Hydraulically driven mechanical powder molding machine

A powder molding machine and driving machinery technology, which is applied in the direction of material molding presses, stamping machines, presses, etc., can solve problems such as complex mechanisms, low powder filling height, and short continuous pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

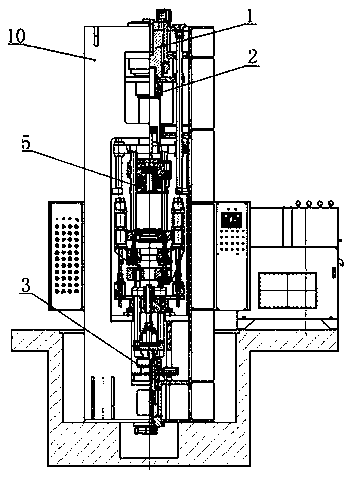

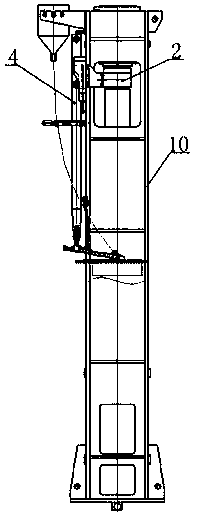

[0041] Reference attached figure 1 , Hydraulically driven mechanical powder molding machine, which includes body 10, upper limit cylinder 1, screw adjustment structure 2, lower cylinder structure 3, feeding mechanism 4 and mold base assembly 5. The body 10 is a frame body, the body 10 The upper limit oil cylinder 1, the screw rod adjustment structure 2, the mold base assembly 5, and the lower oil cylinder structure 3 are sequentially installed in the middle from top to bottom. The feeding mechanism 4 is installed on the side of the body 10, and the upper limit oil cylinder 1 is connected to the screw rod adjustment structure. 2. The lower end of the screw rod adjustment structure 2 is connected to the mold base assembly 5, and the lower end of the mold base assembly 5 is connected to the lower cylinder structure 3.

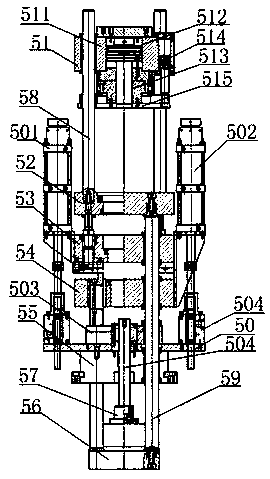

[0042] Such as Figure 2-5 , The die set assembly 5 includes a double upper punch 51, a female template 52, a lower punch 53, a lower two punch 54, a fixed punch 55, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com