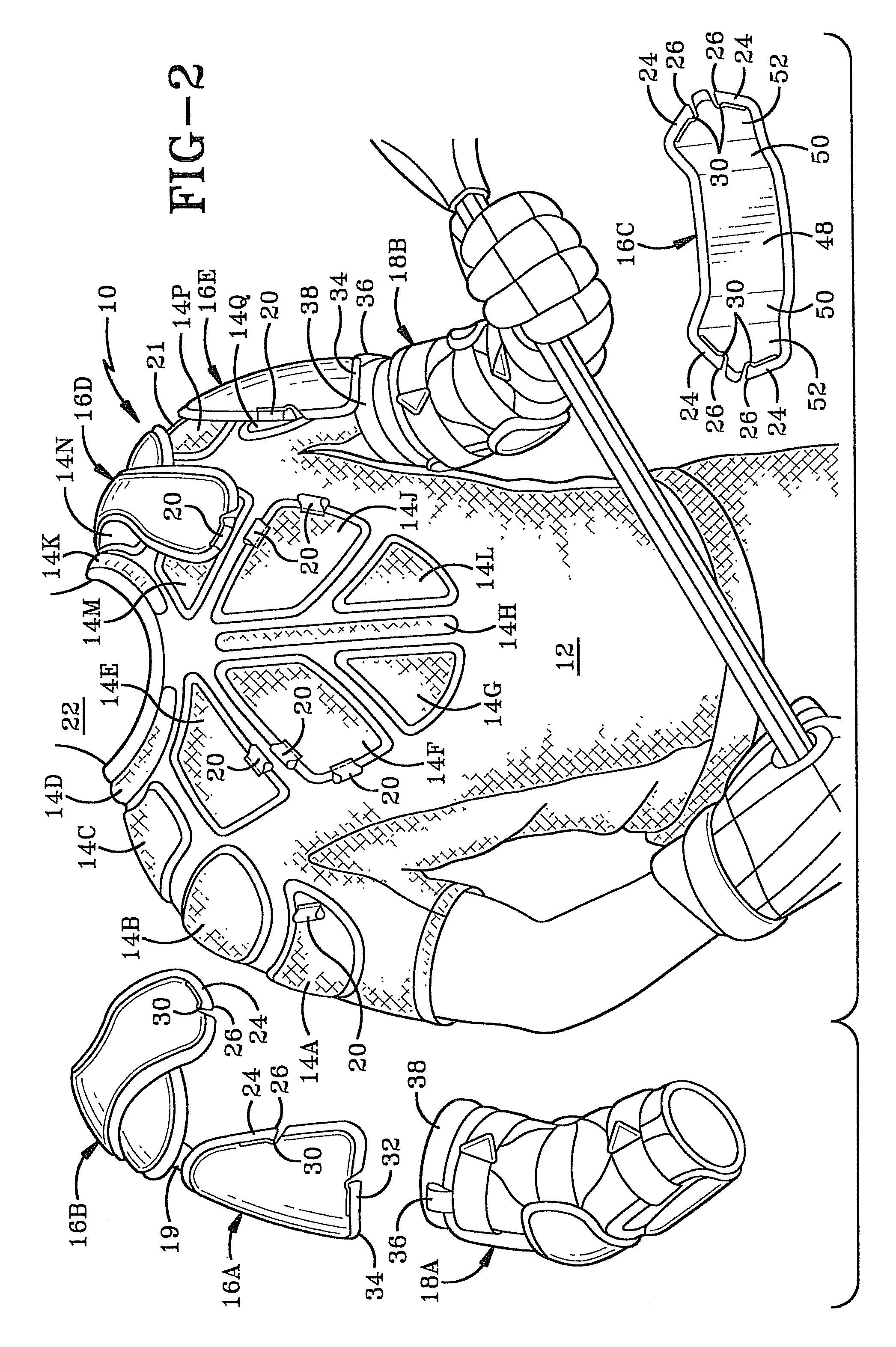

Posture improvement devices and methods for use

ActiveUS20090062704A1Effective trainingExtended range of motionOrthopedic corsetsProtective garmentMedicineMuscle memory

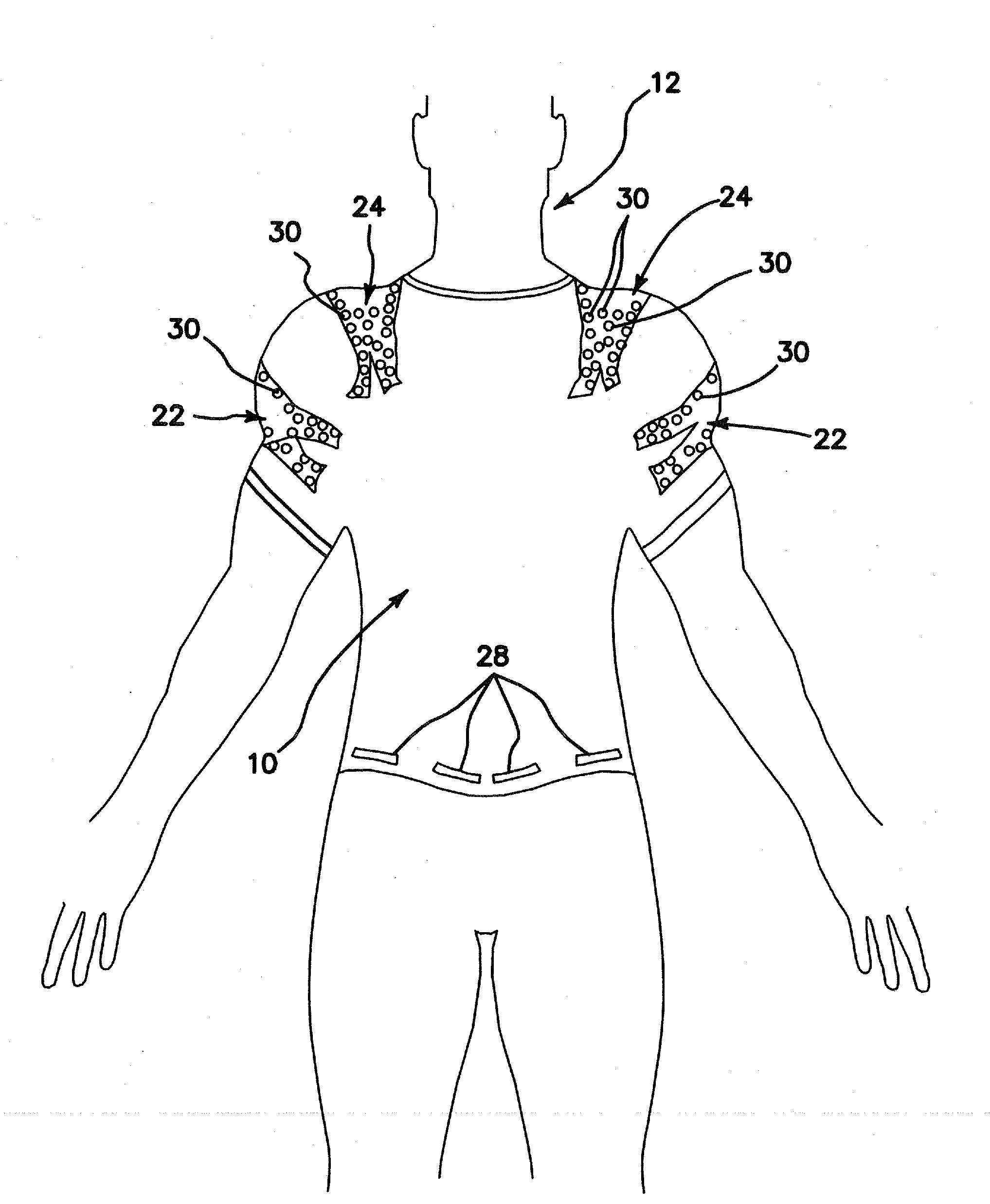

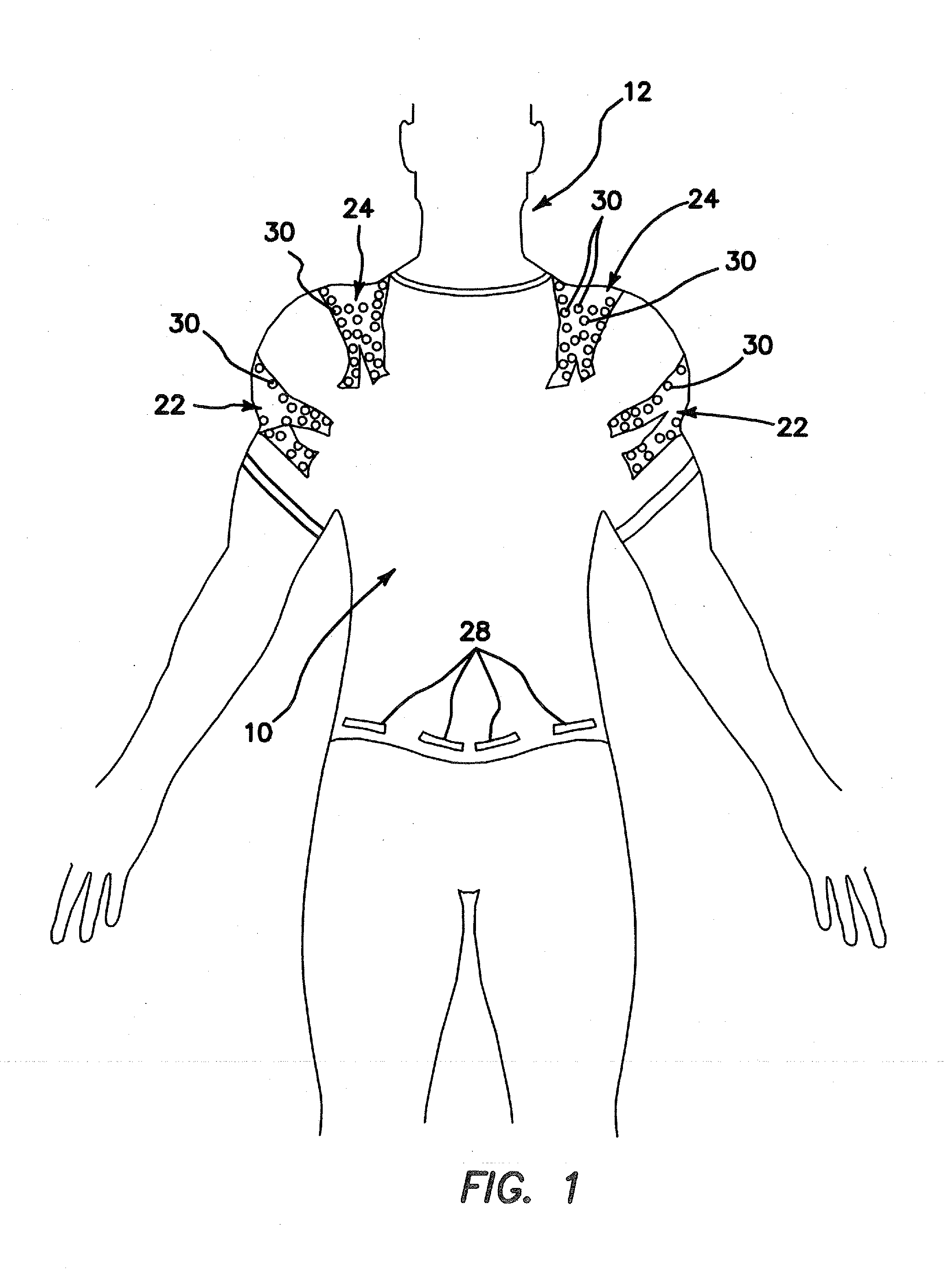

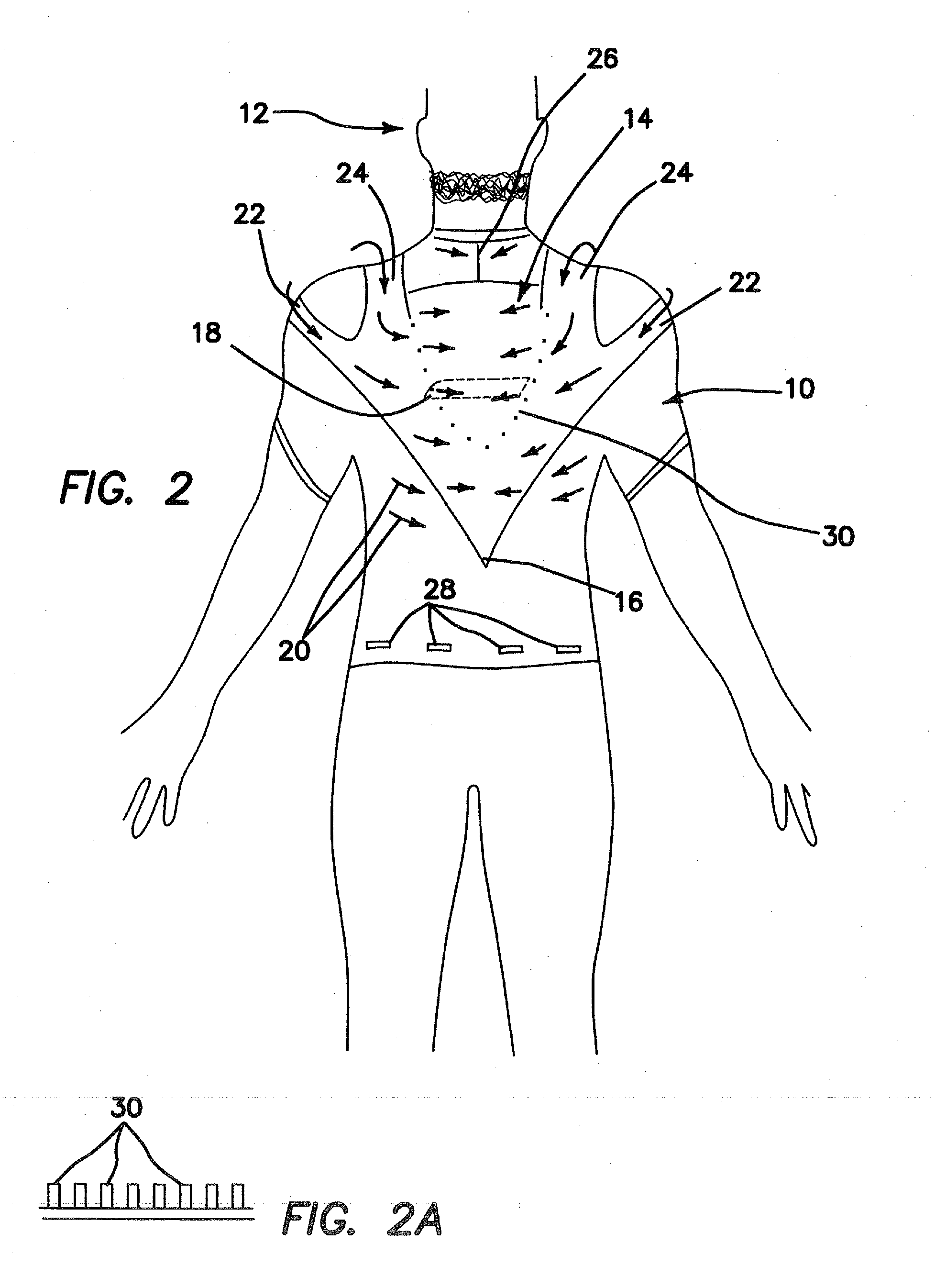

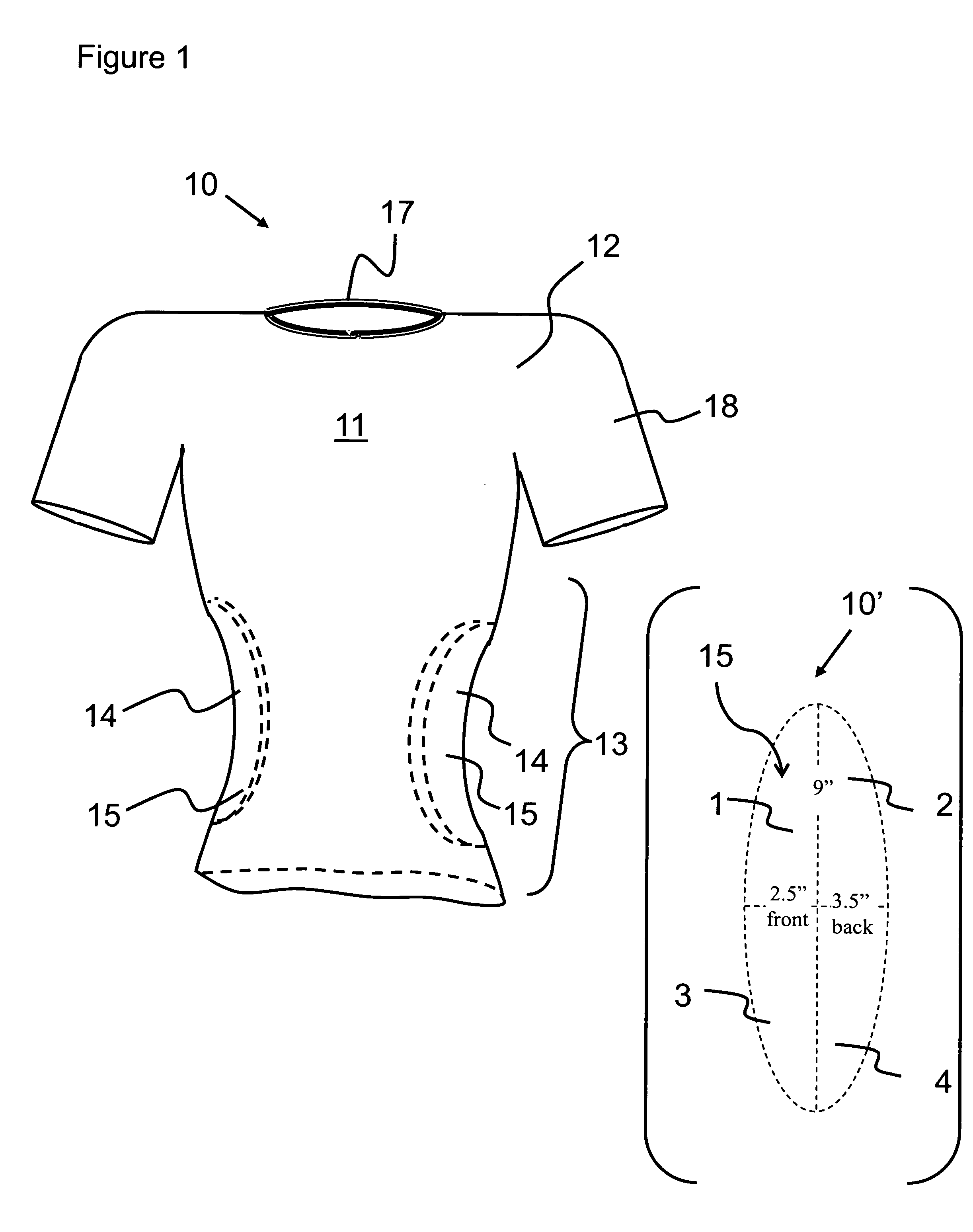

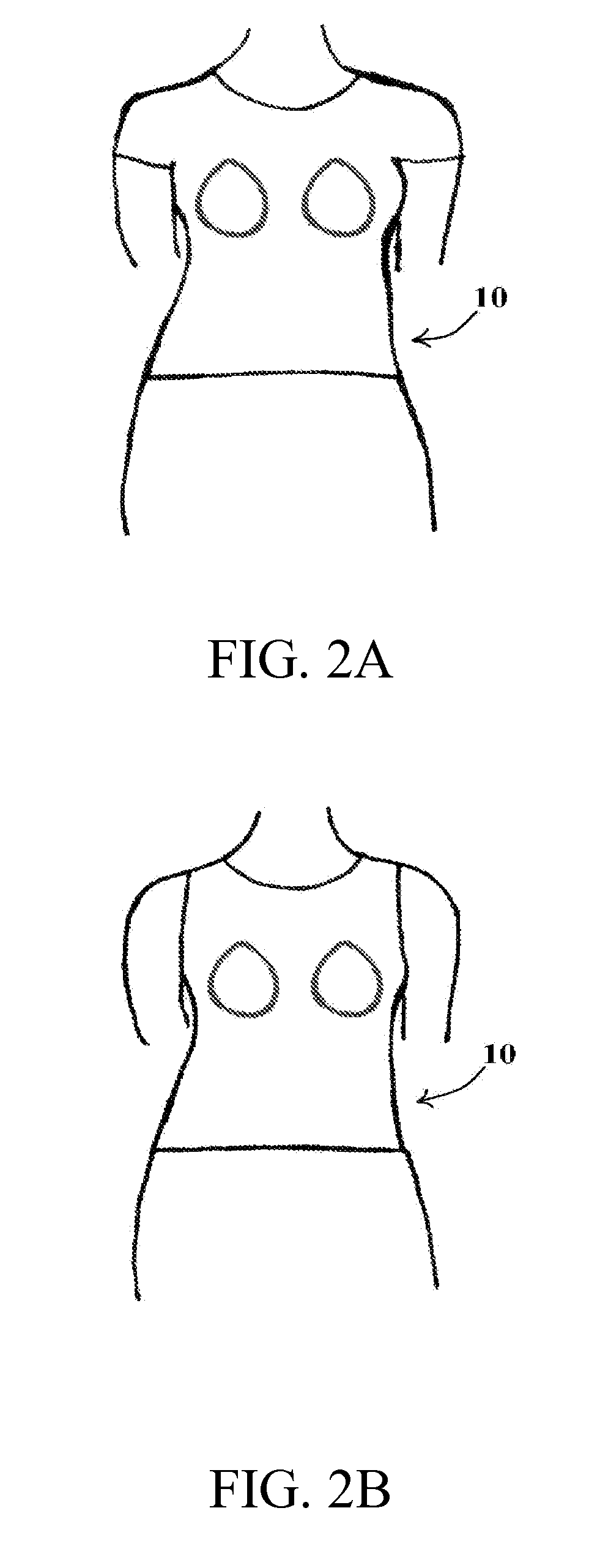

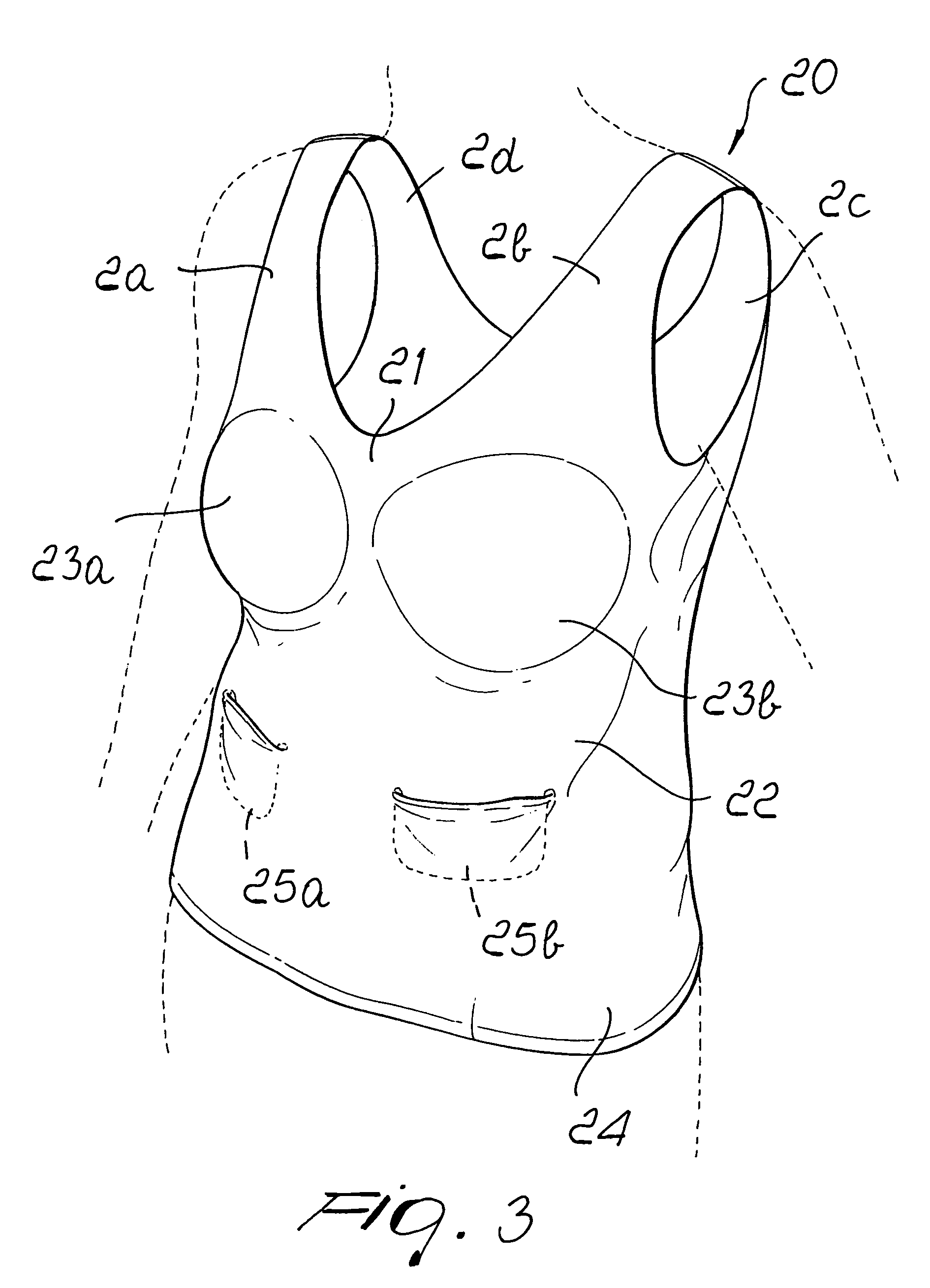

A posture improvement device provides neuromuscular stimulation or proprioceptive therapy using a combination of pressure, torque and angle simultaneously applied to a user in order to train body muscles for proper posture through muscle memory. The device comprises a garment designed to be worn by the user, which is preferably configured like a short-sleeved undershirt or T-shirt. The garment may be fabricated of a stretchable, yet taut material in order to provide the desirable form-fitting feature such that pressure may be readily applied to the surface of the skin for neuromuscular stimulation. This elastomeric material is also preferably breathable and / or which has moisture wicking capabilities.

