Patents

Literature

31results about How to "Keep antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of kapok fiber spunlaced nonwoven fabric

InactiveCN103205862AKeep natural propertiesMaintain propertiesNon-woven fabricsVegetal fibresKapok fiberPulp and paper industry

The invention belongs to the technical field of weaving, in particular to a production method of kapok fiber spunlaced nonwoven fabric. The method includes: pretreating kapok fiber to improve spinnability; using a weighing curtain feeder to feed kapok fiber into a blowing-carding device for opening, blending and purification; using an induced fan to collect web in a blowing-carding machine to feed into a tiny dust removing device for further dust removing and opening; connecting the tiny dust removing device with a spunlaced line carding machine, carding the fiber into web on the spunlaced line carding machine, cross lapping, spunlacing to form fabric, coiling, degreasing and bleaching, drying and slitting to obtain the finished product. The method is safe, environment-friendly, energy-saving, efficient, high in automation level, and advanced in spunlaced kapok nonwoven fabric weaving, and various characteristics of fiber raw materials are protected effectively.

Owner:蒋海彦

Blended yarn of jute fiber, cotton fiber and viscose fiber and application of blended yarn

InactiveCN102493059AHygroscopicMoisture retentionBiochemical fibre treatmentBleaching apparatusYarnMoisture absorption

The invention discloses a blended yarn of a jute fiber, a cotton fiber and a viscose fiber. The blended yarn is made by blending the following raw materials in percentage by weight: 30 to 50 percent of jute fiber, 22 to 30 percent of cotton fiber and 20 to 48 percent of viscose fiber. By blending the jute fiber, the cotton fiber and the viscose fiber in a reasonable proportion, the blended yarn overcomes the defects that the jute fabric is rough and hard and easy to drape, and has the characteristics of moisture absorption, air permeability and antibacterium and the like of the jute fiber; besides, the blended yarn has the advantages of softness, smoothness, breathability, antistatic performance, and the like, and rich color can be obtained by dyeing. Blended fabric made of the yarn is applied to undershirts, sportswear, coats and the like.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Sirospun yarn and spinning method thereof

The invention discloses a sirospun yarn and a spinning method thereof. The yarn consists of 25-35 wt% of coffee carbon fiber, 25-35 wt% of bamboo-carbon fiber and 30-40 wt% of cotton fiber, wherein the fibers are spun into the yarn through a siro spinning process. The spinning method sequentially comprises a loose fiber dyeing process, a cotton carding process, a drawing process, a roving process, a fine yarn siro spinning process and a spooling process. The yarn is formed by blending various fibers, the characteristics of each fiber are highlighted by reasonably setting the weight proportion of each fiber, the advantages of various fibers are integrated, the basic performance of the yarn is kept, the propagation of bacteria is restrained, the release of odor ammonia is reduced, and peculiar smell of alcohol, tobacco and the like can also be effectively removed. Compared with the conventional spinning process, the sirospun yarn disclosed by the invention has less hairness than the ordinary ring spun yarn, particularly the long hairness longer than 3mm is well improved, the method has greater advantages in size dyeing, weaving, singeing and other processes, and the woven fabric has a good wear-resisting property, a good anti-pilling performance and better surface handfeel and softness.

Owner:JIANGNAN UNIV +1

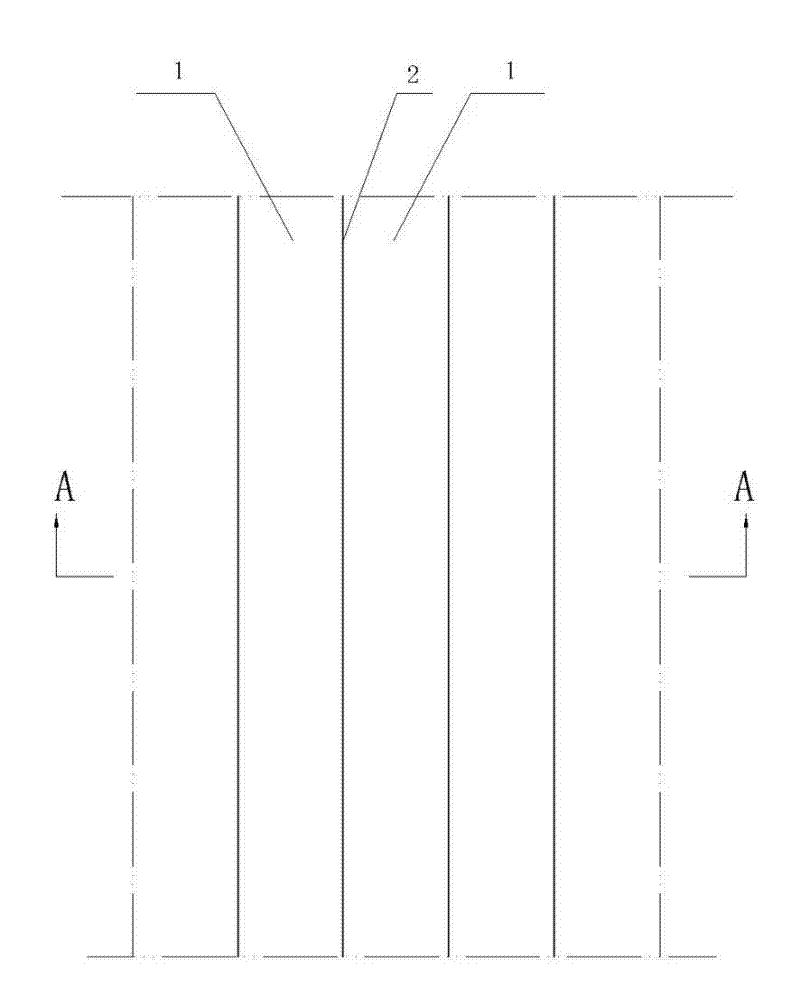

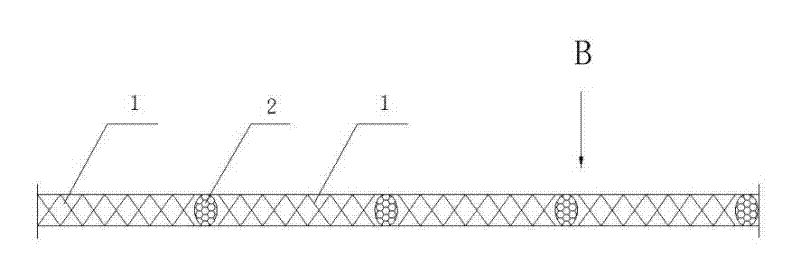

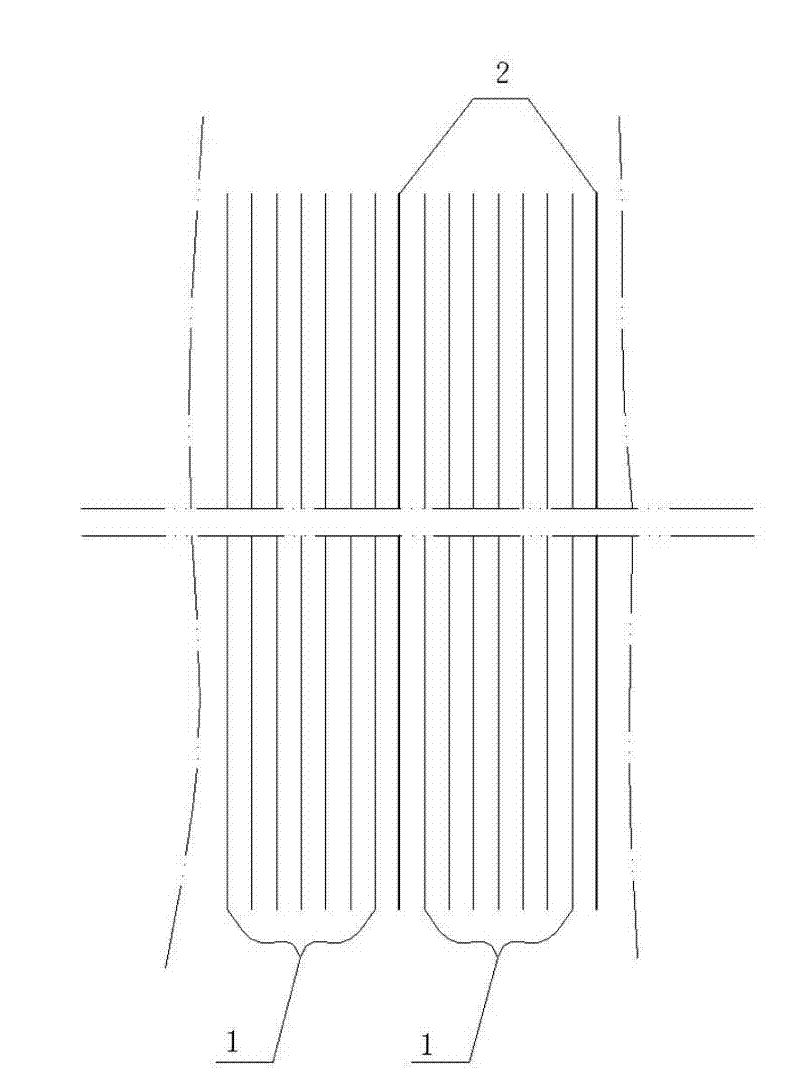

Knitting fabric containing silver fibers and manufacturing process of knitting fabric

InactiveCN102505303ABroad prospects for promotion and applicationBeautiful appearanceWeft knittingWarp knittingPolyesterYarn

Disclosed is a knitting fabric containing silver fibers and manufacturing process of the knitting fabric. The knitting fabric containing silver fibers is knitted by total cotton yarns, spandex and the silver fibers by a circular knitting machine, and the total cotton yarns take 80.8% to 92.5%, the spandex takes 3% to 6%, and the silver fibers take 2% to 15%; or, the knitting fabric is knitted by cotton, modal, spandex and the silver fibers, the cotton takes 51.8% and 65.5%, the modal takes 24% to 28%, the spandex takes 3% to 6%, and the silver fibers take 2% to 15%; or, the knitting fabric is knitted by cotton, polyester fibers, spandex and the silver fibers, the cotton takes 54.8% to 66.5%, the polyester fibers take 22% to 26%, the spandex takes 3% to 6%, and the silver fibers take 2% to 15%; and the single-stranded cotton wrapped with the spandex or the modal is blended with cotton warps, single-stranded yarns wrapped with the spandex or the polyester fibers are blended with cotton warps, the single-stranded yarns wrapped with the spandex and the silver fibers are arrayed at intervals, patterns of the total fabric are stripe-shaped, and the distance between each two adjacent silver fibers ranges from 2mm to 10mm. The knitting fabric is anti-static, antibacterial, deodorized and ultraviolet-resistant.

