Pearl fibre antisepsis spandex jersey and manufacturing technique thereof

A pearl fiber and antibacterial technology, applied in the field of jersey with antibacterial effect and its manufacturing process, can solve the problems of large reflectivity, and achieve the effect of comfortable wearing and outstanding health care performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

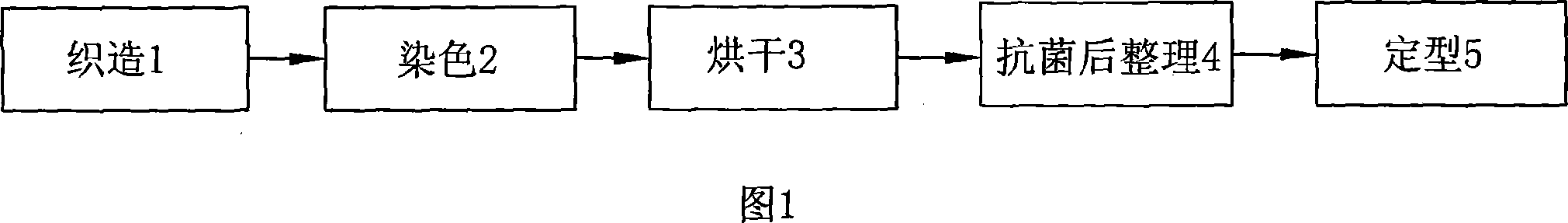

[0020] The present invention will be described in detail below in conjunction with accompanying drawing and embodiment: pearl fiber antibacterial spandex single jersey of the present invention, it selects pearl viscose yarn and spandex yarn to be woven into single jersey with large circular machine at least, And with chitin antibacterial agent on the jersey.

[0021] The single jersey cloth of the present invention selects 40 for use s ~32 s The yarn and 20D~40D spandex yarn are woven on a single-sided circular knitting machine.

[0022] The weight range of the jersey is: 180G / M 2 ~260G / M 2 .

[0023] The jersey material of the present invention mainly uses viscose fiber, and before the wet spinning process, a nano-scale pearl powder liquid slurry with a certain mass ratio concentration is added, and the pearl powder addition can be higher than 4%. Adding 5% to the fiber can significantly increase the content of pearl powder in the fiber, so that the garment can improve t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com