A kind of round steel slitting and rolling process

A split rolling and process technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of large difference in working diameter, accelerated wear and unevenness of pass shape, etc., to improve product surface quality, The surface quality of the finished product is stable and the effect of improving the dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

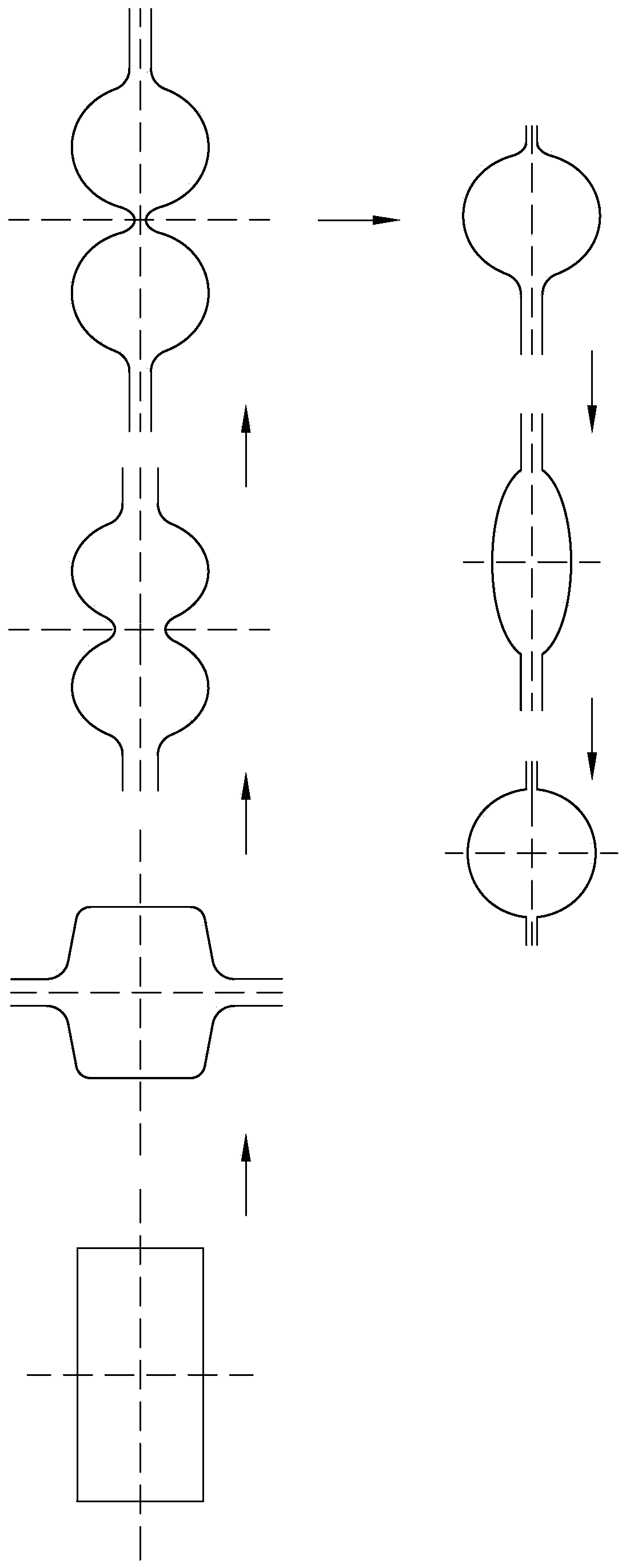

[0022] In the embodiment, in the round steel split rolling process, after the round holes are rolled out in the rough rolling stage, the roll passes adopted in the finish rolling stage are as follows: flat rolling pass, vertical box pass, pre-cut Divided pass, split pass, elliptical pass and circular pass, the structural dimensions of each pass are:

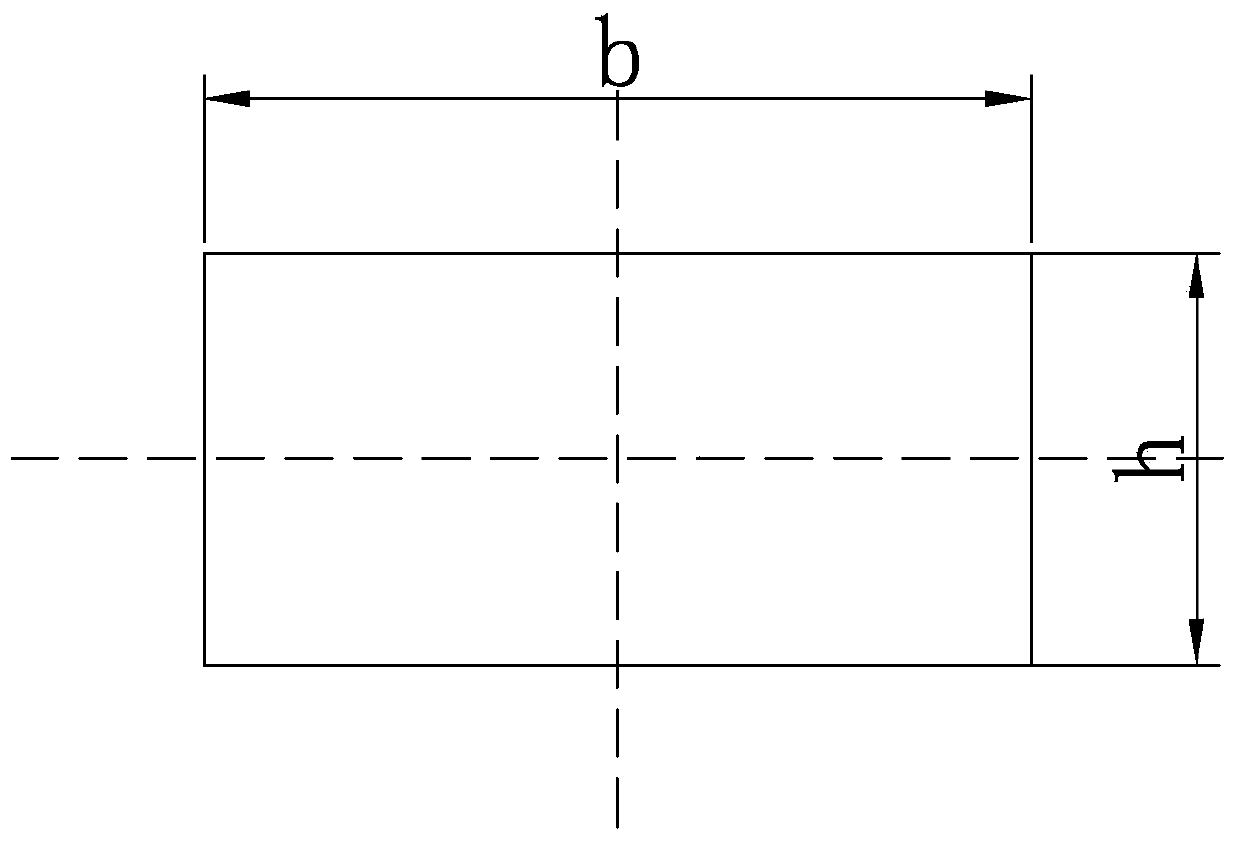

[0023] Height h of flat rolling pass = groove bottom width b of vertical box pass k +(0.5~1.5)mm;