Owner:SHANGHAI AIFA INVESTMENT MANAGEMENT

Sun-proof and antibacterial textile fabric

InactiveCN107881625ALong lasting effectGood antibacterial and UV resistanceWoven fabricsYarnWeather resistanceWeft yarn

The invention discloses a sun-proof and antibacterial textile fabric which is formed by vertically interweaving warp yarns and weft yarns. The warp yarns are made from, by mass, 42-45 parts of polyester and acrylic composite fiber, 3-7 parts of alpha-methyl styrene, 0.8-1.6 parts of cross-linking agent and 1-3 parts of chitosan. The weft yarns are made from, by mass, 60-70 parts of polylactic acidfiber, 16-18 parts of plant fiber, 2-4.8 parts of titanium dioxide, 1-3 parts of vermiculite power and 10-30 parts of polyvinyl alcohol. The sun-proof and antibacterial textile fabric is prepared through a reasonable formula, crosslink bonding of the raw materials is modified, the effect durability is strong, the made wrap and weft yarns have good antibacterial and anti-ultraviolet properties, the weather resistance is good, the breathability, oxygen permeability and hygroscopicity of the textile fabric are good, biodegradable fiber is adopted and matched with the plant fiber, and the sun-proof and antibacterial textile fabric is green, environmentally friendly, calms the mind, reposes a user and is high in comfort level and especially suitable for wearing when it is burning hot and sunlight is strong in summer.

Owner:HEFEI NORMAL UNIV

Antibacterial denim fabric

InactiveCN103361820AImprove antibacterial propertiesHygroscopicWoven fabricsYarnAgricultural engineering

The invention discloses an antibacterial denim fabric. The antibacterial denim fabric is made of, by weight ratio of 100%, 40-60% of spandex stretch yarn, 10%-30% of jute and the balance hemp. The jute adopted in the antibacterial denim fabric has the advantages of moisture absorption, breathability, antibacterial property and anti-mite property; the made fabric is prone to wrinkling as the jute has a harsh handfeel; the jute and the spandex stretch yarn are blended, so that defects of roughness, hardness and proneness to wrinkling of jute fabric are overcome, and the advantages of moisture absorption, breathability, antibacterial property and anti-mite property are kept; hemp fibers contain cannabinol substances, thereby having excellent antibacterial and bacteriostatic effects and an excellent anti-ultraviolet function; therefore, the prepared denim fabric has an excellent antibacterial performance.

Owner:TAICANG QIDE GARMENT

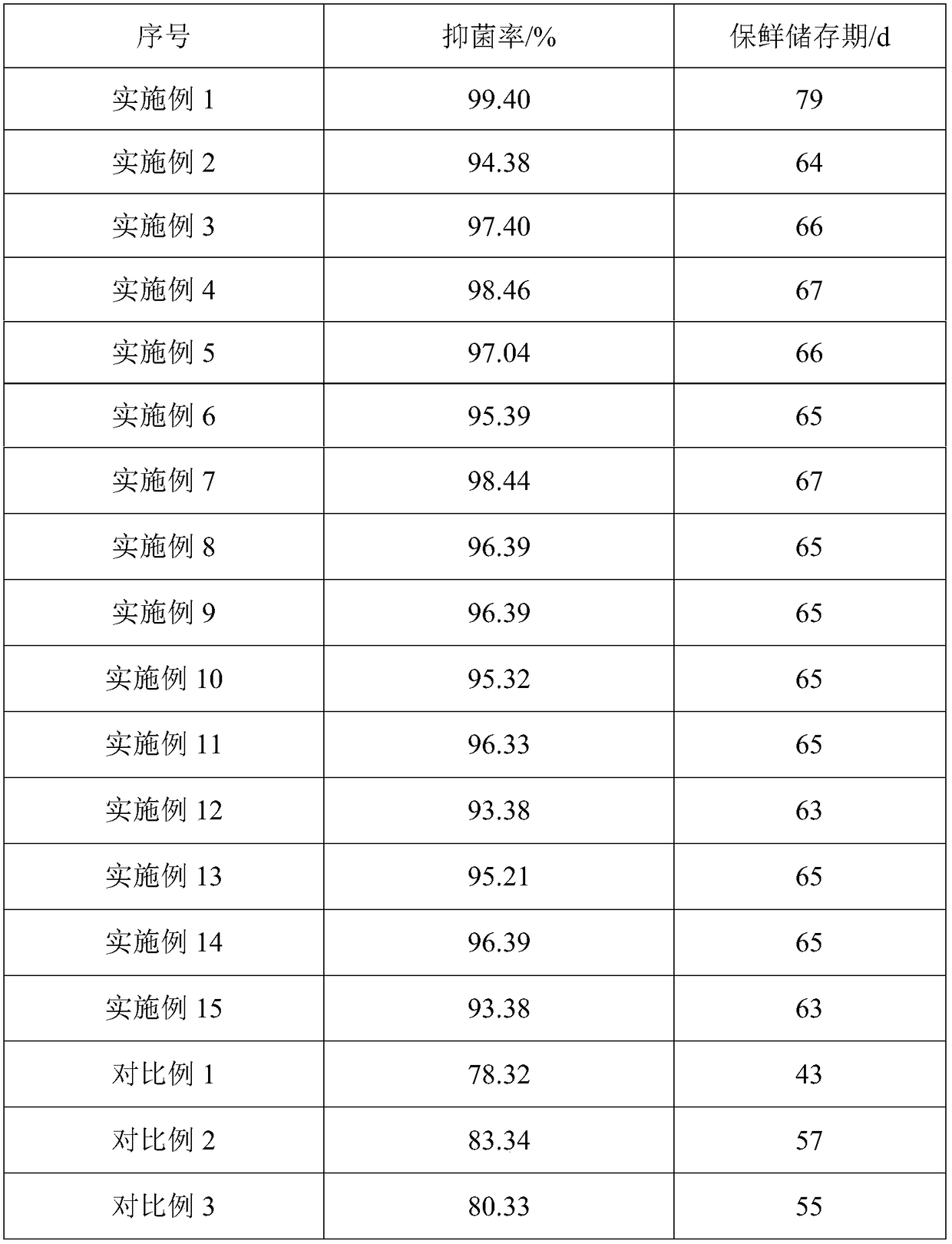

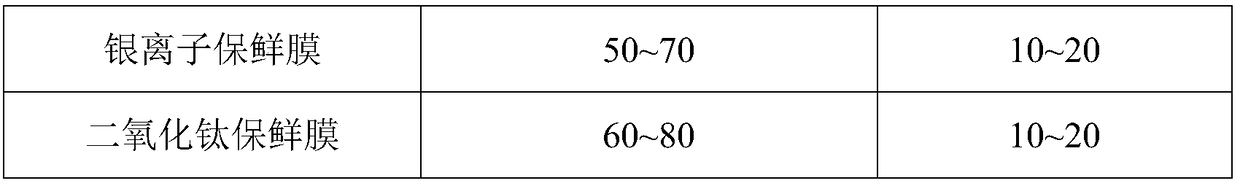

Graphene oxide antibacterial fresh-keeping film

InactiveCN108864465AImprove antibacterial propertiesLong durationAntifouling/underwater paintsPaints with biocidesAntibacterial agentTackifier

The invention provides a graphene oxide antibacterial fresh-keeping film. The graphene oxide fresh-keeping film comprises polyethylene, a tackifier, an antibacterial agent and an antifog agent, wherein the antibacterial agent is a mixture of herba corydalis bungeanae extract, dandelion herb extract and graphene oxide, wherein the mass of the antibacterial agent is 0.2 to 0.8 percent of polyethylene. The mixed antibacterial agent consisting of the graphene material and the plant extract can well ensure the overall bacterial resistance, the fresh-keeping film is stable in antibacterial effect, the lasting time is long, the storage quality and the storage time of fruits and plantings can be apparently improved, the preparation method is simple in operation, the energy consumption is low, andthe graphene oxide antibacterial fresh-keeping film is suitable for the industrial production.

Owner:郴州国盛新材科技有限公司

Cotton, viscose and linen rotor spinning fabric manufacturing method

InactiveCN103849980AImprove rough shortcomingsKeep moistureWoven fabricsYarnAgricultural engineeringViscose fiber

The invention provides a cotton, viscose and linen rotor spinning fabric manufacturing method. The method is characterized in that the fabric is interwoven by warps and wefts, the warps and the wefts are composed of cotton fibers, viscose fibers and linen, the fabric is of a one-up one-down plain weaving structure, the blending ratio of cotton fibers, viscose fibers and linen in the warps is 35 / 45 / 20 and warp fineness is 30, the blending ratio of cotton fibers, viscose fibers and linen in the wefts is 35 / 45 / 20 and weft fineness is 35. The method has the advantages that cotton, viscose and linen are blended according to a reasonable proportion, roughness and hardness of linen can be improved while moisture absorbing, breathability and antimicrobial performance of linen are kept, the manufactured fabric is soft, smooth, breathable, antistatic and the like, and the manufactured fabric is applicable underwear, sportswear, coats and the like and capable of obtaining rich colors by dyeing.

