Diffusion connection method for high-temperature TiAl alloy annular piece and Ti2AlNb alloy annular piece

A technology of diffusion joining and annular parts, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of insufficient technical research, no diffusion connection of annular parts, complicated AlNb alloy diffusion joining process, etc., and achieve reliable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The concrete process of this embodiment is:

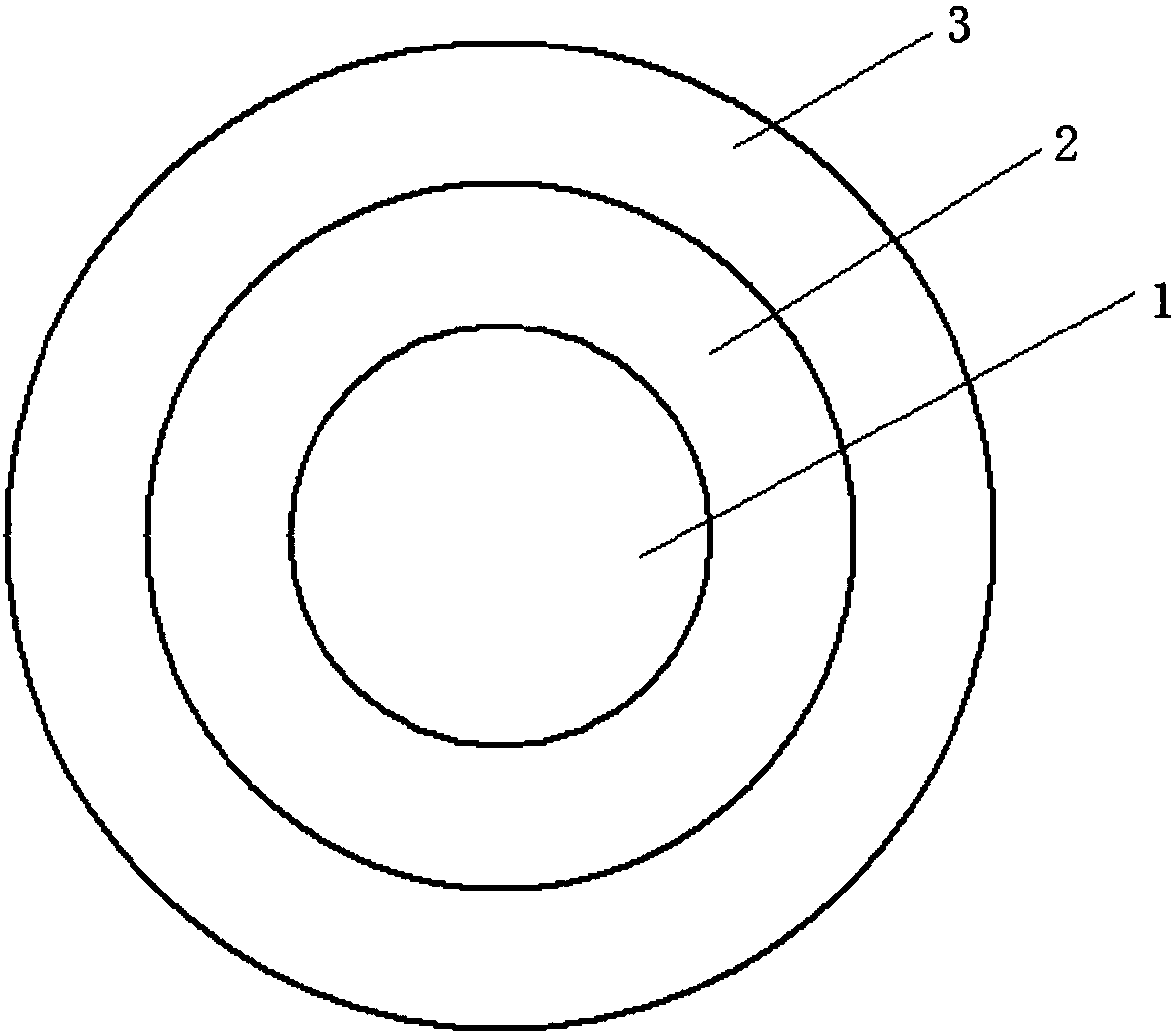

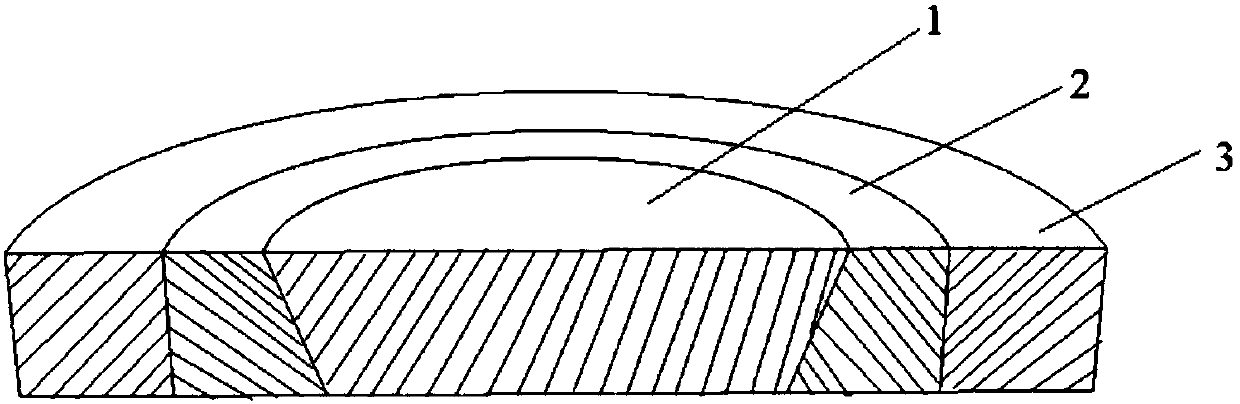

[0030] Step 1: Cut the sample. The high temperature TiAl alloy and Ti 2 The AlNb alloy is processed to obtain the designed size alloy samples to be connected, which are the plate edge 2 and the TiAl alloy of the high temperature TiAl alloy respectively. 2 Disk core of AlNb alloy 1. The inclination angle of the connection interface between the disk edge and the disk core is 10°;

[0031] Step 2: Surface treatment. The high-temperature TiAl alloy plate edge 2 obtained in step 1 and Ti 2 The connection surface of the AlNb alloy disc core 1 is finely ground to eliminate obvious scratches on the surface to be connected. Immerse the sample in absolute ethanol for ultrasonic degreasing treatment for 5 minutes, and store it in absolute ethanol;