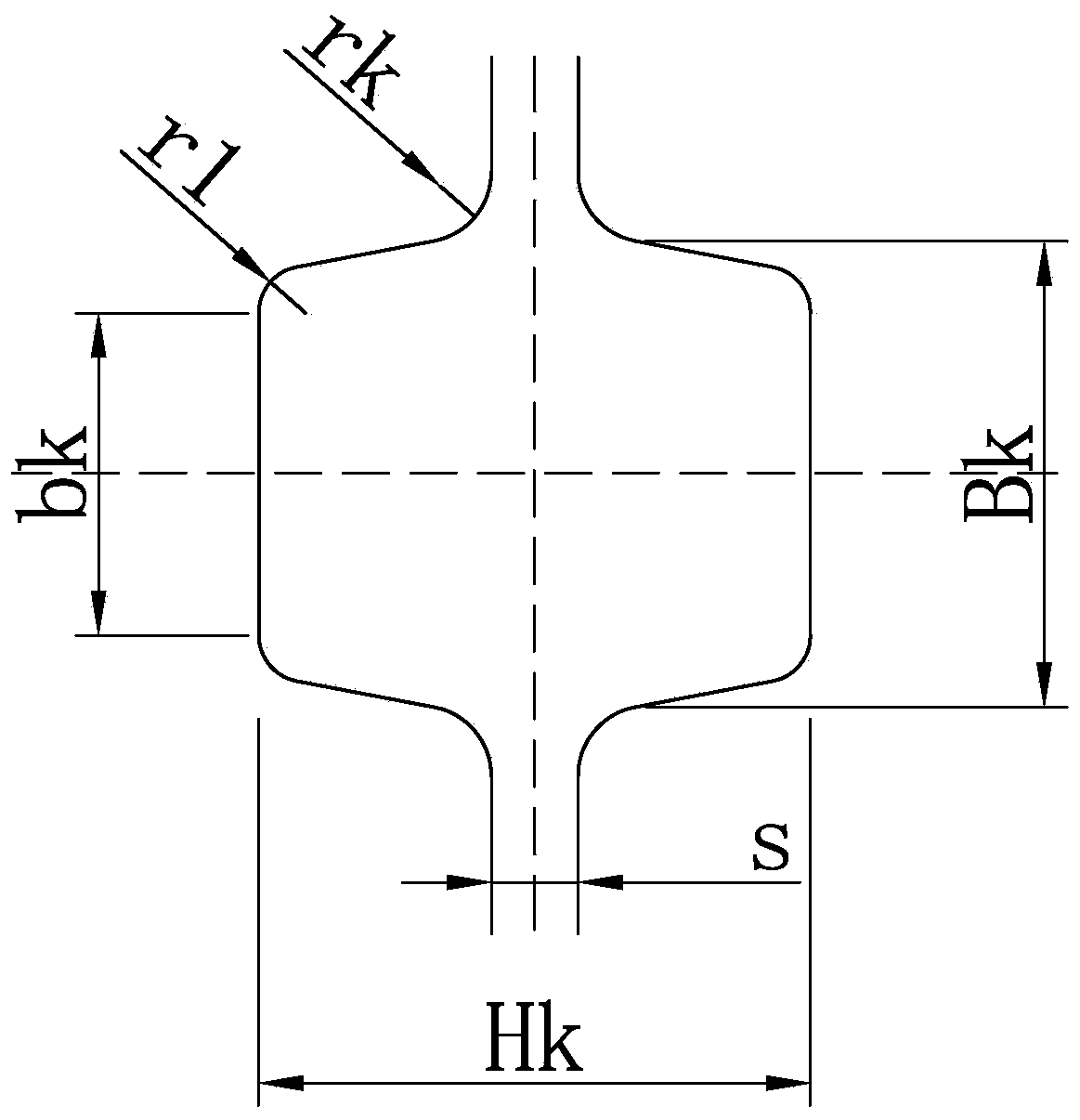

[0024] The area of the vertical box pass = the area of the pre-cut pass × (1.15 ~ 1.20), the notch width B of the vertical box pass k = Height H of the pre-cut hole pattern k +(2~4)mm, the slope of the side wall of the vertical box pass φ=10-15°, the radius r of the inner fillet of the vertical box pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com