Owner:DAFENG XINJING TEXTILE

Cotton, hemp and flax ring spinning fabric manufacturing method

The invention provides a cotton, hem and flax ring spinning fabric manufacturing method. The cotton, hemp and flax ring spinning fabric manufacturing method is characterized in that the fabric is interwoven through warp and weft yarns; the warp and weft yarns are formed by cotton fibers, hemp fibers and flax fibers; the fabric structure of the cotton, hemp and flax ring spinning fabric is formed by upper plain waves and lower plain waves; the blending ratio of the cotton fibers, the hemp fibers and the flax fibers in the warp yarns is 30 to 35 to 35; the warp yarn fineness is 25; the blending ratio of the cotton fibers, the hemp fibers and the flax fibers in the waft yarns is 30 to 35 to 35; the weft yarn fineness of the weft yarns is 25. The cotton, hemp and flax ring spinning fabric manufacturing method has the advantages of overcoming a disadvantage that the hemp fabric is coarse and stiff due to the fact that the cotton, the hemp and the flax are blended according a reasonable matching ratio, meanwhile keeping hemp fabric characters of moisture absorption, ventilation, antibiosis and the like, enabling obtained fabric to be soft, smooth, air permeable, antistatic and applied to undershirts, sportswear, coats and the like and enabling abundant color to be obtained through dyeing.

Owner:DAFENG TENGLONG XIANGSHUN TEXTILE CO LTD

Medical composite dressing and preparation method thereof

InactiveCN105664226AEffective in promoting wound healingEasy to operateAbsorbent padsBandagesDressing changeCotton cloth

The invention discloses a medical composite dressing and a preparation method thereof. The medical composite dressing is made of fabrics such as non-woven fabrics or cotton fabrics as carrier materials, soaked in a mixture composed of carboxymethyl chitosan solution, sesame oil, and beeswax, taken out, packaged in inner packaging bags, and finally irradiated and sterilized. have to. The medical composite dressing has the following advantages: (1) Contains carboxymethyl chitosan, sesame oil and beeswax and other healing-promoting ingredients, which have a significant effect on promoting wound healing; (2) The carrier material endows the film dressing with a certain degree of flexibility and strength. , easy to peel and paste, easy to operate, no adhesion to the wound surface, no secondary damage; (3) It has the functions of keeping moist, antibacterial, and reducing scar formation. The medical composite dressing is a moist composite dressing that can significantly promote wound healing, and is suitable for the treatment of surgical wounds, abrasions, burns, skin donor sites, decubitus ulcers, diabetic ulcers and other difficult-to-heal wounds.

Owner:上海白衣缘生物工程有限公司

Blended yarn of jute fiber, hemp fiber and silk fiber and application of blended yarn

InactiveCN102493060AAntibacterialKeep antibacterialBiochemical fibre treatmentDry-cleaning apparatus for textilesYarnUltraviolet radiation

The invention discloses a blended yarn of a jute fiber, a hemp fiber and a silk fiber. The blended yarn is made by blending the following raw materials in percentage by weight: 30 to 55 percent of jute fiber, 20 to 30 percent of hemp fiber and 25 to 40 percent of silk fiber. By blending the jute yarn, the jute fiber, the hemp fiber and the silk fiber in a reasonable proportion, the blended yarn overcomes the defects that the jute fabric is rough and hard and easy to drape, and has the advantages of moisture absorption, air permeability, antibacterium and the like of the jute fabric. Blended fabric made of the blended yarn is elegant, bright and exquisite in dyeing effect, is smooth and warm, has soft handfeel, and has the functions of dispersing sound wave, broadcast, ultraviolet and the like. Besides, the blended yarn is suitable for making warm clothes, ultraviolet radiation prevention clothes and the like.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

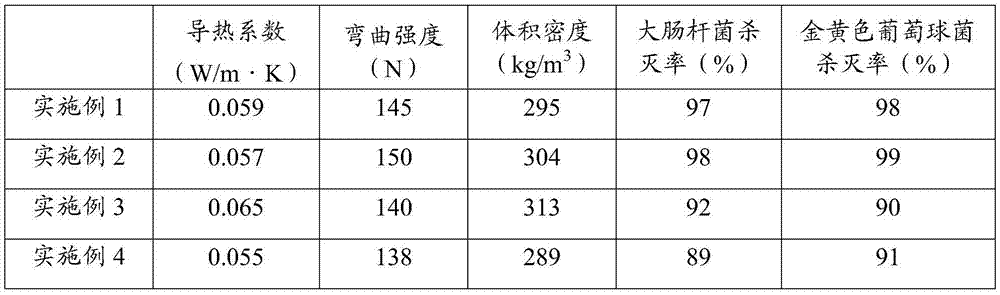

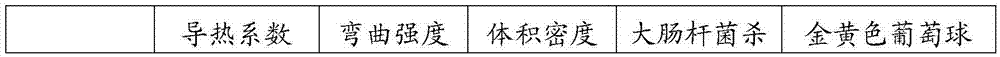

Mineral wool board with antibacterial function and preparation method thereof

The invention discloses a mineral wool board with an antibacterial function and a method of preparing the mineral wood board. An aqueous coating is sprayed to the surface of a slab of the mineral wool. The aqueous coating comprises spinel ferritewhich accounts for 2-4% by mass of the slab. The method comprises the following steps of: adding mineral wool fibers into water and stirring the mixture; adding inorganic enhanced fibers and an adhesive, and stirring; adding a flocculant, stirring, filtering and forming, and drying for 1-2h at 180-200 DEG C to obtain the slab of which the thickness is 10-20mm; and spraying the aqueous coating containing the spinel ferrite to the surface of the prepared slab to obtain the mineral wool board with the antibacterial function. The mineral wool board disclosed by the invention has a photocatalytic antibacterial function in a visible light region and is high in bending strength, low in volume density, non-toxic and incombustible, and the preparation process of the mineral wool board is simple and energy-saving.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Modification method of ramie fibers

InactiveCN107447516AChange orientationImprove finenessBiochemical fibre treatmentGrip property fibresState of artMildew

The invention relates to a modification method of ramie fibers. The modification method comprises the following steps: step 1, proportioning cottonseed shell ash, rice straw ash and sodium hydroxide according to a weight ratio of 10 to (5-8) to (1-2) to obtain a mixture, adding the mixture into water which is 10-15 times the total weight of the mixture, boiling and preparing a modified solution; step 2, adding the ramie fibers into the modified solution to be completely immersed, and cooking for 2-4 hours; and step 3, taking the ramie fibers out of the modified solution, washing the ramie fibers with clear water, and naturally drying the ramie fibers in air. Compared with the prior art, the method disclosed by the invention has the advantages that characteristics such as degree of crystallinity and degree of orientation of the ramie fibers are improved, a prodding and itching feeling generated when the ramie fibers are in contact with a human body is eliminated to certain extent, unique fiber hole cavity structures of the ramie fibers are not damaged, and grooved cavities in the middle of the fibers are not damaged, so that characteristics such as bacteria resistance and bacteriostasis, deodorization and adsorption, moisture absorption and ventilation, mildew prevention and wear resistance of the ramie fibers can be kept.

Owner:厦门盛方生态技术集团有限公司

Preparation method of ultrafine panax notoginseng powder cellulosic fiber

InactiveCN108251914AEnhance immune functionEnhance physical fitnessConjugated cellulose/protein artificial filamentsArtifical filament manufacturePANAX NOTOGINSENG ROOTUltraviolet

The invention discloses a preparation method of ultrafine panax notoginseng powder cellulosic fiber. The method comprises the following technical steps: performing pretreatment, preparing spinning solution, ensuring that the spinning solution is squeezed out from a spinneret orifice to form fine solution flow, ensuring that the fine solution flow is solidified to form nascent fiber, and packagingor directly performing aftertreatment on the nascent fiber, so as to obtain a finished product. Panax notoginseng powder is directly applied to the field of functional fiber and is combined with bamboo pulp with high mechanical strength, novel cellulosic fiber is formed, and the cellulosic fiber overcomes the defect that the natural features of bamboo are damaged during processing of bamboo pulp fiber through the healthcare function of panax notoginseng powder while maintaining the original advantages of the bamboo pulp fiber, so that the cellulosic fiber has a healthcare function while havingfunctions of deodorization, bacteria resistance and ultraviolet prevention, and is reasonable in design, more humanized and suitable for promotion and application.

