Microcellular foaming recycling method of waste car plastics

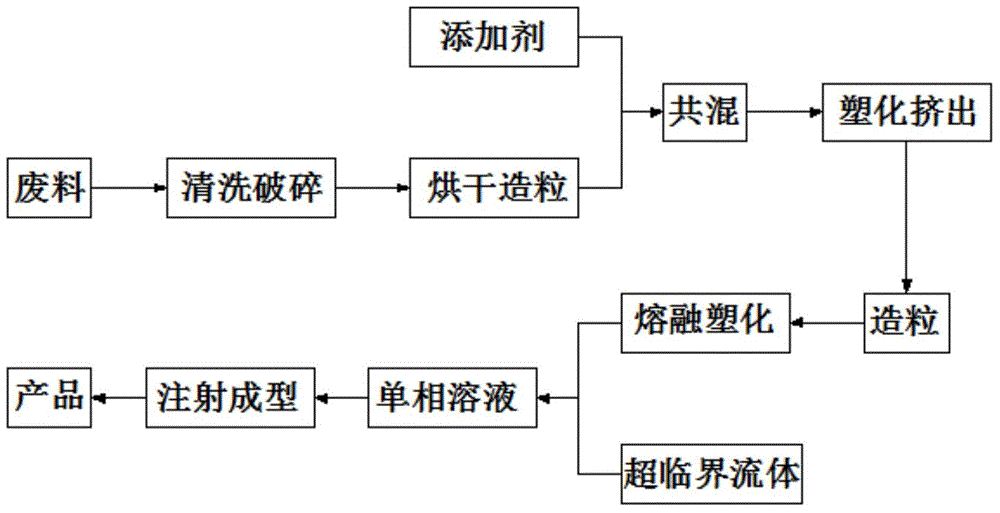

A technology of microcellular foaming and waste recycling, which is applied in the direction of plastic recycling and recycling technology, which can solve the problems of plastic resource recycling and waste plastic environmental pollution, and achieve the effects of saving materials, reducing molding cycle, and reducing clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

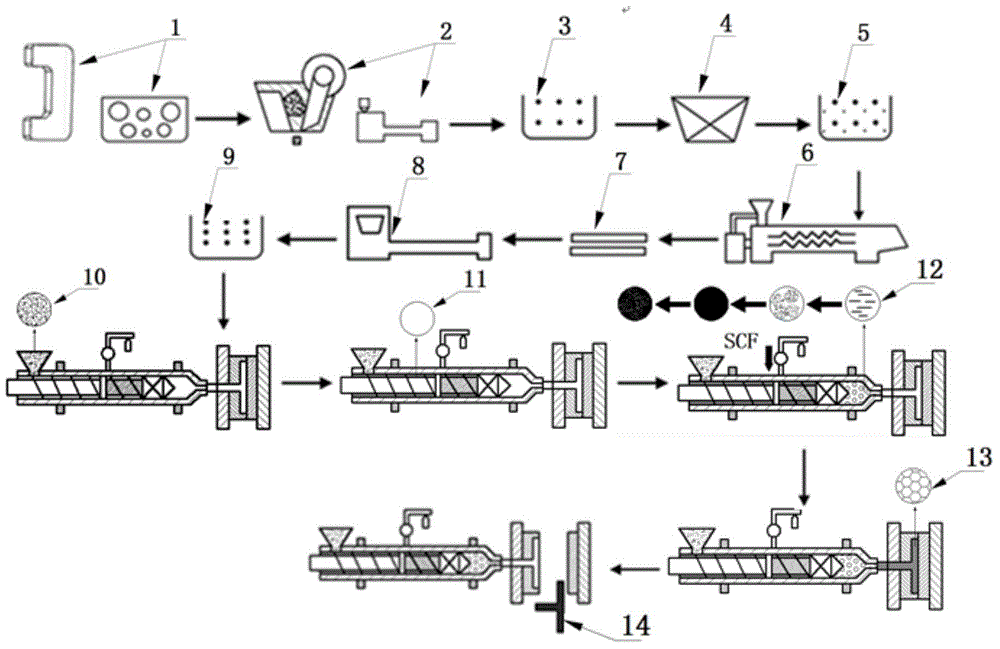

Embodiment 1

[0041] (1) Preparation for the recycling of automobile waste:

[0042] 1) Wash the recycled plastics in a cleaning crusher and break them into small pieces of 10cm×10cm;

[0043] 2) Put the above blocks into the granulation equipment to dry and granulate to obtain granules or powder. The temperature of the drying box is controlled at 50°C, the time is controlled at 10min, and the granulation size is controlled at 3mm×3mm.

[0044] (2) Modified granulation of waste:

[0045] 1) After the above-mentioned pellets or powders and additives are weighed in proportion, they are put into a batching machine and mixed evenly to obtain a compounded material. The weight ratio is; pellets or powders 66.7%; thermoplastic elastomer grafts 3%; antioxidant 1010 tetraerythritol ester 0.1%; talcum powder 15%; glass fiber 15%; titanate coupling agent 0.2%;

[0046] 2) Put the above-mentioned mixed materials into the hopper of the parallel twin-screw extruder, and set the temperature of each sect...

Embodiment 2

[0056] (1) Preparation for the recycling of automobile waste:

[0057] 1) Wash the recycled plastics in a cleaning crusher and break them into small pieces of 10cm×10cm;

[0058] 2) Put the above blocks into the granulation equipment to dry and granulate to obtain granules or powder. The temperature of the drying box is controlled at 60°C, the time is controlled at 20min, and the granulation size is controlled at 3mm×3mm;

[0059] (2) Modified granulation of waste:

[0060] 1) After the above-mentioned pellets or powders and additives are weighed in proportion, put them into the batching machine to obtain the compounded materials uniformly at high speed, and the weight ratio is: 66.7% of pellets or powders; thermoplastic elastomer graft 10%; antioxidant 168 phenyl triphosphite 0.2%; talcum powder 20%; glass fiber 20%; titanate coupling agent 0.4%;

[0061] 2) Put the above-mentioned mixed materials into the hopper of the parallel twin-screw extruder, and set the temperature ...

Embodiment 3

[0070] (1) Preparation for the recycling of automobile waste:

[0071] 1) Wash the recycled plastics in a cleaning crusher and break them into small pieces of 10cm×10cm;

[0072] 2) Put the above blocks into the granulation equipment to dry and granulate to obtain granules or powder. The temperature of the drying box is controlled at 70°C, the time is controlled at 30min, and the granulation size is controlled at 3mm×3mm;

[0073] (2) Modified granulation of waste:

[0074] 1) Weigh the above-mentioned pellets or powder and additives in proportion and put them into the batching machine and mix them uniformly at a high speed to obtain a compounded material. The ratio of additives is as follows: pellets or powder 24%; thermoplastic elastomer graft 15% ; Antioxidant DLTP dilauryl thiodipropionate 0.4%; Talc powder 30%; Glass fiber 30%; Titanate coupling agent 0.6%;

[0075] 2) Put the above-mentioned mixed materials into the hopper of the parallel twin-screw extruder, and set t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com