A kind of polyurethane blood absorption foam, preparation method and use thereof

A polyurethane and blood technology, applied in the field of foam material products, can solve the problems of reducing blood absorption capacity, affecting application, affecting user experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

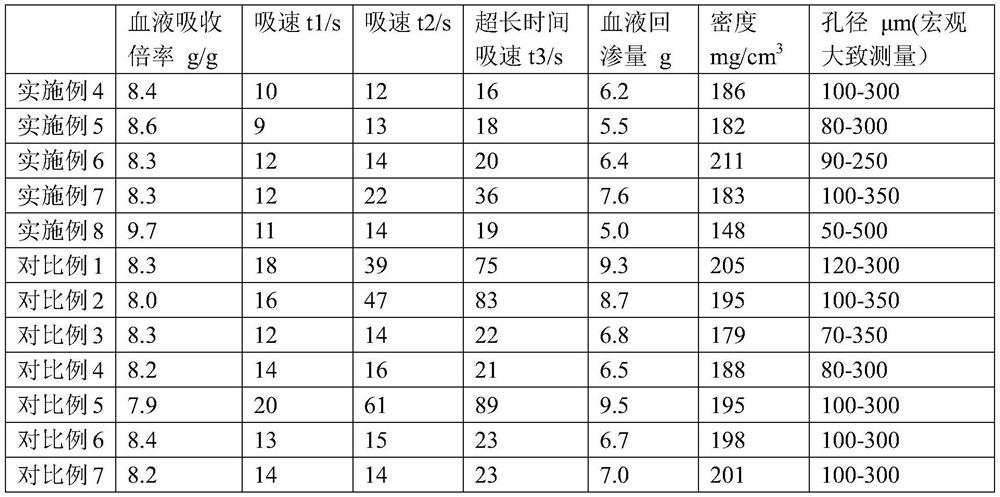

Examples

Embodiment 1

[0080] Preparation of diatomite-nano-silver / copper composite particles:

[0081] A mixed aqueous solution of copper nitrate and silver nitrate is prepared, wherein the concentration of silver nitrate is 0.1 mol / L, and the concentration of copper nitrate is 0.1 mol / L.

[0082] Take the mixed aqueous solution of 10g diatomite (400 mesh particle size) and 100g copper nitrate and silver nitrate, stir for 10min under dark conditions, make it fully infiltrated, and then place it in an ultrasonic cleaner for ultrasonic vibration for 10min, ultrasonic frequency 40kHz, so that silver nitrate and copper nitrate can effectively enter the interior of diatomite, and fully couple with the inner surface of diatomite, and then take it out and quickly wash it in a Buchner funnel with clean water.

[0083] The obtained powder was dried in an oven at 50°C for 12 hours, and then calcined in a muffle furnace at 500°C for 4 hours to obtain diatomite-nano-silver / copper composite particles with a par...

Embodiment 2

[0086] Preparation of diatomite-nano-silver / copper composite particles:

[0087] A mixed aqueous solution of copper nitrate and silver nitrate was prepared, wherein the concentration of silver nitrate was 0.03 mol / L and the concentration of copper nitrate was 0.04 mol / L.

[0088] Take the mixed aqueous solution of 20g diatomite (particle size 300 mesh) and 160g copper nitrate and silver nitrate, stir for 10min under dark conditions, make it fully infiltrated, then place it in an ultrasonic cleaner for ultrasonic vibration for 5min, ultrasonic frequency 30kHz, so that silver nitrate and copper nitrate can effectively enter the interior of diatomite, and fully couple with the inner surface of diatomite, and then take it out and quickly wash it in a Buchner funnel with clean water.

[0089] The obtained powder was dried in an oven at 40°C for 15 hours, and then calcined in a muffle furnace at 800°C for 2 hours to obtain diatomite-nanosilver / copper composite particles with a parti...

Embodiment 3

[0092] Preparation of diatomite-nano-silver / copper composite particles:

[0093] A mixed aqueous solution of copper nitrate and silver nitrate is prepared, wherein the concentration of silver nitrate is 0.2 mol / L and the concentration of copper nitrate is 0.3 mol / L.

[0094] Take the mixed aqueous solution of 5g diatomite (particle size 500 mesh) and 100g copper nitrate and silver nitrate, stir for 10min under dark conditions, make it fully infiltrated, then place it in an ultrasonic cleaner for ultrasonic vibration for 15min, ultrasonic frequency 40kHz, so that silver nitrate and copper nitrate can effectively enter the interior of diatomite, and fully couple with the inner surface of diatomite, and then take it out and quickly wash it in a Buchner funnel with clean water.

[0095] The obtained powder was dried in an oven at 60°C for 10 hours, and then calcined in a muffle furnace at 600°C for 3 hours to obtain diatomite-nanosilver / copper composite particles with a particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com