Owner:天马(安徽)国药科技股份有限公司

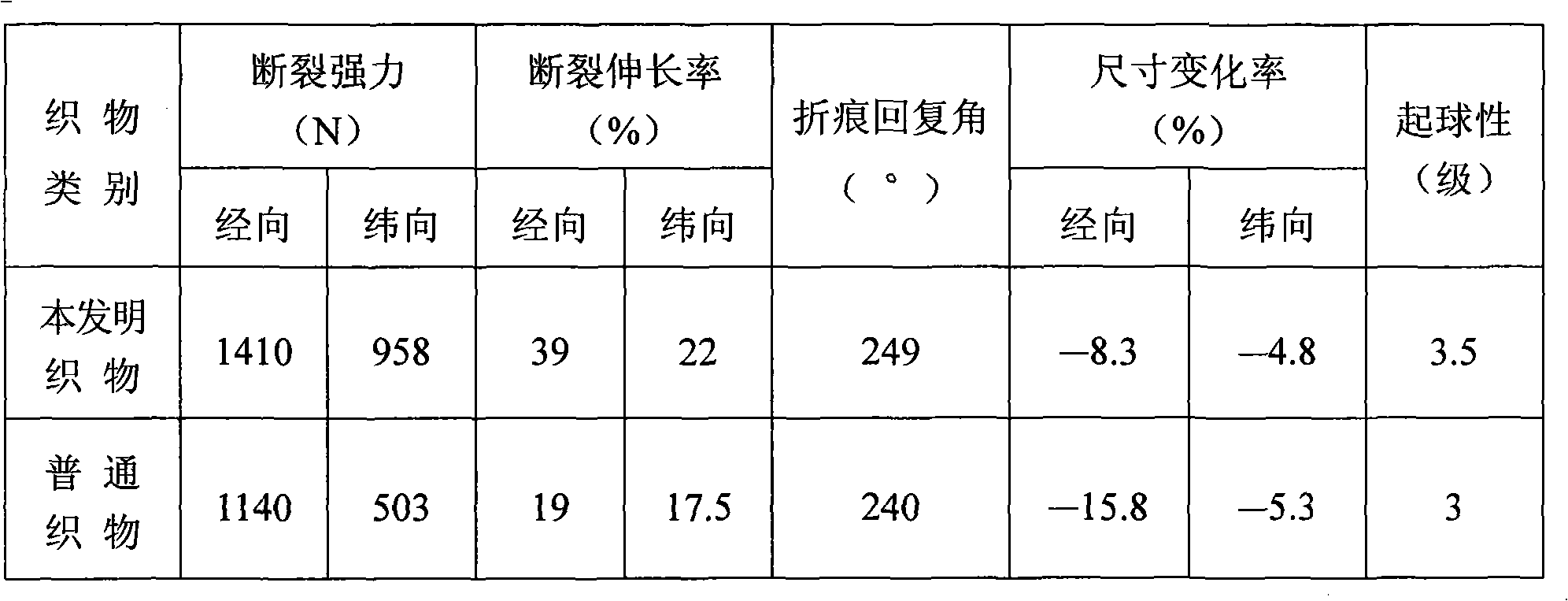

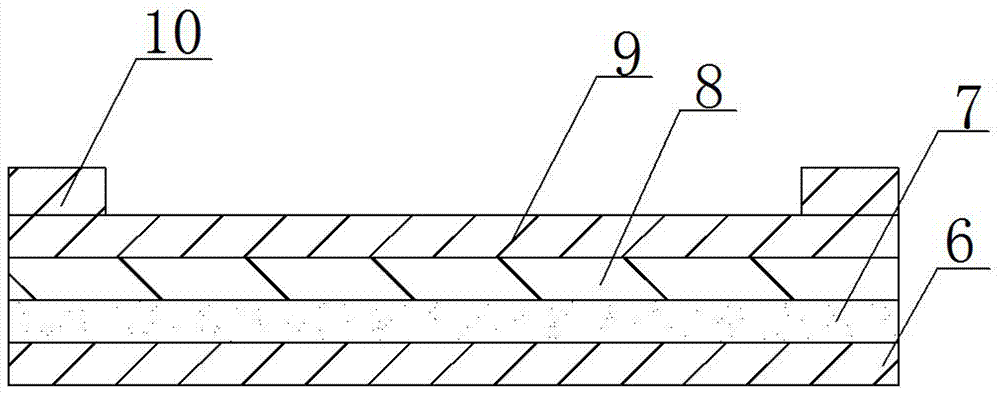

Bamboo pulp fibre blending decoration fabric and its after finishing technique

ActiveCN101343807AKeep antibacterialKeep coolSingeingWoven fabricsPulp and paper industryHigh intensity

The invention relates to a bamboo pulp fiber blended spinning decoration fabric manufactured in the textile industry. The warp and weft yarns comprises bamboo pulp fiber, polybutylece terephthalate propylene glycol ester fiber and crude high elasticity acrylic fiber wrinkle resistant short fiber, the warp and weft yarns adopt combed two-fold yarns of 27.8 tex, the twist degree of the yarns is larger than or equal to 700 twists per meter, the fabric texture adopts satin jacquard, and the densities of the warp and weft yarns respectively adopt 800 to 900 yarns per 10 cm and 380 to 420 yarns per 10 cm; the post-treatment technology of the fabric adopts cellulolytic enzyme SD-05 to perform the desizing and polishing treatment, and then the stentering and shaping treatment is performed to the fabric under the condition that the temperature is controlled to be between 130 to 150 DEG C and the time is controlled to be 20 to 30 minutes. The bamboo pulp fiber blended spinning decoration fabric has the advantages that the advantages of the bamboo pulp fiber fabric of bacterial resistance, ultraviolet ray absorbing, air permeability and cooling, etc. are maintained, the disadvantages of the bamboo pulp fiber fabric are remedied, and the bamboo pulp fiber blended spinning decoration fabric also has the advantages of shrink prevention, wrinkle resistance, high intensity and wear resistance, etc.; the process of the biological enzyme treatment technology is soft, and the treatment technology is environment protective.

Owner:上海龙头纺织科技有限公司

Novel vehicle-mounted air purifying bag

InactiveCN107362384AHas a bactericidal effectKeep antibacterialBiocideDead animal preservationAir cleaningEngineering

A novel vehicle-mounted air purifying bag is formed by compressing forming of bamboo charcoal, mint, borneol and notopterygium root, and packing the bamboo charcoal, the mint, the borneol and the notopterygium root in a non-woven fabric bag. The air purifying bag not only has effects of absorbing odor molecules and removing odor, but also has a sterilizing effect; and long-time bacterial inhibiting and sterilizing can be maintained.

Owner:赵敏

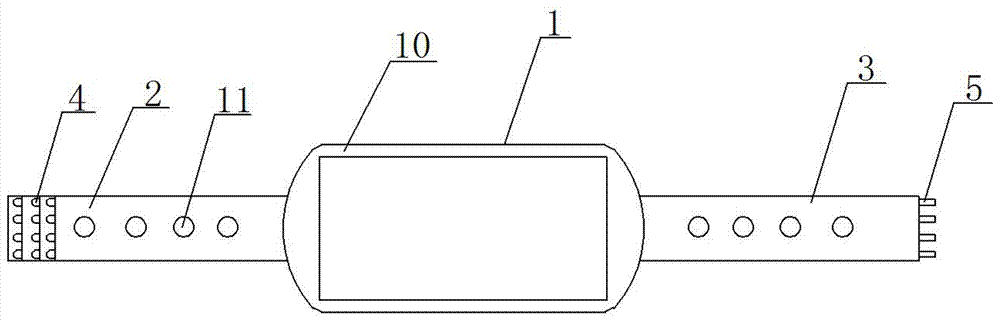

Nursing strap for cesarean section

ActiveCN106923966AAvoid infectionPrevent intrusionAntibacterial agentsBreast bandagesMedicineInjury mouth

The invention discloses a nursing strap for cesarean section, and belongs to the technical field of medical instruments. The nursing strap comprises a belly band as well as a left protecting band and a right protecting band which are arranged at two sides of the belly band, wherein fasteners, in multiple rows, are arranged on the left protecting band; hooks, which are matched with the fasteners, are arranged on the right protecting band; from bottom to top, the belly band comprises an antibacterial fiber layer I, a traditional Chinese medicine layer, a heating layer and an antibacterial fiber layer II; isolating layers are arranged at the edges of four sides of the antibacterial fiber layer I; and air vents are formed in both the left protecting band and the right protecting band. The nursing strap can prevent wounds from getting cracked and can prevent infection, and in addition, the nursing strap, by virtue of the traditional Chinese medicine layer therein, can achieve functions of promoting astringency and stopping bleeding, removing stasis and alleviating pain, diminishing inflammation and inhibiting bacteria, and clearing away heat and toxic materials, so as to promote healing and rapid recovery of the wounds.

Owner:NANYANG CITY CENT HOSPITAL

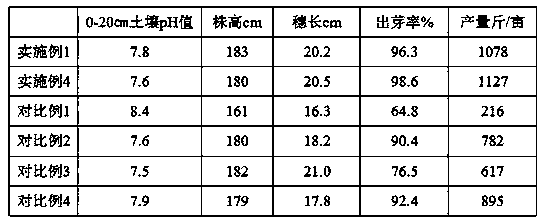

Method for cultivating crops by using liquid mulching film

InactiveCN109504400AWide variety of sourcesLow priceSeed and root treatmentClimate change adaptationPlastic mulchChitin formation

The invention discloses a method for cultivating crops by using a liquid mulching film, and belongs to the technical field of crop planting. The method comprises the following steps: preparing a liquid mulching film forming liquid and a cultivated land soil conditioner; turning soil; and pretreating seeds: soaking corn seeds with chlormequat chloride for 4-8 hours first, then soaking the corn seeds in a mixture containing sodium alginate, chitin, redispersible latex powder and turbid liquid at 30-45 DEG C, fishing out the corn seeds, soaking the corn seeds in water at a temperature of lower than 4 DEG C for 5-60 seconds, then fishing out the corn seeds, and draining water to dry the seeds at 20-30 DEG C. The planting method provided by the invention has the advantages of wide source of rawmaterials, low price and convenient transportation, reduces the production cost of corn, can effectively improve the yield of corn, and makes it feasible to popularize corn planting in saline-alkaliland.

