Construction method of antibacterial and antifouling building

A construction method and building technology, which is applied in the direction of building structure, construction, antifouling/underwater coating, etc., can solve problems such as peeling, reduce the service life of buildings, and not be resistant to dirt, and achieve the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

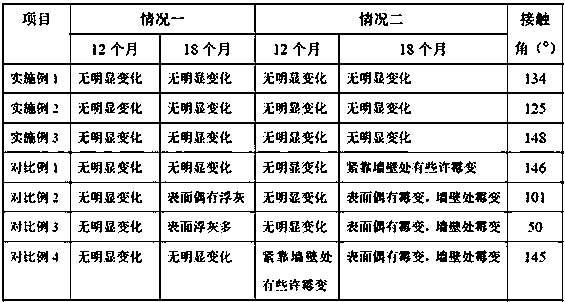

Embodiment 1

[0026] A construction method of an antibacterial and antifouling building, adopting the following steps:

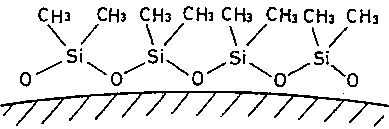

[0027] (1) Preparation of antibacterial and antifouling layer: Take 40g of shell powder, 50g of magnesium oxide, and 200g of paraffin, stir well, then add 100g of silicone oil substituted with side chain amino groups, stir well; add 50g of film-forming aid before use;

[0028] (2) Preparation of paint: Mix 70g of polyvinyl alcohol, 320g of light calcium carbonate, 50g of talcum powder, and 40g of gypsum powder evenly, and add 500g of water to make a paint;

[0029] (3) On the inner wall of the house to be constructed, paint a layer of antibacterial and antifouling layer with a thickness of about 1-2mm and dry;

[0030] (4) Add the antibacterial and antifouling layer of step (1) to step (2), and stir evenly; on the dried wall surface of step (3), evenly smear the paint doped with antibacterial and antifouling layer, with a thickness of 1- 2cm, dry;

[0031] (5) On the wa...

Embodiment 2

[0033] A construction method of an antibacterial and antifouling building, adopting the following steps:

[0034] (1) Preparation of antibacterial and antifouling layer: Take 30g of shell powder, 70g of magnesium oxide, and 300g of paraffin, stir well, then add 150g of silicone oil substituted with side chain amino groups, stir well; add 70g of film-forming aid before use;

[0035] (2)-(5) as in Example 1.

Embodiment 3

[0037] A construction method of an antibacterial and antifouling building, adopting the following steps:

[0038] (1) Preparation of antibacterial and antifouling layer: Take 35g of shell powder, 60g of magnesium oxide, and 25g of paraffin, stir well, then add 125g of silicone oil substituted with side chain amino groups, stir well; add 60g of film-forming aid before use;

[0039] (2)-(5) as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com