Owner:ALIGNMED +1

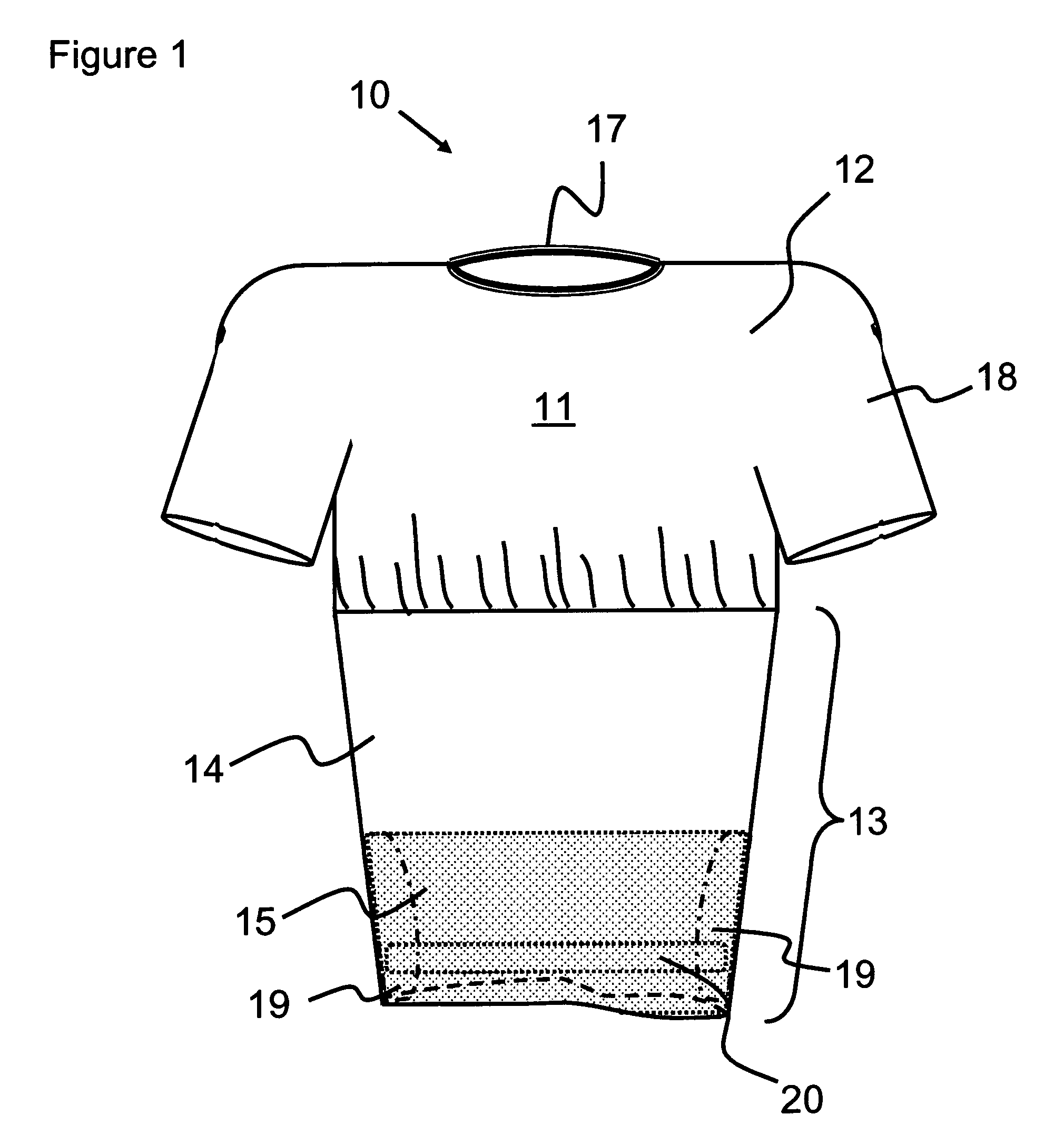

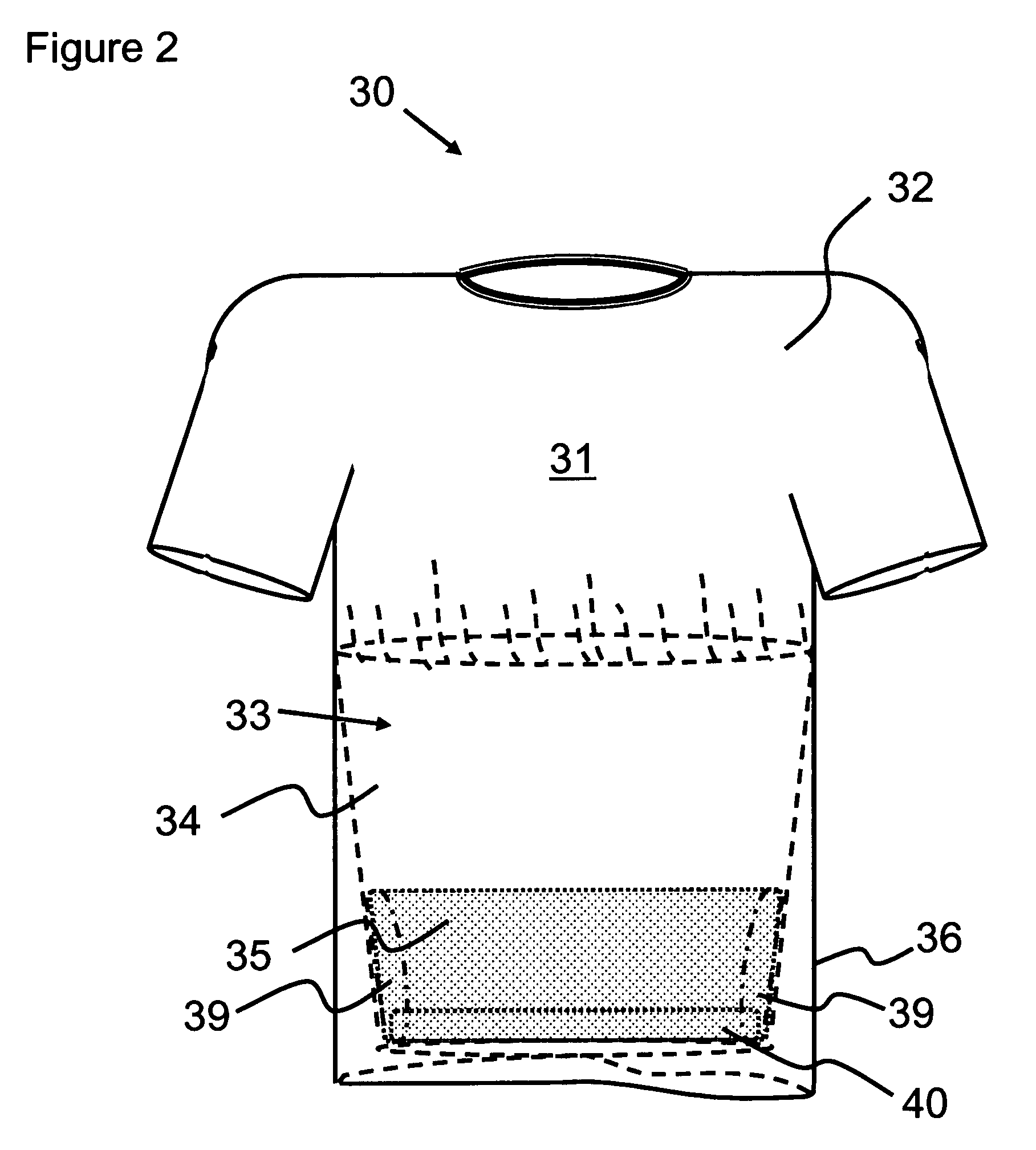

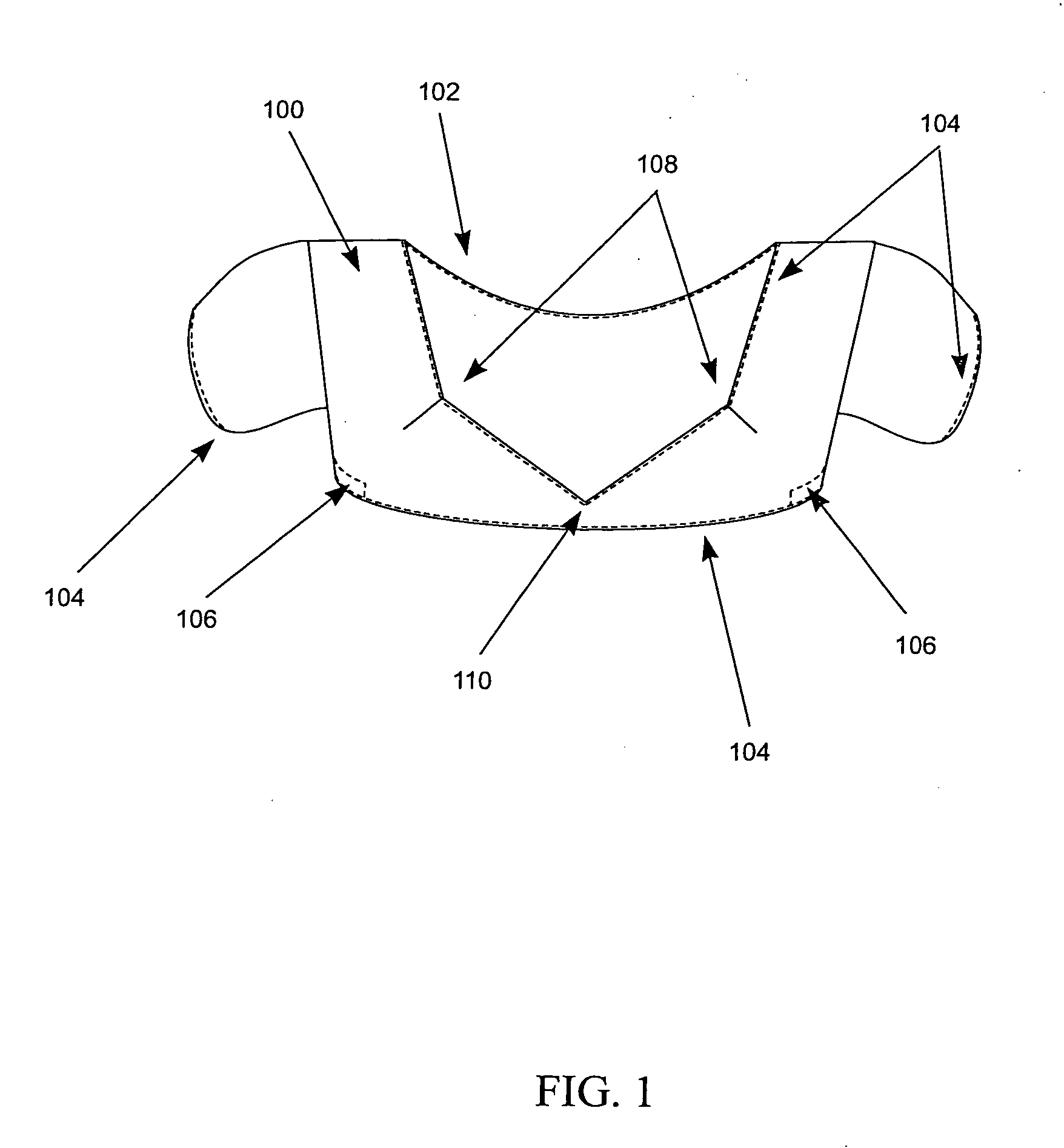

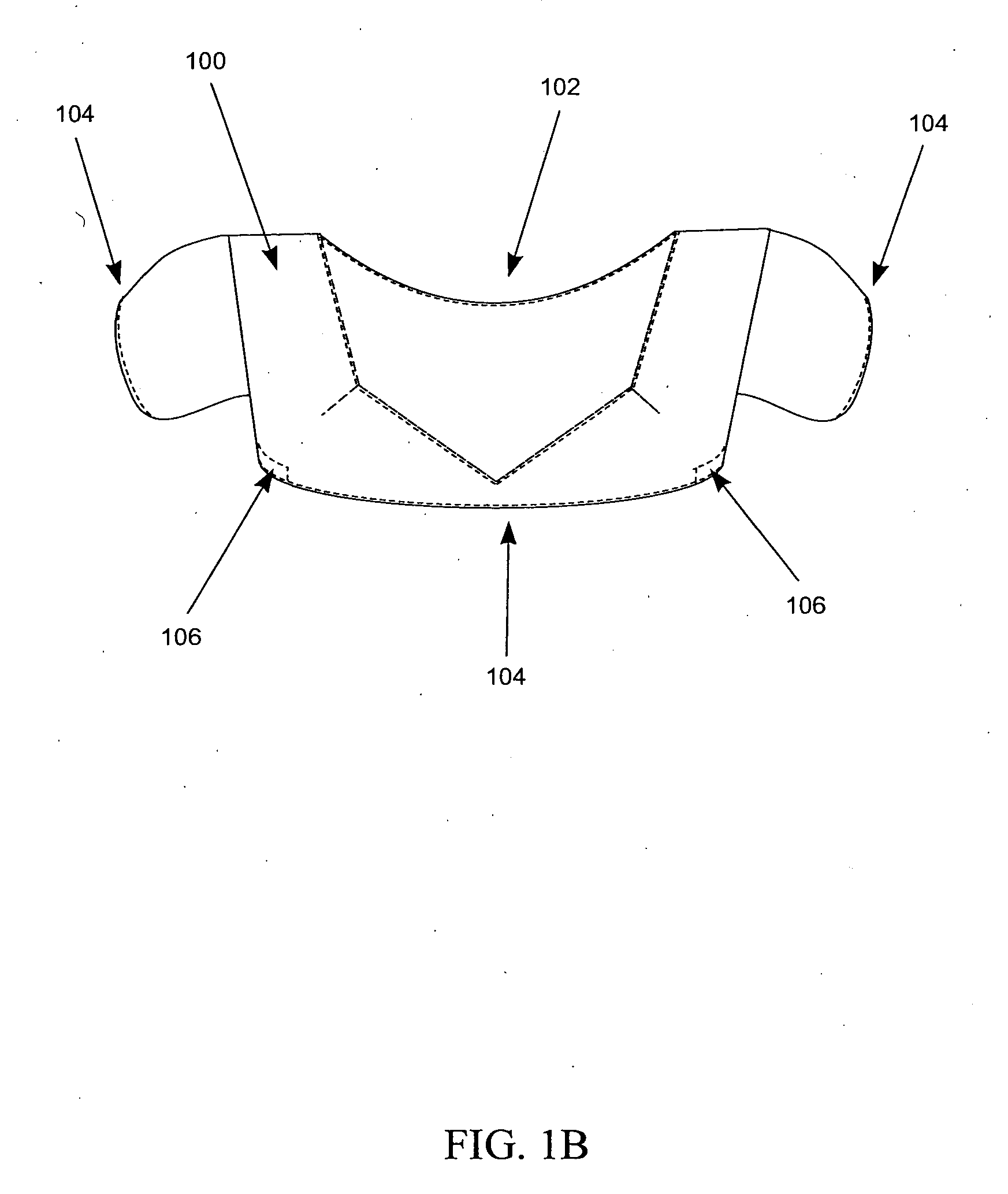

Shirt having form-fitting mid-section support

InactiveUS20080134409A1Area minimizationFacilitates breath-ability and comfortGarment special featuresProtective garmentEngineeringUndershirt

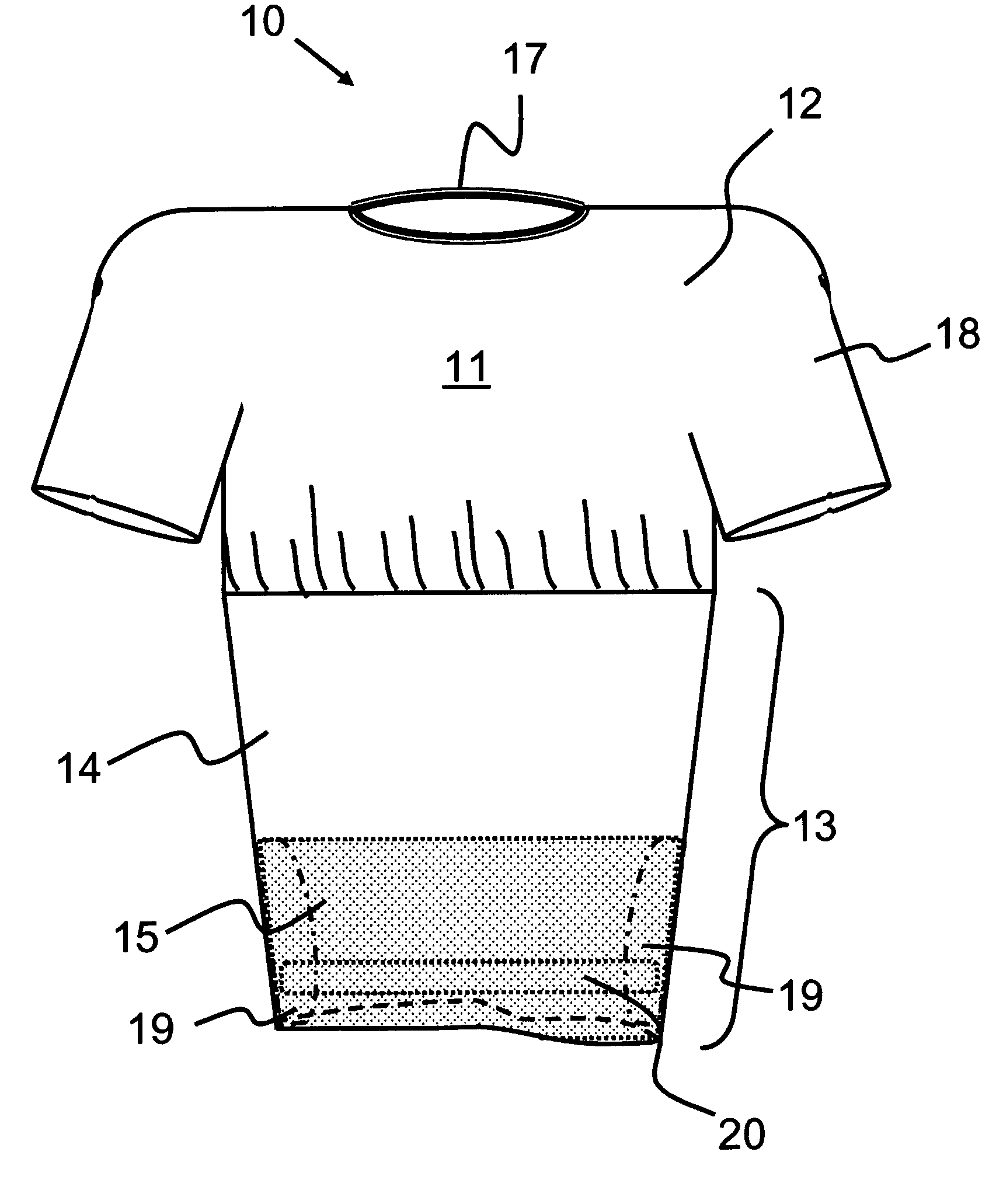

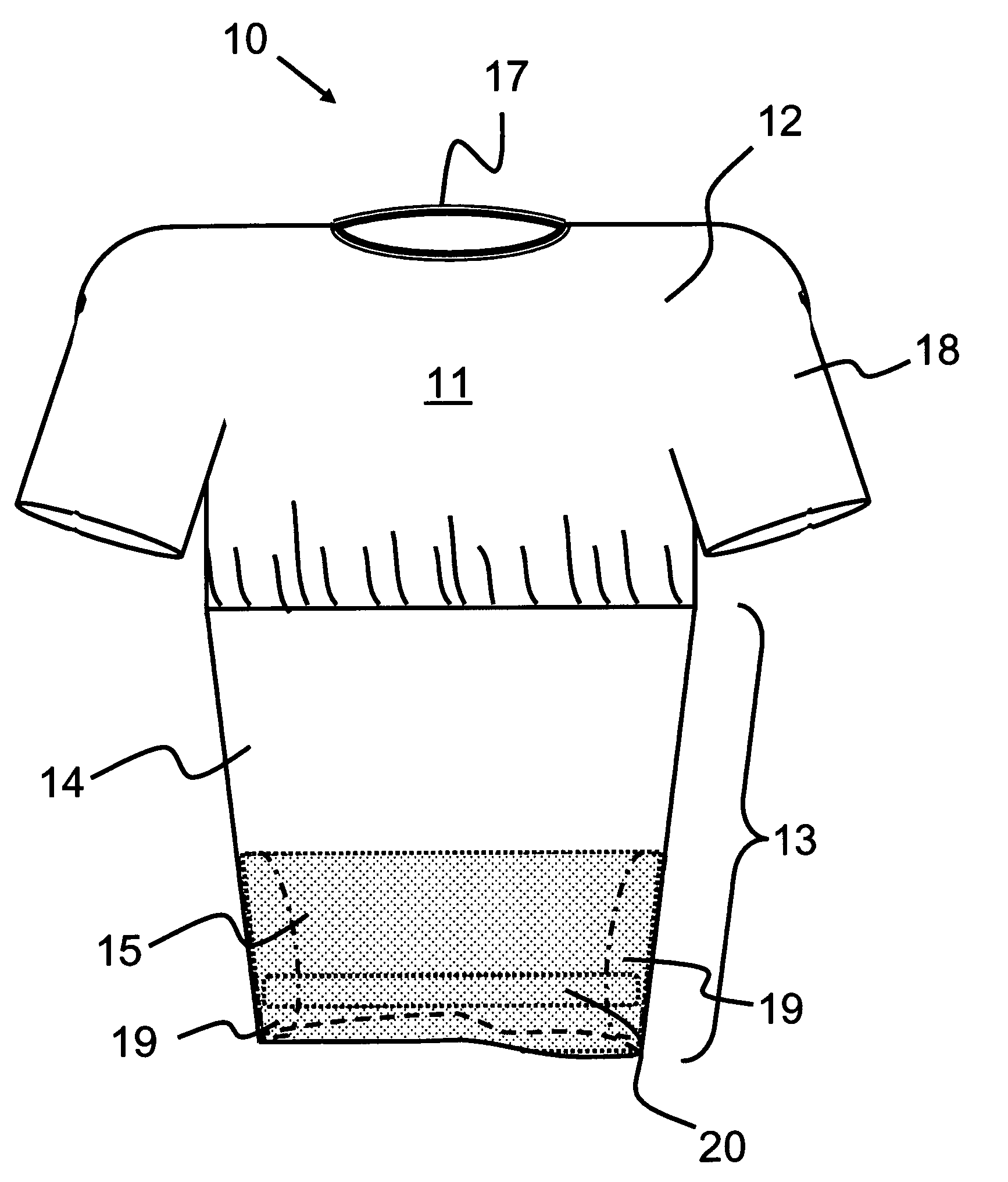

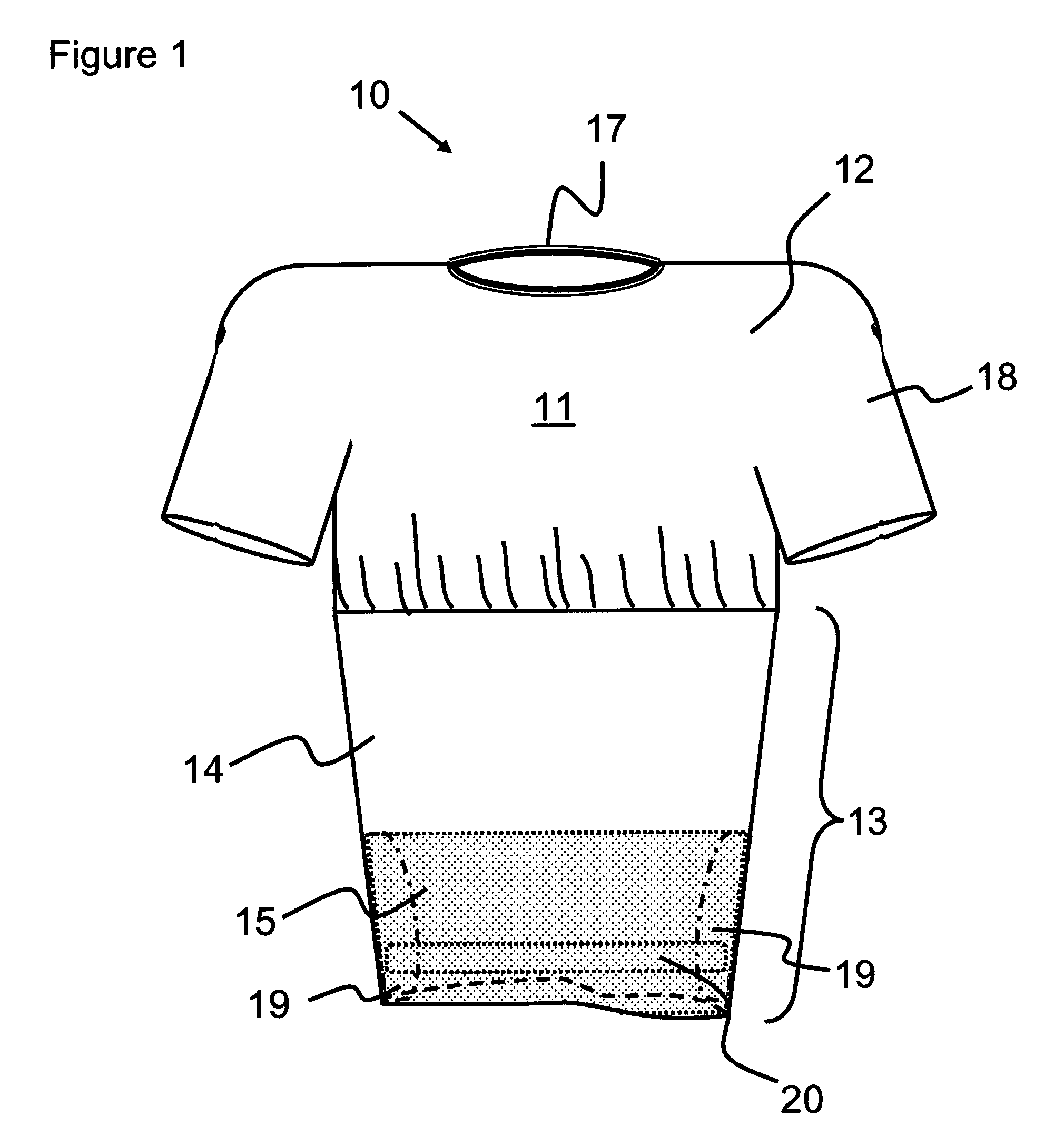

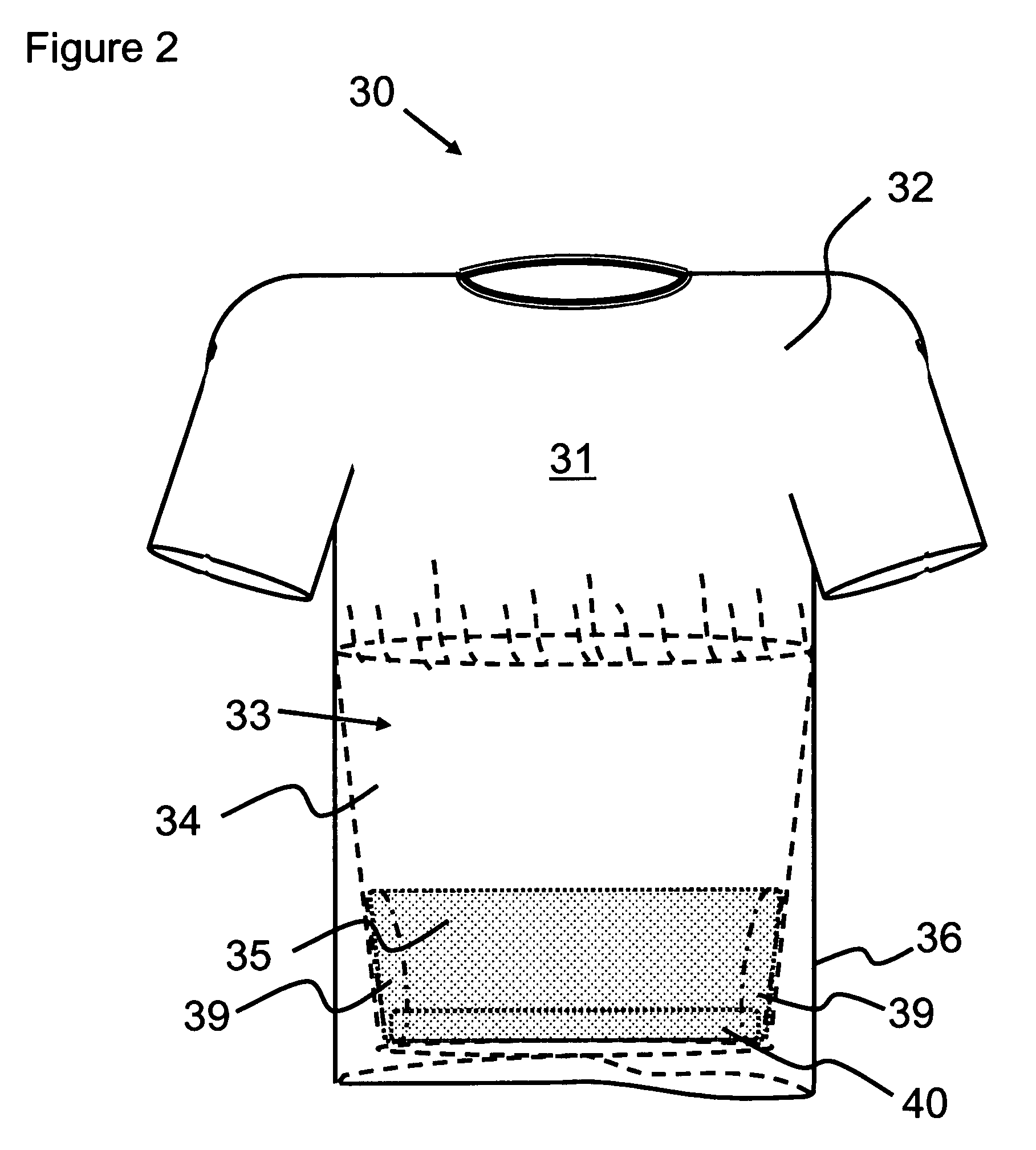

The shirt for supporting and shaping the mid-section of a wearer provides a shirt having a top-section and a mid-section. The mid-section of the shirt includes an upper and lower region each constructed having a plurality of fabric densities or integrated elasticity portions. These elasticity portions provide support for the abdominal region, back, and back-side regions of the wearer where “love handles” sometime develop. The top-section of the shirt has a substantially loose fitting construction to yield a simple, clean and comfortable fit that facilitates breath-ability and comfort to the wearer. The shirt may be worn as an undershirt or as outerwear to minimize the wearer's torso. In another embodiment, the shirt further comprises an outer portion that extends over and covers the mid-section so that the mid-section acts as an internal support structure when the shirt is worn as a T-shirt or outerwear.