Owner:GANSU HUARUI AGRI

Bamboo pulp fibre blending decoration fabric and its after finishing technique

The invention relates to a bamboo pulp fiber blended spinning decorative fabric manufactured in the textile industry. The warp and weft yarns comprise bamboo pulp fibers, polybutylece terephthalate propylene glycol ester fibers and medium-coarse high-elasticity acrylic anti-crease short fibers, the warp and weft yarns adopt 27.8 tex carded two-fold yarns, the twist degree of the yarns is larger than or equal to 700 twists per meter, the fabric texture adopts satin patterns, and the densities of the warp and weft yarns respectively adopt 800 to 900 yarns per 10 cm and 380 to 420 yarns per 10 cm; the post-processing technique of the fabric adopts cellulase SD-05 to perform the desizing and polishing treatment, and then the stentering and shaping treatment is performed to the fabric under the conditions that the temperature is controlled between 130 to 150 DEG C and the time is controlled between 20 to 30 minutes. The bamboo pulp fiber blended spinning decorative fabric has the advantages that the fabric maintains the advantages of bacterial resistance, ultraviolet ray absorbing, air permeability, cooling and the like, and makes up the disadvantages of the bamboo pulp fiber fabric, and the invention also has the advantages of shrink prevention, wrinkle resistance, high intensity, wear resistance and the like; and the process of the biological enzyme treatment technique is soft, and the treatment technique is environment-friendly.

Owner:上海龙头纺织科技有限公司

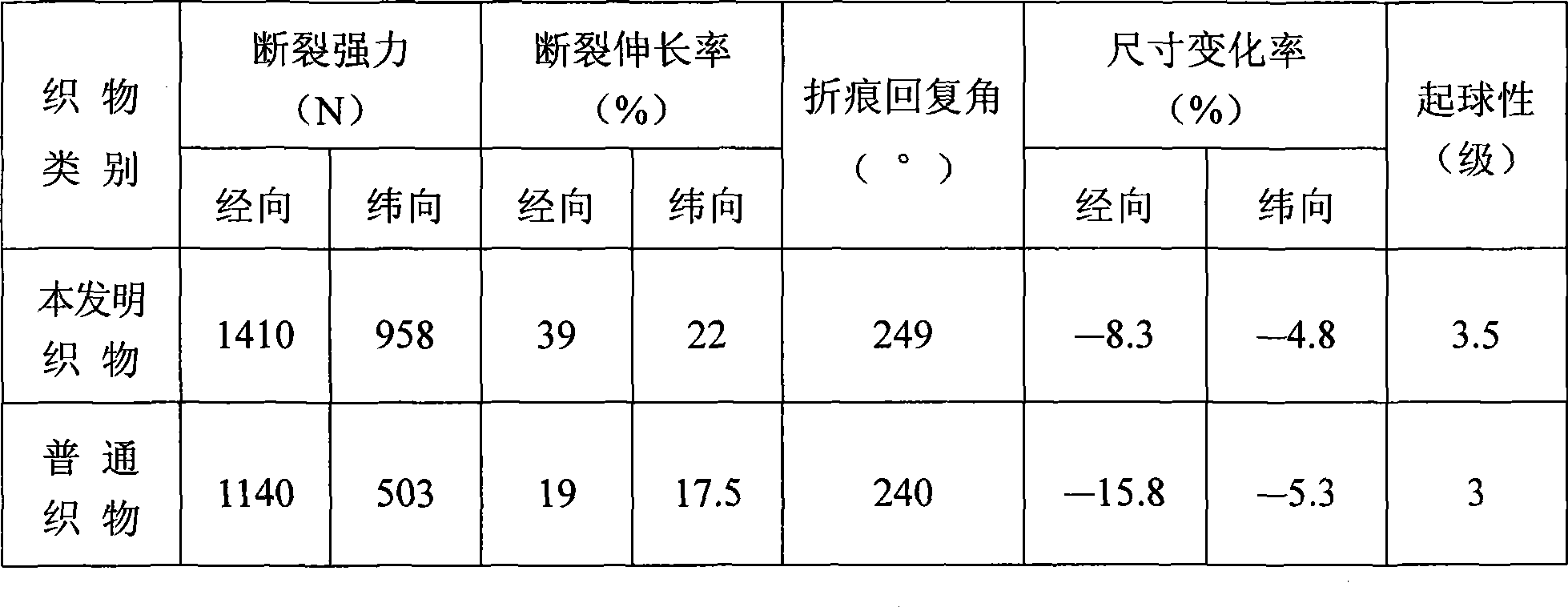

Combed cotton/graphene polyamide interweaved fabric and production process thereof

InactiveCN111005121AReduce usageGuaranteed additional featuresOrnamental textile articlesDyeing processPolymer sciencePolyamide

The invention discloses a combed cotton / graphene polyamide interweaved fabric and a production process thereof. The combed cotton / graphene polyamide interweaved fabric comprises the following components of 60-80 parts of combed cotton and 20-40 parts of graphene polyamide, wherein the combed cotton is the surface, and the graphene polyamide is the bottom. The production process of the combed cotton / graphene polyamide interweaved fabric comprises the following steps of weaving; pre-treatment; primary dyeing; peracid neutralization; first post-treatment; secondary dyeing; second post-treatment;squeezing; and setting. The combed cotton / graphene polyamide interweaved fabric has the characteristics of good wear resistance, better strength, soft hand feeling, difficult wrinkling after water washing and the like; without adding any functional auxiliary agent, the fabric can be endowed with the antistatic, antibacterial, anti-ultraviolet, far-infrared, anti-mite and deodorization functions and other functions; and a high-washability product provided with the functional auxiliary agent realizes the multi-functionality and durability of the fabric.

Preparation method of antipersprant deodorant

InactiveCN107929196AImprove use valueAntibacterialCosmetic preparationsToilet preparationsSide effectMacro level

The invention relates to the field of skin care products, and specifically relates to a preparation method of antipersprant deodorant. The method is characterized in that an octylene hydrophobic groupis introduced into the particle surfaces of corn starch, so that hydroxyl on the starch molecules can be screened out to the maximum; the hydrophilia can be quickly reduced; the intermolecular actionforce of hydrogen bond, van der waals, etc. among the starch particles can be greatly reduced; and as a result, high flowability is realized at the macro level; the starch molecules with octylene arehydrophobic and can freely flow in a dry state, and the flowing form is extremely similar with the liquid form; the starch molecules in water float on the water and are hard to form suspension and are kept in a dry state; when the antipersprant deodorant is coated to oxter, the oxter can be locally kept dry, and sticky feeling is avoided in case of sweating, and the skin is soft, dry and clean; in addition, natural amino acid substrates are added and have the characteristics of naturally moisturizing, being resistant to oxidation, resistant to bacteria, resistant to static resisting, safe, and free from side effect, so that the functions of the antipersprant deodorant applied to a sensitive area in the oxter can be improved.

Owner:石磊

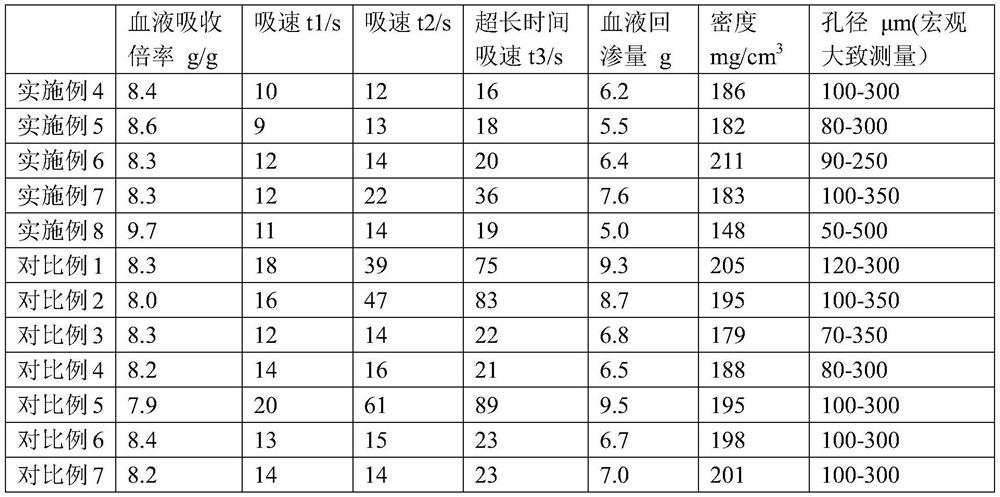

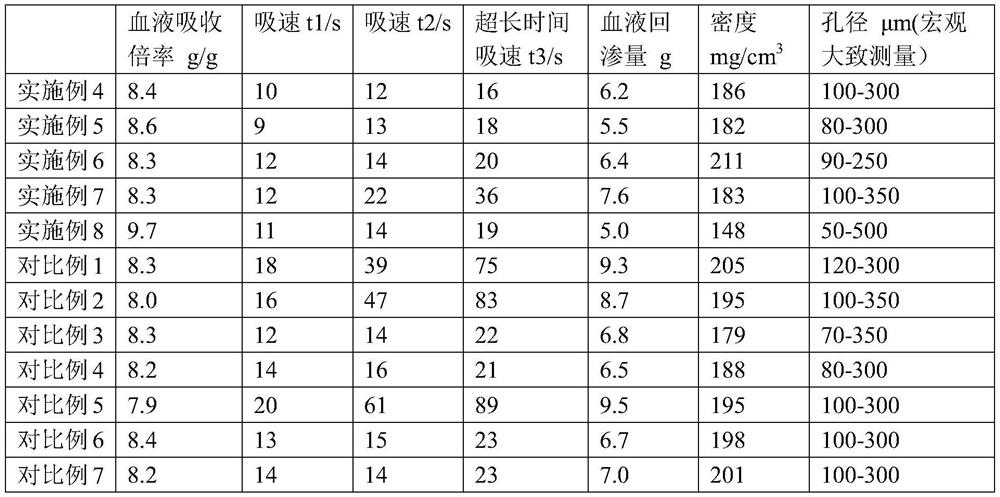

A kind of polyurethane blood absorption foam, preparation method and use thereof

ActiveCN113633812BImprove adsorption capacityEnhanced ion release performanceAbsorbent padsBandagesPolymer sciencePolyol

