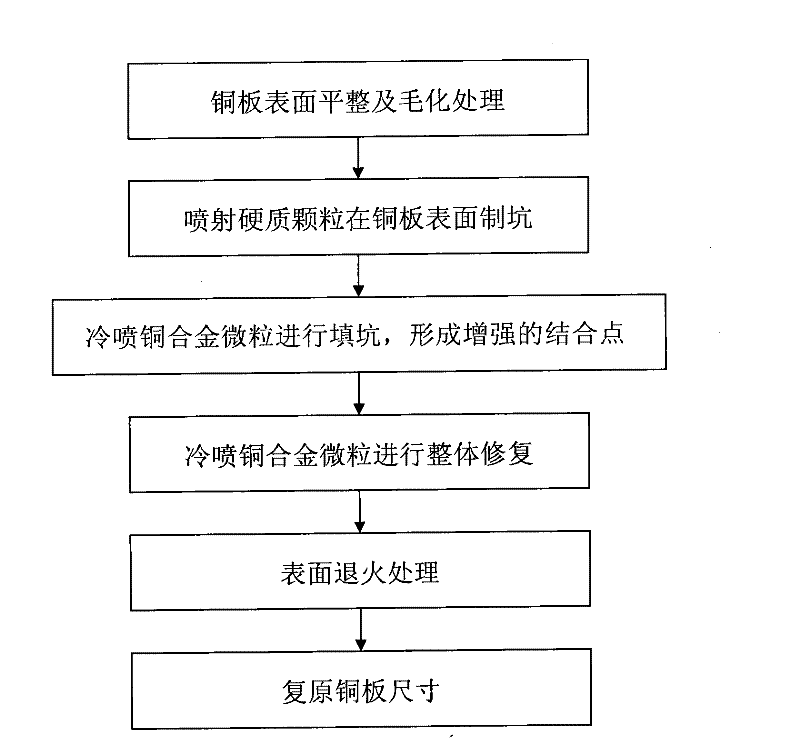

Cold spray repairing method for crystallizer copper plate

A crystallizer copper plate and repair method technology, applied in the field of crystallizer repair, can solve problems affecting the repair effect and performance of the crystallizer, interface macroscopic cracking, poor thermal deformation resistance of the repair layer interface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

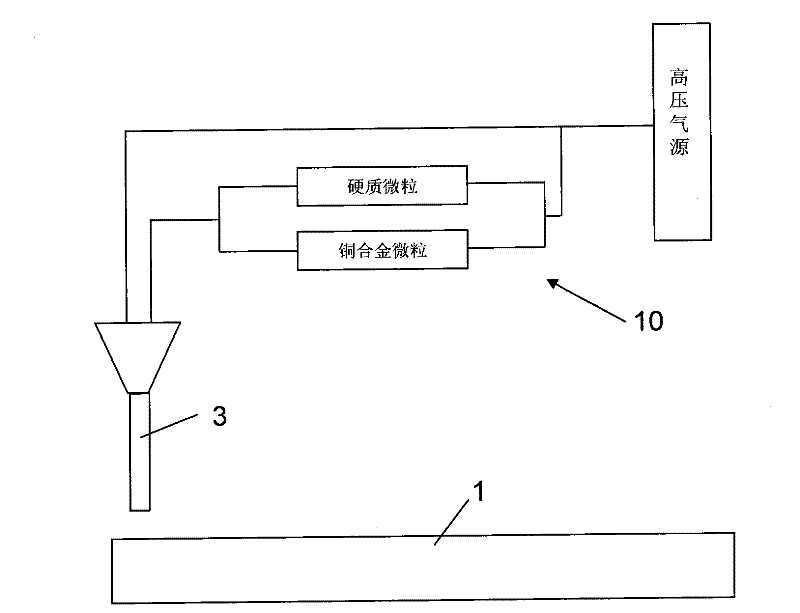

Method used

Image

Examples

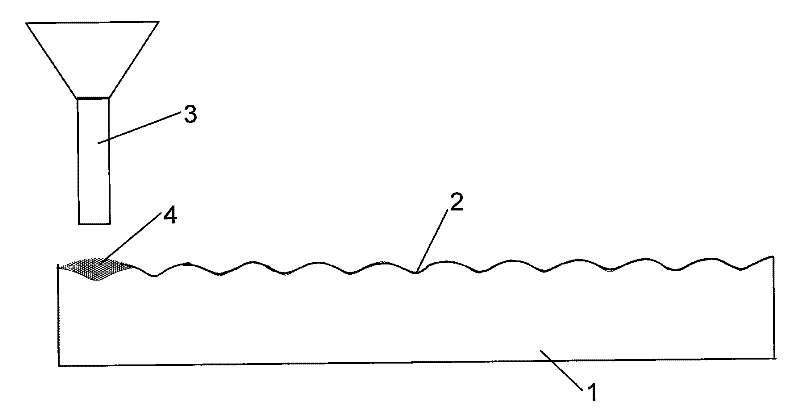

Embodiment 1

[0047] First mill the copper plate surface of the crystallizer to remove oil stains, and then perform surface sandblasting treatment, the roughness is Ra1.8; the driving gas used for the preparation of the reinforced pits is nitrogen, and the hard particles are alumina, spherical in shape, with an average particle size of 23 μm, The angle between the injection direction and the normal direction of the copper plate surface of the crystallizer is 0°, the speed of hard particles is 600m / s, the single-point residence time of the nozzle is 30s, the diameter of the outer circle of the pit is φ8mm, and the depth of the center of the pit is 1mm. The surface of the crystallizer is evenly distributed, the distance between two adjacent pits is 24mm, and the inner surface roughness of the resulting pits is Ra1.2μm; the copper alloy particles used for repairing the reinforcement points are spherical, with an average particle size of 38μm, and the spraying direction of the copper alloy partic...

Embodiment 2

[0049] Grinding the surface of the copper plate of the crystallizer to obtain a flat surface, and then sandblasting the surface, the roughness is Ra2.3; the driving gas used for the preparation of the enhanced pit is argon, and the hard particles are yttrium oxide, which is ellipsoidal. The average particle size is 28μm, the angle between the injection direction and the normal direction of the mold copper plate surface is 5°, the speed of hard particles is 800m / s, the single point residence time of the nozzle is 20s, the diameter of the outer circle of the pit is φ10mm, and the depth of the center of the pit is 0.9mm, the reinforcement pits are evenly distributed within 100mm from the four sides of the crystallizer, the distance between two adjacent pits is 30mm, the inner surface roughness of the obtained pits is Ra1.2μm, and there is no reinforcement pit in the middle; the copper used for repairing the reinforcement points The alloy particles are spherical, with an average pa...

Embodiment 3

[0051] Grinding the surface of the copper plate of the crystallizer to obtain a flat surface, and then performing sandblasting on the surface, the roughness is Ra3.3; the driving gas used for the preparation of the reinforced pit is argon, and the hard particles are yttrium oxide, which is irregular in shape , the average particle size is 64μm, the angle between the injection direction and the normal direction of the mold copper plate surface is 10°, the speed of hard particles is 550m / s, the single point residence time of the nozzle is 43s, the diameter of the outer circle of the pit is φ12mm, and the depth of the center of the pit is The reinforced pits are evenly distributed on the surface of the crystallizer, the distance between two adjacent pits is 28mm, and the inner surface roughness of the obtained pits is Ra1.6μm; the copper alloy particles used for repairing the reinforced points are spherical, with an average particle size of 18μm The particle spraying direction is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com