Owner:KARASINA SVETLANA

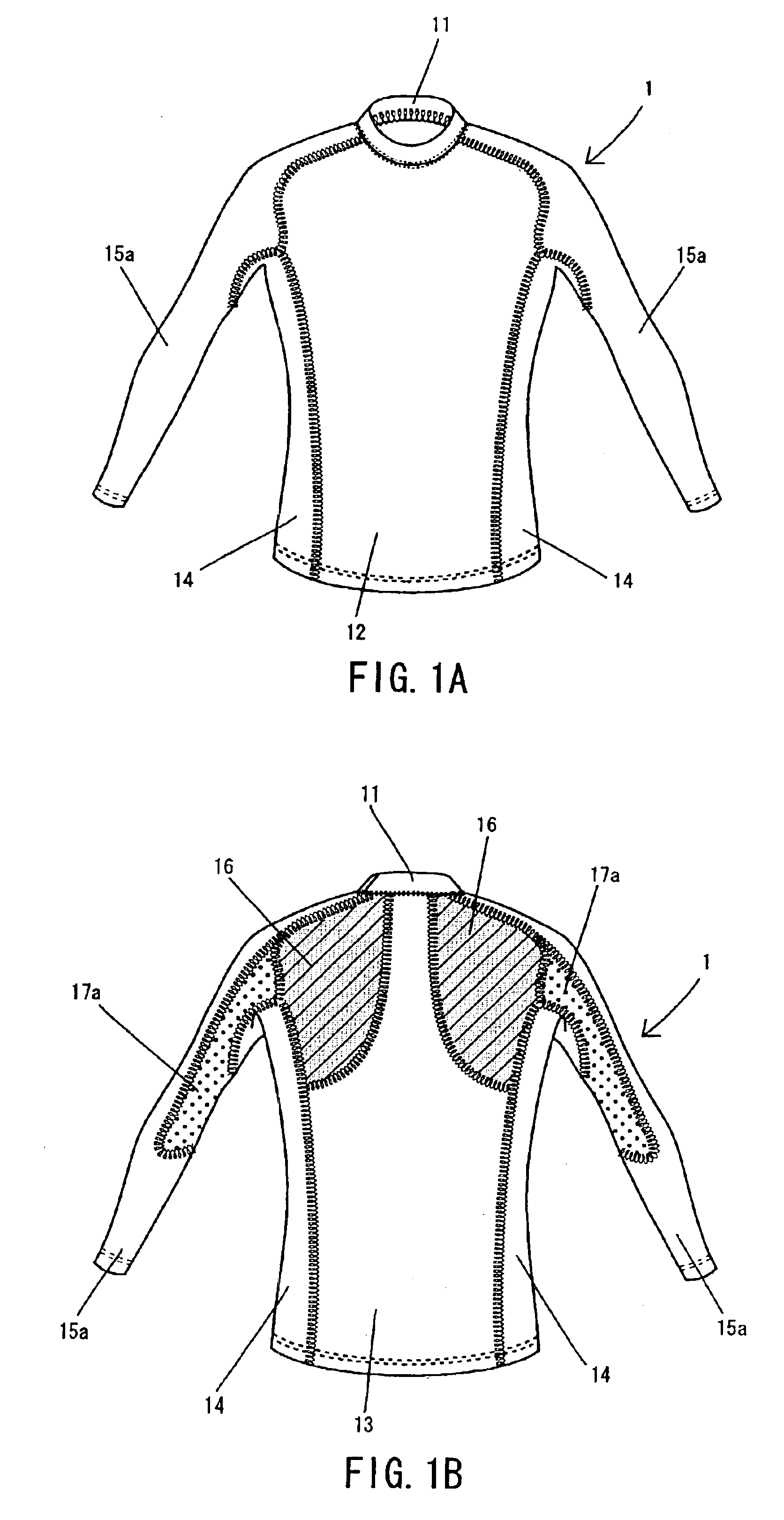

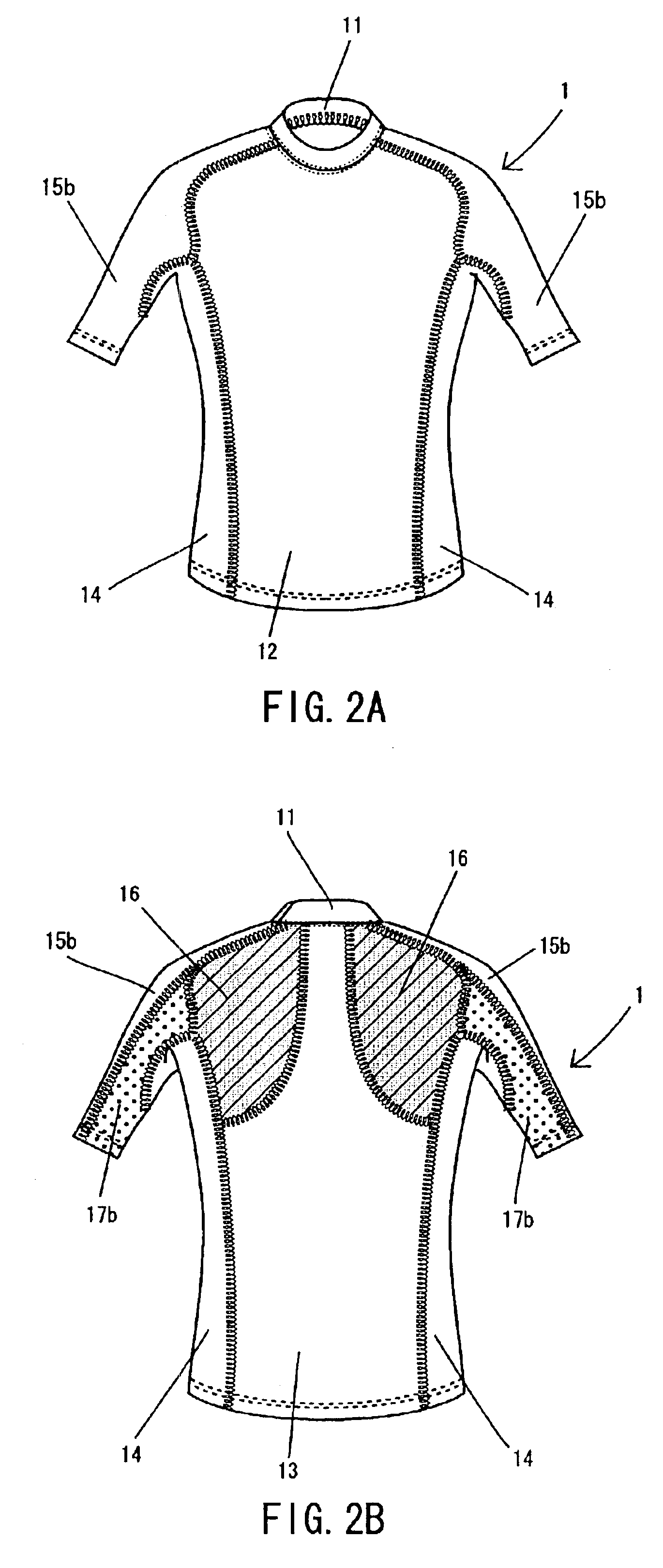

Undershirt

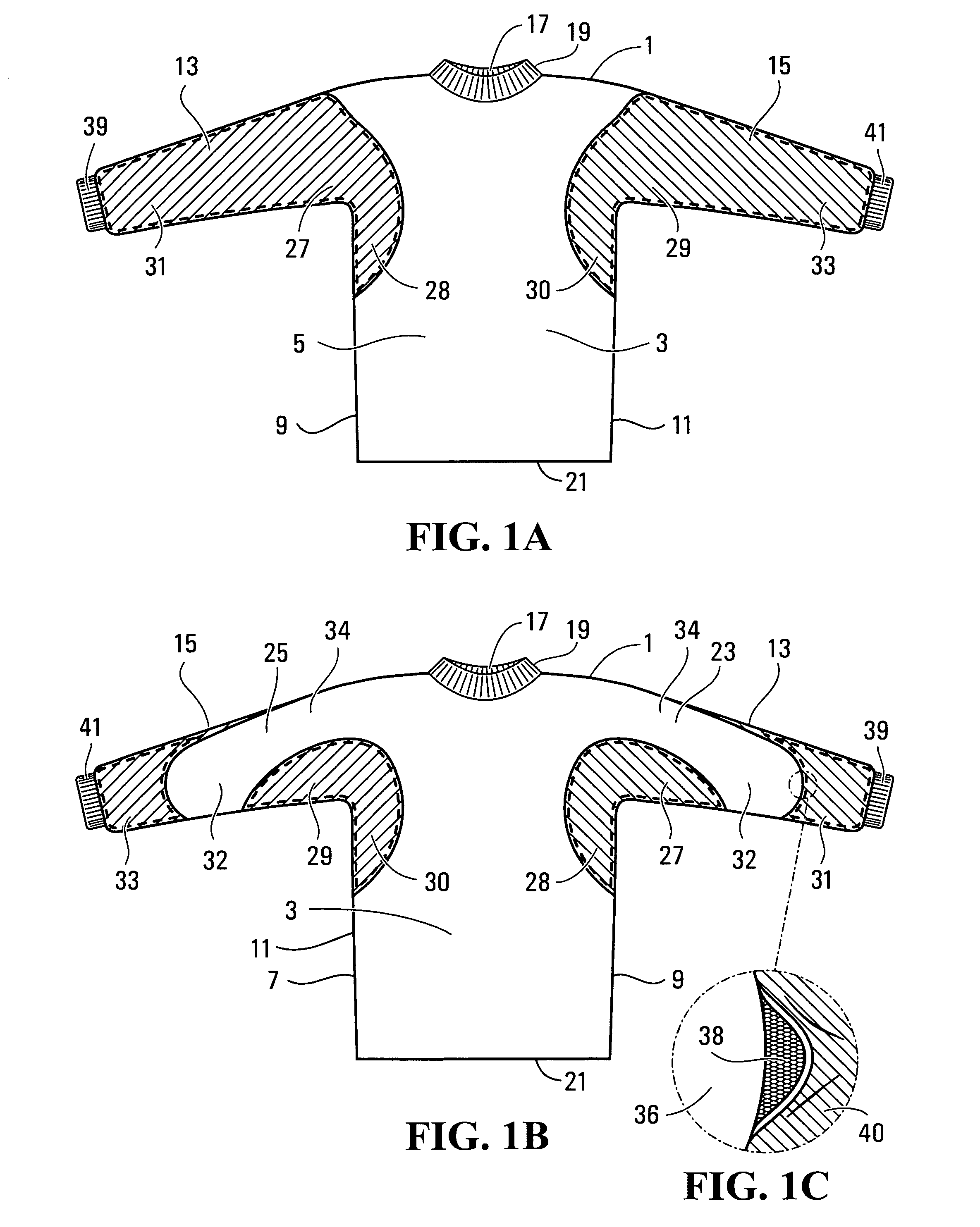

InactiveUS6892396B2Increase relative motionUndergarmentsProtective garmentEngineeringUpper trapezius

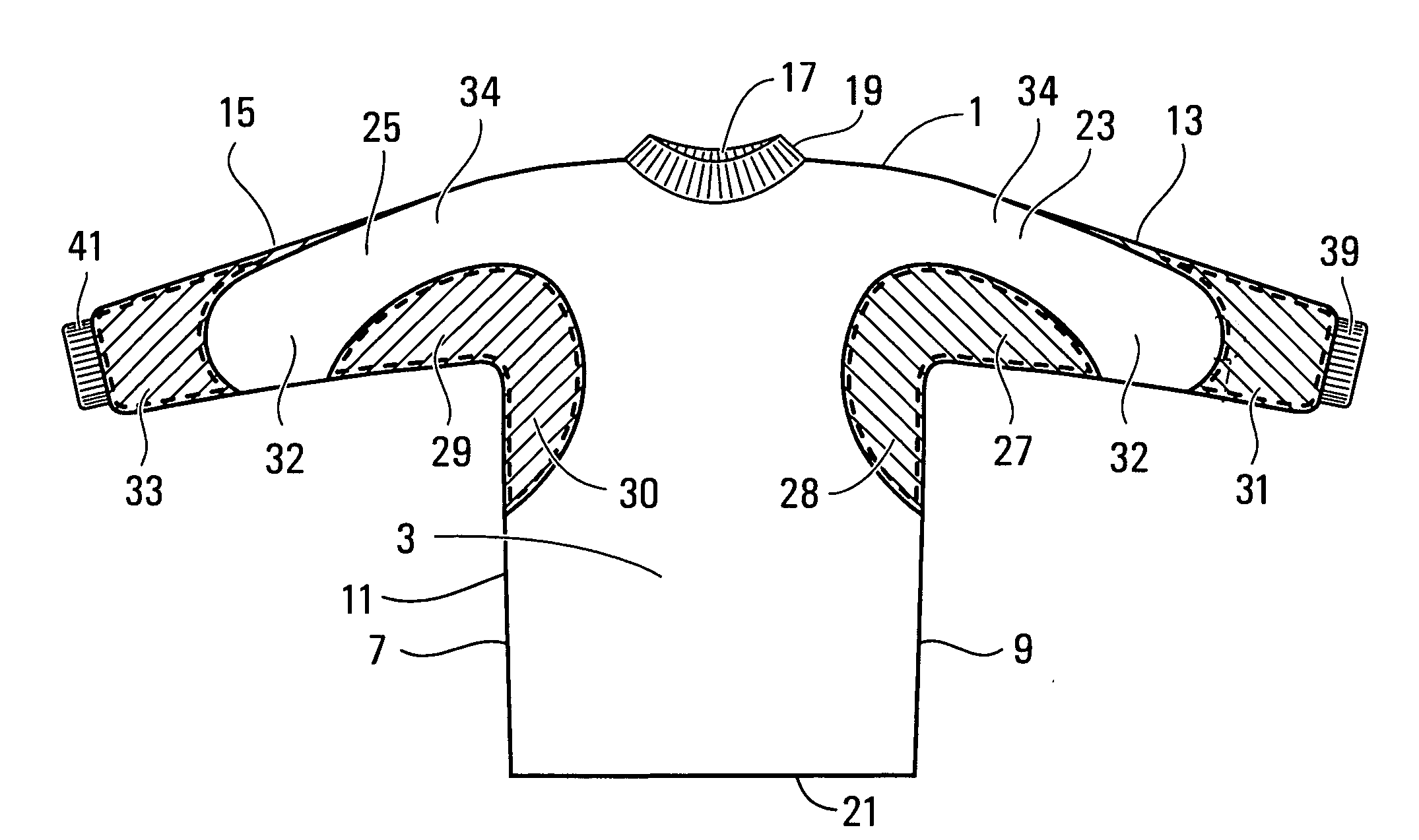

An undershirt including a main constituent portion made of stretchable materials that include a first-type material, a second-type material, and a third-type material. The first-type material has a straining force greater than a straining force of the second-type material, and the second-type material has a straining force greater than a straining force of the third-type material. The first-type material is arranged to cover at least part of musculus triceps brachii. The third-type material is arranged to cover at least a part of a lateral portion of musculus trapezius, at least a part of superior portion of musculus latissimus dorsi, and at least a part of a medial portion of musculus deltoideus in a vicinity of scapula. The second-type material is arranged in regions other than the regions where the first-type and third-type materials are arranged.

Owner:MIZUNO CORPORATION

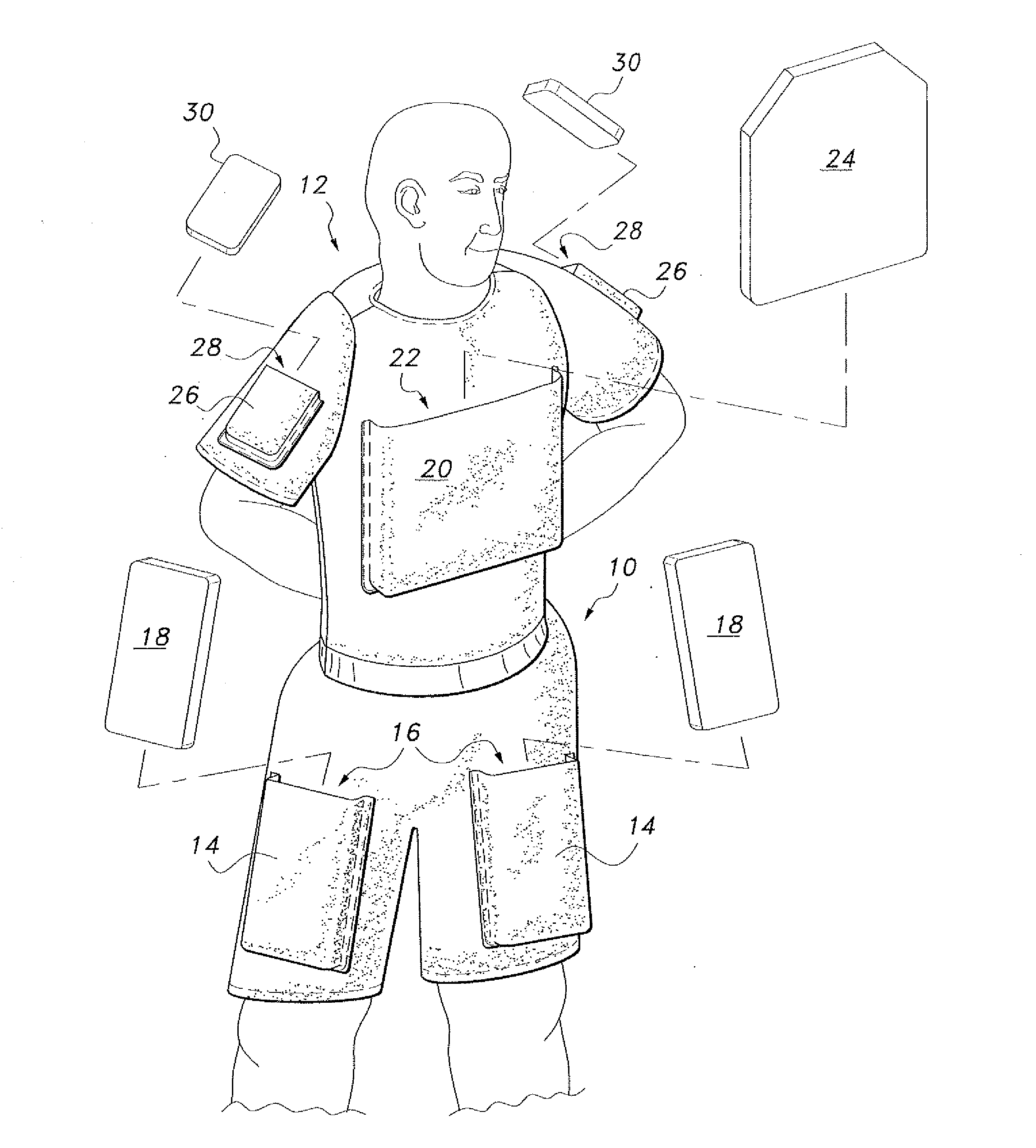

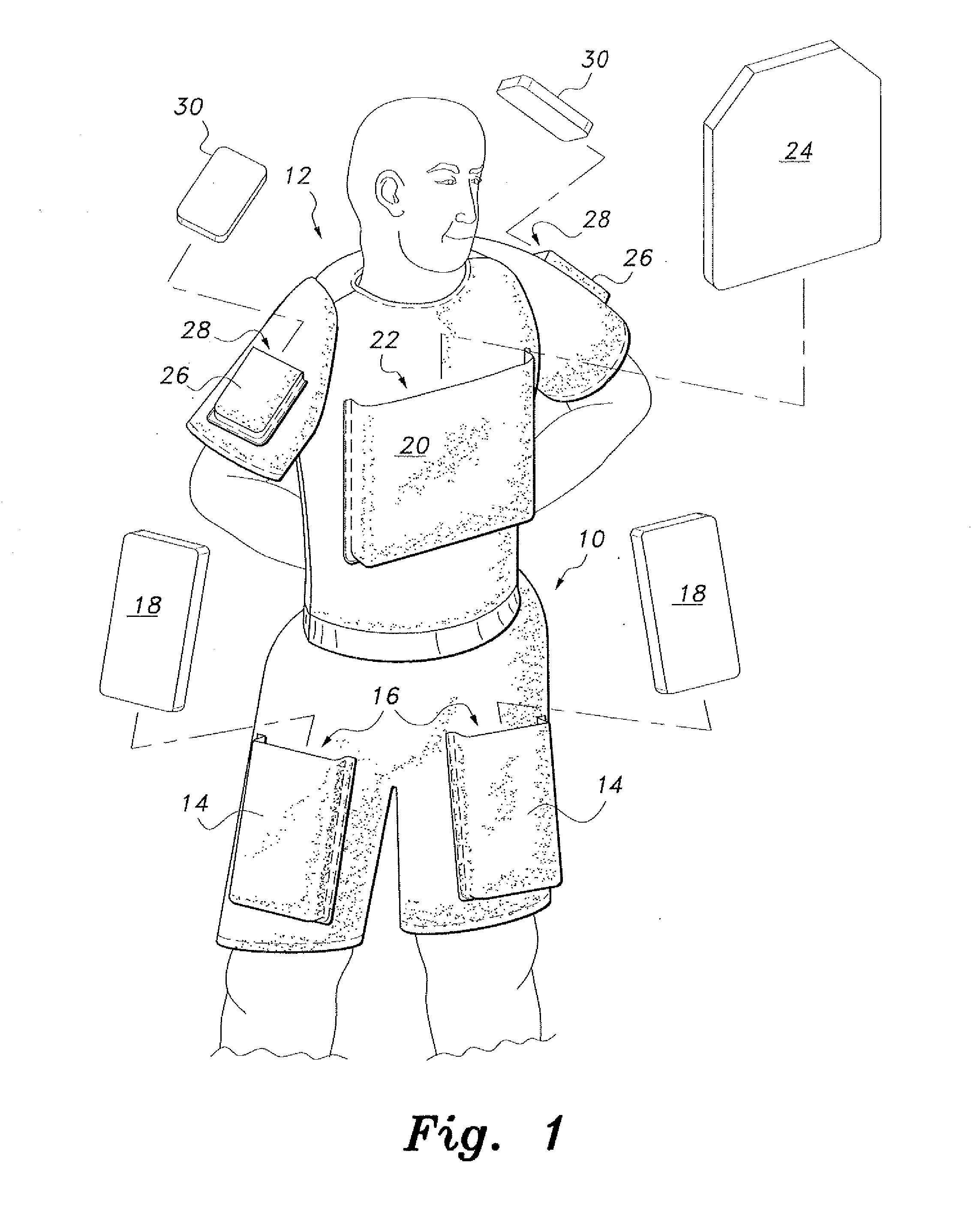

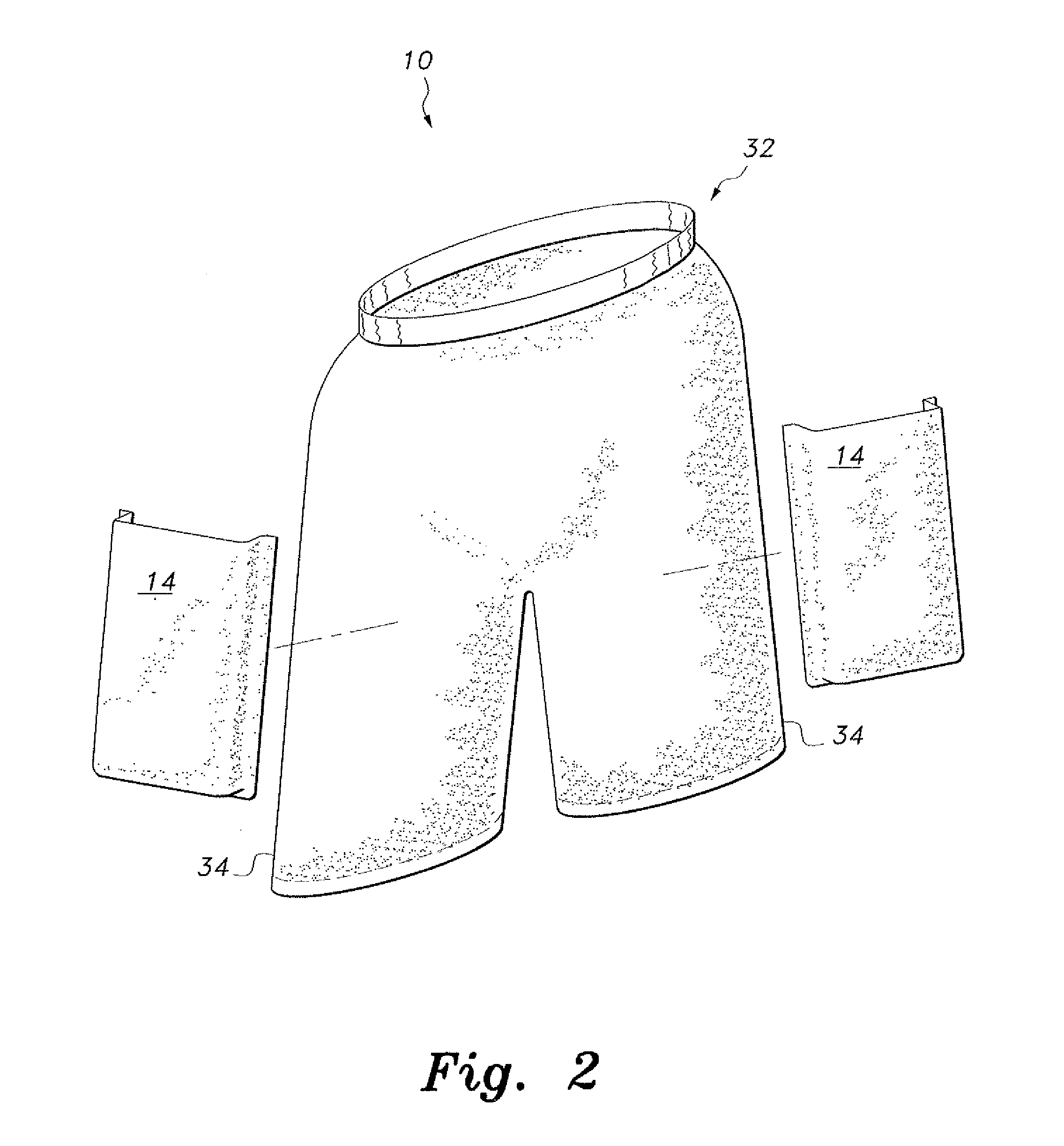

Ballistic shield support undergarments

InactiveUS20110131694A1Comfortable supportPersonal protection gearProtective garmentFemoral arteryMechanical engineering

The ballistic shield support undergarments are undergarments for use by soldiers, tactical personnel and the like, providing comfortable support for ballistic shielding, without limiting the wearer's dexterity or freedom of movement. The ballistic shield support undergarments include both underpants and an undershirt, preferably worn as a set. The pair of undershorts include a waist portion and a pair of leg portions, as is conventionally known. A pair of pockets are provided, with each pocket being secured to a respective one of the leg portions by stitching or the like. A pair of ballistic shields, such as small arms protective inserts (SAPIs) or the like, are further provided, with each ballistic shield being removably received within a respective one of the pockets. Each pocket is positioned on the respective leg portion so that the respective ballistic shield received therein covers the wearer's femoral artery.