Owner:WANHUA CHEM GRP CO LTD

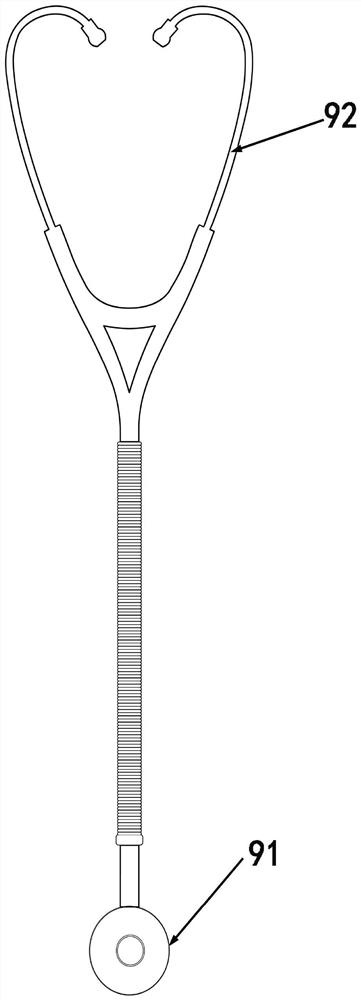

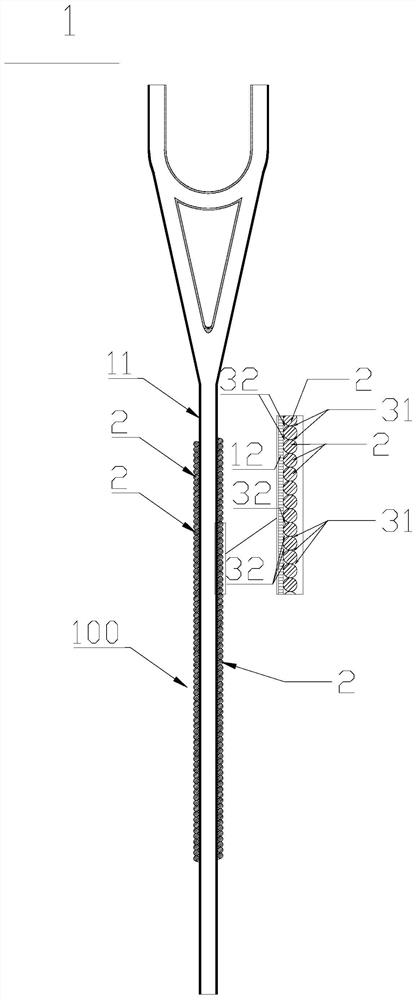

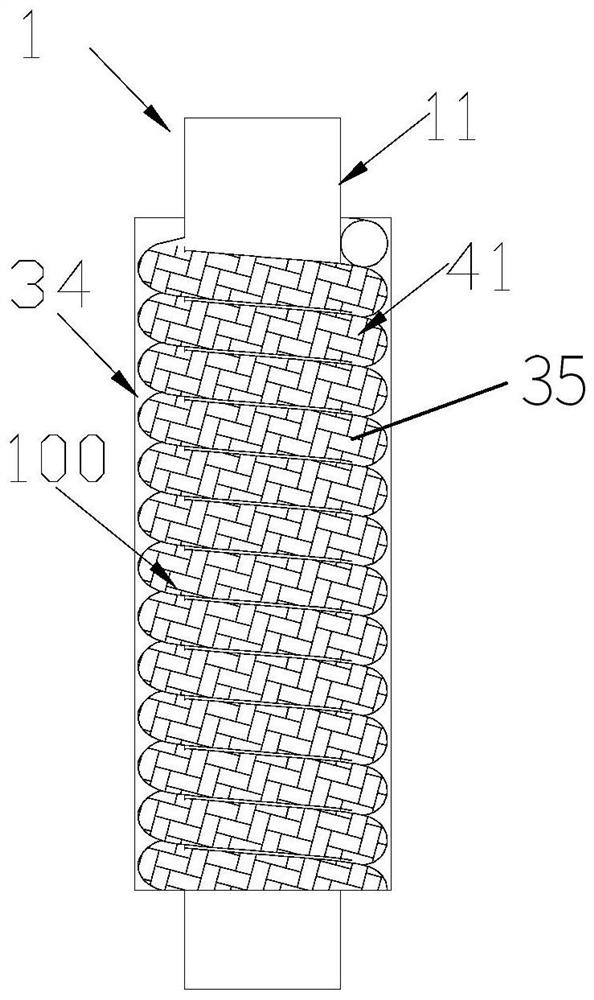

Rubber tube for stethoscope

InactiveCN112075951ATouch sound reductionReduce incomingStethoscopeAuscultationBiomedical engineering

The invention relates to a rubber tube for a stethoscope. The rubber tube for the stethoscope is not easy to break, and is anti-aging, the service life can be prolonged, and meanwhile, the influence of invalid sounds such as external noises and touch sound which are transmitted into a tube cavity of the rubber tube on auscultation can be reduced. In the rubber tube for the stethoscope, a coveringformed by arranging strip-shaped objects is arranged outside the tube wall of the rubber tube, and is formed by surrounding the strip-shaped objects on the outer side wall of the rubber tube. The rubber tube for the stethoscope has the advantages of smoothness, antibiosis and antianaphylaxis when the rubber tube is held and used.

