Dyeing and finishing method of rose essential oil viscose rattan single jersey

A technique of rose essential oil, viscose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1.1 Fabrics, medicines and instruments

[0044] Fabric: rose essential oil viscose / spandex (95 / 5) blended fabric;

[0045] Medicines: degreasing agents, reactive dyes, acetic acid, sodium sulfate, sodium carbonate, glacial acetic acid, soap flakes,

[0046] Instruments: color measuring and matching instrument, automatic dripping machine, small setting machine, small prototype in room temperature water bath

[0047] 1.2 Dyeing process

[0048] In the experiment, reactive dyes red 3BS and yellow 3RS were selected for dyeing.

[0049] 1.2.1 Process flow

[0050] Pre-setting→pretreatment→dyeing→soaping→washing→dehydration and drying

[0051] details as follows:

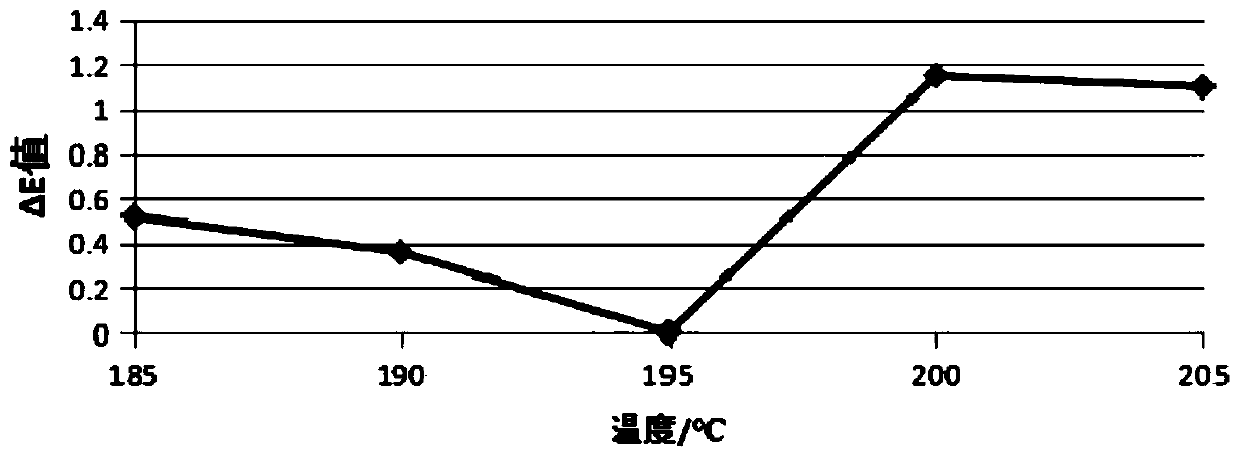

[0052] (1) Pre-forming: temperature 190°C, floating within 3°C, cloth speed 20 m / min;

[0053] (2) Pretreatment: degreaser 2g / L, temperature 80°C, time 30 minutes;