Owner:FEARON WILLIAM G

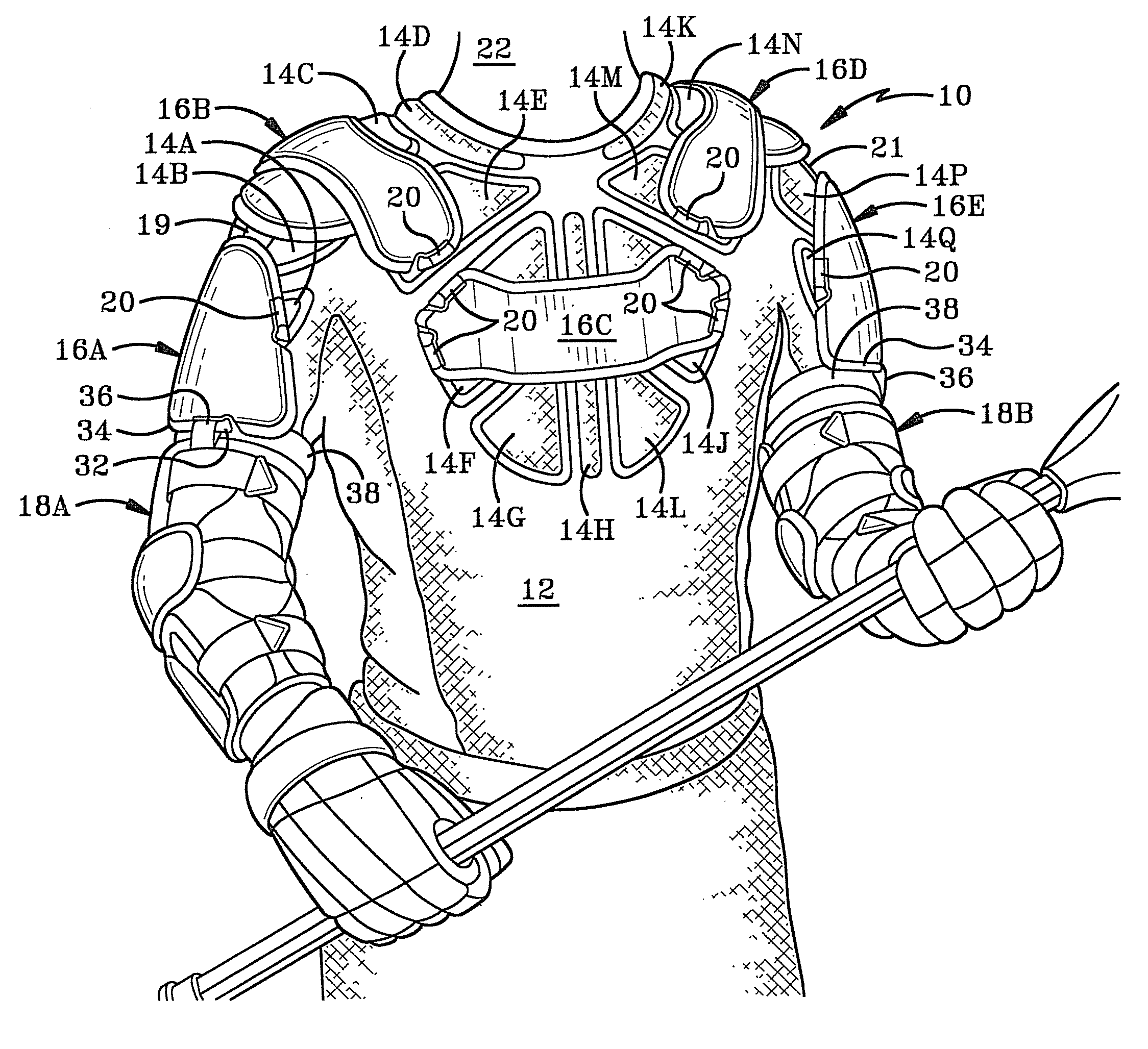

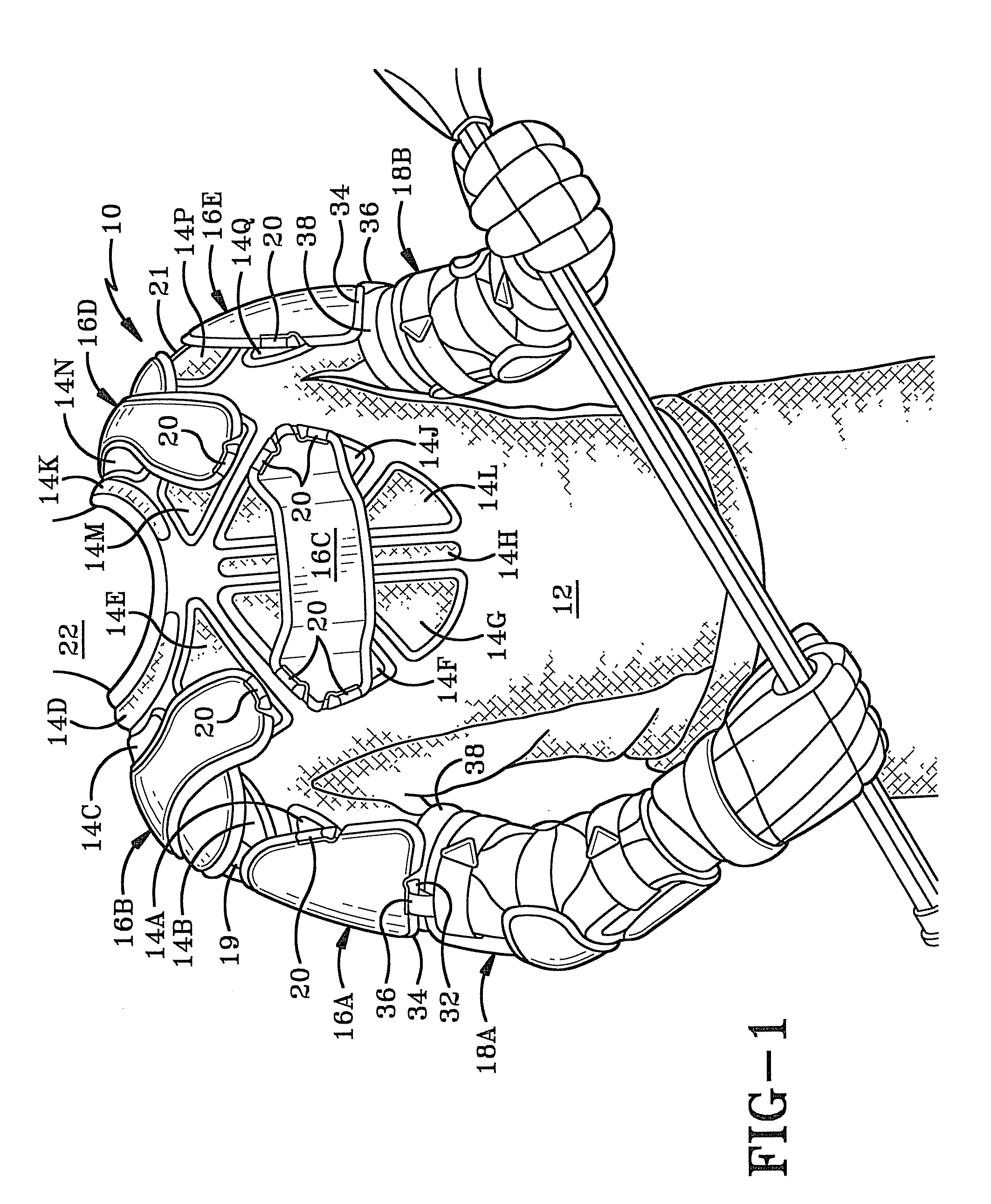

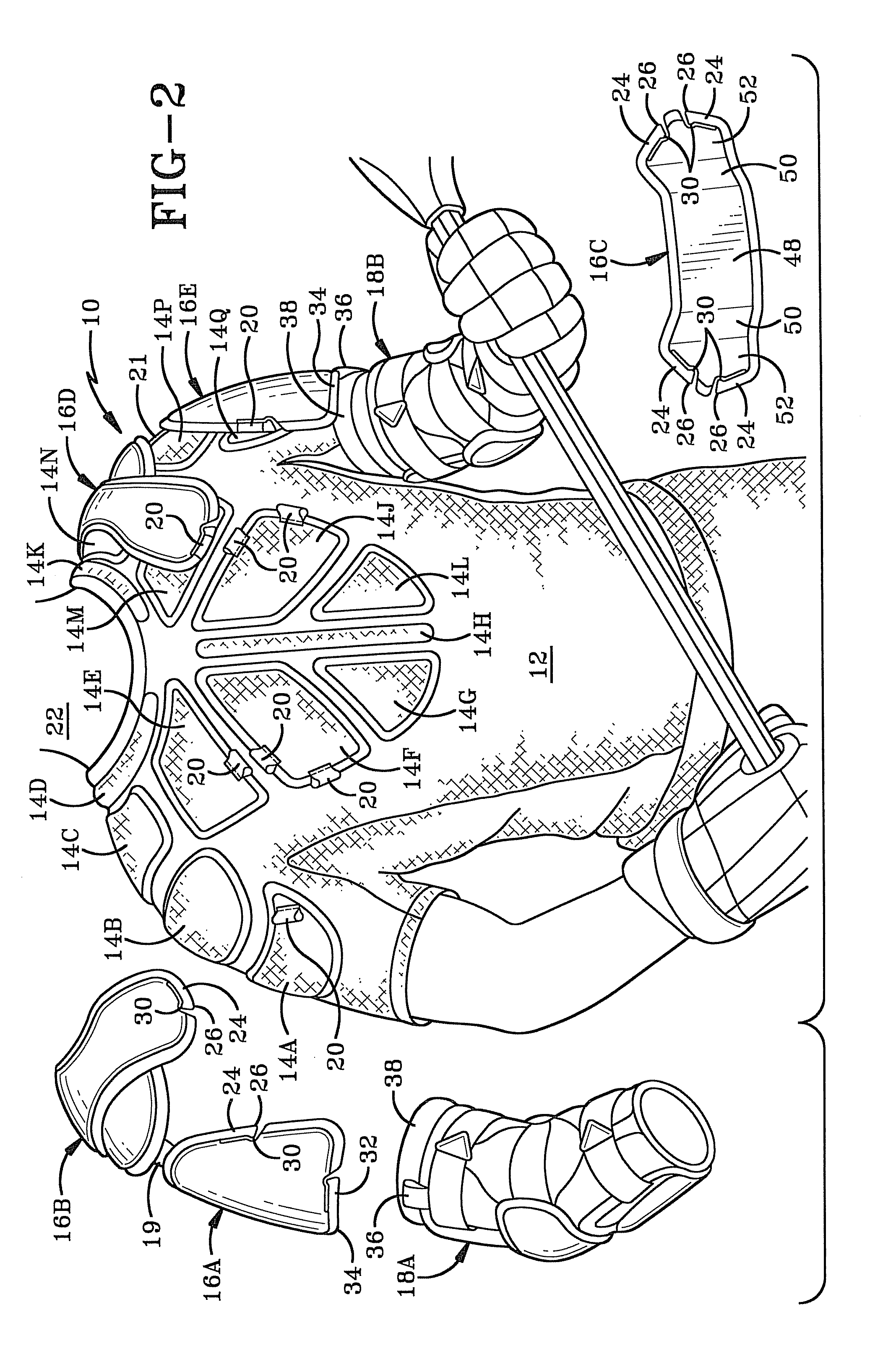

Lacrosse shirt and protective pad assembly

A garment comprising an undershirt having at least one first pad disposed proximate a wearer's sternum, and at least one second pad dimensioned wider than the wearer's sternum and secured to the undershirt at the at least one first pad, wherein the at least one second pad is removably secured to the undershirt.

Owner:HENSON CO INC

Body armour protection system protective hockey undershirt

ActiveUS8418262B2Reducing chaffingRelieve itchingPersonal protection gearUndergarmentsEngineeringCuff

A hockey shirt with a lower trunk opening, a neck opening and collar, including sleeves and cuff assembly. The shirt has special protective cover stitched, surged or fused on the lower sleeves, underarm parts and armpits to prevent against gashes, cuts and other injuries caused by skate blades.

Owner:BASE360

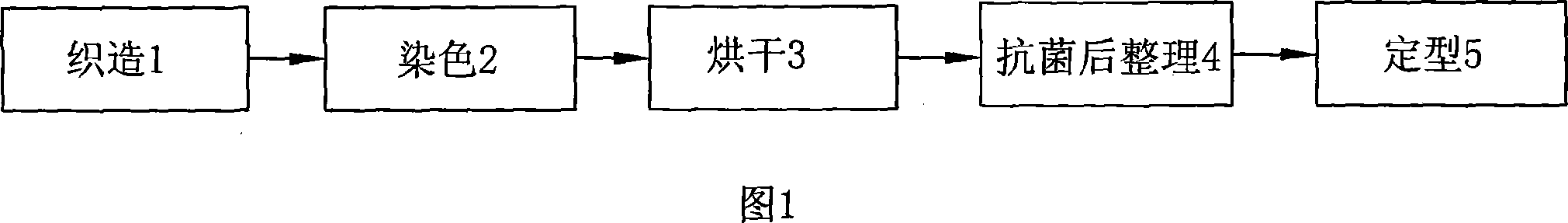

Pearl fibre antisepsis spandex jersey and manufacturing technique thereof

The present invention relates to pearl fiber antibacterial spandex undershirt cloth and the manufacturing process thereof. The undershirt cloth is woven by at least adopting pearl viscose fiber yarn and spandex yarn and through a circular knitting machine, and a chitin antibacterial agent is attached on the undershirt cloth. The manufacturing process comprises the following steps: firstly, weaving: the pearl viscose fiber yarn and the spandex yarn are woven on a weaving machine to make the required undershirt cloth; secondly, dyeing processing: the undershirt cloth is pre-processed, dyed and dried by adopting active environmentally friendly dye; thirdly, post finishing processing: the undershirt cloth is post-processed by using the chitin antibacterial finishing agent; and during the shaping, the antibacterial processed undershirt cloth is unfolded and shaped under the condition that the temperature is controlled at 150 DEG C to 160 DEG C. The present invention has the skin caring, the heat clearing and toxin counteracting, the skin whitening and the anti-ultraviolet effectiveness of the pearl and the health protection antibacterial and bacteriostasis effectiveness of the chitin antibacterial agent.

Owner:NINGBO SEDUNO GRP

Upper body undergarment (undershirt garment)

InactiveUS20110271420A1Cooler and comfortable wearing experienceFew propensityGarment special featuresUndergarmentsPerspirationEngineering

An Upper-Body Undergarment (undershirt garment) that can be worn directly on top of the skin but beneath the next layer of garment as outer garment protection from upper body perspiration stains. The said undergarment is fashioned to allow ventilation and concealment and is ideal for wearing under outer garments such as shirts, T-shirts, coats, jackets, sweaters and the likes, especially in climates that are hot and the need to wear less clothing becomes important.

Owner:LAWRENCE GREGORY MICHEL

Blended yarn of jute fiber, cotton fiber and viscose fiber and application of blended yarn

InactiveCN102493059AHygroscopicMoisture retentionBiochemical fibre treatmentBleaching apparatusYarnMoisture absorption

The invention discloses a blended yarn of a jute fiber, a cotton fiber and a viscose fiber. The blended yarn is made by blending the following raw materials in percentage by weight: 30 to 50 percent of jute fiber, 22 to 30 percent of cotton fiber and 20 to 48 percent of viscose fiber. By blending the jute fiber, the cotton fiber and the viscose fiber in a reasonable proportion, the blended yarn overcomes the defects that the jute fabric is rough and hard and easy to drape, and has the characteristics of moisture absorption, air permeability and antibacterium and the like of the jute fiber; besides, the blended yarn has the advantages of softness, smoothness, breathability, antistatic performance, and the like, and rich color can be obtained by dyeing. Blended fabric made of the yarn is applied to undershirts, sportswear, coats and the like.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

