Decorative panel assembly bonding method

A bonding method and technology for decorative panels, which are applied in heating methods, connecting components, household stoves/stoves, etc., can solve the problems of high requirements for bonding tooling, fragile glass panels, and easy deformation of decorative panels. Bending deformation and bonding reliability, solving dimensional stability, solving the effect of bonding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

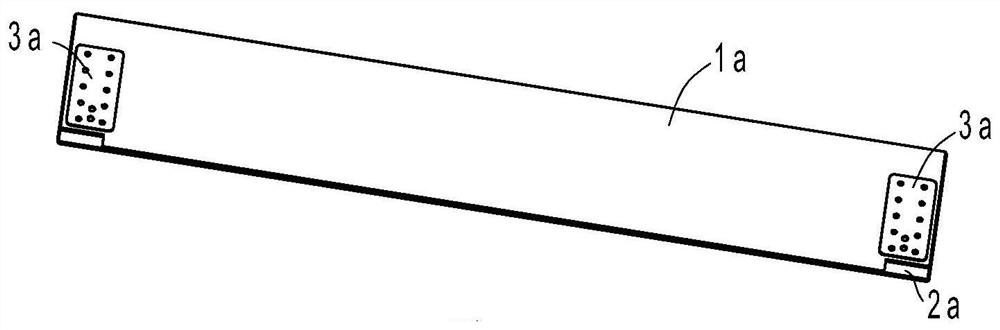

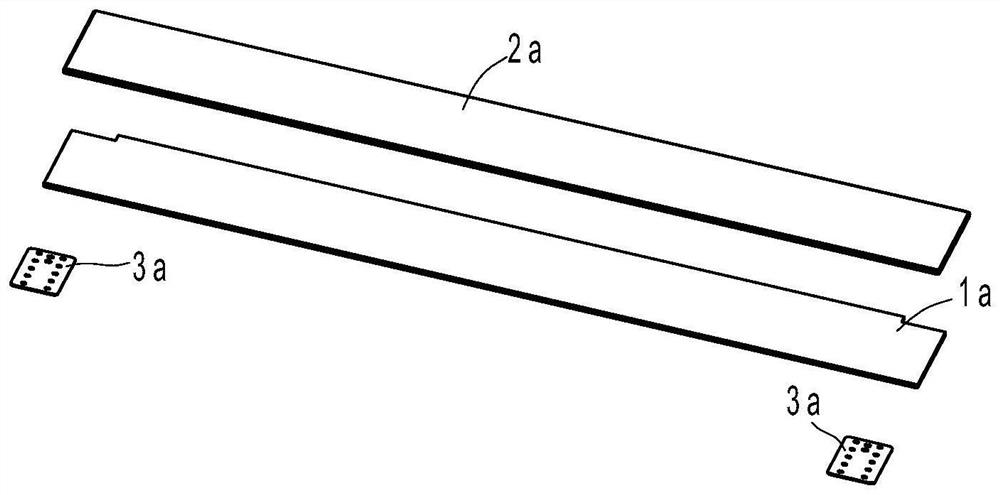

[0034] Such as Figure 4 with Figure 5 As shown, the decorative panel assembly bonding tooling includes a worktable 1, a positioning frame 5, a first limit block 51, a second limit block 52 and a downward pressure cylinder 2, a workbench 1, and two support brackets on the upper end surface The positioning seat 6 provided on the connecting plate 3a has a support block 15 for supporting the glass panel 1a between the positioning seats 6; a support leg 12 is provided below the worktable 1, and a pulley 13 is provided at the bottom of the support leg for easy transportation.

[0035] There are two positioning frames 5, which are arranged around the corresponding positioning seats 6. The vertical direction of the positioning frame 5 is elastic and the inner ring is adapted to the glass panel 1a. The inside of the positioning frame 5 has a support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com