Bamboo pulp fibre blending decoration fabric and its after finishing technique

A bamboo pulp fiber and decorative fabric technology, applied in the field of decorative fabrics, can solve the problems of unstable shape, large elongation, relative slippage, etc., and achieve the effect of soft processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

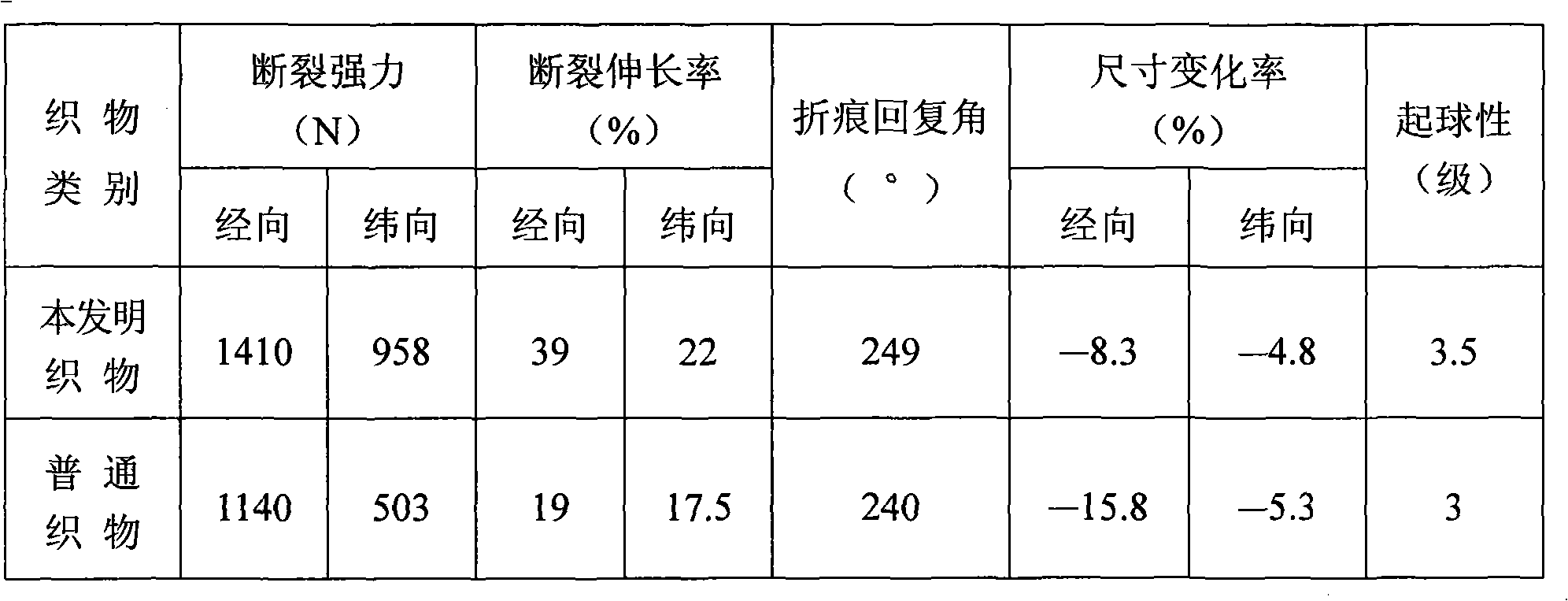

Image

Examples

Embodiment 1

[0017] Embodiment 1, bamboo pulp fiber blended decorative fabric type 1.

[0018] The warp and weft yarns of the fabric contain 65% bamboo pulp fiber, 30% polytrimethylene terephthalate fiber, and 5% 3.33dtex high-elastic acrylic anti-wrinkle short fiber; Twist / m, all bamboo blue, jacquard satin fabric, warp and weft density are 820, 380 / 10cm respectively.

Embodiment 2

[0019] Embodiment 2, bamboo pulp fiber blended decorative fabric type 2.

[0020] The warp and weft yarns of the fabric contain 68% bamboo pulp fiber, 28% polytrimethylene terephthalate fiber, and 4% 5.56dtex high-elastic acrylic anti-wrinkle staple fiber; Twist / m, the warp yarn is bamboo green, and the weft yarn is natural white; the dobby satin fabric has a warp and weft density of 850 and 400 threads / 10cm respectively.

Embodiment 3

[0021] Example 3, finishing process 1 of bamboo pulp fiber blended decorative fabric.

[0022] The amount of cellulase SD-05 treated by biological enzyme desizing and polishing is 28g per L of water, the pH value of the treatment solution is 4.8, the padding treatment solution has a 100% residual rate, and it is stacked at room temperature for 12 minutes after padding; tenter setting treatment The temperature is 140°C and the time is 25min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com