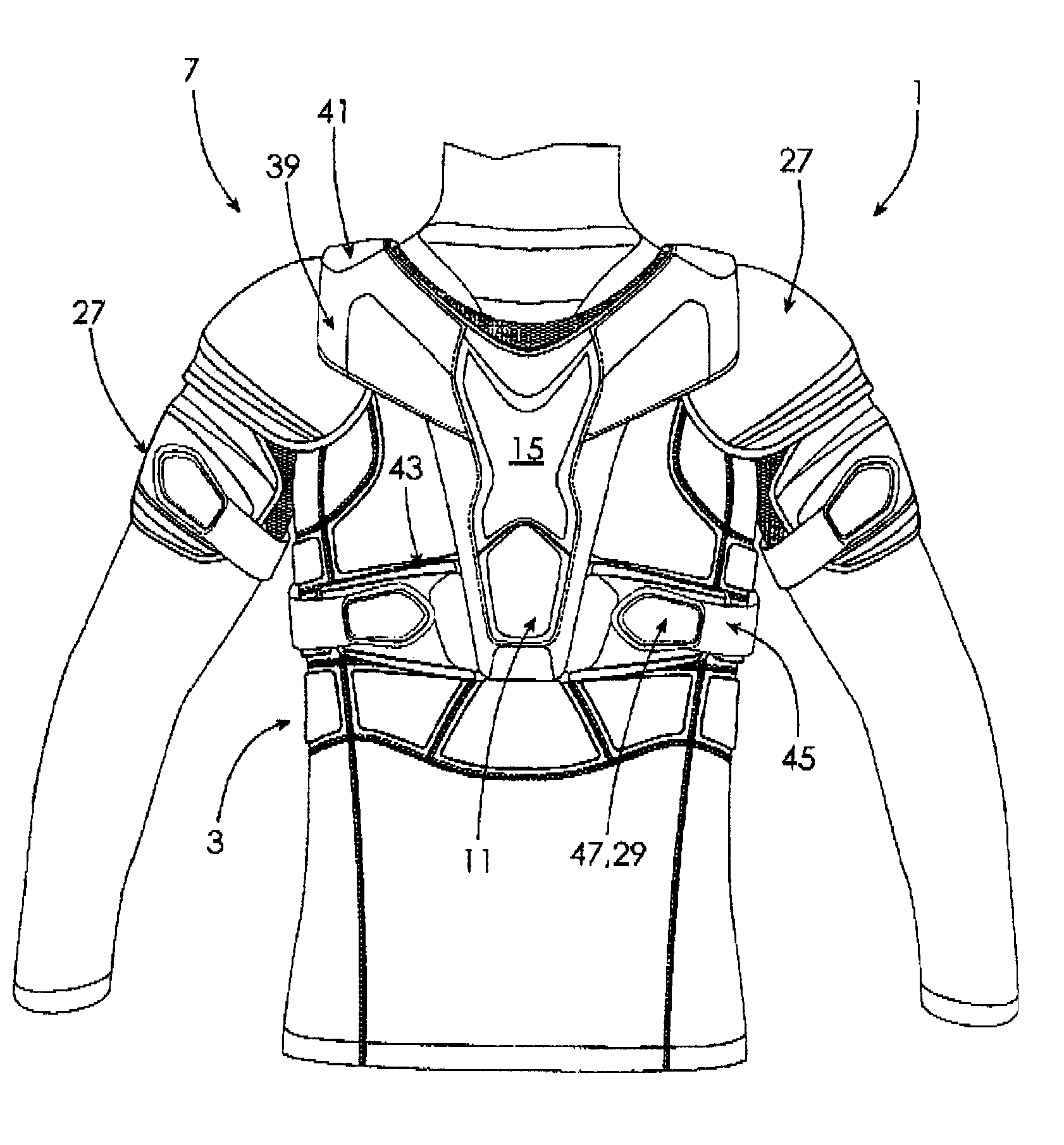

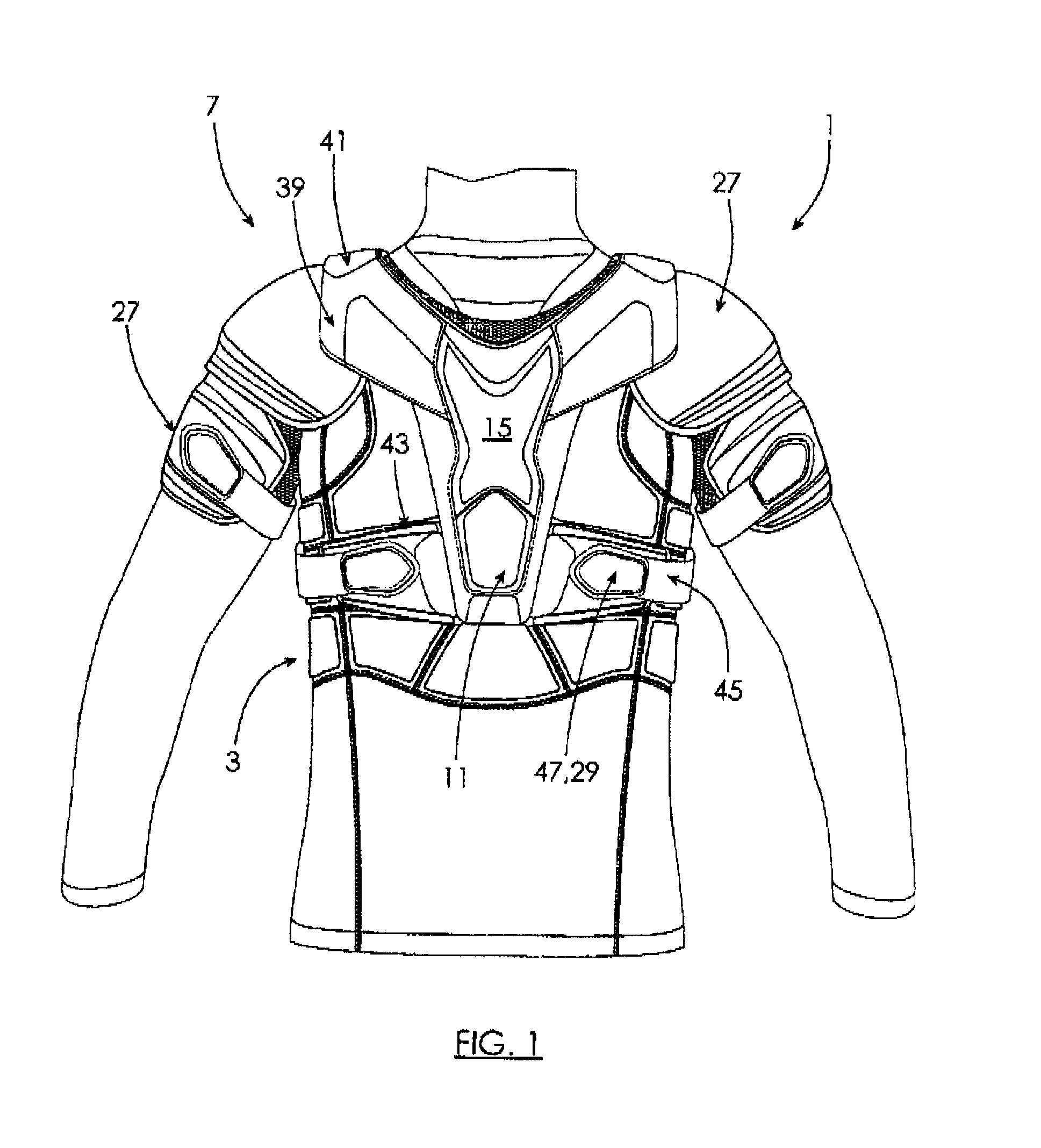

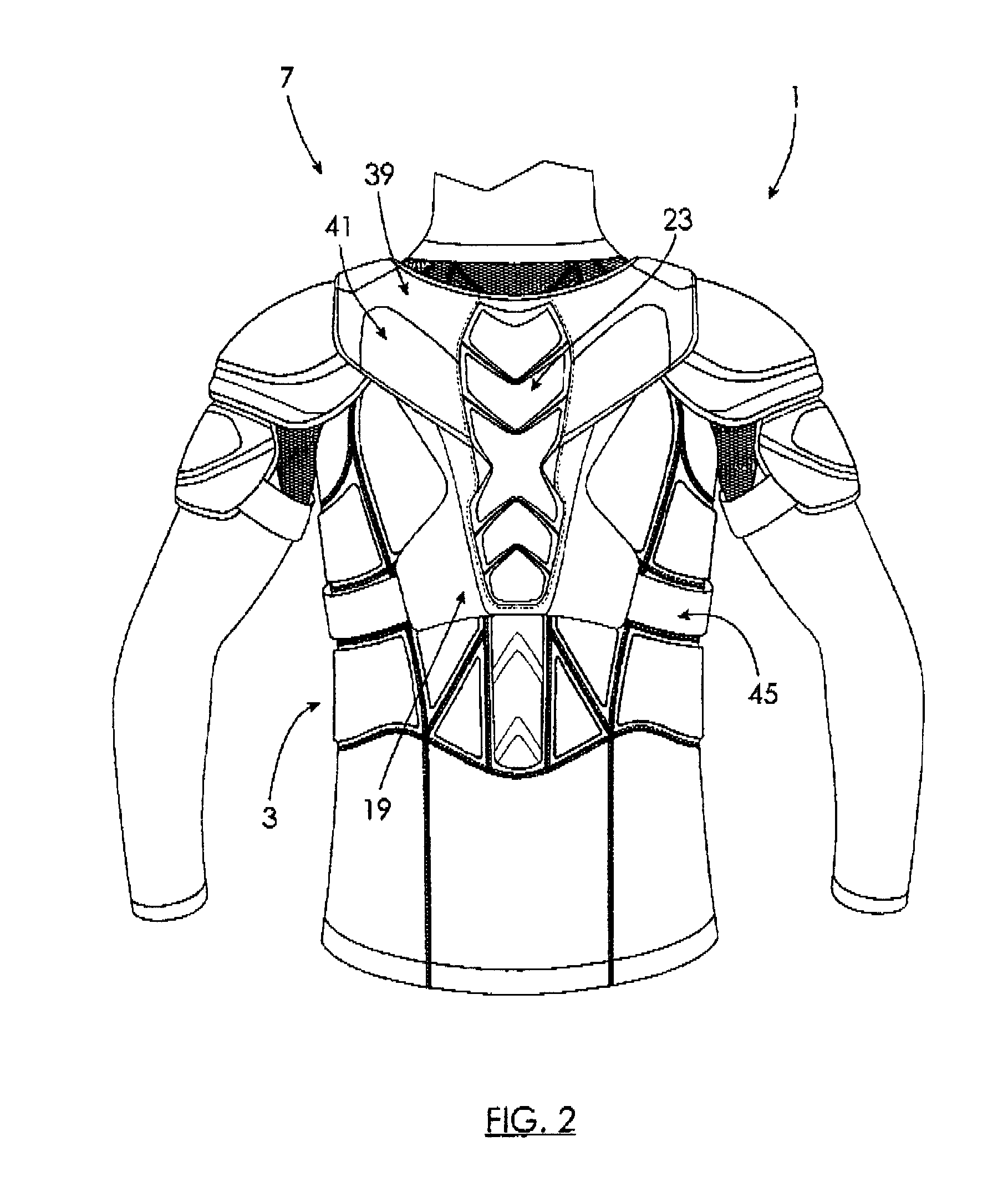

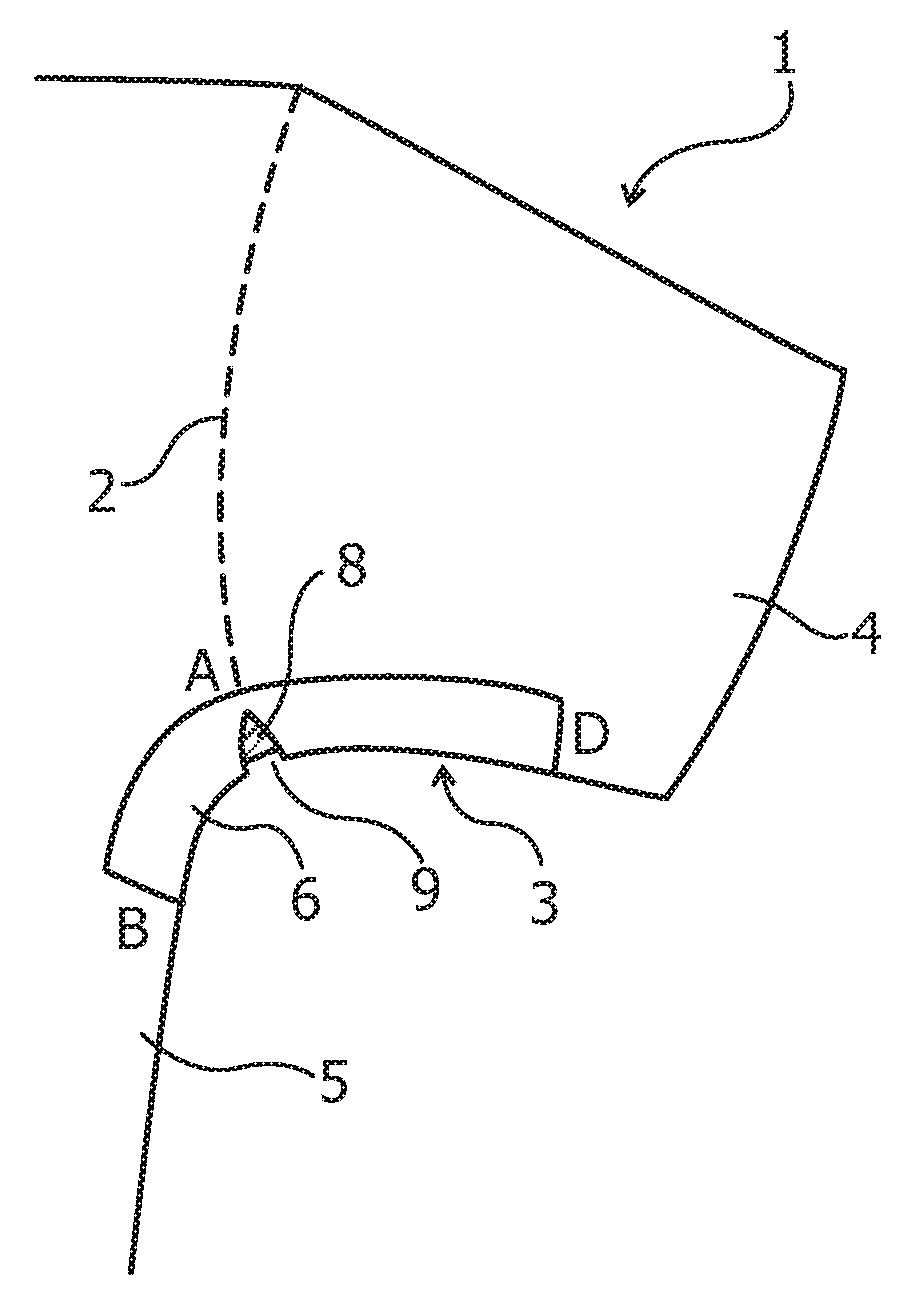

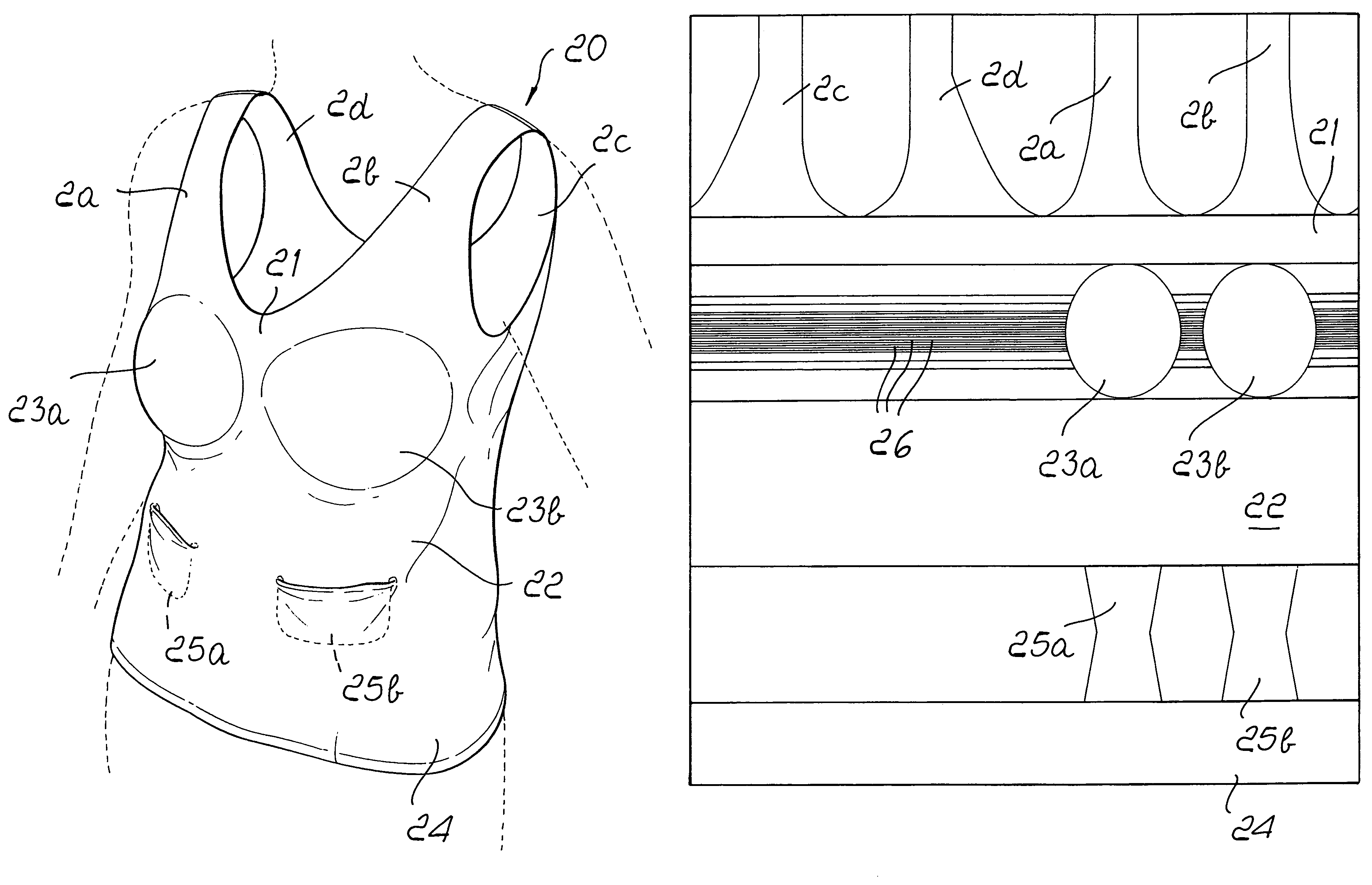

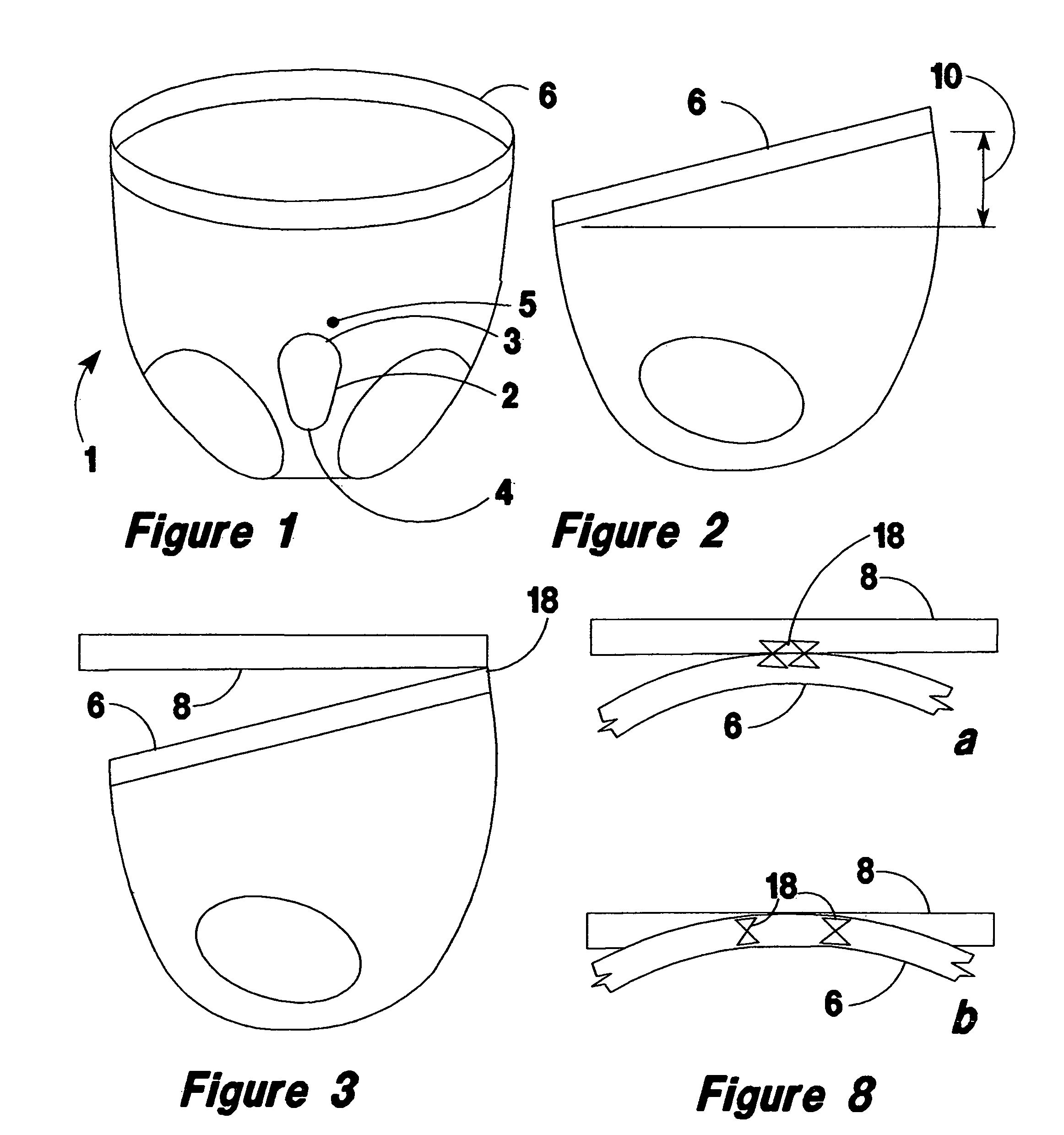

Complementary and adjustable protective system

A protective system (1) for protecting a user during a contact sport includes an undershirt (3) and an outer shell (7). The undershirt (3) is configured to be worn by the user, and is provided with a plurality of shock- absorbing pads (5) each being shaped and sized to protect different body parts of the user, each shock-absorbing pad (5) providing a close-to-the-body protection for a corresponding body part of the user. The outer shell (7) is configured to be worn by the user, over the undershirt (3), and is provided with a plurality of impact-dispersion pads (9) each being shaped and sized to protect different body parts of the user, each impact-dispersion pad (9) providing a floating protection for a corresponding body part of the user. Shock-absorbing pads (5) of the undershirt (3) are disposed so as to be complementary to impact-dispersion pads (9) of the outer shell (7), and pads (5,9) of either one of the undershirt (3) and the outer shell (7) are selectively customizable by the user, so as to provide the user with a complementary and adjustable protective system (1).

Owner:ID LAB

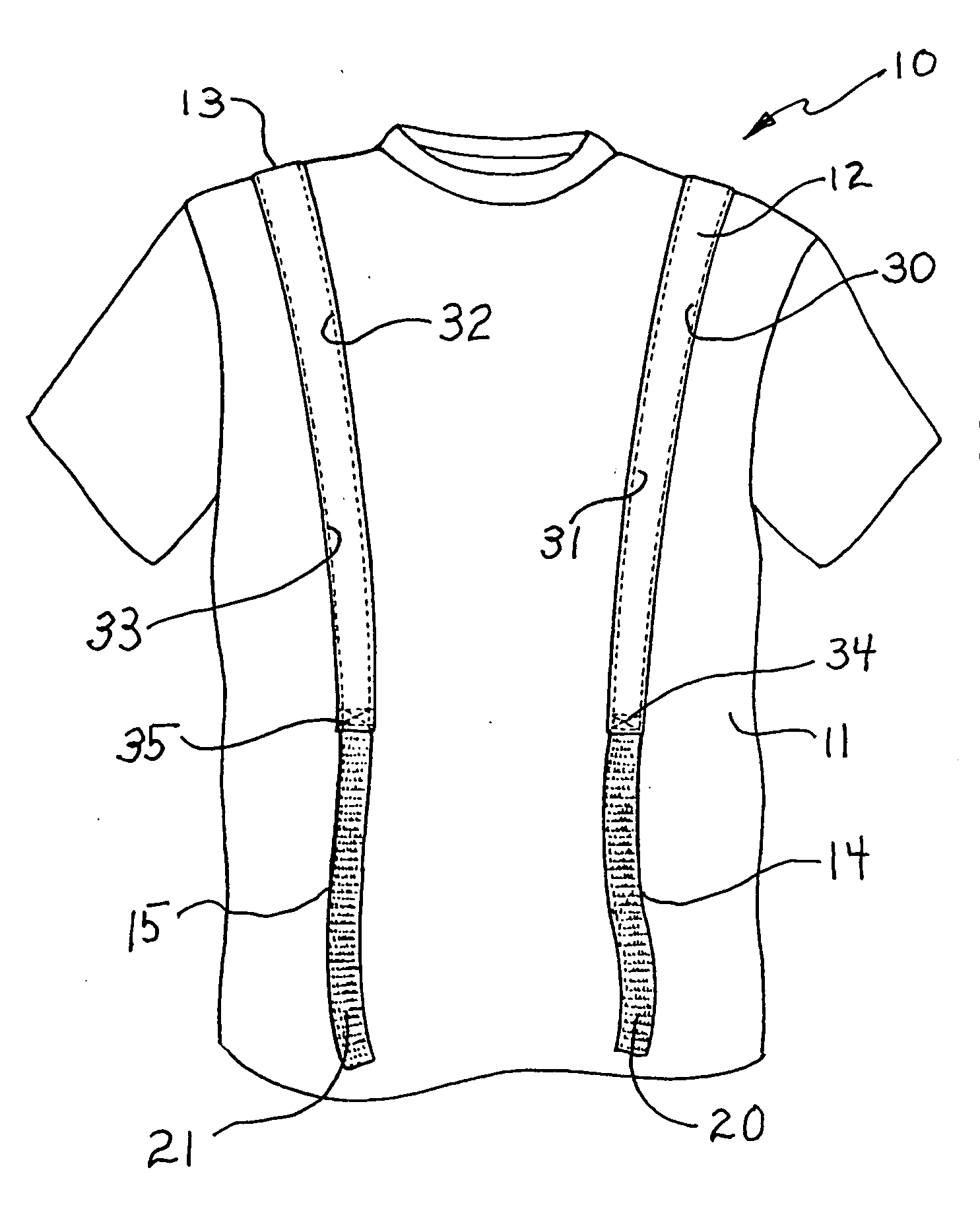

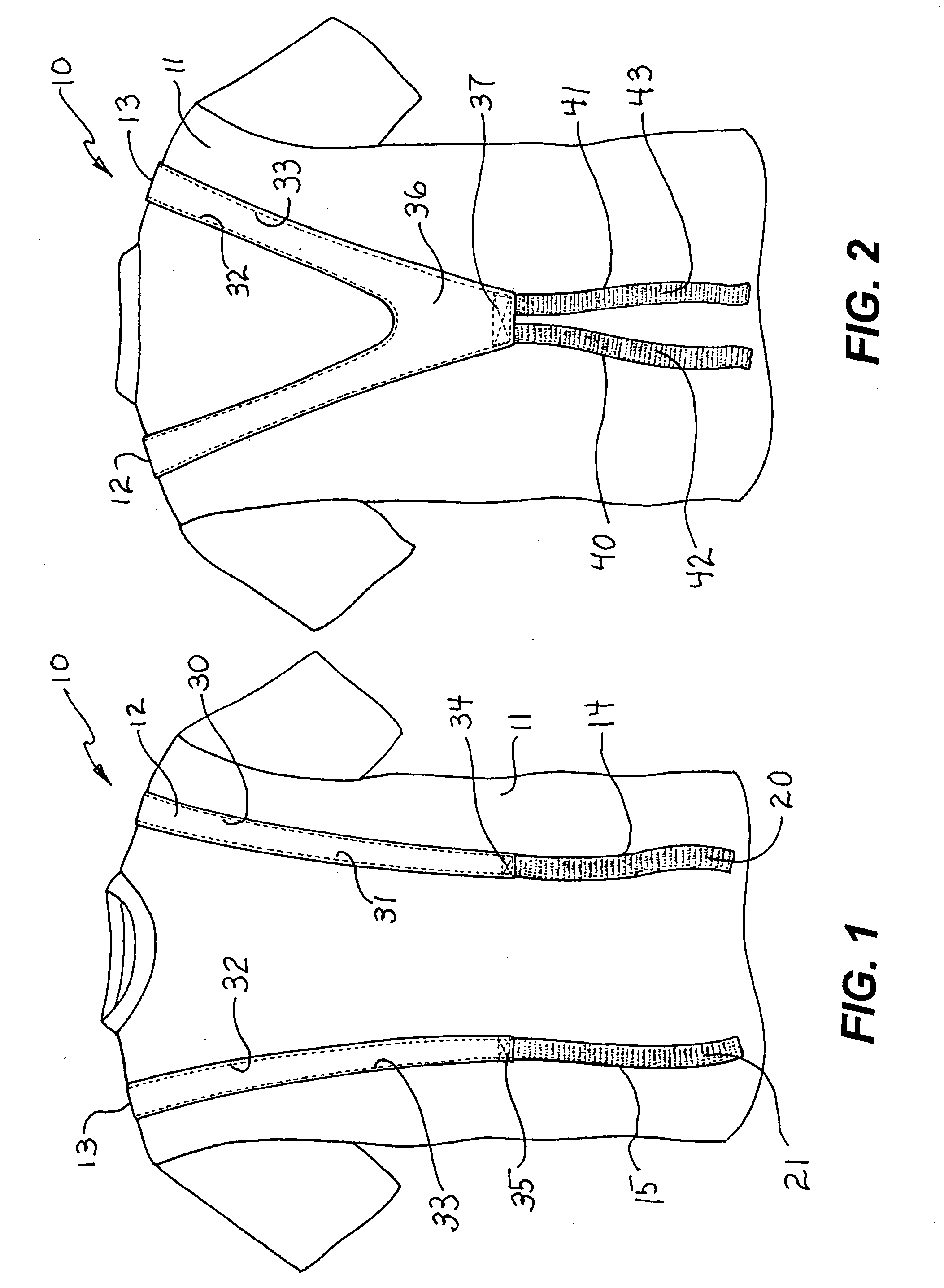

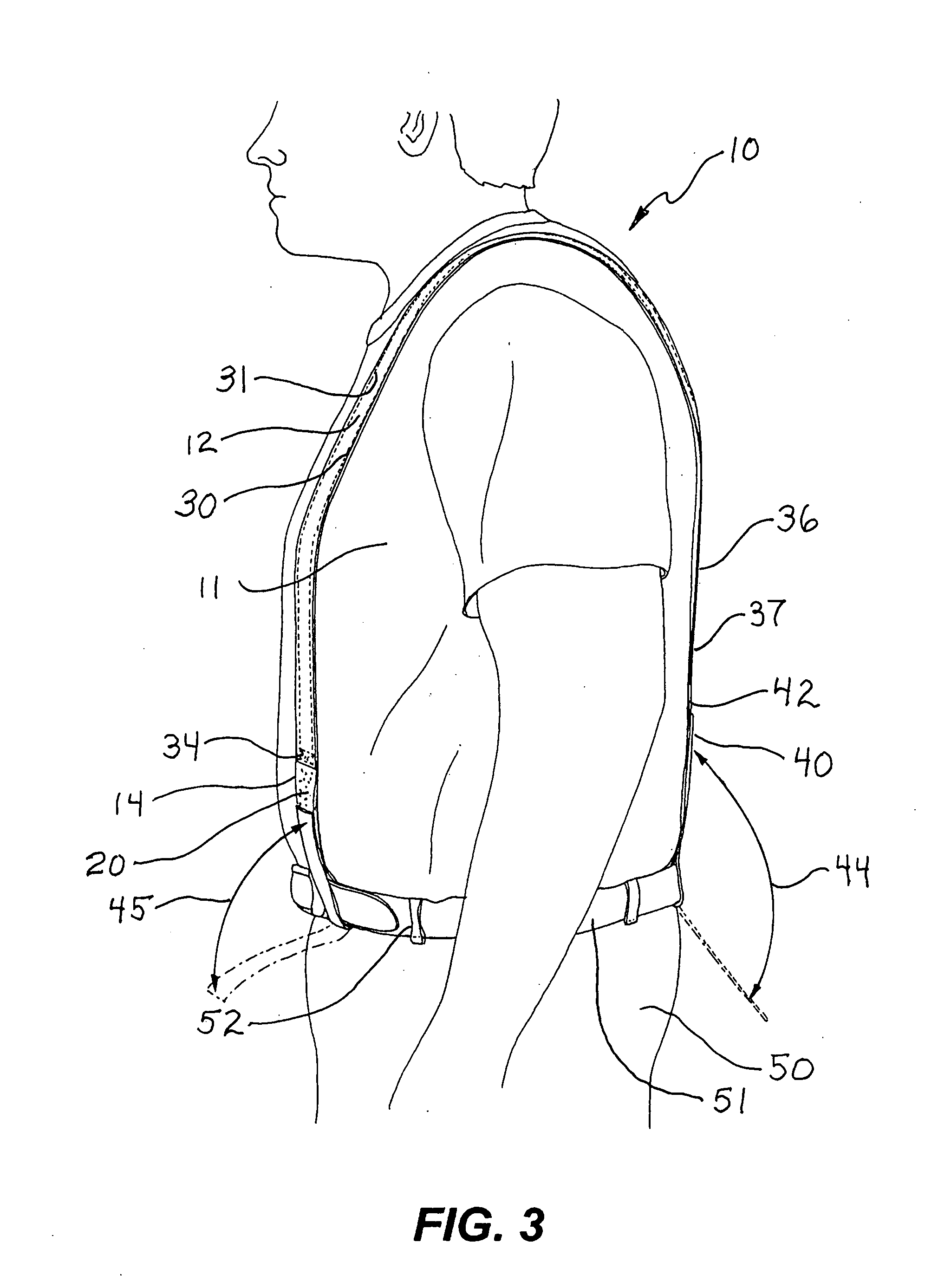

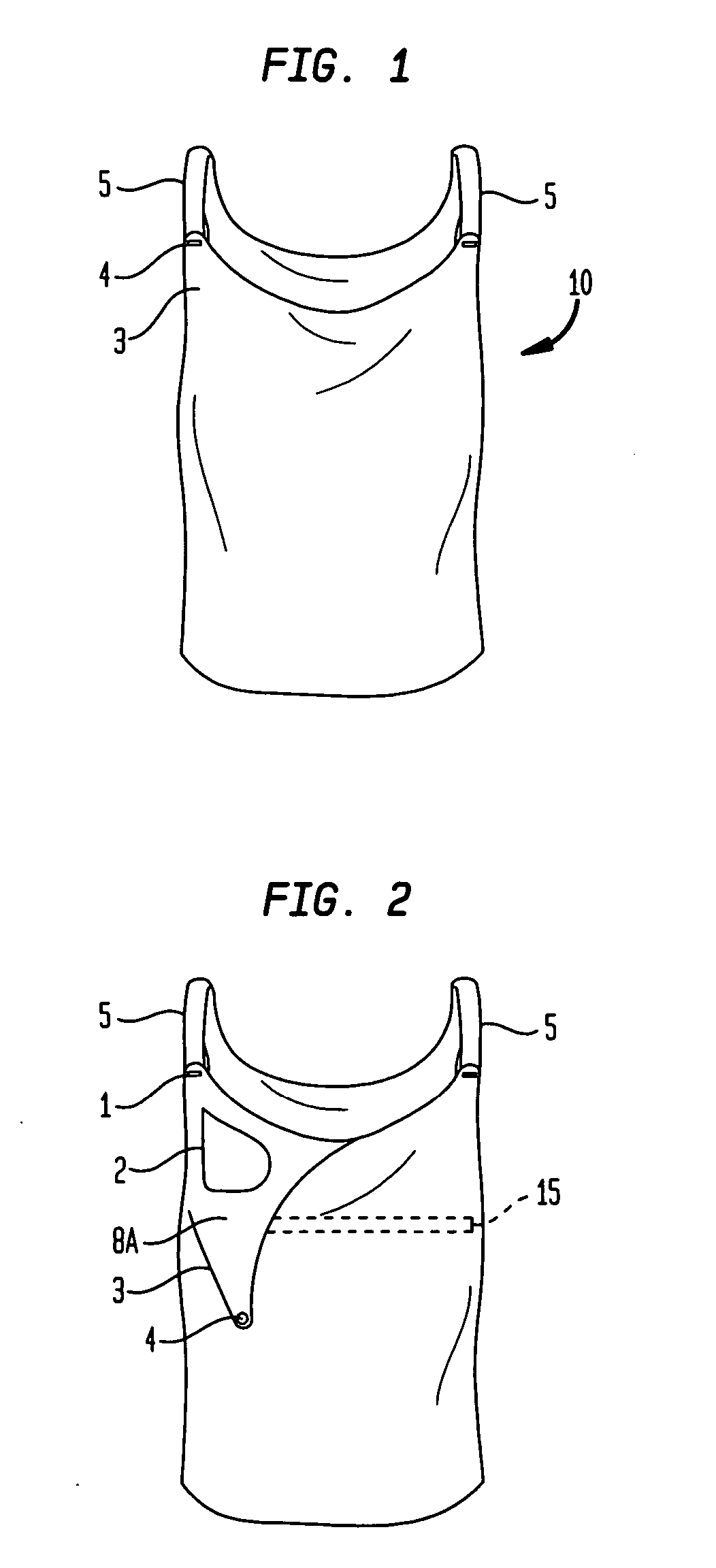

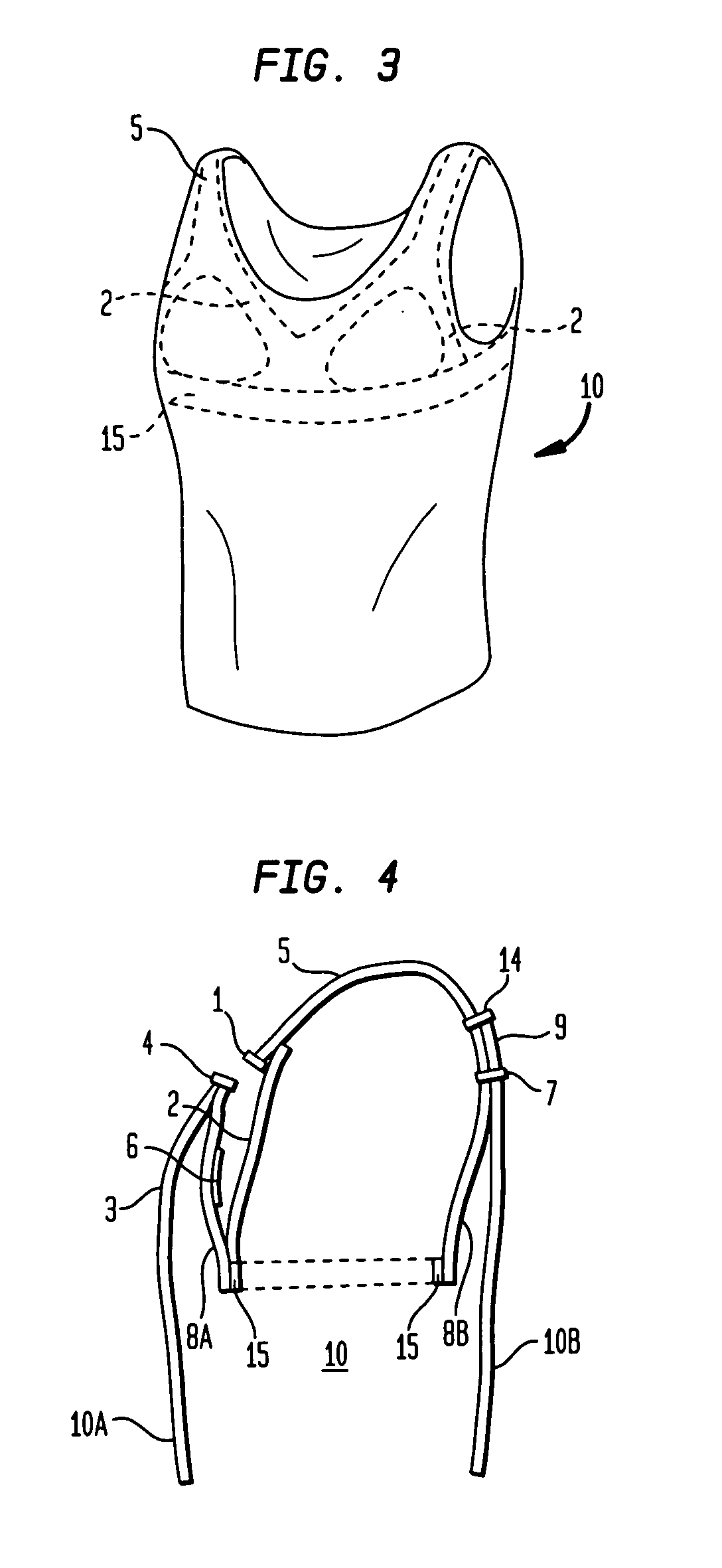

Combination shirt and suspenders

A combination shirt and suspenders includes an undershirt or t-shirt together with a pair of suspender straps. The suspender straps are secured to the underlying shirt surface by sewn seams. Each suspender strap further supports an end strap having a fabric attachment portion thereon. The user wears the shirt in a conventional manner and secures the suspender straps to a pants belt or waistband to provide suspender support of the wearer's pants.

Owner:HANDY JOHN N

Shirt having form-fitting mid-section support

InactiveUS8516614B2More synchedMinimize appearanceGarment special featuresProtective garmentLateral regionEngineering

Owner:KARASINA SVETLANA

Wool spandex undershirt cloth and manufacturing method of the same

ActiveCN102443922AAchieve diversificationPromote perfectionHeating/cooling textile fabricsWoven fabricsYarnEngineering

The invention discloses a wool spandex undershirt cloth and a manufacturing method of the same. The wool spandex undershirt cloth is formed by dual-yarn coverage of wool and spandex, the wool is on the front face of the fabric, and the spandex is on the back face of the fabric. The manufacturing method of the wool spandex undershirt cloth comprises four steps of yarn dying, weaving, bleaching anddyeing, and gapping and shaping. In the method, wool and spandex are woven together to form the undershirt cloth, in this way, high-grade undershirt cloth fabrics are developed, diversification of the undershirt cloth is realized, and the wool spandex undershirt cloth meets high-grade requirements and is beneficial for improving the diversity of dress and home furnishing of people. In order to realize the fabric of the wool spandex undershirt cloth, low-temperature spandex is used, and the technology is improved in steps of weaving, bleaching and dyeing, and gapping and shaping, particularly,a low-temperature shaping technology is used, thus, the defective rate of cloth blanks is reduced, and qualified products are manufactured.

Owner:NANTONG TIMES CLOTHING

Body armour protection system protective hockey undershirt

ActiveUS20060162043A1Light weightImprove tensile propertiesPersonal protection gearUndergarmentsEngineeringCuff

A hockey shirt with a lower trunk opening, a neck opening and collar, including sleeves and cuff assembly. The shirt has special protective cover stitched, surged or fused on the lower sleeves, underarm parts and armpits to prevent against gashes, cuts and other injuries caused by skate blades.