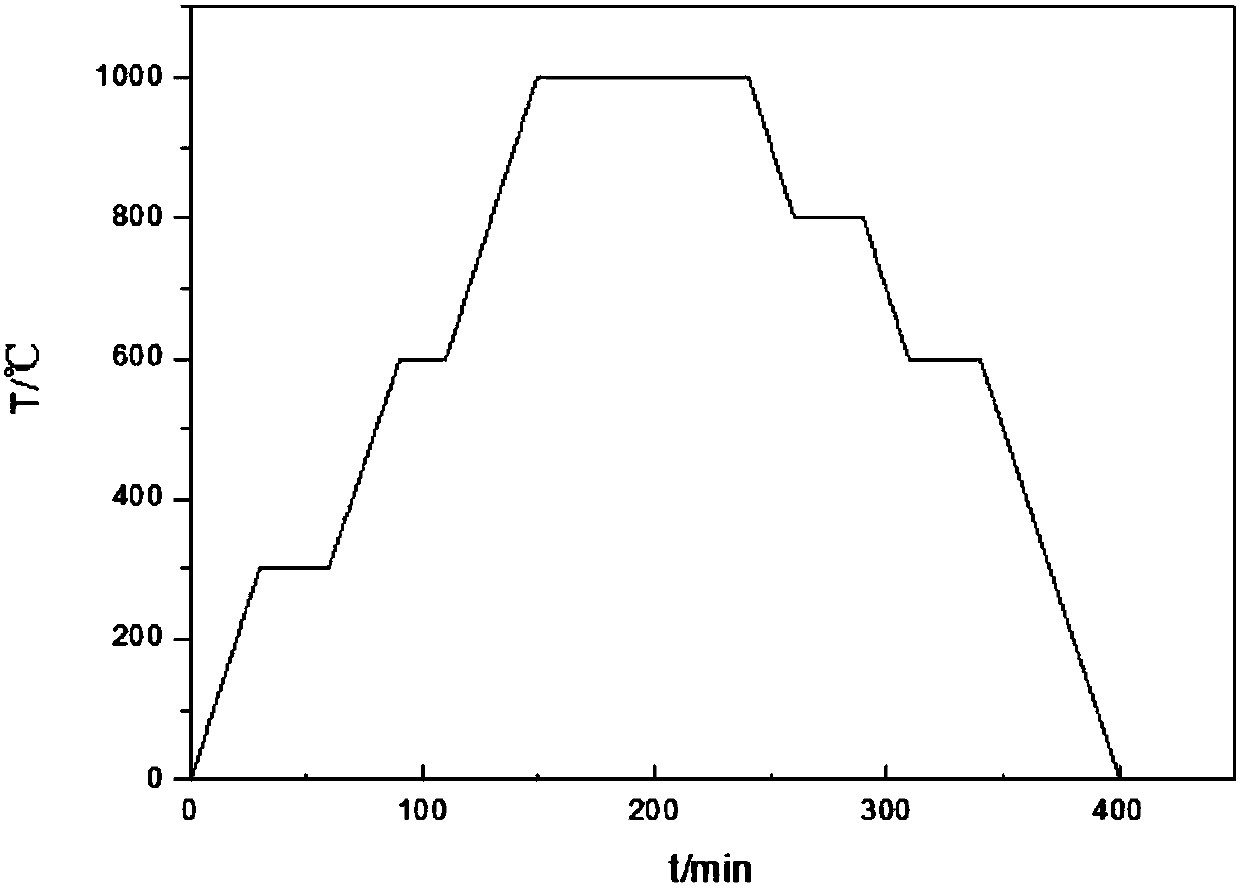

[0032] Step 3: Clamping and assembly. Apply boron nitride solder stopper on the surface of fixture 3 in contact with the test piece, and place the high-temperature TiAl alloy plate e...

Embodiment 2

[0035] The concrete process of this embodiment is:

[0036] Step 1: Cut the sample. The high temperature TiAl alloy and Ti 2 The AlNb alloy is processed to obtain the designed size alloy samples to be connected, which are the plate edge 2 and the TiAl alloy of the high temperature TiAl alloy respectively. 2 Disk core of AlNb alloy 1. The inclination angle of the connection interface between the disk edge and the disk core is 15°;

[0037] Step 2: Surface treatment. The high-temperature TiAl alloy plate edge 2 obtained in step 1 and Ti 2 The connection surface of the AlNb alloy disc core 1 is finely ground to eliminate obvious scratches on the surface to be connected. Immerse the sample in absolute ethanol for ultrasonic degreasing treatment for 5 minutes, and store it in absolute ethanol;

[0038] Step 3: Clamping and assembly. Apply boron nitride solder stopper on the surface of fixture 3 in contact with the test piece, and place the high-temperature TiAl alloy plate e...

Embodiment 3

[0041] The concrete process of this embodiment is:

[0042] Step 1: Cut the sample. The high temperature TiAl alloy and Ti 2 The AlNb alloy is processed to obtain the designed size alloy samples to be connected, which are the plate edge 2 and the TiAl alloy of the high temperature TiAl alloy respectively. 2 Disk core of AlNb alloy 1. The inclination angle of the connection interface between the disk edge and the disk core is 20°;

[0043] Step 2: Surface treatment. The high-temperature TiAl alloy plate edge 2 obtained in step 1 and Ti 2 The connection surface of the AlNb alloy disc core 1 is finely ground to eliminate obvious scratches on the surface to be connected. Immerse the sample in absolute ethanol for ultrasonic degreasing treatment for 5 minutes, and store it in absolute ethanol;

[0044] Step 3: Clamping and assembly. Apply boron nitride solder stopper on the surface of fixture 3 in contact with the test piece, and place the high-temperature TiAl alloy plate e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com