Owner:WUXI KAISHUN MEDICAL DEVICE MFG CO LTD

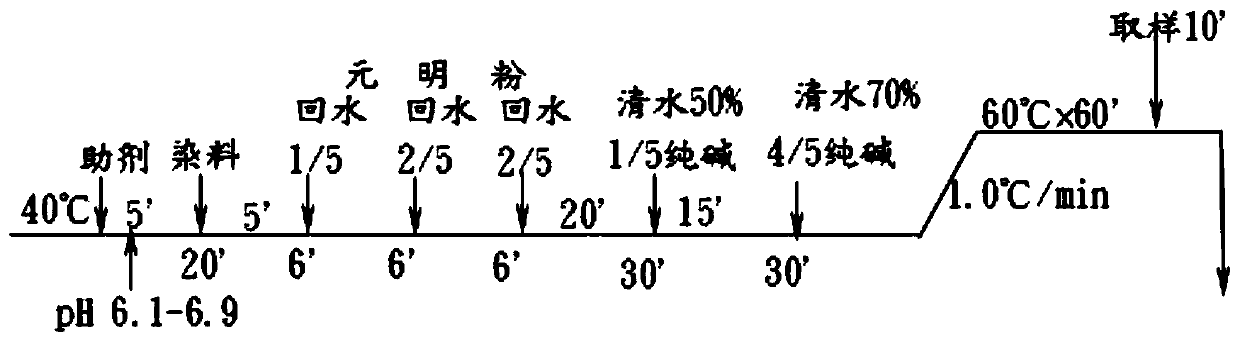

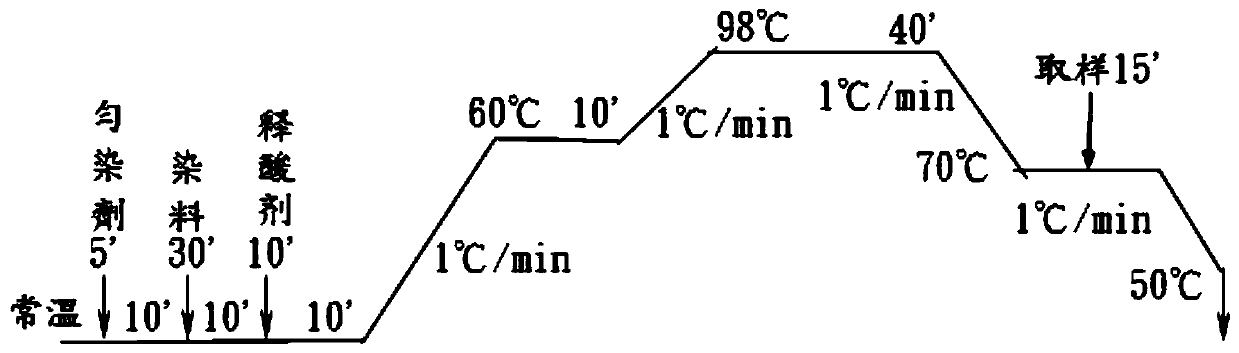

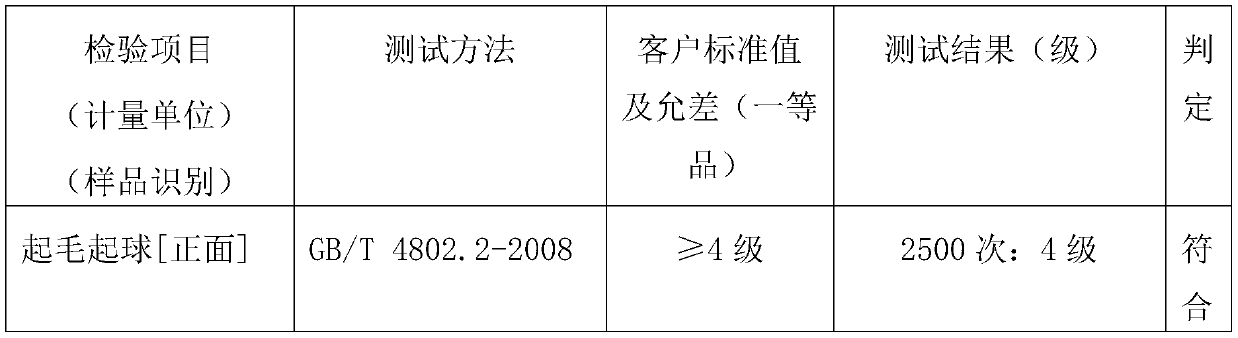

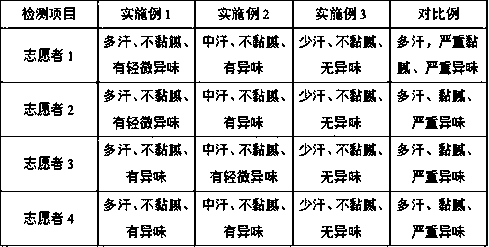

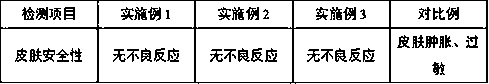

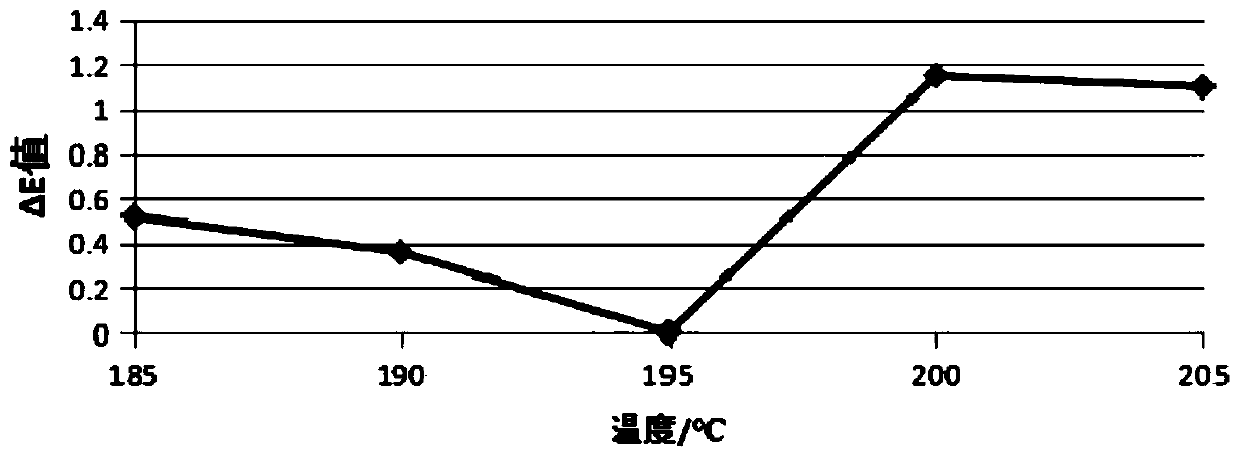

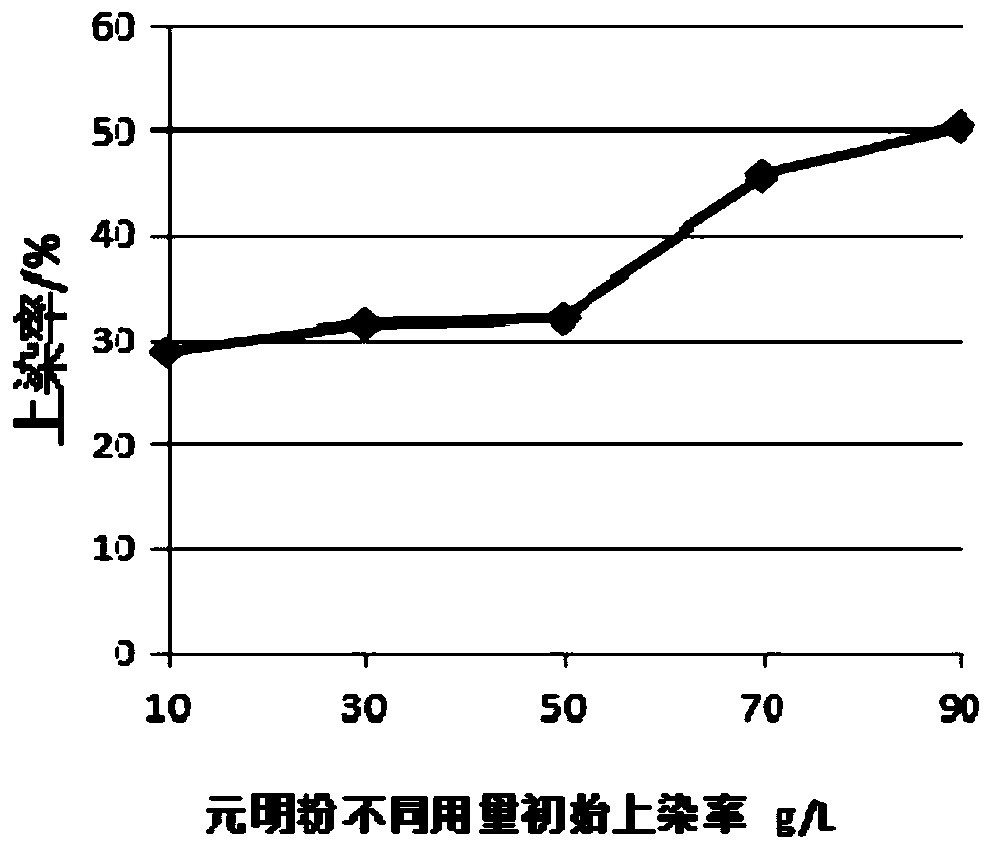

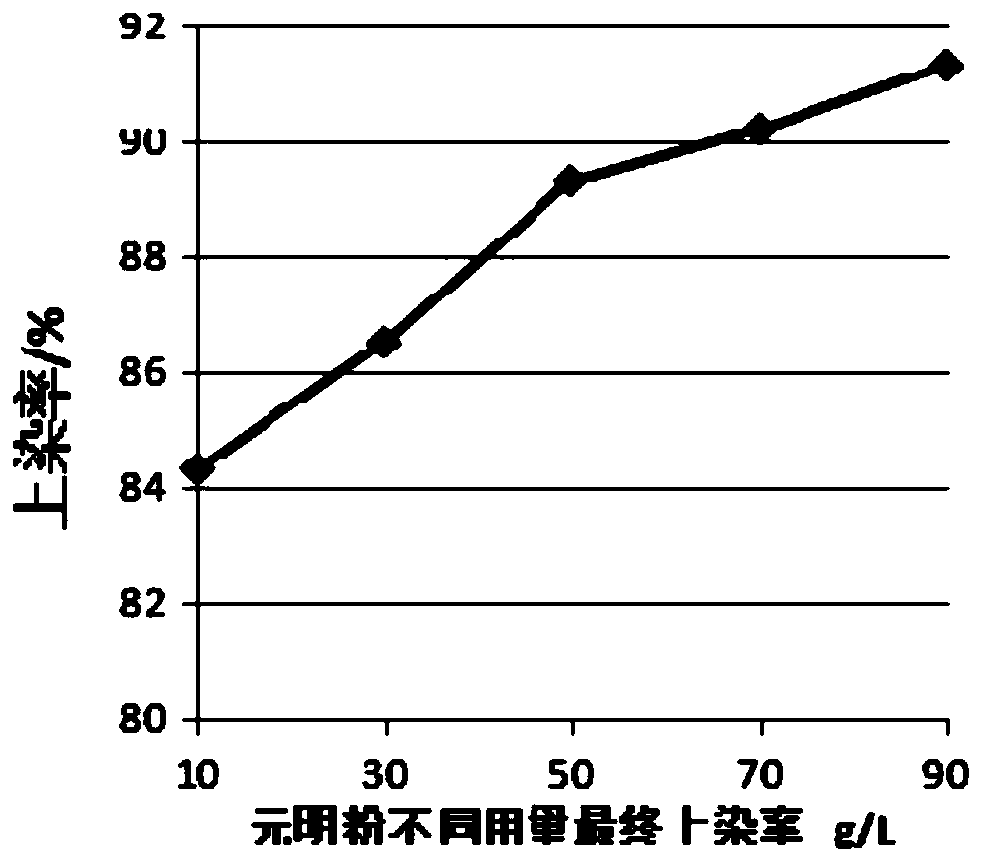

Dyeing and finishing method of rose essential oil viscose rattan single jersey

PendingCN111364261AKeep antibacterialGuaranteed moisturizing effectHeating/cooling textile fabricsLiquid/gas/vapor removalViscoseEngineering

The invention discloses a dyeing and finishing method of rose essential oil viscose rattan single jersey, and belongs to the technical field of textile dyeing and finishing. The dyeing and finishing method of the rose essential oil viscose rattan single jersey comprises the following steps of (1), pre-shaping; (2), pre-processing; (3), dyeing; (4), soaping; (5), washing with water; and (6), dewatering and drying. The dyeing and finishing method for the rose essential oil viscose rattan single jersey is provided from the aspects of the preset temperature, the dyeing temperature rising method, the using amount of a leveling agent, the using amount of anhydrous sodium sulphate and the using amount of alkali, uneven dye can be prevented, the essential oil performance can be guaranteed, and thebenefits of dyeing and finishing enterprises are improved.