Owner:BASE360

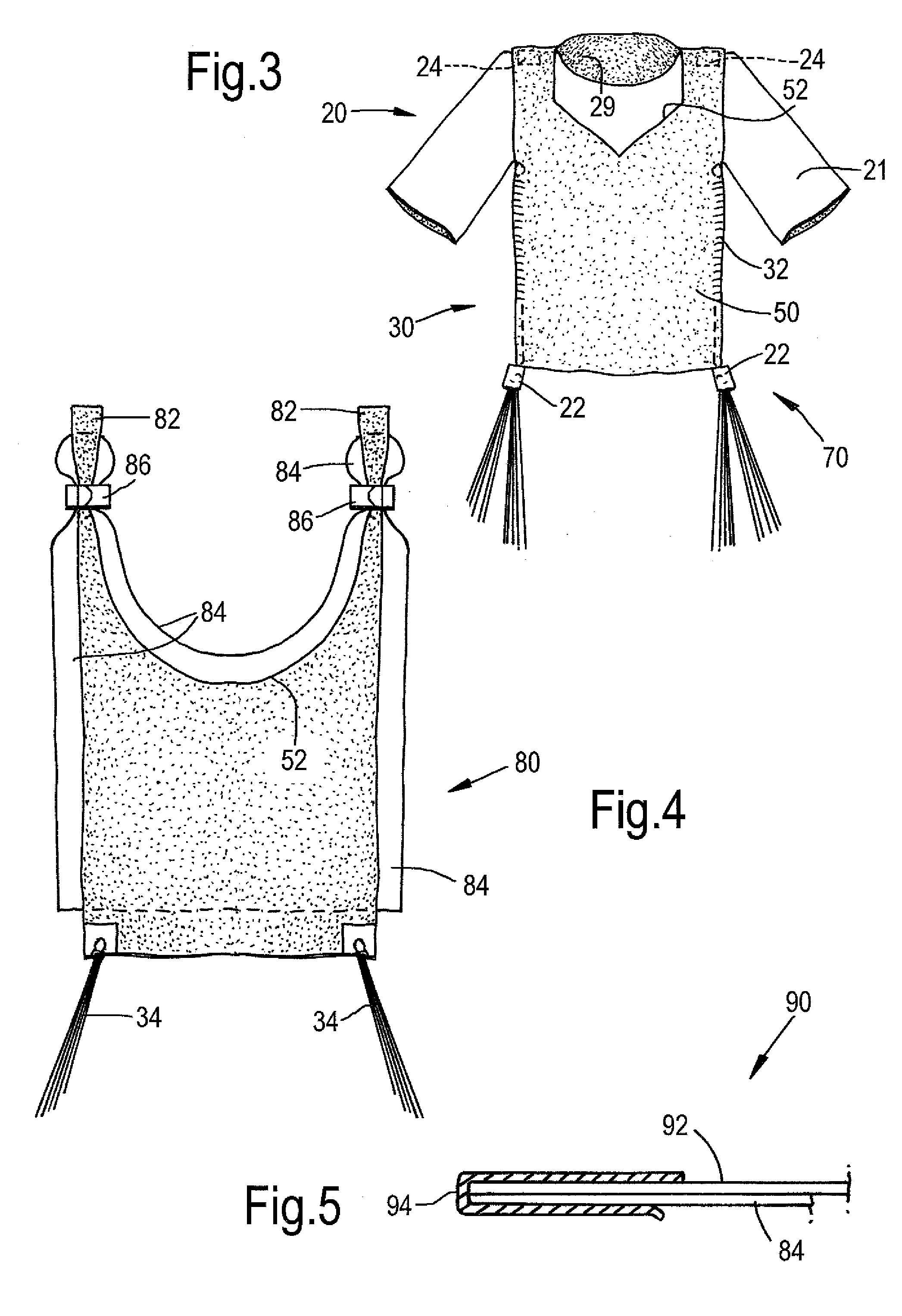

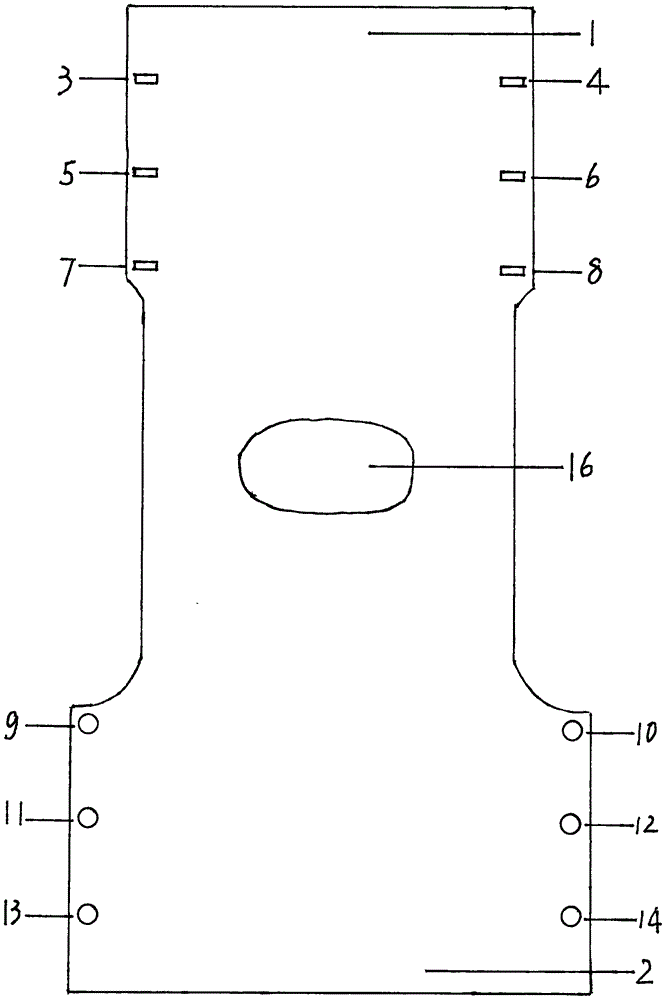

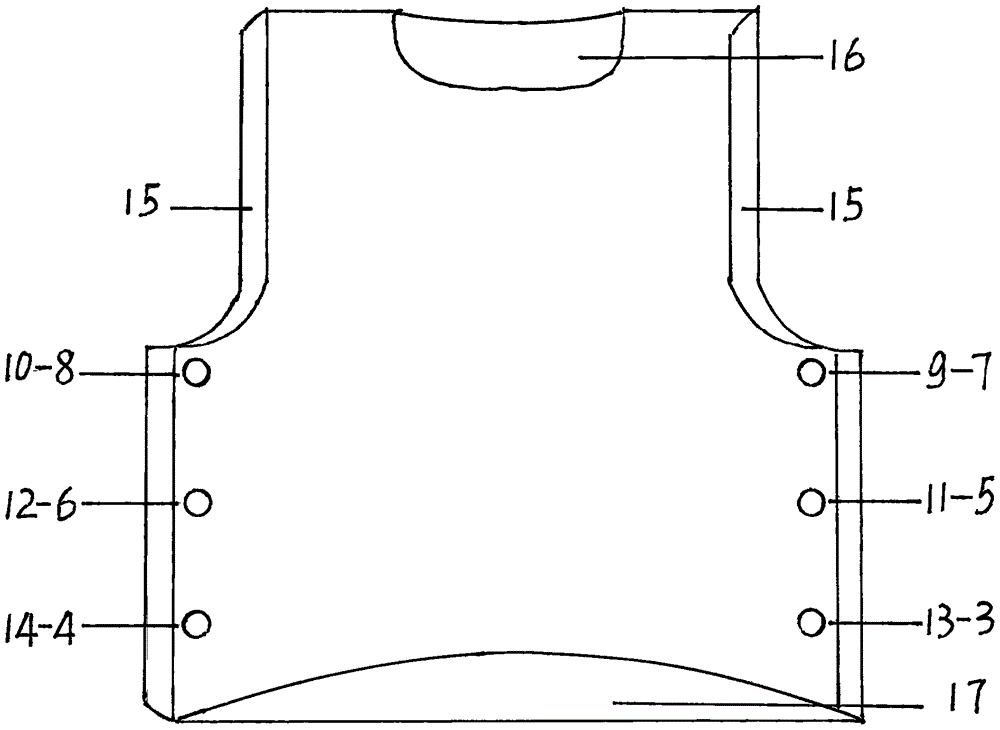

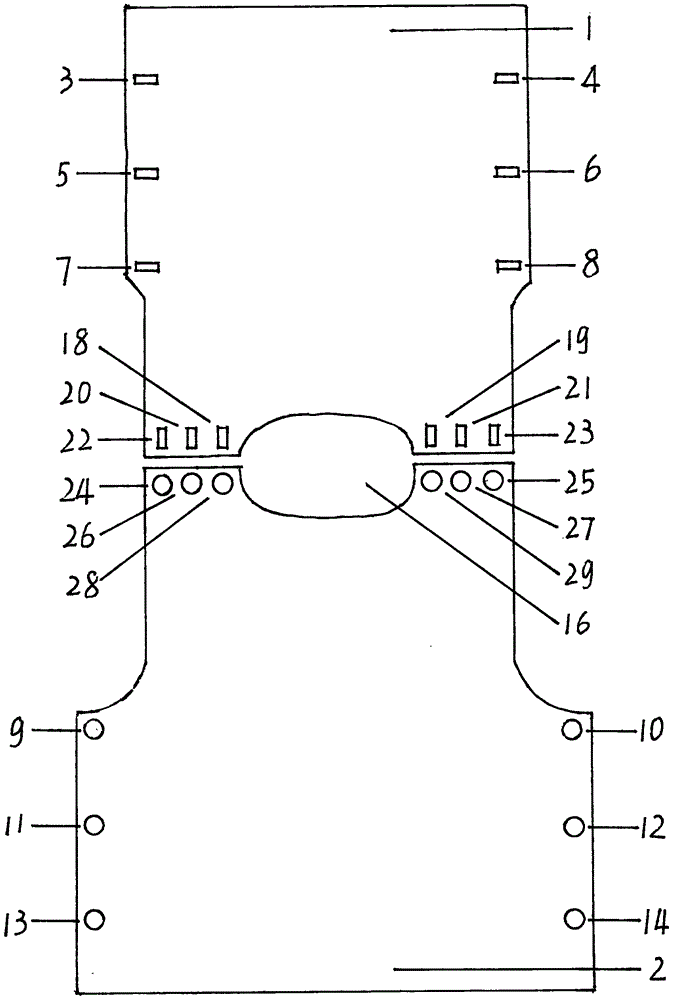

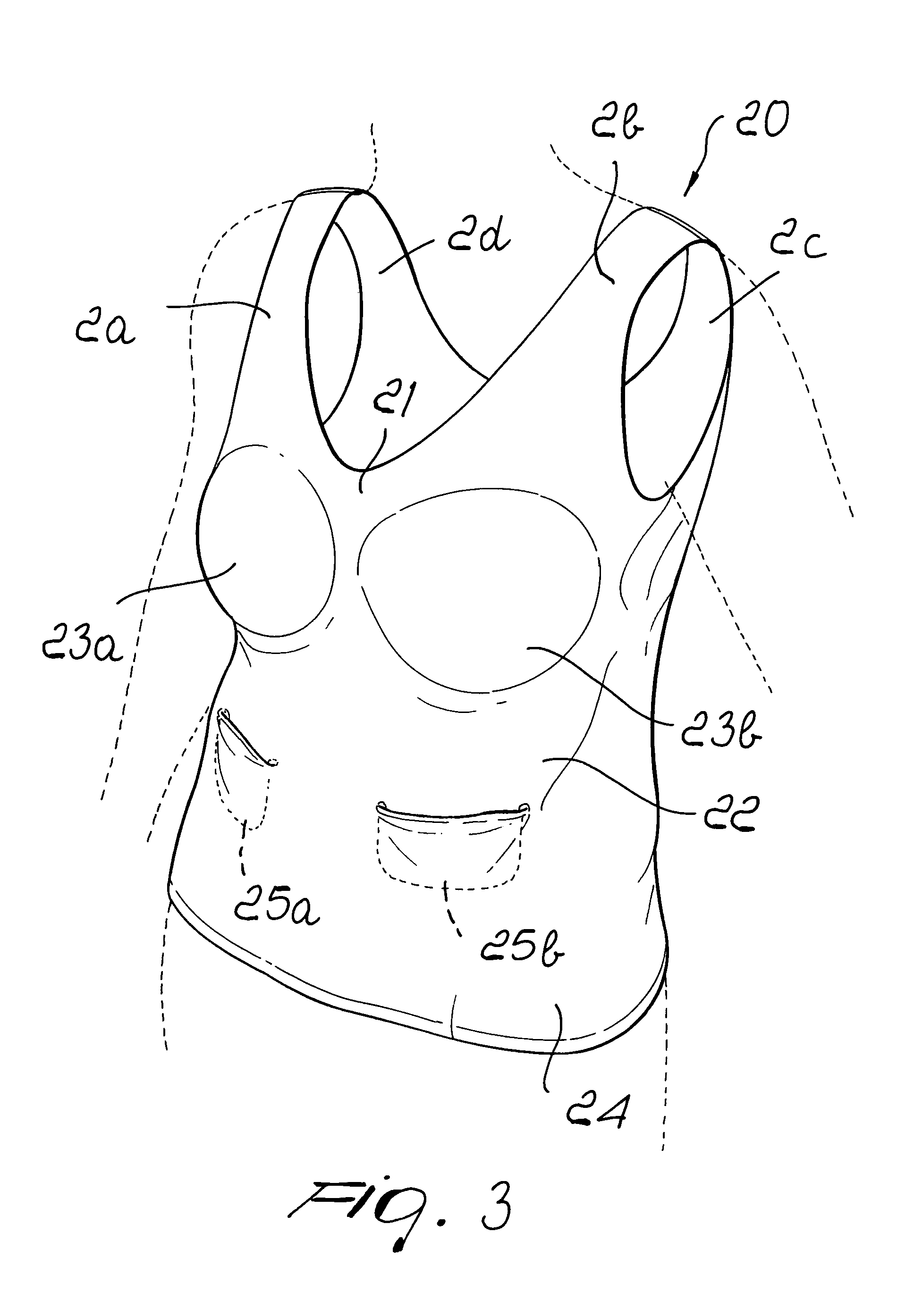

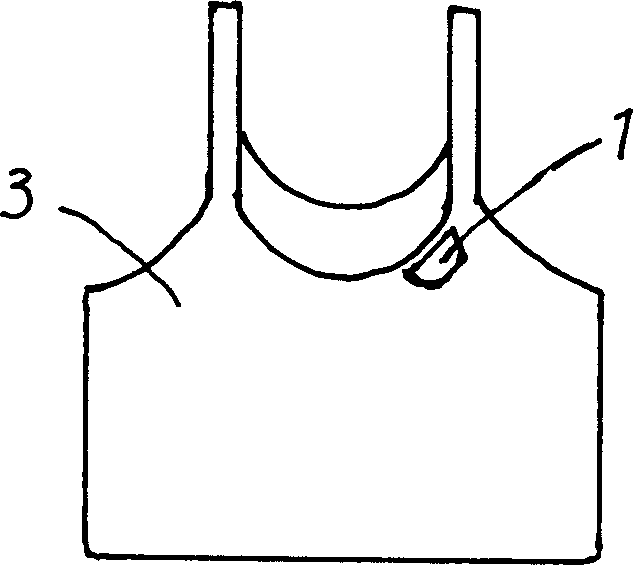

Combination of an undershirt and a four-cornered garment with fringes

InactiveUS20080271223A1Space be allowRestrict movementUndergarmentsProtective garmentUndershirtBiomedical engineering

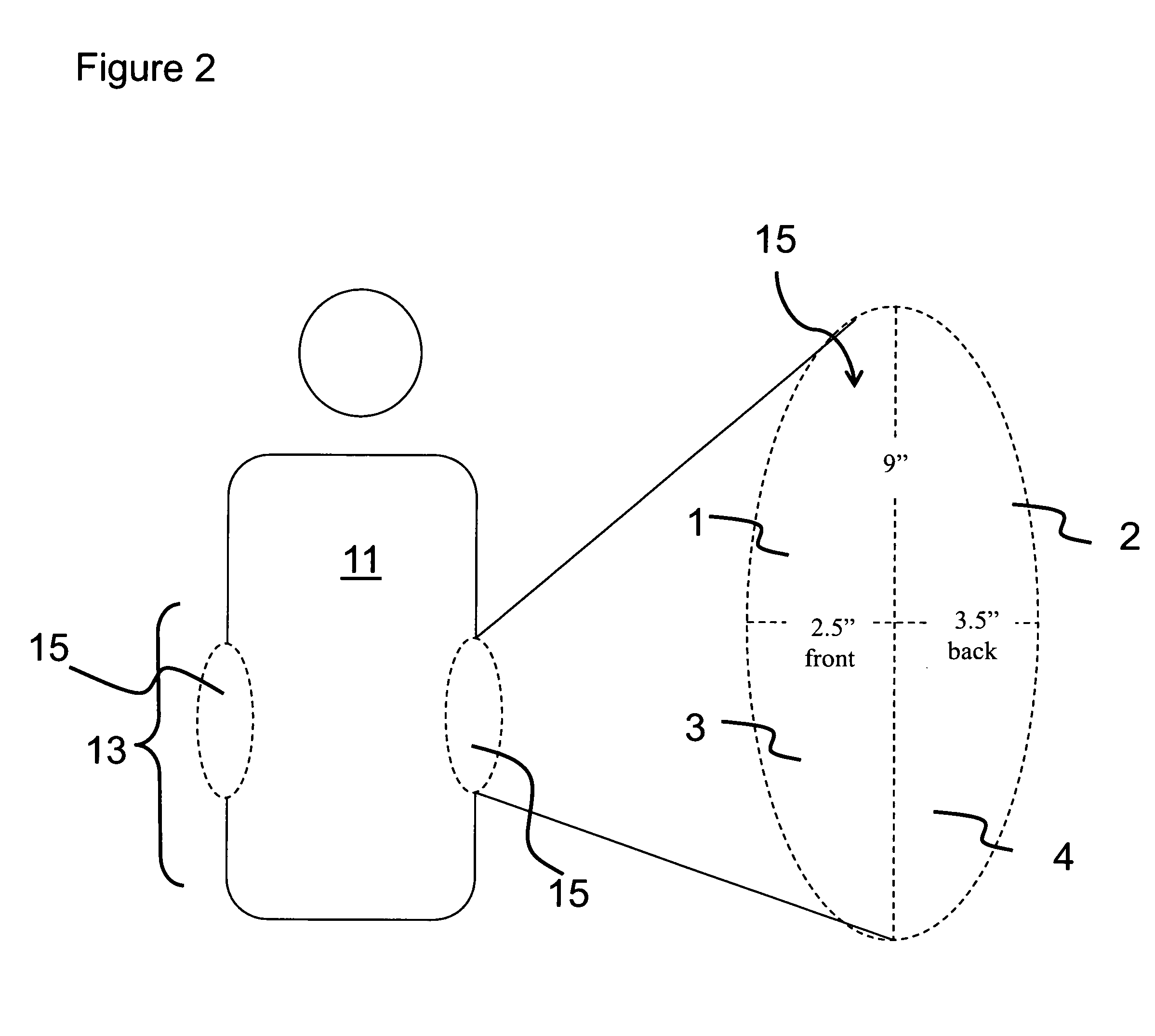

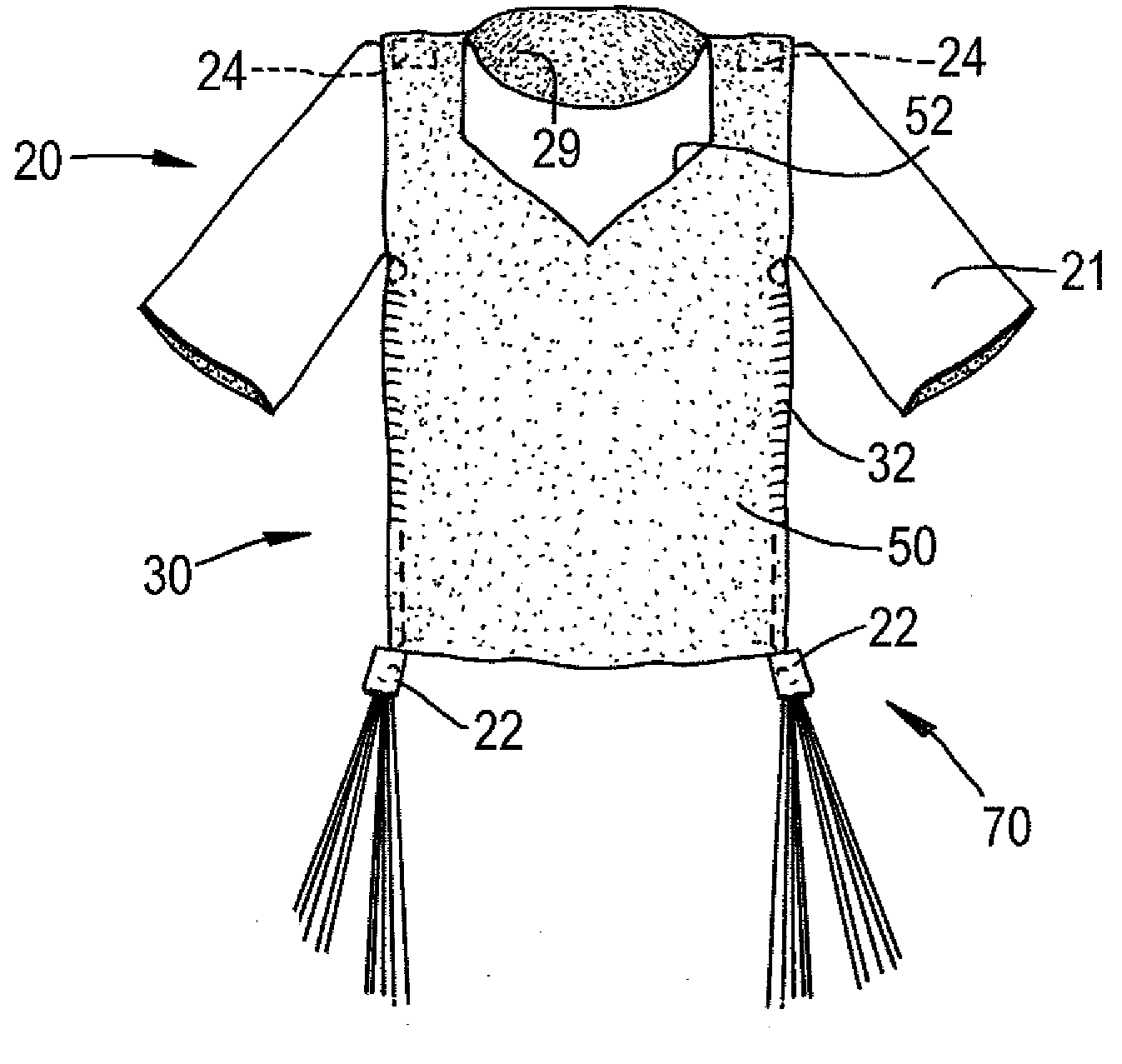

The present invention provides an undershirt provided with means for releasable attachment thereto of a component of a four-cornered garment with fringes as well as providing a four-cornered garment with fringes having a releasable attachment means for attachment thereof to a garment.

Owner:COHEN SARAH

Undershirt capable of being replaced without taking off coat

The invention discloses an undershirt capable of being replaced without taking off a coat. According to the undershirt capable of being replaced without taking off the coat, the original fixed connecting part, close to the rib parts on the two sides of a human body, of the two side edges of a front cloth piece and a rear cloth piece of an undershirt in the prior art can be changed into flexible connection through a button and a button hole, and shoulder parts can also be added. The disadvantage that the undershirt can be replaced by taking off all clothes worn by a wearer when the undershirt is worn snugly is overcome. In the seasons of late autumn, severe winter or early spring, when people travel in famous mountains or rives and scenic spots, exercise on a playground in the open countryside, and work in the fields, once the undershirt is wetted by sweat, the undershirt can be tucked into or withdrawn from the collar or the lower hem of the worn coat at any time and any place, so that the undershirt can be replaced without taking off the coat and without being affected by the inconvenience caused by outside cold or public place privacy. The undershirt can certainly also be used when there is a need for warm, privacy and the like indoors.

Owner:茆荣林

Lacrosse shirt and protective pad assembly

A garment comprising an undershirt having a plurality of first pads, at least two mounting loops extending from the undershirt, a plurality of second pads, each of the plurality of second pads having at least two fingers, and wherein the at least two fingers are engaged with the at least two mounting loops to secure the plurality of second pads to the undershirt.

Owner:ADIDAS

Underarm garment protector

An armpit sweat absorption system comprised of a disposable absorption pad that is placed inside a pocket located under the armpit of a conventional yet modified men and women's undershirt. The pocket, located at the arm pit location serves as an “under-pocket” to contain the disposable absorption pad. The under-pocket is a simple layer of undershirt material that reinforces the under arm and has room to hold the pad. The pad material is a composite of gauze-like cotton material suitable for absorbing moisture. The combined effort of under pocket and absorption pad is meant to absorb unsightly underarm perspiration and provide garment protection from clothes fading and discoloration due to sweating and deodorant stains that tend to drain through.

