A kind of resin composition and its application

A technology of resin composition and epoxy resin, which is applied in the field of copper-clad laminates, can solve problems such as poor dimensional stability and heat resistance, and achieve improved heat resistance and dimensional stability, improved thermal expansion coefficient, and improved dimensional stability The effect of sex and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

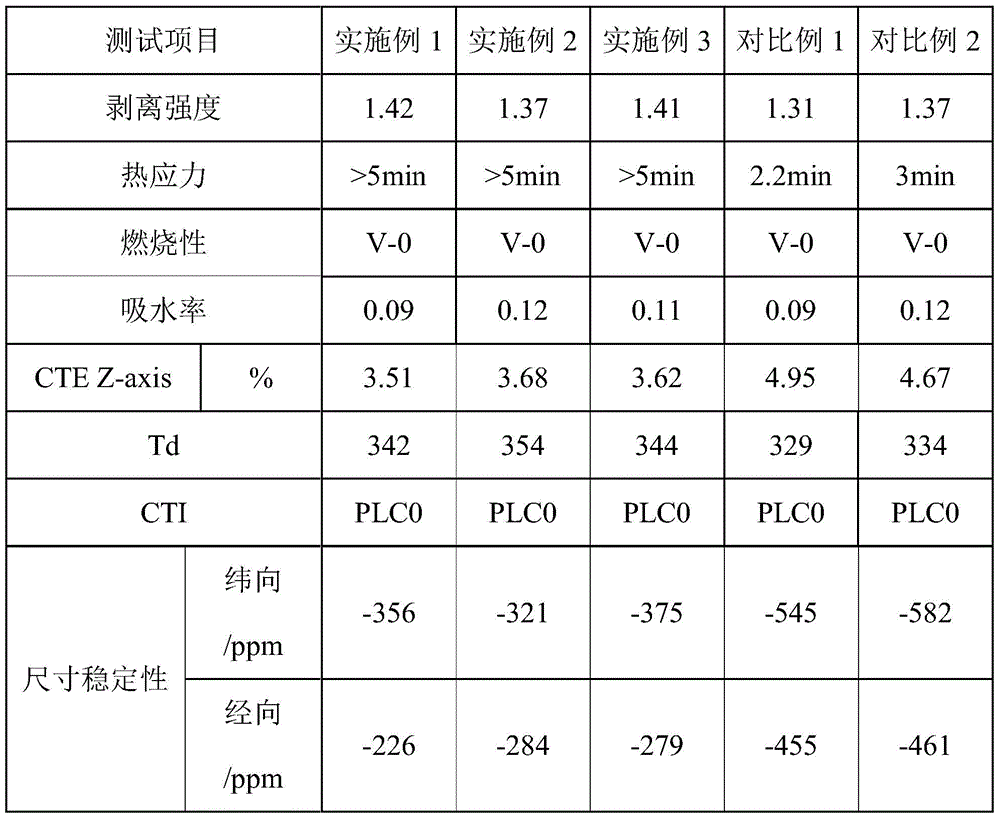

Examples

Embodiment 1

[0036]Step 1: Weigh the following components according to parts by weight: 10 parts of epoxy soybean oil modified epoxy resin, 90 parts of DOPO-HQ modified phosphorus-containing epoxy resin, 15 parts of biphenyl type phenolic resin, nonyl 20 parts of phenol-modified benzoxazine, 70 parts of silicon dioxide, 50 parts of boehmite, 0.08 parts of diphenylimidazole, 60 parts of acetone, and 50 parts of ethylene glycol methyl ether; among them, silicon dioxide is spherical Silicon, mixed with 60 parts of silicon dioxide with an average particle size of 5 μm and 10 parts of silicon dioxide with an average particle size of 80 nm; boehmite is granular, with an average particle size of 2 μm;

[0037] Use KH560-ethanol solution with a volume concentration of 30%, the amount of KH560 is 2% of the mass of silica and boehmite, use dry spray to treat the surface of silica and boehmite in a kneader for 2 hours, then take it out for use ;

Embodiment 2

[0042] Step 1: Take the following components in parts by weight: 30 parts of epoxy soybean oil modified epoxy resin, 70 parts of DOPO-HQ modified phosphorus-containing epoxy resin, 20 parts of biphenyl type phenolic resin, nonyl 5 parts of phenol-modified benzoxazine, 103 parts of silicon dioxide, 20 parts of boehmite, 0.15 parts of diphenylimidazole, 60 parts of acetone, and 50 parts of ethylene glycol methyl ether; among them, silicon dioxide is spherical Silicon, mixed with 100 parts of silicon dioxide with an average particle size of 5 μm and 3 parts of silicon dioxide with an average particle size of 80 nm; boehmite is granular, with an average particle size of 2 μm;

[0043] Use KH560-ethanol solution with a volume concentration of 30%, the amount of KH560 is 2% of the mass of silica and boehmite, use dry spray to treat the surface of silica and boehmite in a kneader for 2 hours, then take it out for use ;

[0044] Step 2: using ethylene glycol methyl ether and acetone ...

Embodiment 3

[0048] Step 1: Take the following components in parts by weight: 22 parts of epoxy soybean oil modified epoxy resin, 78 parts of DOPO-HQ modified phosphorus-containing epoxy resin, 18 parts of biphenyl phenolic resin, nonyl 15 parts of phenol-modified benzoxazine, 95 parts of silicon dioxide, 40 parts of boehmite, 0.1 part of diphenylimidazole, 60 parts of acetone, and 50 parts of ethylene glycol methyl ether; among them, silicon dioxide is spherical Silicon, mixed with 88 parts of silicon dioxide with an average particle size of 5 μm and 7 parts of silicon dioxide with an average particle size of 80 nm; boehmite is granular, with an average particle size of 2 μm;

[0049] Use KH560-ethanol solution with a volume concentration of 30%, the amount of KH560 is 2% of the mass of silica and boehmite, use dry spray to treat the surface of silica and boehmite in a kneader for 2 hours, then take it out for use ;

[0050] Step 2: using ethylene glycol methyl ether and acetone to disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com