Owner:QINGDAO XUEDA GRP

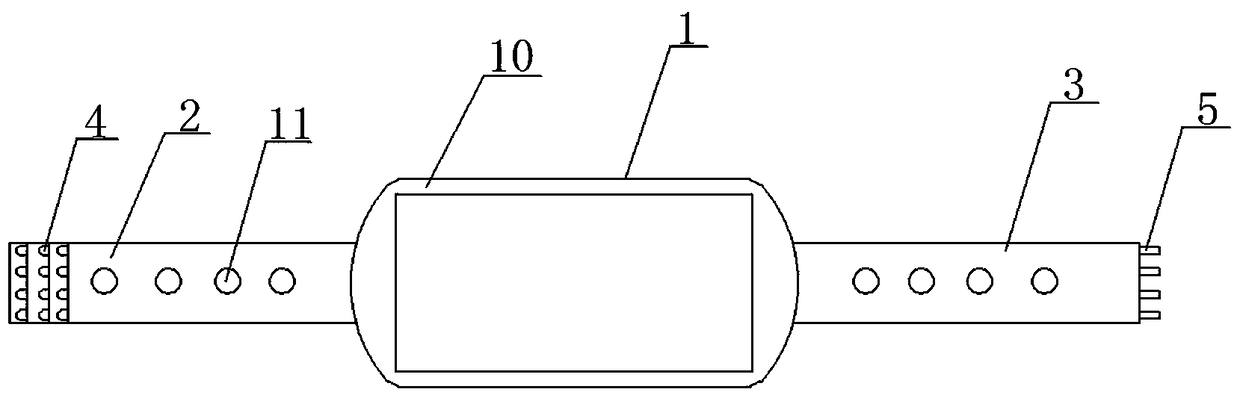

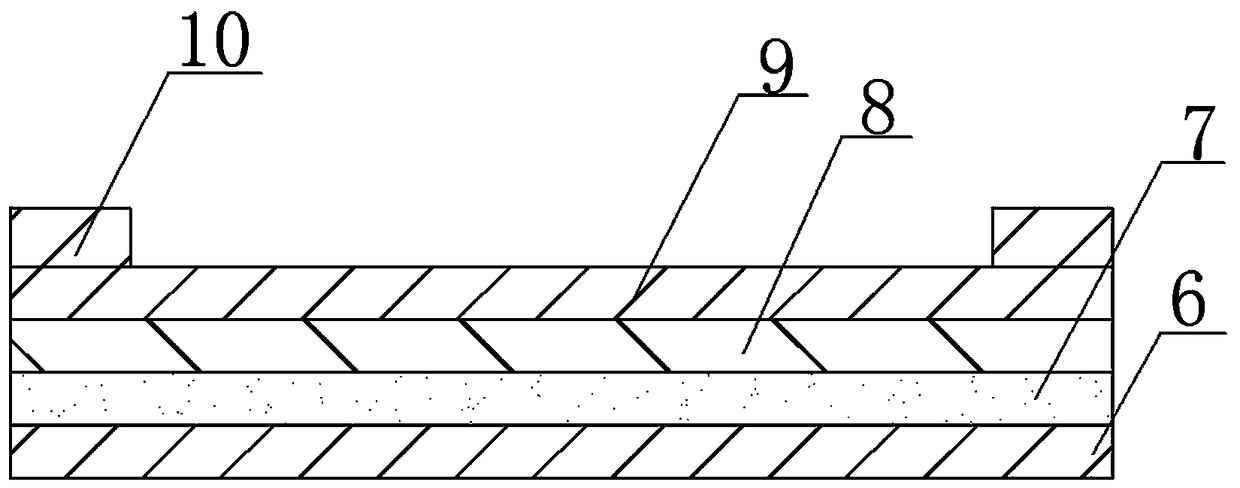

Caesarean section nursing belt

ActiveCN106923966BAvoid infectionPrevent intrusionAntibacterial agentsBreast bandagesMedicineInjury mouth

The invention discloses a nursing strap for cesarean section, and belongs to the technical field of medical instruments. The nursing strap comprises a belly band as well as a left protecting band and a right protecting band which are arranged at two sides of the belly band, wherein fasteners, in multiple rows, are arranged on the left protecting band; hooks, which are matched with the fasteners, are arranged on the right protecting band; from bottom to top, the belly band comprises an antibacterial fiber layer I, a traditional Chinese medicine layer, a heating layer and an antibacterial fiber layer II; isolating layers are arranged at the edges of four sides of the antibacterial fiber layer I; and air vents are formed in both the left protecting band and the right protecting band. The nursing strap can prevent wounds from getting cracked and can prevent infection, and in addition, the nursing strap, by virtue of the traditional Chinese medicine layer therein, can achieve functions of promoting astringency and stopping bleeding, removing stasis and alleviating pain, diminishing inflammation and inhibiting bacteria, and clearing away heat and toxic materials, so as to promote healing and rapid recovery of the wounds.

Owner:NANYANG CITY CENT HOSPITAL

Mineral wool board with antibacterial function and preparation method thereof

The invention discloses a mineral wool board with an antibacterial function and a method of preparing the mineral wood board. Raw materials of preparing the mineral wool board comprise 2-4% by mass of spinel ferrite. The method comprises the following steps of: adding mineral wool fibers and spinel ferrite into water and stirring the mixture; adding inorganic enhanced fibers and an adhesive, and stirring; and adding a flocculant, stirring, filtering and forming, and drying for 1-2h at 180-200 DEG C to obtain the mineral wool board with the antibacterial function, wherein the thickness of the mineral wood board is 10-20mm. The invention also discloses use of the spinel ferrite as an inorganic photocatalytic antibacterial material. The mineral wool board disclosed by the invention has a photocatalytic antibacterial function in a visible light region and is high in bending strength, low in volume density, non-toxic and incombustible, and the preparation process of the mineral wool board is simple and energy-saving.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Preparation method and application of viscose-based zinc ion antibacterial fibers

PendingCN111778578AGood antibacterial effectKeep antibacterialBed linenArtificial filaments from viscosePolymer scienceSpinning

The invention relates to a preparation method and application of viscose-based zinc ion antibacterial fibers. The preparation method disclosed by the invention comprises the following steps of: (1) weighing 5-10 g of a dispersing agent with the concentration of 10 g / L, adding the dispersing agent into an acid bath with the volume of 1-2 L, which is formed by mixing 18-21 g of ZnSO4.7H2O, 200-220 gof Na2SO4 and 110-120 g of concentrated H2SO4, and uniformly stirring to obtain a mixed spinning solution; and (2) carrying out oxidation-reduction reaction in a coagulating bath, namely adding 18-21g of ZnSO4.7H2O again after the reaction is carried out for 2-3 hours, heating the coagulating bath to 60-65 DEG C when the nascent filament starts to be stretched, adding a rotating rod, and carryingout stirring acceleration reaction at 120-150r / min to gradually obtain the antibacterial finished fibers.

Owner:SHANGHAI SHUIXING HOME TEXTILE

A kind of hemp shirt fabric and preparation method thereof

The invention provides a hemp shirt fabric with antibacterial and anti-ultraviolet properties, the warp and weft yarns are hemp primary fiber / hemp viscose fiber / long-staple cotton fiber blended yarn 11.8×2tex; the preparation method comprises the following steps : a. Spinning: including hemp primary fiber pretreatment, opening and cleaning, carding, drawing, roving, spun yarn, winding; b. Package dyeing: including loose tube, pretreatment, dyeing, posttreatment, dehydration , drying and tight cylinder; pretreatment temperature 105-115°C, time 40-50min, hydrogen peroxide 3.5-4.5g / L, caustic soda 1.0-1.5g / L, dyeing bath ratio 1:15, Jingren double reactive dye; c , Weaving: including warping, sizing, drafting, and weaving; d, finishing.

Owner:JIANGSU YUEDA HOME TEXTILE

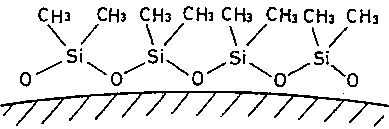

Construction method of antibacterial and antifouling building

InactiveCN111117326AHigh bonding strengthHigh strengthWax coatingsAntifouling/underwater paintsSide chainSilicone oil

The invention relates to a construction method of an antibacterial and antifouling building, and belongs to the technical field of antibacterial and antifouling of building construction. The method comprises the following steps: taking 3-4 parts by weight of seashell powder, 5-7 parts by weight of magnesium oxide and 20-30 parts by weight of paraffin, performing uniform stirring, then adding 10-15parts by weight of side chain amino substituted silicone oil, and performing uniform stirring; and adding 5-7 parts by weight of a coalescing agent before use in order to prepare an antibacterial andantifouling layer. The side chain amino modified silicone oil, the seashell powder, the magnesium oxide and the like are added to improve the binding force with the cement wall surface, the super-hydrophobic property is realized by utilizing the super-strong surface tension, and dusts and the like are not prone to adhering to the cement wall surface.

Owner:山东高速齐鲁建设集团有限公司

Polyurethane blood absorption foam, preparation method and application of polyurethane blood absorption foam

ActiveCN113633812AImprove adsorption capacityEnhanced ion release performanceAbsorbent padsBandagesPolymer sciencePolyol

The invention provides polyurethane blood absorption foam, a preparation method and application of the polyurethane blood absorption foam. The polyurethane blood absorption foam is prepared from the following raw materials: isocyanate, polyol, a chain extender, an antioxidant, an amino-containing polycarboxylic acid polymer, a hydrophilic surfactant, diatomite-nano silver / copper composite particles and water. The amino-containing polycarboxylic acid polymer and the diatomite-nano-silver / copper composite material are introduced into a foaming material at the same time, so that the prepared polyurethane absorber foam has the fluid characteristics of being antibacterial, deodorizing, being high in blood affinity, inhibiting blood coagulation, being high in safety, being capable of rapidly absorbing blood and the like.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com