Owner:PRICE JASON ANDREW

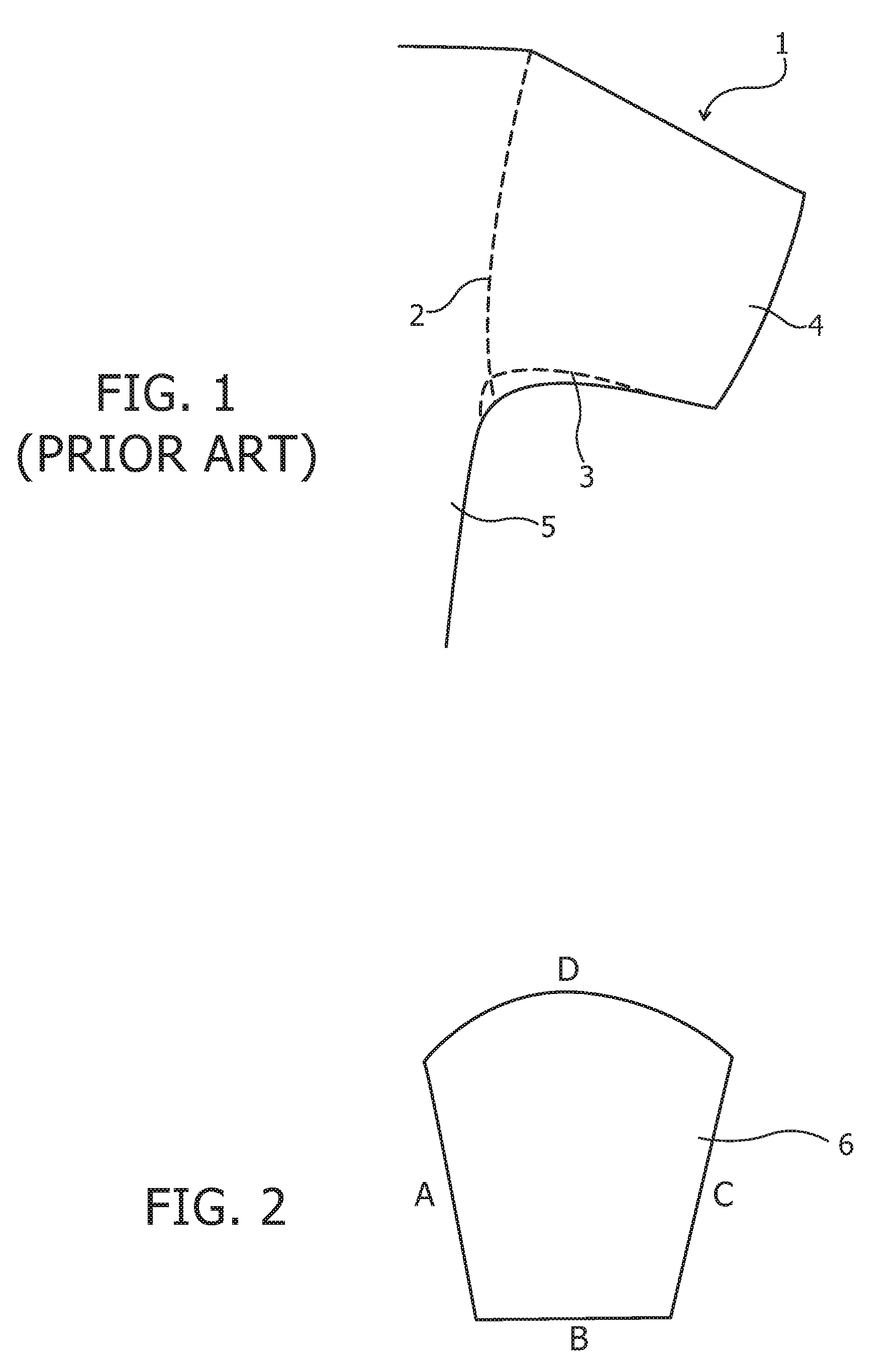

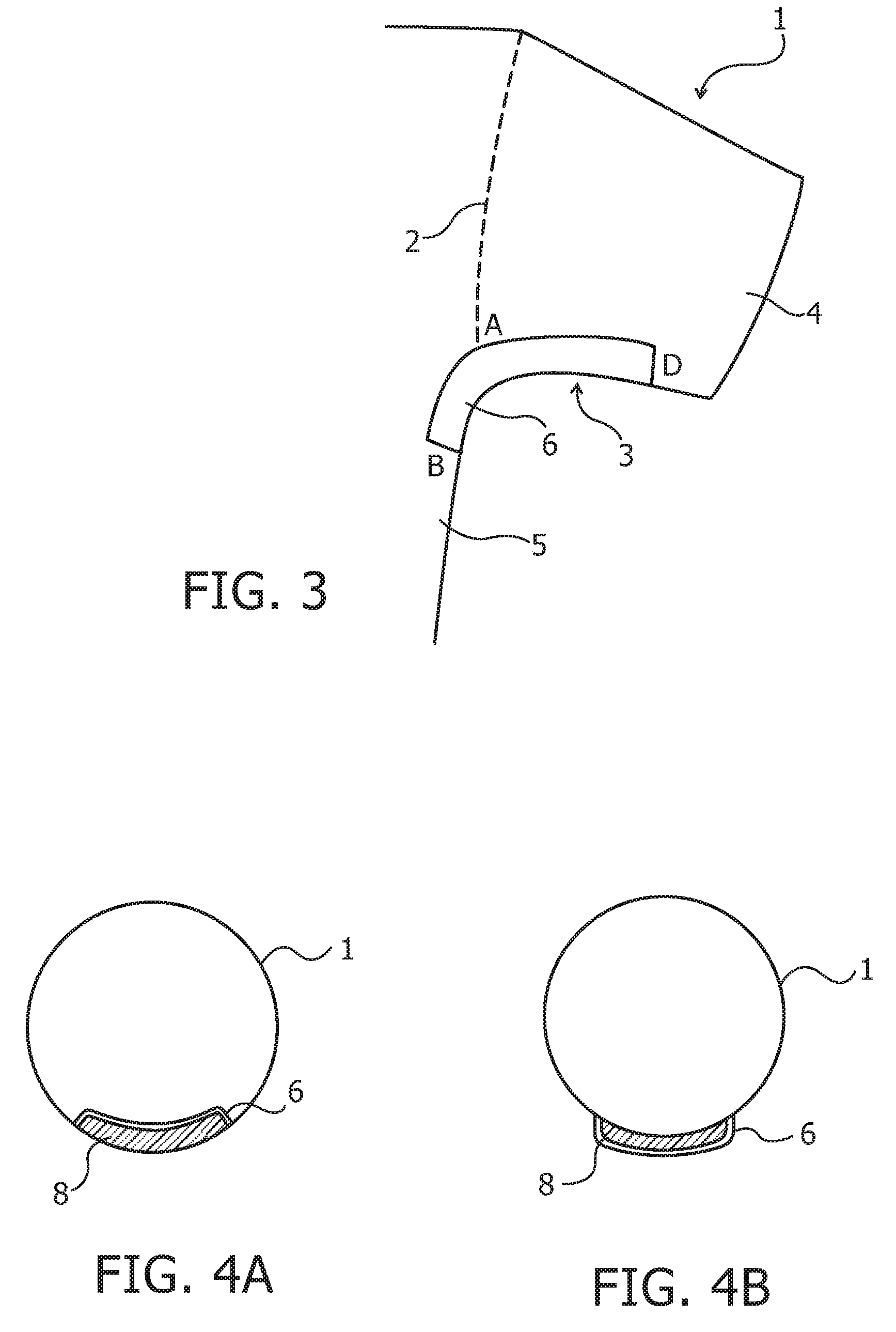

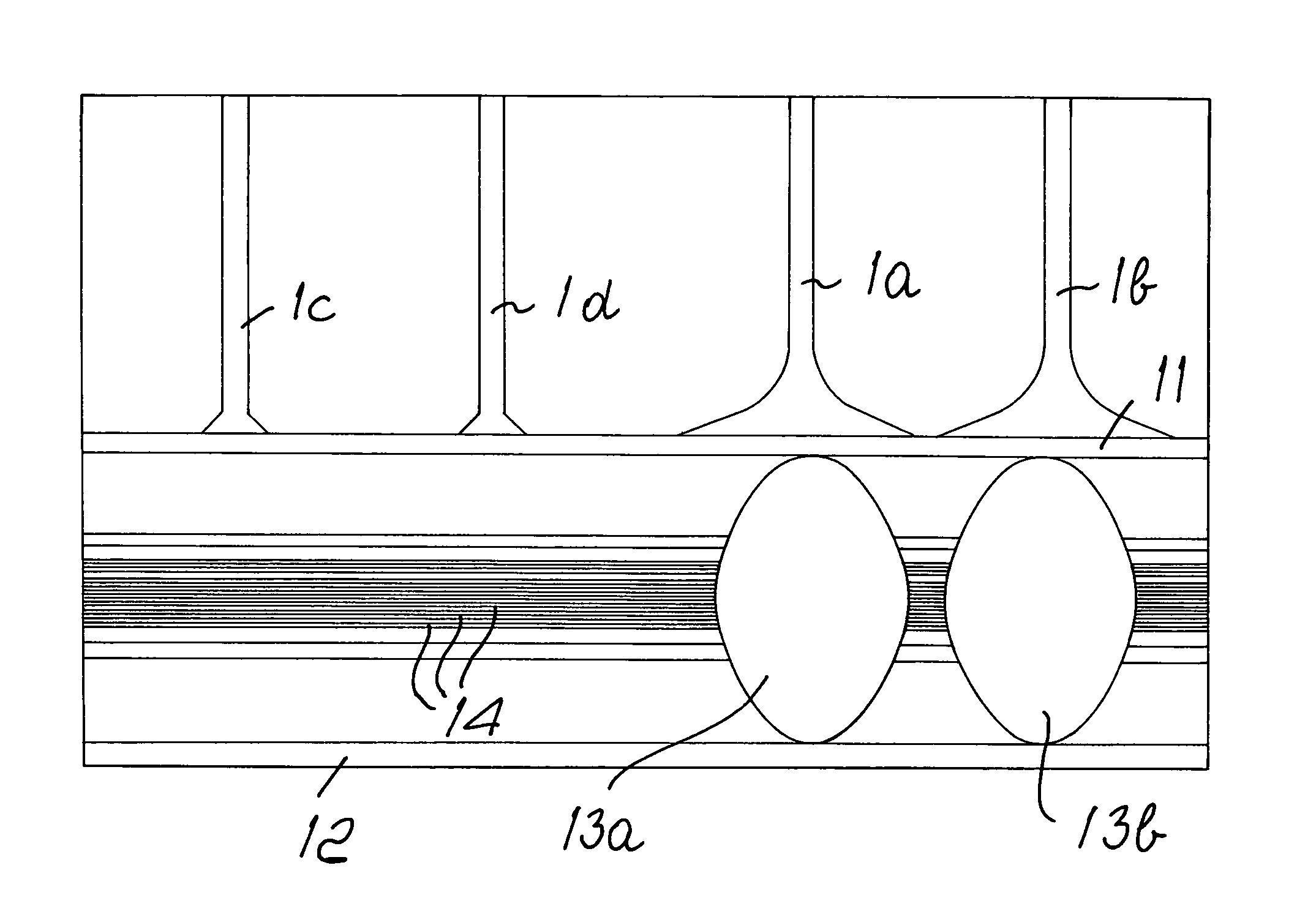

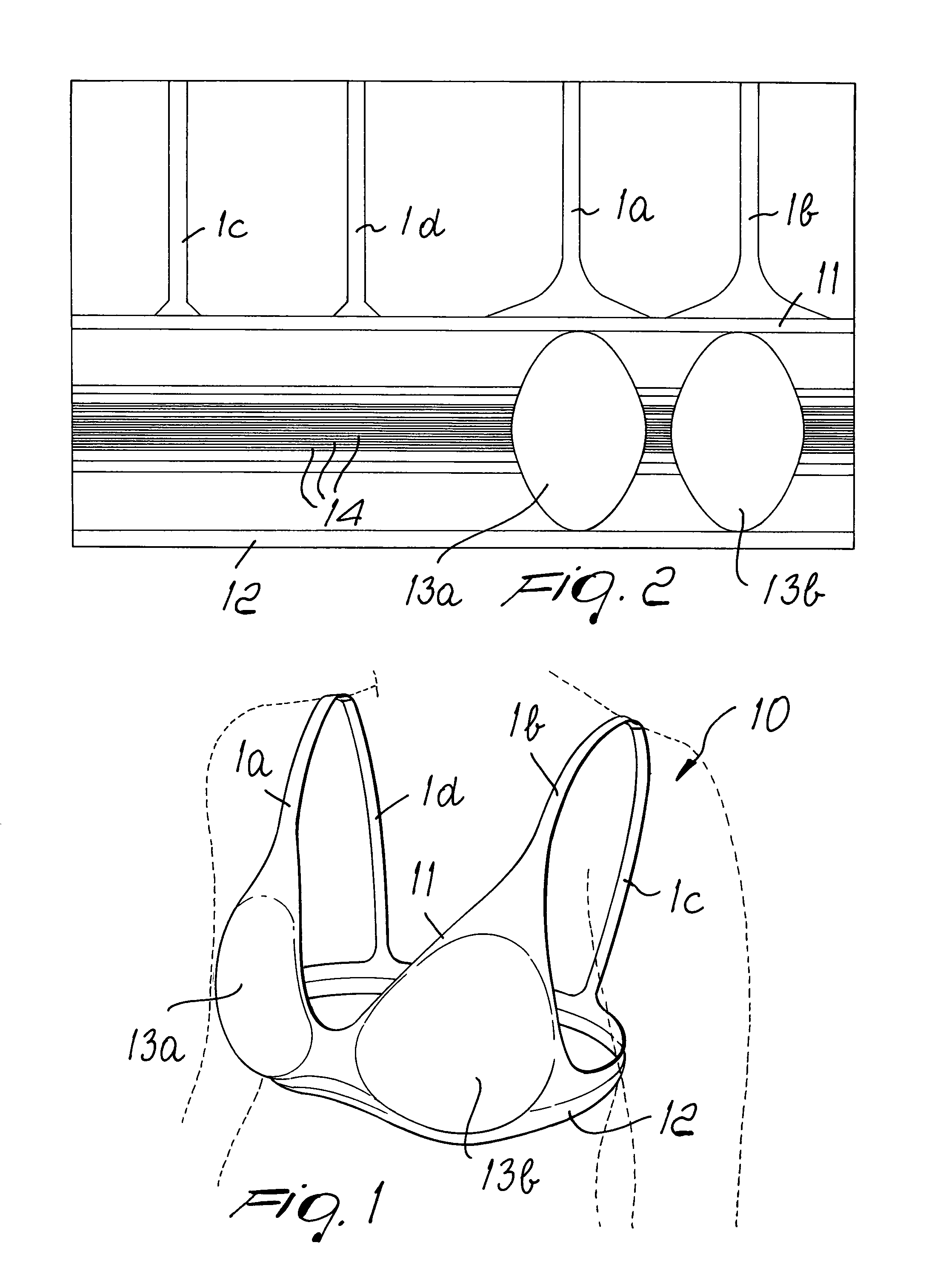

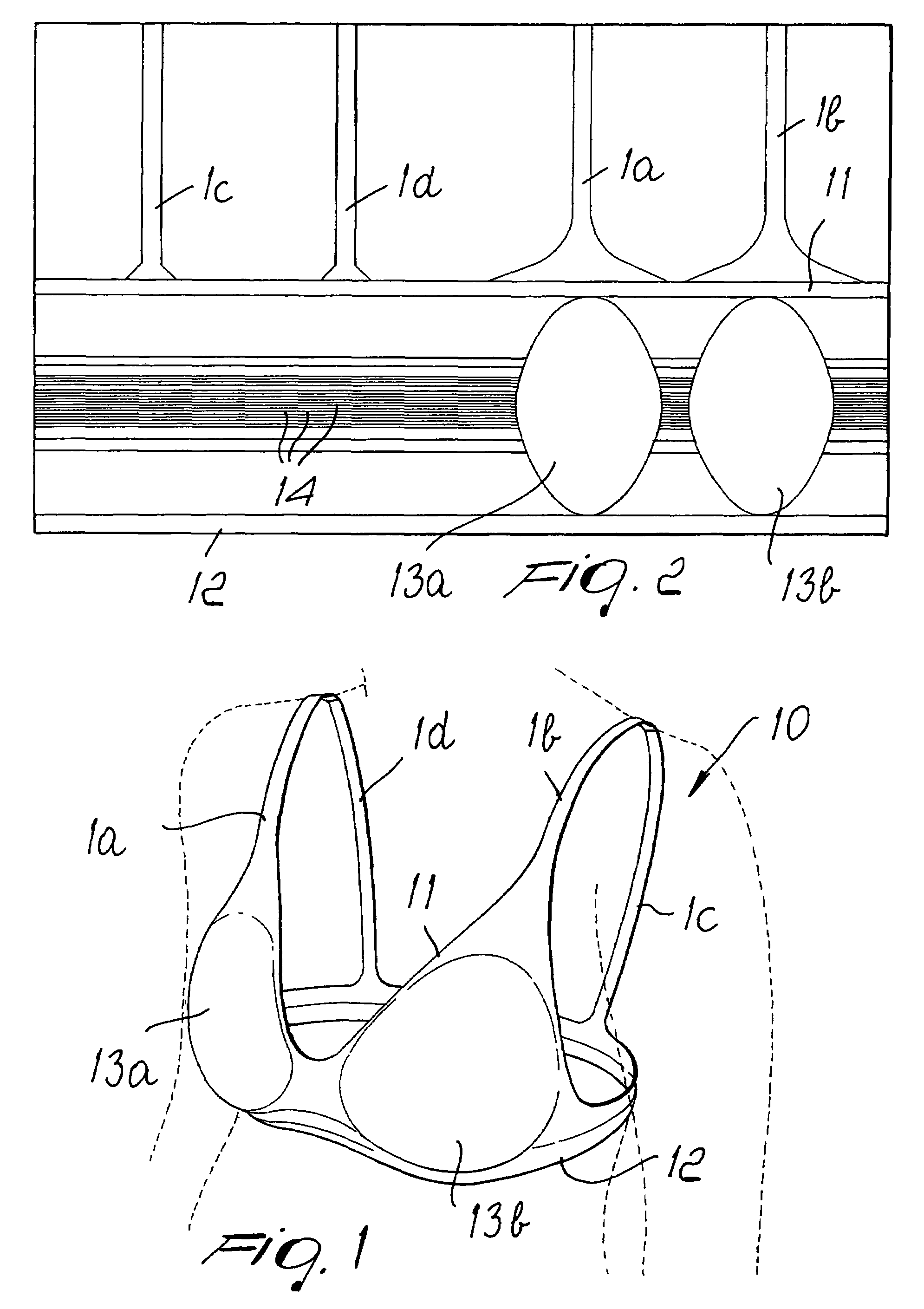

Method for manufacturing knitted articles with a circular knitting machine for forming items of clothing without lateral seams

InactiveUS7328595B2Improve the finishEliminate wasteCircular knitting machinesUndergarmentsEngineeringMechanical engineering

A method for manufacturing knitted articles for forming items of clothing, such as body suits, sleeveless tops, undershirts, bras, underpants or the like, without lateral seams, with a circular knitting machine, comprising at least one tab forming step, in which all or some of the needles that belong to at least one sector of the needle cylinder are moved to knit at at least one feed or drop of the machine, the needle cylinder of the machine being actuated with alternating rotary motion about its own axis, with an oscillation extent sufficient to produce transit, at the at least one feed, of all the needles of the at least one sector that are moved to knit at that feed, in order to make these needles form a preset number of rows of knitting.

Owner:SANTONI SPA

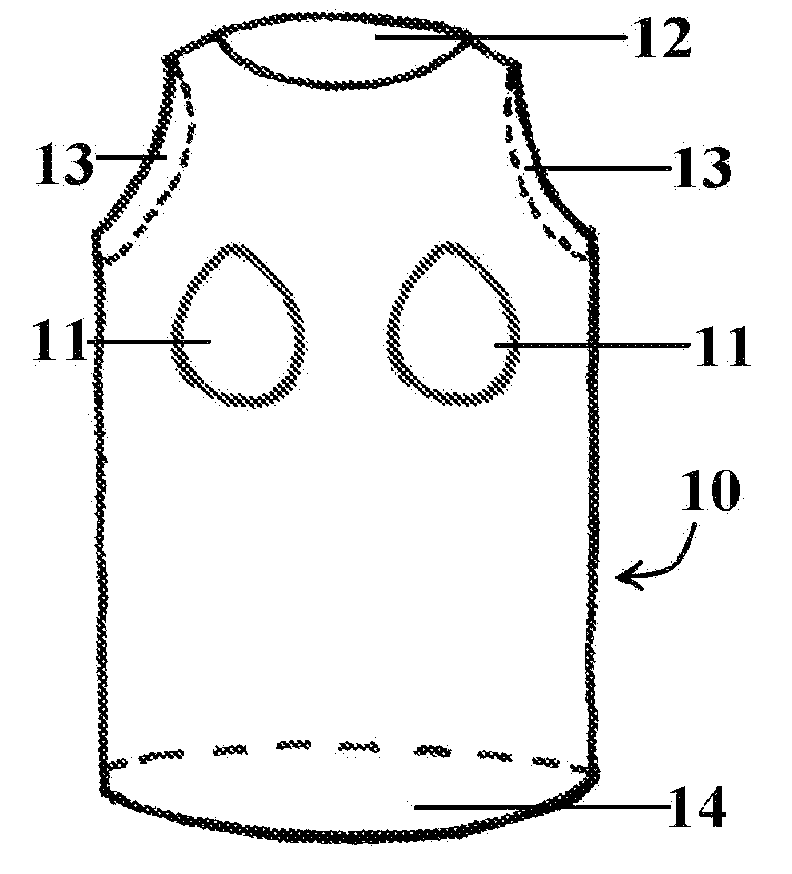

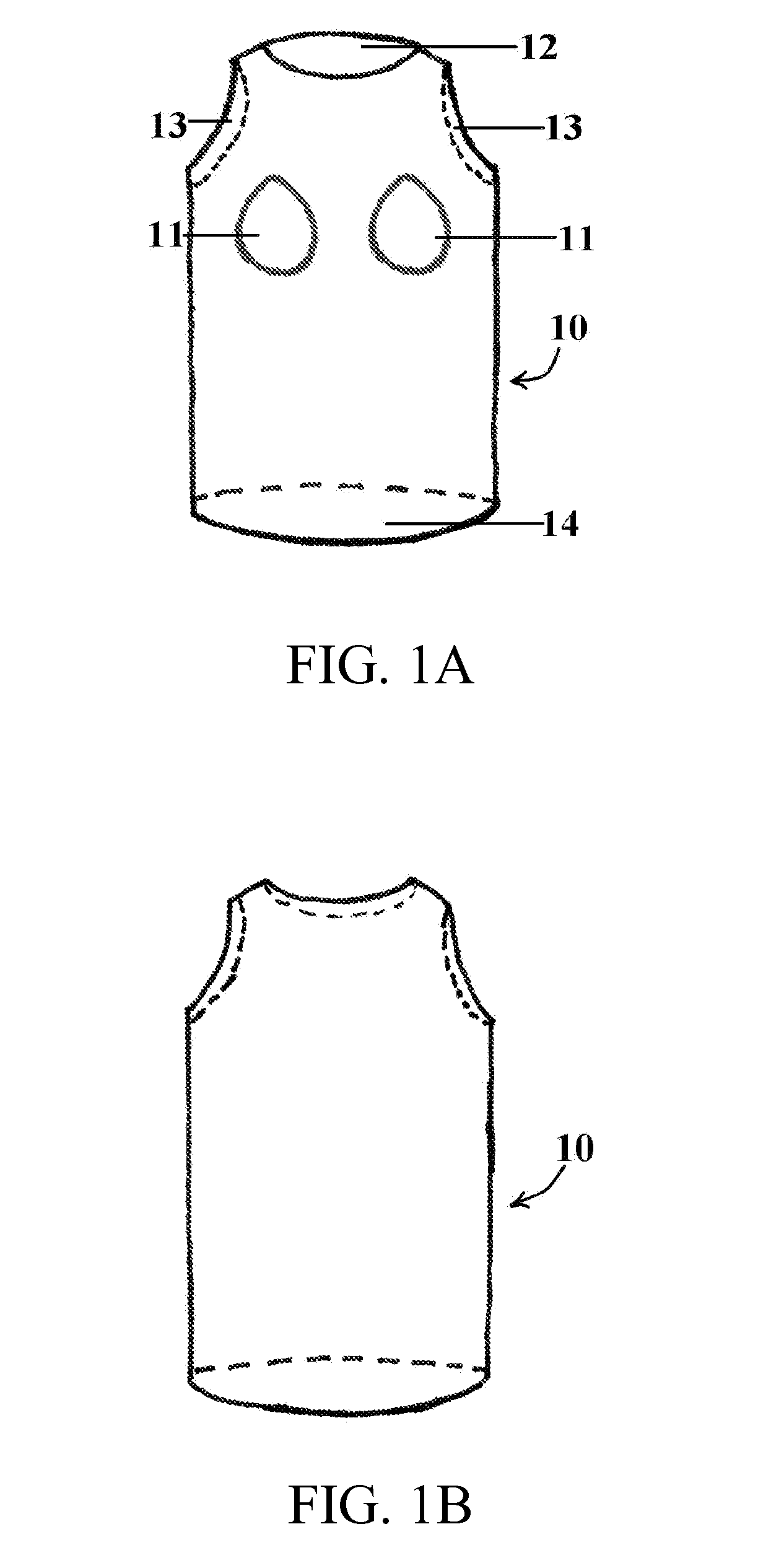

Nursing undershirt

This invention is intended as an undershirt for nursing mothers. The invention consists of a form-fitting undershirt, which can have short sleeves, be sleeveless (like a tank top) or be a camisole type undershirt. The shirt has holes, which expose the breast area. The holes allow for opening a nursing bra and revealing enough of the breasts for nursing a baby. The undershirt covers the woman's back, upper chest and torso beneath the breasts. This undershirt allows a nursing mother to wear the nursing bra of her choice along with any shirt or blouse that can be lifted up or unbuttoned to access the breasts. Thus, a woman can nurse her baby in public without revealing her breast and / or other body parts. Use of the nursing undershirt does not compromise the mother's personal style of dress.

Owner:LEHANE ANGELA NICOLE

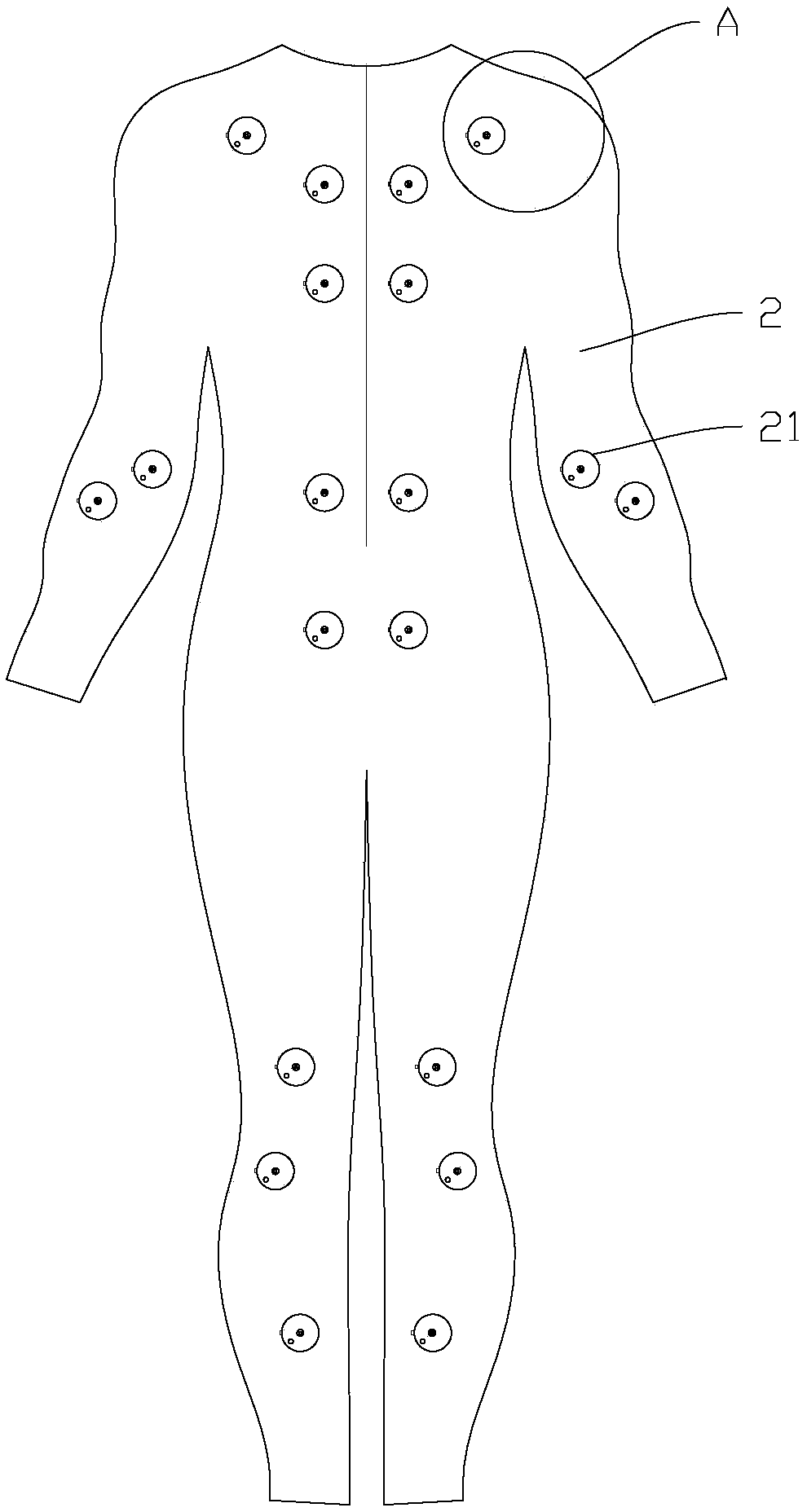

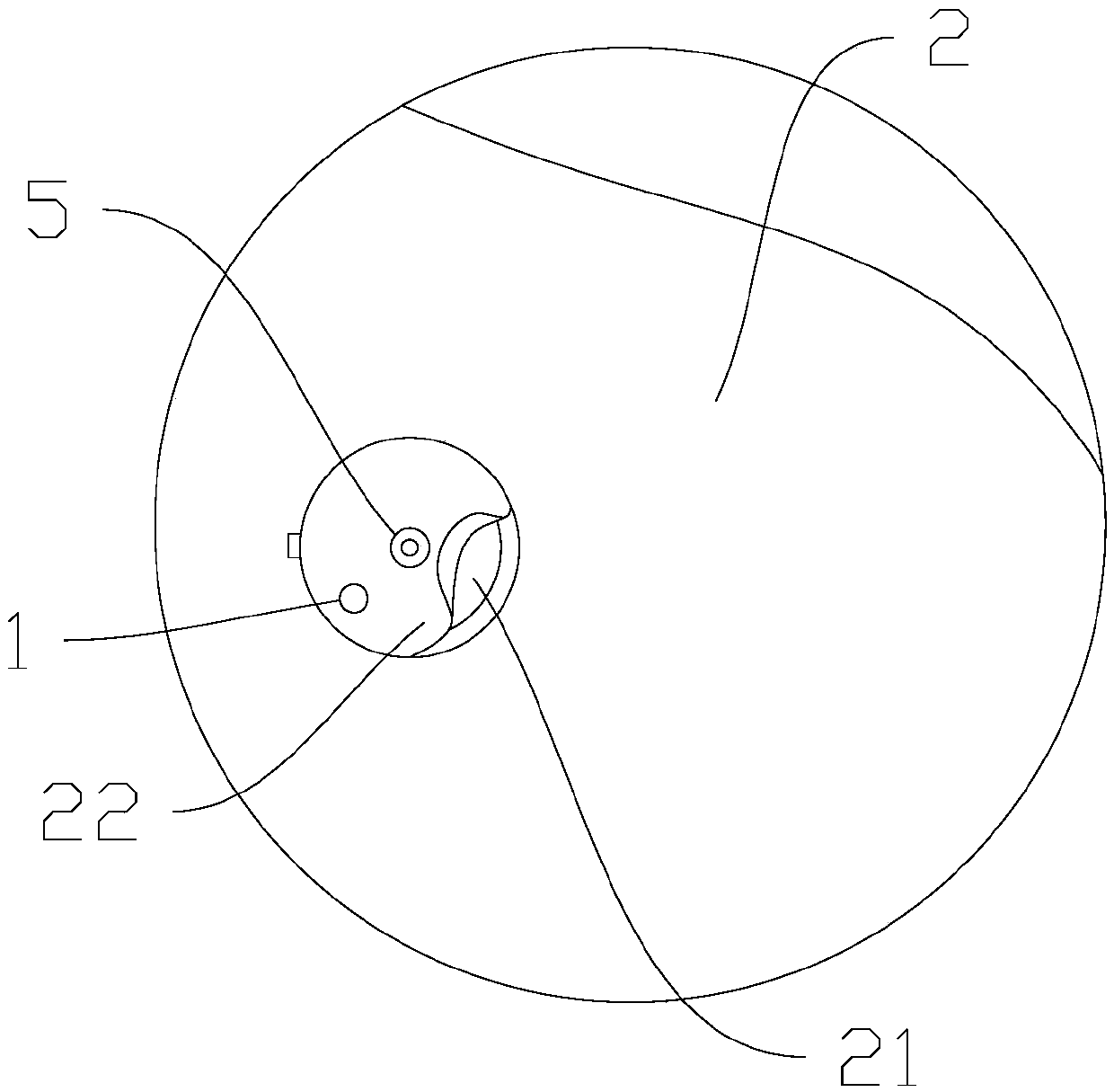

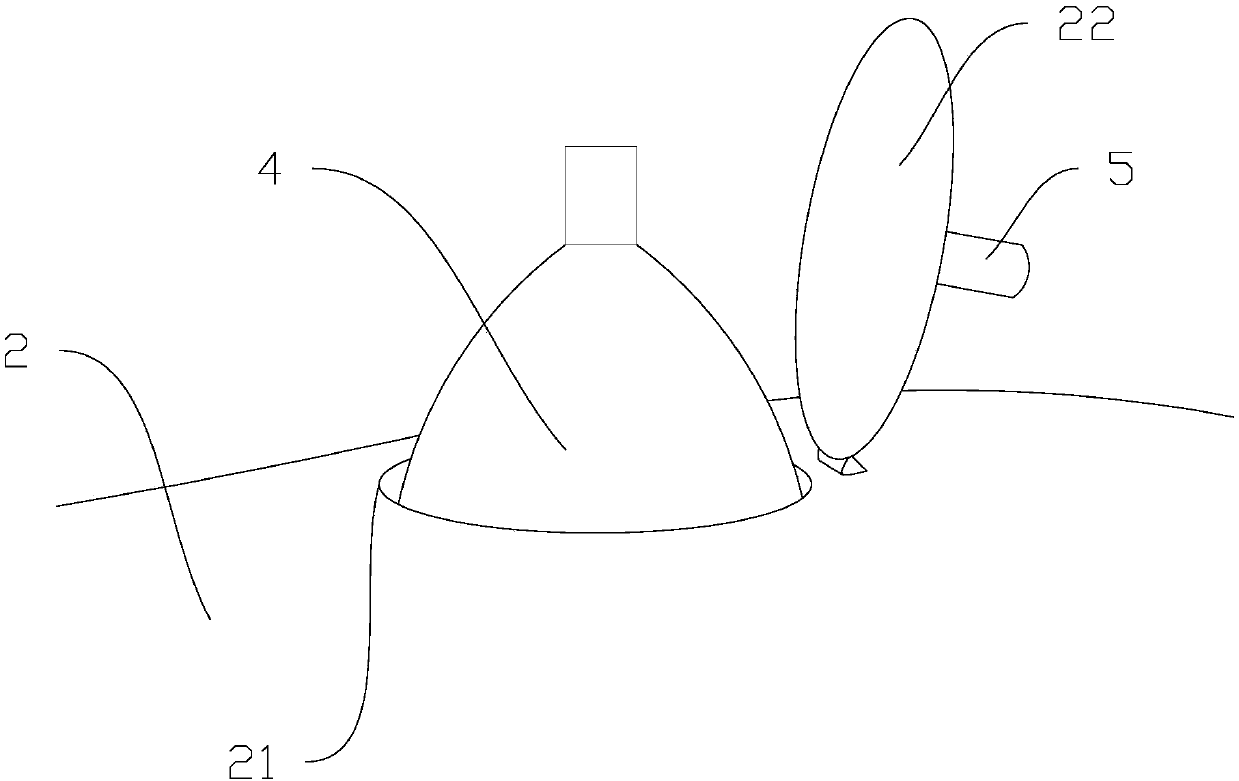

Comprehensive acupuncturing-and-cupping physical therapy device

The invention discloses a comprehensive acupuncturing-and-cupping physical therapy device. The comprehensive acupuncturing-and-cupping physical therapy device comprises an undershirt, multiple needletools and multiple cupping jars, circular holes are formed in the portions, corresponding to acupoints of the human body, of the outer surface of the undershirt, stopping sheets capable of covering the circular holes are pasted at the circular holes, the edges of one sides of the stopping sheets are connected with the edges of one sides of the circular holes, and acupoint names and acupoint position markers are marked on the outer surfaces of the stopping sheets; the needle tools comprise needle handles and needle bodies, cylinders are arranged at the acupoint position markers, the diameters of cylinder holes of the cylinders correspond to the outer diameters of the needle bodies, the needle bodies can penetrate through the cylinder holes, and the diameters of the needle handles are largerthan the hole diameters of the cylinder holes; the heights of the cylinders on all the stopping pieces are different according to the different puncturing depths of the needle tools at different acupoints. By means of the comprehensive acupuncturing-and-cupping physical therapy device, the technical problem that the existing acupuncturing technology seriously depends on personal experiences of acupuncturists is solved.