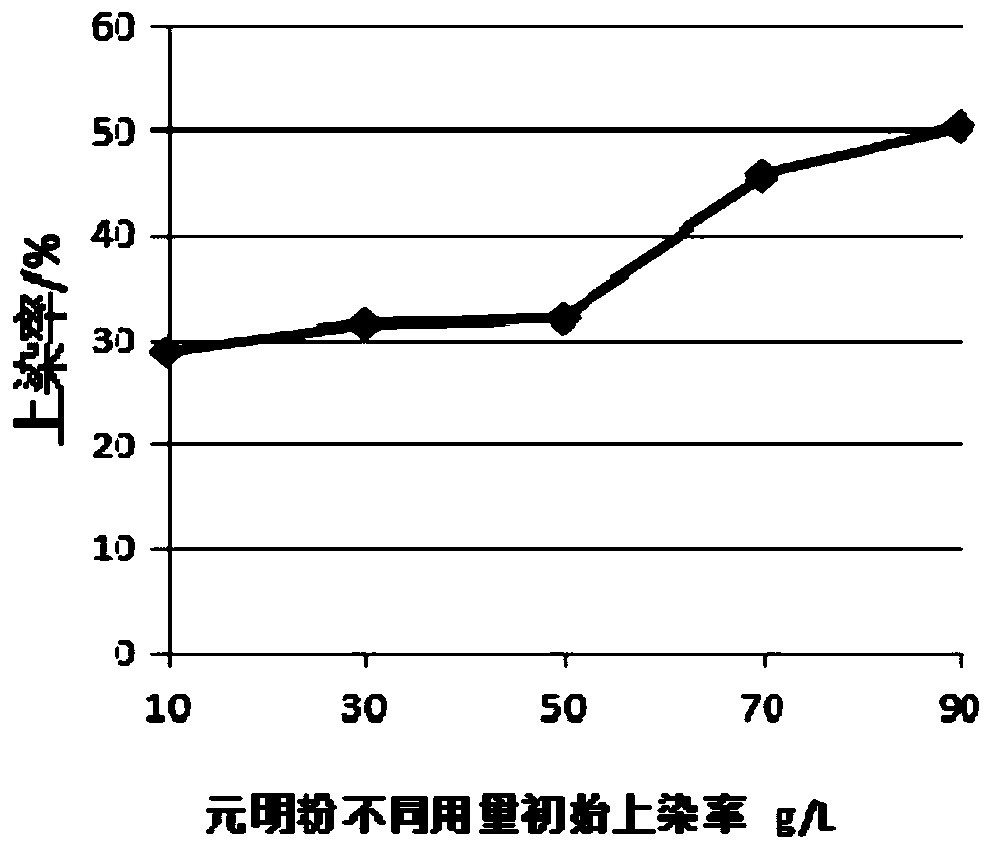

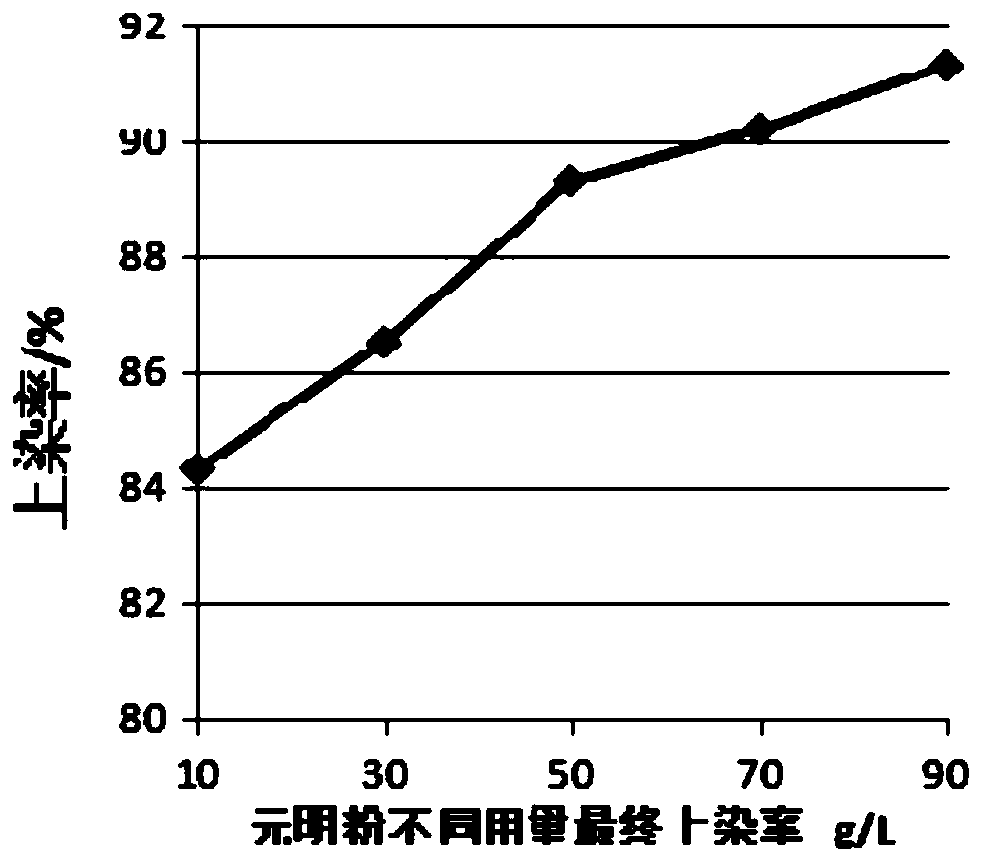

[0054] (3) Dyeing: dyestuff, leveling agent 1g / L, sodium sulfate 10-50g / L, soda ash ≤ 20g / L;

[0055] ① Add water to the fabric to be dyed, ad...

Embodiment 2

[0114] Adopt the processing example of technology of the present invention

[0115] process flow

[0116] Pre-setting→pretreatment→dyeing→soaping→washing→dehydration and drying

[0117] details as follows:

[0118] (1) Pre-forming: temperature 190°C, floating within 3°C, cloth speed 20 m / min;

[0119] (2) Pretreatment: degreaser 2g / L, temperature 80°C, time 30 minutes;

[0120] (3) Dyeing: dyestuff, leveling agent 1g / L, Yuanming powder 20g / L, soda ash 10g / L;

[0121] ① Add water to the fabric to be dyed, add leveling agent, keep at 35-40°C for 5 minutes;

[0122] ②The dye is added in 35-40 minutes and kept for 10 minutes;

[0123] ③ 1 / 5 of Yuanmingfen was added in 20-25 minutes and kept for 7 minutes;

[0124] ④ 4 / 5 Yuanmingfen was added in 20-25 minutes and kept for 7 minutes;

[0125] ⑤ Pre-add soda ash at 1g / L for 20-25 minutes and keep for 10 minutes;

[0126] ⑥Raise the temperature to 80°C, cool down to 60°C, add the remaining soda ash in 50-55 minutes; keep for 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com