Device for positioning an object in space

A positioning device and target positioning technology, applied in the field of positioning devices or micro-moving positioning devices, can solve problems such as loss of dimensional stability, achieve good distribution, and solve the effect of dimensional stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

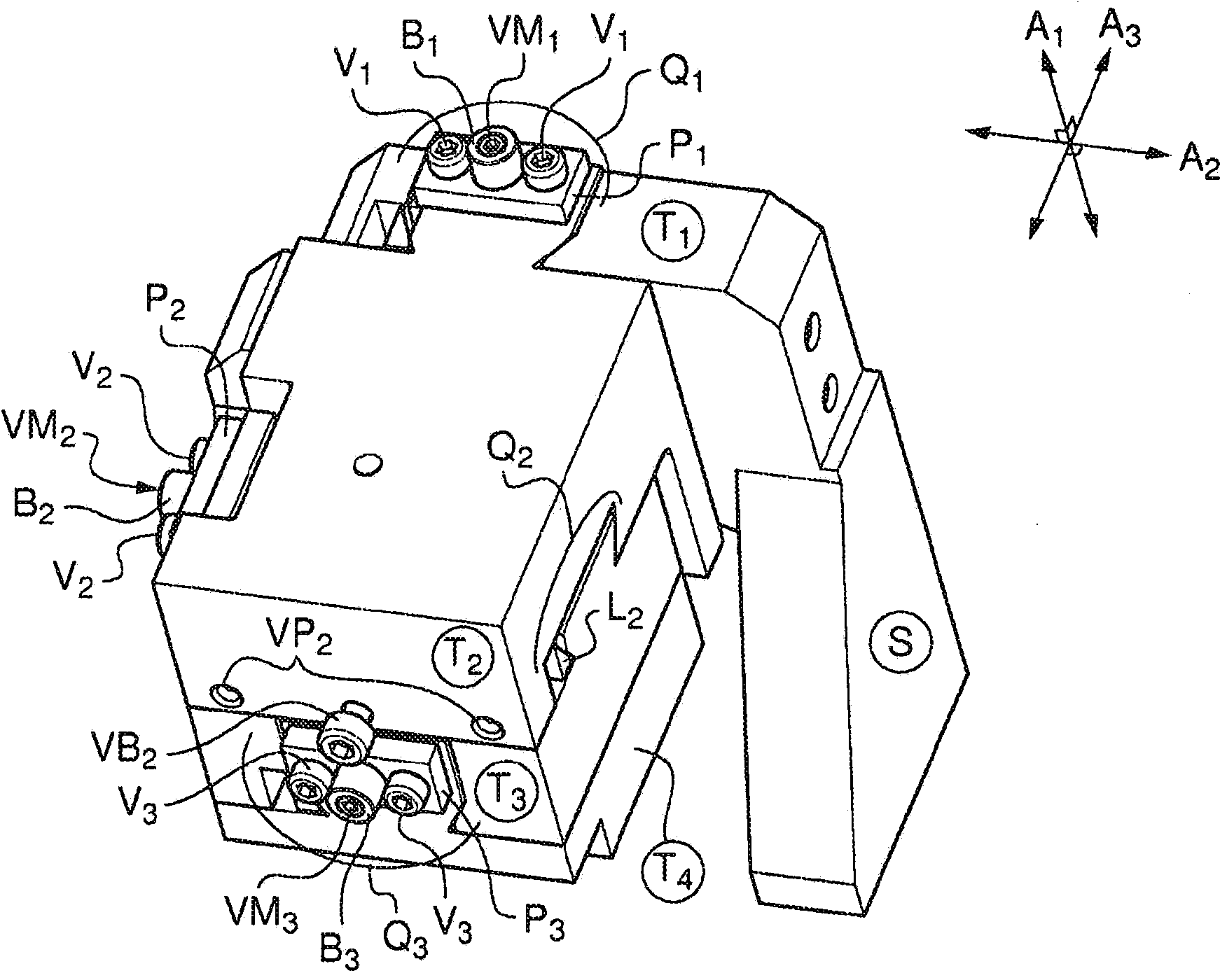

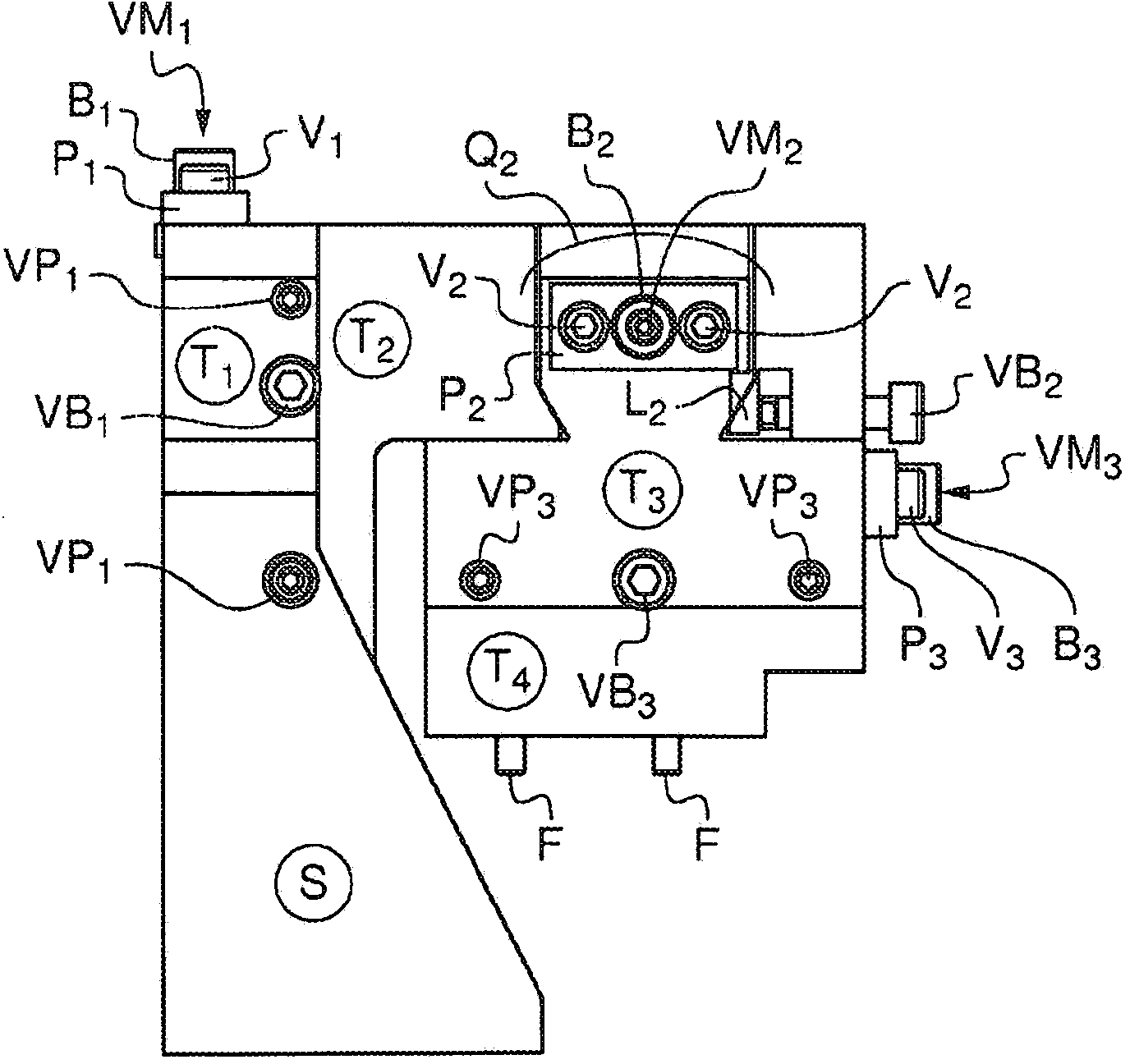

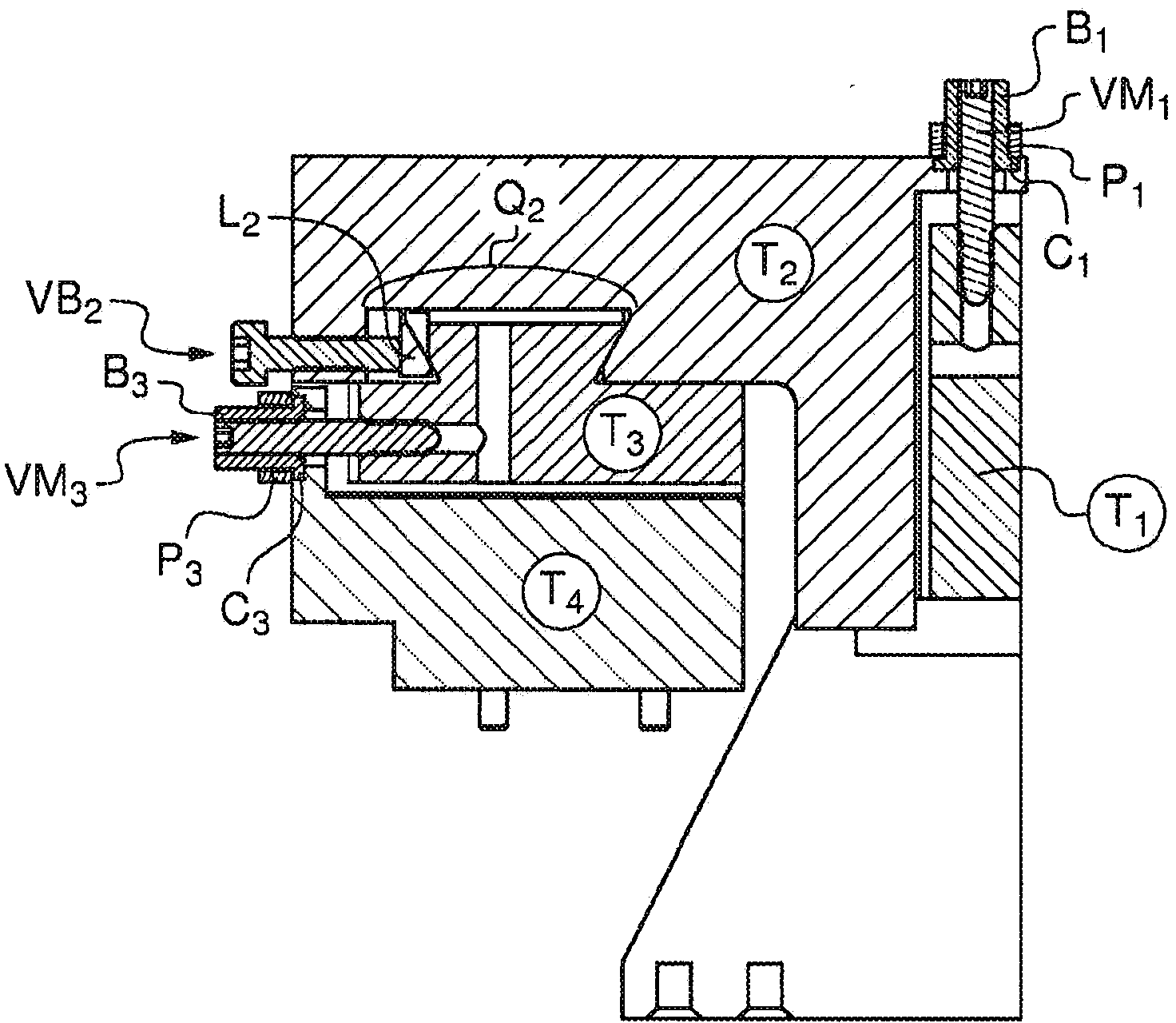

[0062] figure 1 is a three-dimensional view of an implementation variant of the device of the present invention, showing the four plates (T1, T2, T3 and T4) of the device, and the possibility to make the plates T1 and T2 (Q1), T2 and T3 (Q2) and T3 and T4 (Q3) a dovetail pin / groove system (Q) that moves relative to the other.

[0063] Note that for each pin / tongue-and-groove system there is one microscrew VM (VM1 for system Q1, VM2 for system Q2, VM3 for system Q3). Each microscrew VM is held connected to the plate with said microscrew by a ring B (B1, B2 and B3), which is itself supported by a mounting plate P (P1, P2 , P3), said mounting plate P (P1, P2, P3) itself is held by two screws V (V1 for ring B1, V2 for ring B2, V3 for ring B3).

[0064] It is to be noted that on plate T2 a locking screw (VB2) is visible which acts on the pin / tongue and groove system Q2 (the locking screws VB1 and VB3 acting on the pin / tongue and groove system Q1 and Q3 are not shown on the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com