Owner:张璐

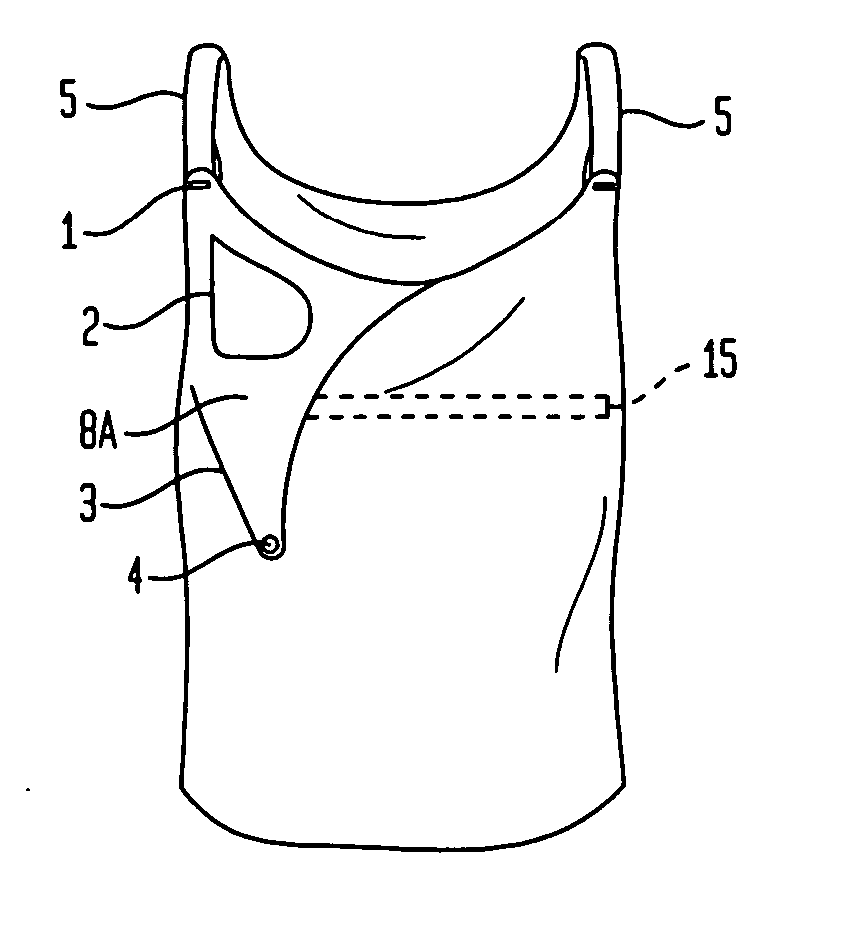

Stretchable nursing tank top with invisible breast support

A form fitting nursing tank top / undershirt made with a stretch fabric includes an invisible built in nursing bra. The invisible nursing bra is partly internal and partly external. The external portion of the built in nursing bra is the left and right shoulder straps, which from outside appearances form an integral part of the tank top / undershirt. The internal portion of the built in nursing bra is formed by a soft cup frame attached at the bottom to an elastic chest band and attached at the top to the front of the shoulder straps. In the back of the garment, the elastic chest band is attached to an internal back piece of fabric on the inside of the tank top. The internal back piece of fabric extends upward from the elastic chest band to the shoulder straps at the back, which shoulder straps each include an adjustable length section. Internal nursing flaps are attached at the bottom to the soft cup frame and at the top to the tank top body which forms external nursing flaps. The tank top / undershirt includes a continuous stretch body extending upward from the torso and forming the external nursing flaps which are attached to the internal nursing flaps and to the shoulder straps, to give a smooth single piece garment appearance.

Owner:ROTHMAN LINE

Method for manufacturing knitted articles for forming items of clothing, such as body suits, sleeveless tops, undershirts, bras, underpants or the like, without lateral seams, with a circular knitting machine

A method for manufacturing knitted articles for forming items of clothing, without lateral seams, with a circular knitting machine, comprising a step for forming at least one pouch-like region, in which part of the needles or all the needles that belong to at least one sector of the needle cylinder are moved to knit at at least one feed of the machine by way of an alternating rotary motion of the needle cylinder about its axis and with an oscillation extent sufficient to produce transit, at the feed, of all the needles of the sector that are moved to knit at the feed, in order to form, with the needles that belong to the sector and are moved to knit, a number of rows of knitting in excess with respect to the number of rows of knitting formed by the needles contiguous to the sector.

Owner:SANTONI SPA

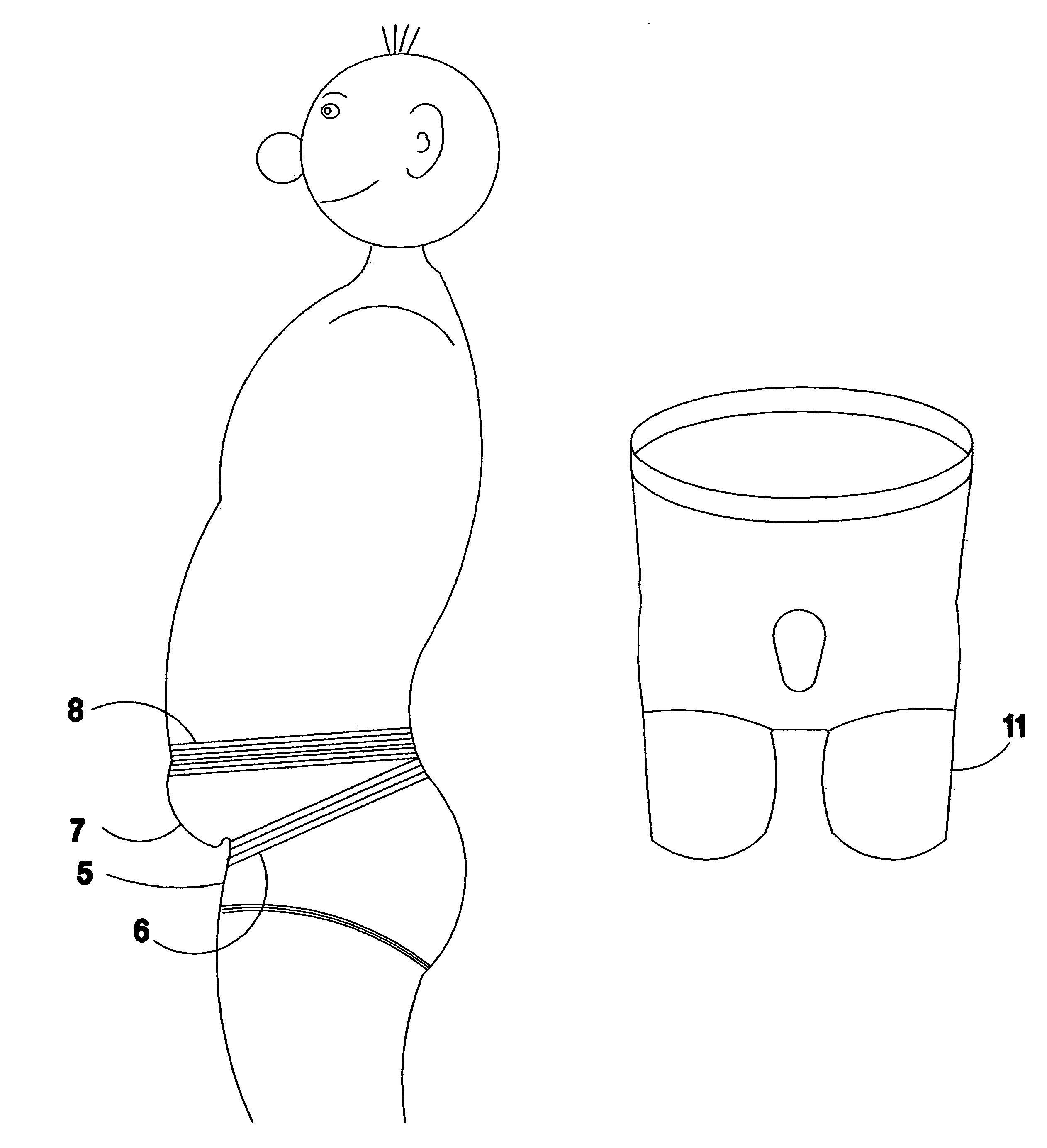

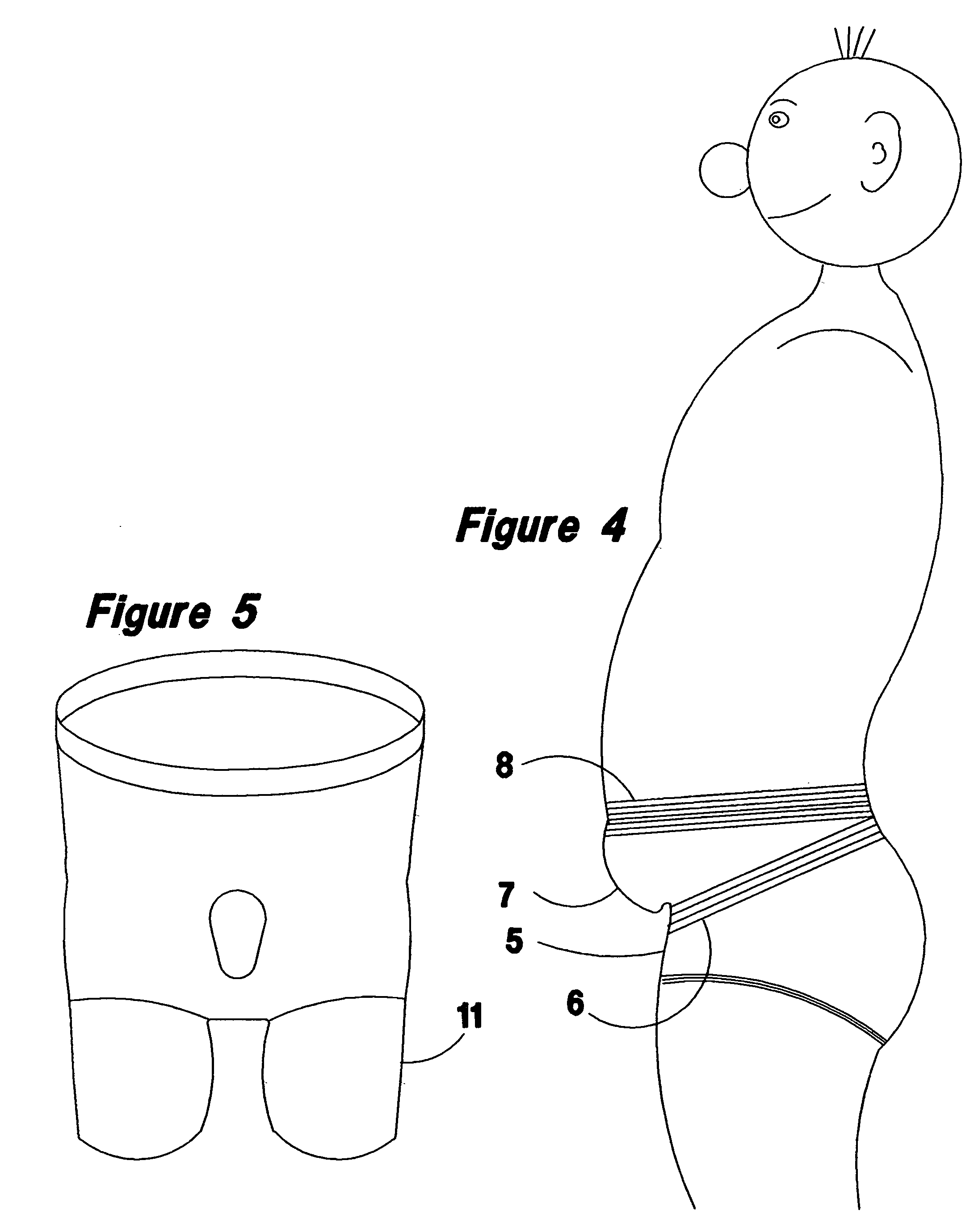

Undergarment for hernia relief and other purposes

InactiveUS8615815B2Solve bulkyPrevent creepNon-surgical orthopedic devicesUndergarmentsPenisAbdominal cavity

Owner:DAHLQUIST DARYL LERVY

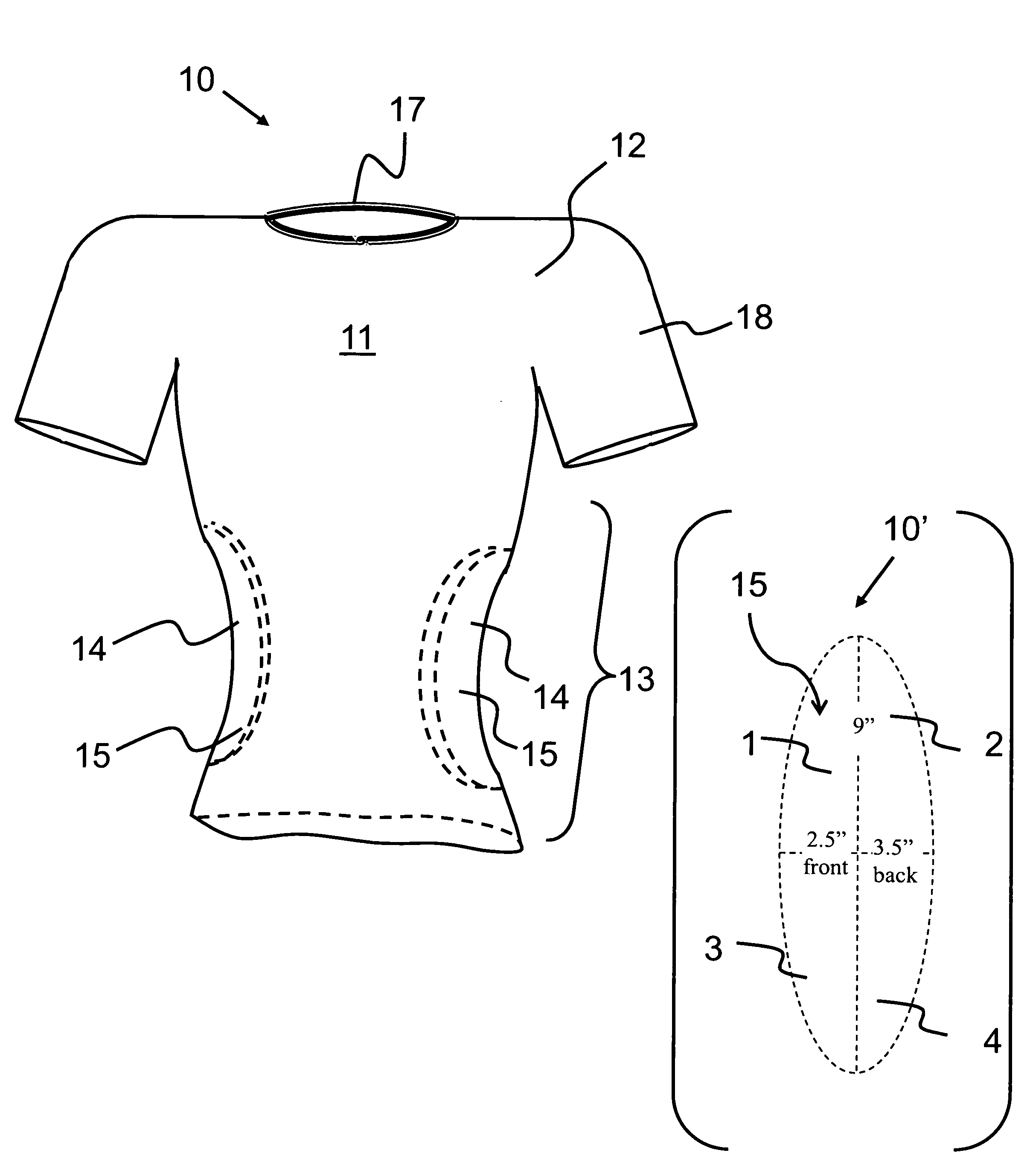

Shirt having form-fitting mid-section support

InactiveUS8087094B2Area minimizationEasy to cleanGarment special featuresProtective garmentEngineeringUndershirt

The shirt for supporting and shaping the mid-section of a wearer provides a shirt having a top-section and a mid-section. The mid-section of the shirt includes an upper and lower region each constructed having a plurality of fabric densities or integrated elasticity portions. These elasticity portions provide support for the abdominal region, back, and back-side regions of the wearer where “love handles” sometime develop. The top-section of the shirt has a substantially loose fitting construction to yield a simple, clean and comfortable fit that facilitates breath-ability and comfort to the wearer. The shirt may be worn as an undershirt or as outerwear to minimize the wearer's torso. In another embodiment, the shirt further comprises an outer portion that extends over and covers the mid-section so that the mid-section acts as an internal support structure when the shirt is worn as a T-shirt or outerwear.

Owner:KARASINA SVETLANA

Cotton, hemp and flax ring spinning fabric manufacturing method

The invention provides a cotton, hem and flax ring spinning fabric manufacturing method. The cotton, hemp and flax ring spinning fabric manufacturing method is characterized in that the fabric is interwoven through warp and weft yarns; the warp and weft yarns are formed by cotton fibers, hemp fibers and flax fibers; the fabric structure of the cotton, hemp and flax ring spinning fabric is formed by upper plain waves and lower plain waves; the blending ratio of the cotton fibers, the hemp fibers and the flax fibers in the warp yarns is 30 to 35 to 35; the warp yarn fineness is 25; the blending ratio of the cotton fibers, the hemp fibers and the flax fibers in the waft yarns is 30 to 35 to 35; the weft yarn fineness of the weft yarns is 25. The cotton, hemp and flax ring spinning fabric manufacturing method has the advantages of overcoming a disadvantage that the hemp fabric is coarse and stiff due to the fact that the cotton, the hemp and the flax are blended according a reasonable matching ratio, meanwhile keeping hemp fabric characters of moisture absorption, ventilation, antibiosis and the like, enabling obtained fabric to be soft, smooth, air permeable, antistatic and applied to undershirts, sportswear, coats and the like and enabling abundant color to be obtained through dyeing.

Owner:DAFENG TENGLONG XIANGSHUN TEXTILE CO LTD

Multifunctional textile fabric finishing agent and preparation and after-finishing methods thereof

InactiveCN102605624AImprove microcirculationImprove insulation effectFibre treatmentFiberPolymer science

The invention discloses a multifunctional textile fabric finishing agent and preparation and after-finishing methods thereof. The finishing agent comprises nano-fibers, dispersing agents, adhesives, coupling agents and water. The preparation method includes: weighing the polyaniline nano-fibers, the adhesives, the dispersing agents, the coupling agents and the water; heating the water, adding the polyaniline nano-fibers and the dispersing agents into the water and oscillating, dispersing and stirring the polyaniline nano-fibers by the aid of an ultrasonic oscillator until completely and uniformly dispersing the polyaniline nano-fibers; adding the adhesives and the coupling agents into slurry and continuing stirring; and realizing ball milling for the slurry by the aid of a ball mill to form the finishing agent. The after-finishing method includes: selecting a textile fabric and placing the textile fabric into multifunctional finishing agent solution; and soaking, drying and curing the textile fabric at normal temperature to form a microcirculation healthcare, warm and static-free finished product with anions after curing. The textile fabric has the performances of moisture absorption, sweat removal, air permeability, energy storage, heat storage and anion release, and is widely used for manufacturing undershirts, thermal wear, socks, bedding, military tents, knee pads, elbow pads, wrist supports, medical supplies and the like.

Owner:西安华捷科技发展有限责任公司

Cotton, viscose and shengma ring spinning fabric manufacturing method

The invention provides a cotton, viscose and shengma ring spinning fabric manufacturing method. The cotton, viscose and shengma ring spinning fabric manufacturing method is characterized in that the fabric is interwoven through warp and weft yarns; the warp and weft yarns are formed by cotton fibers, viscose fibers and shengma fibers; the fabric structure of the cotton, viscose and shengma ring spinning textile fabric is formed by upper plain waves and lower plain waves; the blending ratio of the cotton fibers, the viscose fibers and the shengma fibers in the warp yarns is 25 to 35 to 40; the warp yarn fineness is 30; the blending ratio of the cotton fibers, the viscose fibers and the shengma fibers in the waft yarns is 25 to 35 to 40; the weft yarn fineness of the weft yarns is 25. The cotton, viscose and shengma ring spinning fabric manufacturing method has the advantages of overcoming a disadvantage that the hemp fabric is coarse and stiff due to the fact that the cotton, the hemp and the flax are blended according a reasonable matching ratio, meanwhile keeping hemp fabric characters of moisture absorption, ventilation, antibiosis and the like, enabling obtained fabric to be soft, smooth, air permeable, antistatic and applied to undershirts, sportswear, coats and the like and enabling abundant color to be obtained through dyeing.

Owner:DAFENG TENGLONG XIANGSHUN TEXTILE CO LTD

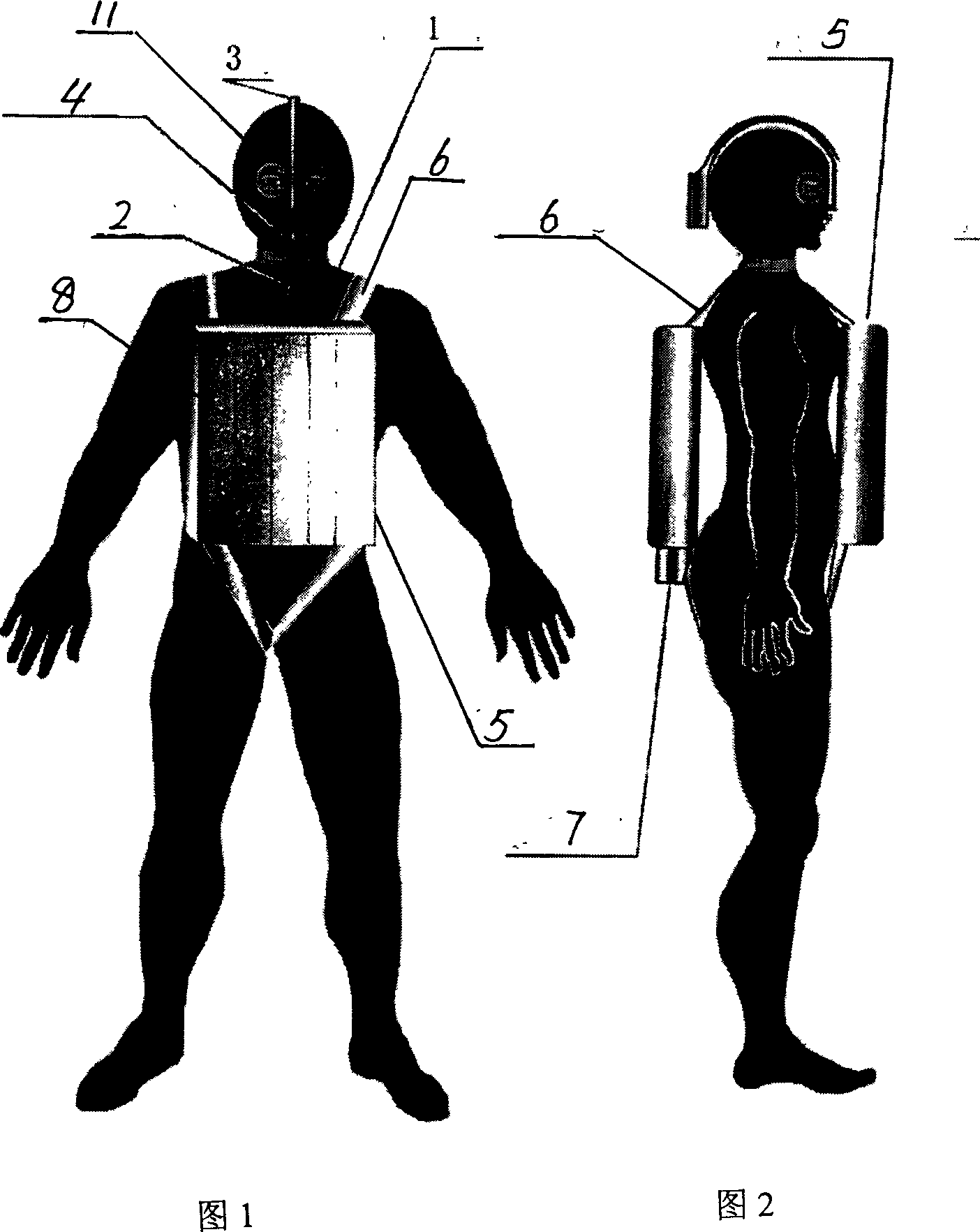

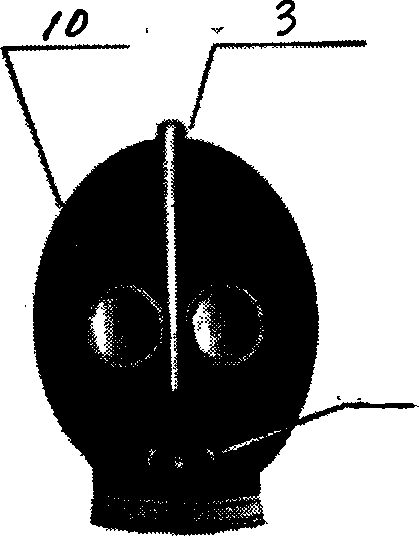

Multifunctional waterborne lifesaving protection equipment

This is a multi-functional water lifesaving protective equipment belonging to the technological field of water lifesaving articles. It consists of waterproof breathing device and floating clothing, among which the floating clothing for man to wear and breathing device is put on people's head. The water- repellent and breathing device includes waterproof cover, breathing waterproof implement and breathing straw. The intracavity of the waterproof cover is connected with the breathing straw, which is linked with the breathing waterproof implement. The floating clothing is one-piece undershirt, including waterproof cold-proof clothes and the one-piece undershirt. The water cold-proof clothes is of elastic one-piece style, with the one-piece undershirt tightly fixed outside. This invention can prevent from being choked, drowned, frozen, and can keep the drowned warm and alive to win the valuable time for the succour's arrival. This Invention is especially suitable for salvage by perils of the sea, and for the divers who works underwater in short of oxygen equipments.

Owner:宫生铭

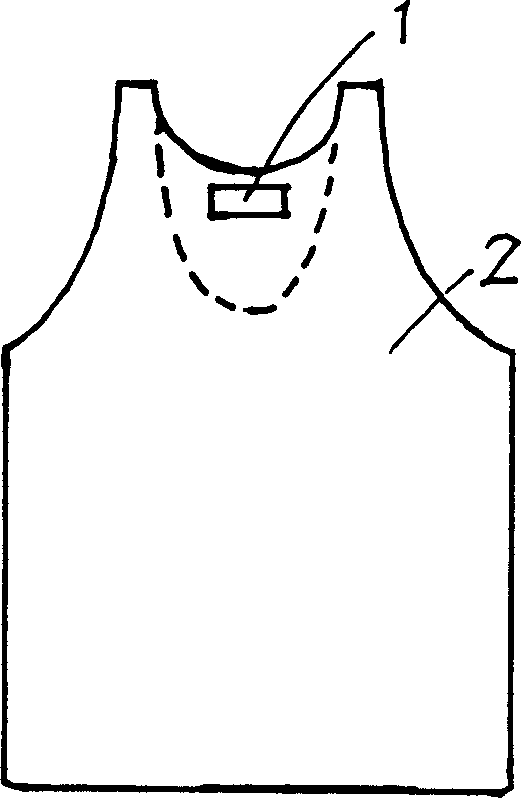

Garment with trade mark

The invention discloses a garment having brand mark, at the present time, the skin tight garments arrange the brand mark inside the nearside of the garment, e.g. underclothes, whose projection makes it uncomfortable to wear, the present invention provides a garment that fixes the brand mark on the outboard of the garment, so it is not only comfortable to be wore on, but enables others to recognize the trade mark of the underclothes.

Owner:林炜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com